Applying plaster to the wall is of the utmost importancepart of the repair. Correctly plastered walls will have a high degree of sound insulation, will insulate the room, and will level the surface. It is customary to distinguish 3 main types of plaster for walls. These are decorative, special and ordinary plaster. They all have their own characteristics. Correctly plastered walls will have good sound insulation.

Correctly plastered walls will have good sound insulation.

Preparation for work

But no matter what plaster you use,you need to follow important rules that will help make the process as easy and high-quality as possible. To do this, you need to immediately stock up on the necessary materials, tools and prepare the wall properly. For work you will need:

- primer;

- putty;

- spatula and large brush;

- plaster mixture;

- lighthouses;

- building level;

- rule;

- pencil for marking;

- small scoop;

- Master OK;

- a trowel;

- pure cold water.

Tools for plastering walls.Particular attention is paid to the choice of a solution for plastering. If you are going to decorate the walls inside the room, it is best to use a gypsum mixture or a lime-sand mortar. Cement-sand mortar is used both for interior and exterior finishing. However, it is preferable to use it for exterior finishing. But special magnesite mixtures are advisable to use when decorating hospital premises and chemical laboratories, where walls can be exposed to different types of radiation. Before plastering, the wall must be prepared. To do this, the surface is covered with a primer, and then all visible cracks are covered with putty. After it dries, the wall is primed again, and then you can start plastering. Return to contents</a>

Tools for plastering walls.Particular attention is paid to the choice of a solution for plastering. If you are going to decorate the walls inside the room, it is best to use a gypsum mixture or a lime-sand mortar. Cement-sand mortar is used both for interior and exterior finishing. However, it is preferable to use it for exterior finishing. But special magnesite mixtures are advisable to use when decorating hospital premises and chemical laboratories, where walls can be exposed to different types of radiation. Before plastering, the wall must be prepared. To do this, the surface is covered with a primer, and then all visible cracks are covered with putty. After it dries, the wall is primed again, and then you can start plastering. Return to contents</a>

Wall plastering in several stages

Before applying plaster onsurface, you need to install beacons. They are special metal strips that can regulate the thickness of the plaster layer, thereby almost perfectly leveling the wall. Return to contents</a>Installation of reference beacons The plaster layer is leveledrule. First, you need to make markings. Measure all visible irregularities with a building level to get an approximate idea of the degree of deviation. After that, take a long rule and, applying it to the wall, draw a horizontal line with a pencil where the defects are most significant and visible. There may be several such places on the wall, which should not be frightening. The ideal option is to use special laser devices that optically make a perfectly straight line. But using a rule is a cheaper option. At the same time, remember that the distance between individual beacon profiles should be approximately 35 cm less than the length of the rule. This will make it possible to optimally adjust the lines. This was considered the process of installing horizontal beacons. But they also need to be positioned vertically, which is where a special cord will come in handy. To do this, holes are drilled at the top of the wall every meter, into which dowels are driven, and small screws are driven into them. In this case, the screws need to be deepened into the dowels only slightly. Now, a thread with a small weight is attached to each of these screws. The length of the thread should be equal to the approximate height of the wall. After that, stand to the side and see where the most convex place is according to the thread level. Now you need to screw the screw into the wall so that the convexity and the thread are as close to each other as possible. Do the same manipulations with the other beacons. This way, you will get reference points that will help you optimally align the wall. In this case, you can even secure the thread in the same way at the bottom of the wall so that it does not twitch.

The plaster layer is leveledrule. First, you need to make markings. Measure all visible irregularities with a building level to get an approximate idea of the degree of deviation. After that, take a long rule and, applying it to the wall, draw a horizontal line with a pencil where the defects are most significant and visible. There may be several such places on the wall, which should not be frightening. The ideal option is to use special laser devices that optically make a perfectly straight line. But using a rule is a cheaper option. At the same time, remember that the distance between individual beacon profiles should be approximately 35 cm less than the length of the rule. This will make it possible to optimally adjust the lines. This was considered the process of installing horizontal beacons. But they also need to be positioned vertically, which is where a special cord will come in handy. To do this, holes are drilled at the top of the wall every meter, into which dowels are driven, and small screws are driven into them. In this case, the screws need to be deepened into the dowels only slightly. Now, a thread with a small weight is attached to each of these screws. The length of the thread should be equal to the approximate height of the wall. After that, stand to the side and see where the most convex place is according to the thread level. Now you need to screw the screw into the wall so that the convexity and the thread are as close to each other as possible. Do the same manipulations with the other beacons. This way, you will get reference points that will help you optimally align the wall. In this case, you can even secure the thread in the same way at the bottom of the wall so that it does not twitch. Before plastering the walls, it is necessary to install beacons.So, the preparation of the wall for the plastering process is complete. Now you need to dilute the solution, which is best done strictly following the instructions on the package of the dry mix to get the highest quality consistency. When the solution is ready, you can start plastering directly. First, you need to fix horizontal beacon strips on the wall surface. For this, a solution is used, on which they are seated. In this case, special attention is paid to the convex parts, where there should be a minimum amount of solution, but it should hold on most firmly. After work, you need to wait about 6-7 hours until the beacons are fixed. Return to the table of contents</a>Spraying and applying a primer coat HowAs a rule, professional plastering is done in several layers. But if you are doing it for the first time, you should use this method, as it will in any case be better than all the others and will provide a good, long-lasting coating. Only 3 layers of plaster mixture are applied. This is spraying, priming and covering layer. Each of these layers has its own application features, which are important to consider when working. Otherwise, you will not achieve good quality.

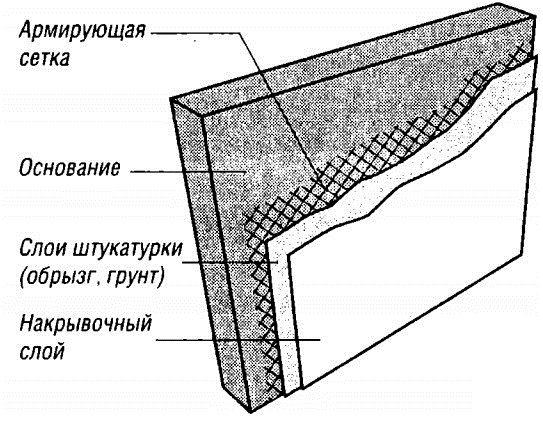

Before plastering the walls, it is necessary to install beacons.So, the preparation of the wall for the plastering process is complete. Now you need to dilute the solution, which is best done strictly following the instructions on the package of the dry mix to get the highest quality consistency. When the solution is ready, you can start plastering directly. First, you need to fix horizontal beacon strips on the wall surface. For this, a solution is used, on which they are seated. In this case, special attention is paid to the convex parts, where there should be a minimum amount of solution, but it should hold on most firmly. After work, you need to wait about 6-7 hours until the beacons are fixed. Return to the table of contents</a>Spraying and applying a primer coat HowAs a rule, professional plastering is done in several layers. But if you are doing it for the first time, you should use this method, as it will in any case be better than all the others and will provide a good, long-lasting coating. Only 3 layers of plaster mixture are applied. This is spraying, priming and covering layer. Each of these layers has its own application features, which are important to consider when working. Otherwise, you will not achieve good quality. Wall plastering scheme.First, the surface is sprayed. As a rule, for this purpose it is necessary to use a small ladle and a plaster mixture, which in its consistency resembles thick sour cream. The solution is collected in the ladle and thrown directly onto the wall. At the same time, try to ensure that the thickness of such "sprays" does not exceed about 8.5 mm for a wooden surface, and about 5 mm for a brick, cinder block or concrete wall. At the same time, make sure that the solution does not go beyond the beacons, both horizontal and vertical. To make the work with the 1st layer more qualitative, experts recommend adding a little alabaster or gypsum to the solution. This will increase the degree of adhesion to the initial base surface and to subsequent layers of plaster. So, work with the 1st layer of plaster can be considered complete. Now we move on to the next layer - the primer. It is the main one in its functionality, so when working with it, it is very important to ensure maximum filling of all cracks and holes. This layer is best applied by regular spreading with a trowel. But if the thickness of the layer in some places on the wall exceeds 1.5 cm, then it is better to apply it in several stages, while waiting for the previous layer to dry completely. Otherwise, the plaster simply will not stick to the wall. Do not forget to follow the beacons Return to the table of contents</a>Applying the top coat and grouting When thisthe work is completed and the plaster dries, you can move on to the last stage of the work - applying the top coat. Keep in mind that the main part should already be leveled along all the beacons. After all, the last layer is more decorative and is designed to level out only minor defects, making the surface as smooth as possible. Therefore, its thickness should ultimately be no more than 3.5 mm. So, after the plaster dries, the main part of the work can be considered complete. Now you just have to grout the plaster. It is very important that the plaster is not too fresh during this work, since it will be difficult to fix the flaws. The best option is dried plaster, when it is no longer wet, but not completely dry either. Grouting is done using a special smooth board, water and a small amount of cement if necessary. To do this, dip the board in water and make circular movements with it on the surface of the wall. In this case, in areas where strong roughness is felt during work, it is advisable to use a small amount of cement. After grouting, the entire process of applying plaster to the wall with your own hands can be considered complete. As you can see, it is not difficult to do the work yourself.

Wall plastering scheme.First, the surface is sprayed. As a rule, for this purpose it is necessary to use a small ladle and a plaster mixture, which in its consistency resembles thick sour cream. The solution is collected in the ladle and thrown directly onto the wall. At the same time, try to ensure that the thickness of such "sprays" does not exceed about 8.5 mm for a wooden surface, and about 5 mm for a brick, cinder block or concrete wall. At the same time, make sure that the solution does not go beyond the beacons, both horizontal and vertical. To make the work with the 1st layer more qualitative, experts recommend adding a little alabaster or gypsum to the solution. This will increase the degree of adhesion to the initial base surface and to subsequent layers of plaster. So, work with the 1st layer of plaster can be considered complete. Now we move on to the next layer - the primer. It is the main one in its functionality, so when working with it, it is very important to ensure maximum filling of all cracks and holes. This layer is best applied by regular spreading with a trowel. But if the thickness of the layer in some places on the wall exceeds 1.5 cm, then it is better to apply it in several stages, while waiting for the previous layer to dry completely. Otherwise, the plaster simply will not stick to the wall. Do not forget to follow the beacons Return to the table of contents</a>Applying the top coat and grouting When thisthe work is completed and the plaster dries, you can move on to the last stage of the work - applying the top coat. Keep in mind that the main part should already be leveled along all the beacons. After all, the last layer is more decorative and is designed to level out only minor defects, making the surface as smooth as possible. Therefore, its thickness should ultimately be no more than 3.5 mm. So, after the plaster dries, the main part of the work can be considered complete. Now you just have to grout the plaster. It is very important that the plaster is not too fresh during this work, since it will be difficult to fix the flaws. The best option is dried plaster, when it is no longer wet, but not completely dry either. Grouting is done using a special smooth board, water and a small amount of cement if necessary. To do this, dip the board in water and make circular movements with it on the surface of the wall. In this case, in areas where strong roughness is felt during work, it is advisable to use a small amount of cement. After grouting, the entire process of applying plaster to the wall with your own hands can be considered complete. As you can see, it is not difficult to do the work yourself.