Changing the appearance of your living space is easy withusing decorative finishing. Can liquid wallpaper be applied to the ceiling of a kitchen or living room? What knowledge should a craftsman have when starting to wallpaper a living space? Directions for applying liquid wallpaper to the ceiling.

Directions for applying liquid wallpaper to the ceiling.

Liquid wallpaper as a finishing building material

Striving to improve the design of the apartment,builders purchase various materials for finishing. When carrying out work of any level of complexity, liquid wallpaper is the best material. The main component of wallpaper remains cellulose, containing additives of decorative elements. Wall stickers in a liquid state for finishing the ceiling are not inferior in aesthetic value to wall textiles. Liquid wallpaper allows you to give the surface a soft texture, create a feeling of comfort. Ceiling finishing emphasizes the uniqueness of the entire living space. The decorative coating contains 11 names of its components: from cellulose fibers to antifungal additives. In dry form, liquid wallpaper resembles children's material for various crafts. The coating is a product of the highest quality, capable of providing seamless application to the surface. Return to contents</a>

Coating composition for ceiling decoration

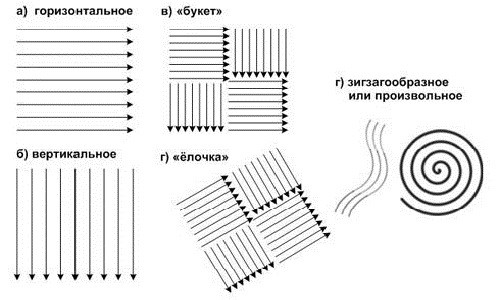

Finishing the ceiling with liquid wallpaper begins with studying the components of the raw materials. The exact proportions of all components are known only to the manufacturer, but the general list of materials includes the following elements: Stages of applying liquid wallpaper.

Stages of applying liquid wallpaper.

- cellulose fibers;

- silk thread;

- cotton;

- fibers of woolen yarn;

- lavsan thread;

- acrylic;

- glue CMC;

- mineral materials (sequins);

- antifungal components;

- dyes.

Cellulose fibers consist of cotton wool dyed in various colors. Textile threads create the necessary fibers:

- woolen;

- synthetic;

- х / б.

"Bustilat" is used as glue.Glitters are used in the form of fine-grained mineral additives. Dyes are used in the production of the coating, allowing for multiple color transition effects. Sodium silicate is used as an antifungal additive. In appearance, liquid wallpaper resembles a dry mixture that must be diluted with water in the required proportions. Return to Contents</a>

Decorating wallpapers: their types

An example of the consumption of one package of liquid wallpaper.Builders confirm that liquid wall covering is the best means for decoration. For finishing ceilings with liquid wallpaper, products from leading companies are used, which are applied on surfaces:

An example of the consumption of one package of liquid wallpaper.Builders confirm that liquid wall covering is the best means for decoration. For finishing ceilings with liquid wallpaper, products from leading companies are used, which are applied on surfaces:

- concrete;

- gypsum;

- gypsum plasterboard.

Products from Russian manufacturers containfire retardant, providing non-flammability of the coating. Wallpaper on plaster is used as a heat insulator or leveling component, replacing putty. Applying wallpaper to the ceiling allows to provide a wide color palette with a characteristic shine, full saturation of the color background. Wallpaper for finishing ceilings is divided into several types:

- cellulose;

- silk;

- combined.

On the ceiling surface they form a coating 1-10 mm thick with a matte surface and soft structure. Return to contents</a>

How to choose the right coating

The choice of wallpaper for the ceiling depends on the locationwindow openings in the room and the presence of natural light. A combination of several contrasting shades of wall wallpaper is considered successful. The owners prefer to decorate the bedroom with liquid wallpaper containing silk threads. Calm, pastel colors are popular. In a child's room, a combination of liquid wallpaper with additional elements is required to give the room a unique look. Scheme of plasterboard joint filling.The ceiling finish fits perfectly into the interior design of the living space. The finishing coating is a safe for health, ecological product, without additional impurities and toxic substances. High heat-insulating qualities allow to increase the temperature in the living space, to keep the coating on the walls dry and warm. When processing ceilings, the resistance of the material to low temperatures is taken into account. Wallpaper retains its properties after complete freezing. Soundproofing is an important quality of wallpaper material. The microporous surface creates a stable effect of noise absorption. Wallpaper masks numerous cosmetic defects on the surface of the ceiling and walls and allows to design arched openings, columns and rounded surfaces in the interior. Another positive quality of the material is high antistatic qualities. Wallpaper prevents the settling of dust, smoke deposits, soot flakes. They retain their color under the influence of ultraviolet rays. The hygroscopicity of the coating material is high enough, allowing to keep the room dry. Return to the table of contents</a>

Scheme of plasterboard joint filling.The ceiling finish fits perfectly into the interior design of the living space. The finishing coating is a safe for health, ecological product, without additional impurities and toxic substances. High heat-insulating qualities allow to increase the temperature in the living space, to keep the coating on the walls dry and warm. When processing ceilings, the resistance of the material to low temperatures is taken into account. Wallpaper retains its properties after complete freezing. Soundproofing is an important quality of wallpaper material. The microporous surface creates a stable effect of noise absorption. Wallpaper masks numerous cosmetic defects on the surface of the ceiling and walls and allows to design arched openings, columns and rounded surfaces in the interior. Another positive quality of the material is high antistatic qualities. Wallpaper prevents the settling of dust, smoke deposits, soot flakes. They retain their color under the influence of ultraviolet rays. The hygroscopicity of the coating material is high enough, allowing to keep the room dry. Return to the table of contents</a>

Preparatory works, tools and materials

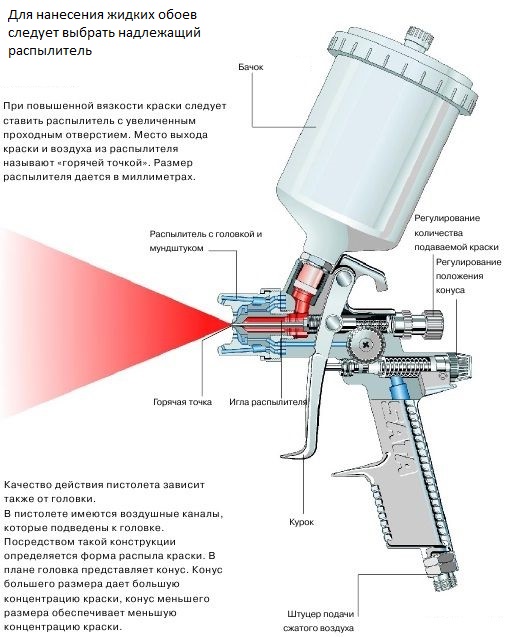

Is it possible on an unprepared surface?ceiling? First of all, it is necessary to eliminate the remains of putty or glue so that after the ceiling treatment there are no numerous defects. Dust is removed from the surface, problem areas are treated with fungicides. For the work you will need tools and materials: Texture gun device for applying liquid wallpaper.

Texture gun device for applying liquid wallpaper.

- grater (semifinished);

- wallpaper spray gun (Hopper);

- compressor (with mechanical spraying);

- smoothing transparent TR / S-10;

- trowel curly;

- smooth plastic smoothing iron;

- structural roller;

- textured gun AHG-02G.

An experienced craftsman will provide his work place with the following materials in advance:

- a bucket for preparing the mixture;

- a set of dry additives;

- a container for clean water;

- gypsum mixture;

- PVA glue;

- Oil paint;

- putty.

Return to Contents</a>

Technology of applying liquid wallpaper to the ceiling of plasterboard

Is it possible to apply liquid wallpaper to the ceiling once the preparatory work is completed? Scheme of priming the ceiling before applying liquidwallpaper. The craftsman proceeds to the direct processing of plasterboard surfaces. The contents of the bag with dry powder are placed in a bucket. Having carefully studied the instructions, the required amount of liquid is poured into the container. The contents are mixed until the solution of the required consistency is obtained. The experience of craftsmen shows that plasterboard sheets are best covered with a liquid composition. Their smooth surface does not require additional processing. It is only necessary to seal the defects between adjacent sheets. The heads of the screws for fastening are pre-coated with light paint so as not to spoil the surface of the ceiling after applying liquid wallpaper. The surface is primed using a special composition that completely dissolves in the plasterboard coating. To obtain a primer, the dry composition is placed in a container and filled with water. The resulting composition is kept for 10 minutes for complete swelling. After mixing, it is spread with a spatula over the surface of the seams. Then the entire surface is polished. The next stage of work is Distribution of putty on plasterboard sheets. It is applied in a 3 cm layer with subsequent grouting. Is it possible to apply after the putty has been distributed? A sufficient amount of the mixture is collected on the trowel and carefully distributed over the surface of the plasterboard sheets. The layer should not exceed 2 mm. The work is carried out in the direction from the lighter areas of the ceiling to the dark ones. The coated areas are dried for at least two hours, and then the walls are treated again using a trowel. The coating is applied at a temperature of at least +16 °C. Liquid wallpaper is applied to plasterboard sheets with the aim of saving: such a process is cheaper than using a thick layer of plaster. The upper part of the living space is coated manually or using a gun («Hopper»). Manually, the surface treatment process is carried out using a structural roller, which significantly facilitates the work. In the bathroom, you can apply the liquid composition to the ceiling, but it should be protected with acrylic varnish, which is applied to the ceiling at least 3 times with 2-hour drying intervals. Amateur craftsmen can create interesting panels with decorative elements on the ceiling using liquid wallpaper: glitter, threads, beads. Return to contents</a>

Scheme of priming the ceiling before applying liquidwallpaper. The craftsman proceeds to the direct processing of plasterboard surfaces. The contents of the bag with dry powder are placed in a bucket. Having carefully studied the instructions, the required amount of liquid is poured into the container. The contents are mixed until the solution of the required consistency is obtained. The experience of craftsmen shows that plasterboard sheets are best covered with a liquid composition. Their smooth surface does not require additional processing. It is only necessary to seal the defects between adjacent sheets. The heads of the screws for fastening are pre-coated with light paint so as not to spoil the surface of the ceiling after applying liquid wallpaper. The surface is primed using a special composition that completely dissolves in the plasterboard coating. To obtain a primer, the dry composition is placed in a container and filled with water. The resulting composition is kept for 10 minutes for complete swelling. After mixing, it is spread with a spatula over the surface of the seams. Then the entire surface is polished. The next stage of work is Distribution of putty on plasterboard sheets. It is applied in a 3 cm layer with subsequent grouting. Is it possible to apply after the putty has been distributed? A sufficient amount of the mixture is collected on the trowel and carefully distributed over the surface of the plasterboard sheets. The layer should not exceed 2 mm. The work is carried out in the direction from the lighter areas of the ceiling to the dark ones. The coated areas are dried for at least two hours, and then the walls are treated again using a trowel. The coating is applied at a temperature of at least +16 °C. Liquid wallpaper is applied to plasterboard sheets with the aim of saving: such a process is cheaper than using a thick layer of plaster. The upper part of the living space is coated manually or using a gun («Hopper»). Manually, the surface treatment process is carried out using a structural roller, which significantly facilitates the work. In the bathroom, you can apply the liquid composition to the ceiling, but it should be protected with acrylic varnish, which is applied to the ceiling at least 3 times with 2-hour drying intervals. Amateur craftsmen can create interesting panels with decorative elements on the ceiling using liquid wallpaper: glitter, threads, beads. Return to contents</a>

Creating a liquid suspended ceiling

To create a relief structure on the suspendedTo apply liquid wallpaper to the ceiling, use a hopper gun. No additional plastering of the ceiling is required, since the thick mixture covers the defects. The wallpaper forms a coating up to 10 mm thick. They should immediately have a loose, not pressed structure. Wallpaper is not plaster, so do not press too hard on the spatula, otherwise the surface of the wallpaper will be compressed, which will lead to additional material consumption. Work is carried out based on the consumption of one package of wallpaper on a flat surface of 4 m². Excess material consumption is possible when covering an additional surface in the form of corners, arched openings. If the composition is distributed evenly, without reducing the pace of work, you can achieve the formation of seams and joints. To increase the resistance of wallpaper to moisture, acrylic varnish is applied to the finished surface. It is used in 2 stages. First, the varnish is added to the prepared mixture, and at the second stage of work, the dried ceiling is covered with a layer of acrylic varnish. Liquid wallpaper - This is always the best finishing of walls and ceilings of a living space. With their help it is easy to transform an ordinary room into a cozy and comfortable one.</ ul>