Despite the apparent simplicity of the work, installationlaminate should be approached responsibly. When watching professionals do it, they think that inserting panels into grooves is quite easy. But a person who assembles laminate easily has certain skills and dexterity. And not every beginner will be able to repeat the actions of the master. To begin with, you will need to at least figure out how to lay laminate with your own hands and practice. And speed will appear over time. The main advantage of laminate is quick assembly and ease of use. To cope with the work successfully, you need to prepare a set of tools:

The main advantage of laminate is quick assembly and ease of use. To cope with the work successfully, you need to prepare a set of tools:

- roulette;

- building level;

- wooden lath for padding (15x25 cm);

- a hammer;

- a metal square;

- electric jigsaw (or a regular hacksaw);

- wedges-restraints;

- wooden bracket;

- pencil.

How to put laminate floor by yourself?

Comparative characteristics of substrateslaminate. Before laying the laminate, it is kept indoors for several days so that the material can undergo so-called acclimatization. After the final "adaptation" to the surrounding humidity and temperature conditions, the panels take the required dimensions and shape. Please note: the planks should be laid strictly horizontally, but not vertically. If they are laid on their edge, they will bend. And then the laborious process of assembling and laying the covering cannot be avoided. The sequence of actions when laying laminate panels is as follows:

Comparative characteristics of substrateslaminate. Before laying the laminate, it is kept indoors for several days so that the material can undergo so-called acclimatization. After the final "adaptation" to the surrounding humidity and temperature conditions, the panels take the required dimensions and shape. Please note: the planks should be laid strictly horizontally, but not vertically. If they are laid on their edge, they will bend. And then the laborious process of assembling and laying the covering cannot be avoided. The sequence of actions when laying laminate panels is as follows:

It is important to note here that the panels have 2 types of locking connections: “Click” - disassemblable and “Lock” latch lock. Return to contents</a>

Substrate preparation

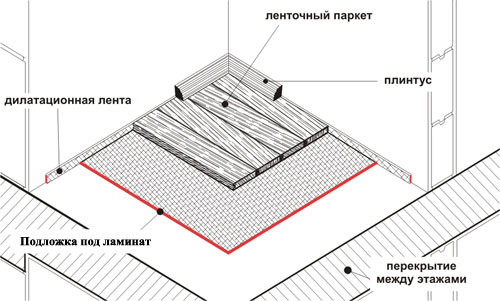

Substrate installation diagram.Leveling the base before laying is half the success of the whole event. The list of works on leveling the base surface directly depends on the material. If the base is old wooden boards or parquet boards that creak, then it is necessary to eliminate the distortions by strengthening the sagging elements. Floorboards that have become unusable are replaced with new ones. All existing irregularities are smoothed out with a grinding machine, the depressions are filled with wood putty. The concrete floor is cleaned of crumbs and leveled by pouring it with a self-leveling construction mixture. Having prepared the base, there will be a better chance of getting a smooth and durable surface, rather than a shaky structure. Return to the table of contents</a>

Substrate installation diagram.Leveling the base before laying is half the success of the whole event. The list of works on leveling the base surface directly depends on the material. If the base is old wooden boards or parquet boards that creak, then it is necessary to eliminate the distortions by strengthening the sagging elements. Floorboards that have become unusable are replaced with new ones. All existing irregularities are smoothed out with a grinding machine, the depressions are filled with wood putty. The concrete floor is cleaned of crumbs and leveled by pouring it with a self-leveling construction mixture. Having prepared the base, there will be a better chance of getting a smooth and durable surface, rather than a shaky structure. Return to the table of contents</a>

Substrate device

Once the base surface is leveled and prepared, a backing is laid on it. The main functions of backing materials are:

- moisture protection;

- heat protection;

- soundproofing;

- depreciation.

The 1st layer is a waterproofing film, with 20 cm overlaps. The joints are sealed with wide tape. The concrete base is covered with 1 cm thick plywood sheets. Scheme of correct laminate joining.If the previous covering is old linoleum, then the laminate is laid directly on it, waterproofing is not provided in this case. If the underlay is a roll material, then it will be more correct and much more effective to roll out the underlay only under the strip of panels that is planned to be laid, leaving a small reserve. There is no point in rolling out the entire roll and covering the entire surface. Excess material is cut off using a stationery knife. Return to contents</a>

Scheme of correct laminate joining.If the previous covering is old linoleum, then the laminate is laid directly on it, waterproofing is not provided in this case. If the underlay is a roll material, then it will be more correct and much more effective to roll out the underlay only under the strip of panels that is planned to be laid, leaving a small reserve. There is no point in rolling out the entire roll and covering the entire surface. Excess material is cut off using a stationery knife. Return to contents</a>

Coating

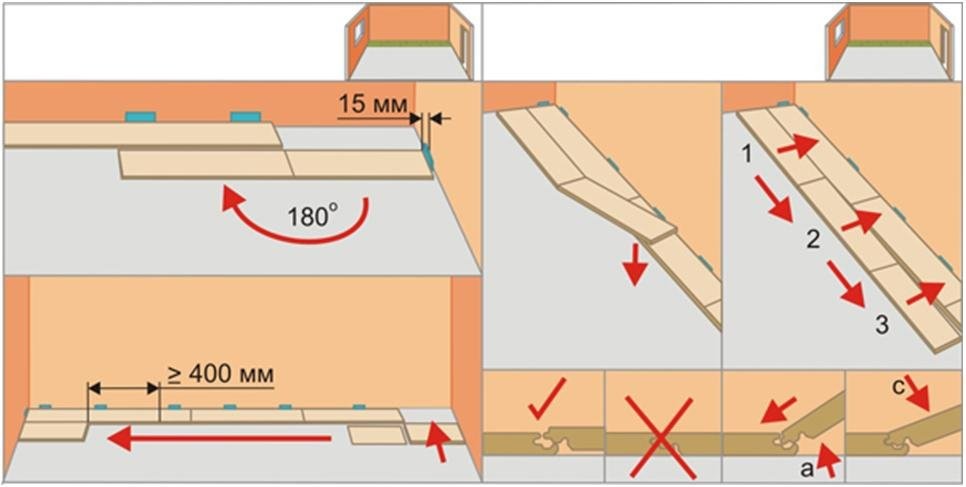

Connect laminate planks togetheras follows: each ridge on the plank is aligned with the groove on the adjacent one. After that, the planks are adjusted to each other using a hammer. You can start laying from any side of the room. But it is considered more correct to lay the covering in a perpendicular direction to the window so that the stripes from the joints between the planks are not visible. First, lay the underlay along the wall. After that, lay 1 strip of planks along the wall line, end to end. For a tighter fit, the boards are adjusted with a hammer. In this way, all the boards in 1 strip along the wall are laid and adjusted. The last one is cut to the required size. Layout of laminate flooring. The 1st strip has been laid.It is pressed tightly against the wall, having been supported with wedges on each side in advance. The 2nd strip is laid in the same way. Laying begins with a plank cut to 30-50 cm. The 2nd strip begins with a solid plank. This way, the laminate flooring can be laid in a checkerboard pattern, which looks attractive and impressive. At the end, the 2nd strip is adjusted with a hammer, just like the 1st. The next step is to connect the 1st and 2nd strips. To do this, take the 2nd strip and insert it into the end groove of the initial one. Work is carried out at an angle of 20-30 °. First, squeeze tightly, then press from above. The 2nd strip should fit tightly with its comb into the groove of the 1st wall strip. If a gap is found in some place, using a tamping bar and a hammer, the strips are adjusted tightly to each other. Tapping with a hammer is done carefully, without applying much force. In the same way as the first 2 strips, install the covering over the entire floor surface. Please note: do not forget to insert wedges-supports between the strips and the wall surface. Use a jigsaw to bypass pipes and other communications. When you really have to deal with laying the laminate, then all the rules that were revealed above will come in handy. The main thing in this matter is not to rush. Haste will not lead to good. Better slower, but more thoroughly, and everything will work out. Happy renovation!

Layout of laminate flooring. The 1st strip has been laid.It is pressed tightly against the wall, having been supported with wedges on each side in advance. The 2nd strip is laid in the same way. Laying begins with a plank cut to 30-50 cm. The 2nd strip begins with a solid plank. This way, the laminate flooring can be laid in a checkerboard pattern, which looks attractive and impressive. At the end, the 2nd strip is adjusted with a hammer, just like the 1st. The next step is to connect the 1st and 2nd strips. To do this, take the 2nd strip and insert it into the end groove of the initial one. Work is carried out at an angle of 20-30 °. First, squeeze tightly, then press from above. The 2nd strip should fit tightly with its comb into the groove of the 1st wall strip. If a gap is found in some place, using a tamping bar and a hammer, the strips are adjusted tightly to each other. Tapping with a hammer is done carefully, without applying much force. In the same way as the first 2 strips, install the covering over the entire floor surface. Please note: do not forget to insert wedges-supports between the strips and the wall surface. Use a jigsaw to bypass pipes and other communications. When you really have to deal with laying the laminate, then all the rules that were revealed above will come in handy. The main thing in this matter is not to rush. Haste will not lead to good. Better slower, but more thoroughly, and everything will work out. Happy renovation!