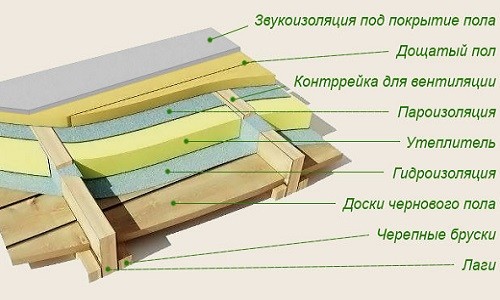

Many home and apartment owners are thinking abouthow to improve the microclimate in your home. One of the ways to create more comfortable conditions in the house is to insulate the floors. How to insulate the floor with different materials? No need to talk about installing a warm floor. Such a design is not insulation, but a heating system. The insulation performs a different task (insulating the room from the effects of adverse external factors). Thermal insulation of the floor is different from its heating. A warm floor will not effectively heat the room if it is not reliably insulated. Floor insulation scheme with vapor and waterproofing.

Floor insulation scheme with vapor and waterproofing.

Materials for thermal insulation

The answer to the question of what can be used to insulate the floor will be a list of the most popular materials for thermal insulation. This list includes:

- mineral wool (and roll, and plate);

- expanded polystyrene (expanded and extruded);

- expanded clay;

- wood;

- board materials from wood;

- linoleum.

Scheme of insulation of wooden floor. All these materials to a greater or lesser extent possess such properties necessary for insulation of the floor as:

Scheme of insulation of wooden floor. All these materials to a greater or lesser extent possess such properties necessary for insulation of the floor as:

- low thermal conductivity;

- high ecological compatibility;

- great service life;

- Ease of installation.

True, it is possible to insulate floors with their helpwill only be possible with a significant reduction in the space between the lower and upper floors of the room. Insulation made of plywood or linoleum, after the installation of which the height of the room practically does not change, turns out to be ineffective without the use of other thermal insulation materials. It should be noted that the insulation will only be able to fully perform its functions when it is protected from moisture. Wet thermal insulation loses its properties. In addition, the moisture accumulated in it will cause mold to form on the building materials and their subsequent rotting. Return to contents</a>

Laying of waterproofing on the first floor

Insulation of floors on joists.Before insulating the floor, it is necessary to carry out its thorough preparation. Waterproofing is arranged on a base cleared of the old coating. It is also necessary to remove the old screed in order to subsequently provide protection of the new floor from condensation. It should be said that waterproofing laid on the ceiling counteracts moisture only above it, and the base of the room itself remains unprotected. Residents of apartment buildings, or rather, residents of the first floors, face this problem. If there is a basement under the apartment, then you can cover its ceiling under your living space with waterproofing. This operation is best carried out in the warm season, so that there is an opportunity to dry the ceiling as well as possible. Before drying, peeling fragments are removed from the ceiling, cracks and depressions are sealed with mortar. After drying, the ceiling is treated:

Insulation of floors on joists.Before insulating the floor, it is necessary to carry out its thorough preparation. Waterproofing is arranged on a base cleared of the old coating. It is also necessary to remove the old screed in order to subsequently provide protection of the new floor from condensation. It should be said that waterproofing laid on the ceiling counteracts moisture only above it, and the base of the room itself remains unprotected. Residents of apartment buildings, or rather, residents of the first floors, face this problem. If there is a basement under the apartment, then you can cover its ceiling under your living space with waterproofing. This operation is best carried out in the warm season, so that there is an opportunity to dry the ceiling as well as possible. Before drying, peeling fragments are removed from the ceiling, cracks and depressions are sealed with mortar. After drying, the ceiling is treated:

- antiseptic;

- a primer;

- waterproofing mastic in 2-3 layers.

Scheme of floor insulation with polystyrene foam.Each impregnation is applied to the surface after the previous composition has dried. As an option for installing moisture protection, you can use pasting the ceiling with polystyrene foam boards. Extruded EPS should be used, since its moisture absorption coefficient is minimal. The boards are treated with an adhesive composition and glued to the surface tightly to each other. It is important to ensure that the panels fit tightly to it over their entire area. If there are protrusions on the ceiling, the boards are trimmed to fit their shape. The space between the sheets is filled with pieces of EPS or the same, but diluted in a solvent. The seams are coated with glue, and the surface of the boards is covered with a primer. Return to the table of contents</a>

Scheme of floor insulation with polystyrene foam.Each impregnation is applied to the surface after the previous composition has dried. As an option for installing moisture protection, you can use pasting the ceiling with polystyrene foam boards. Extruded EPS should be used, since its moisture absorption coefficient is minimal. The boards are treated with an adhesive composition and glued to the surface tightly to each other. It is important to ensure that the panels fit tightly to it over their entire area. If there are protrusions on the ceiling, the boards are trimmed to fit their shape. The space between the sheets is filled with pieces of EPS or the same, but diluted in a solvent. The seams are coated with glue, and the surface of the boards is covered with a primer. Return to the table of contents</a>

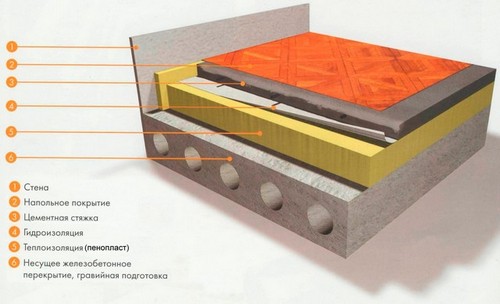

Isolation of a new floor

Insulating the floor using isolon.When building a house that will stand on a strip foundation, preliminary waterproofing is arranged before pouring the concrete floor slab. In addition, laying a blind area will help insulate the floor, which will not allow moisture to penetrate into the foundation. And inside the strip foundation on the compacted soil, a backfill of sand and gravel mixture is made. After leveling, it is compacted, and a waterproofing membrane is laid on it. For this purpose, bitumen roll materials or a dense polyethylene film in 2 layers are used. To prevent water from seeping through the membrane, adjacent sheets of insulators are laid with an overlap (15 cm). The joints of the roofing felt are sealed with bitumen, and the film joints are sealed with tape. The top layer is laid perpendicular to the bottom. It is necessary that the membrane overlaps the walls to the height of the screed. After laying the reinforcement, the floor is poured. After hardening, it is ready, like the ceilings in an apartment building, for insulation. But before laying the insulation, the base must be impregnated with an antiseptic, primer, covered with bitumen mastic or roofing felt. Return to contents</a>

Insulating the floor using isolon.When building a house that will stand on a strip foundation, preliminary waterproofing is arranged before pouring the concrete floor slab. In addition, laying a blind area will help insulate the floor, which will not allow moisture to penetrate into the foundation. And inside the strip foundation on the compacted soil, a backfill of sand and gravel mixture is made. After leveling, it is compacted, and a waterproofing membrane is laid on it. For this purpose, bitumen roll materials or a dense polyethylene film in 2 layers are used. To prevent water from seeping through the membrane, adjacent sheets of insulators are laid with an overlap (15 cm). The joints of the roofing felt are sealed with bitumen, and the film joints are sealed with tape. The top layer is laid perpendicular to the bottom. It is necessary that the membrane overlaps the walls to the height of the screed. After laying the reinforcement, the floor is poured. After hardening, it is ready, like the ceilings in an apartment building, for insulation. But before laying the insulation, the base must be impregnated with an antiseptic, primer, covered with bitumen mastic or roofing felt. Return to contents</a>

Warming of concrete floor with expanded clay

Insulation of the floor with expanded clay.Expanded clay is not only a high-quality insulator, but also a good sound insulator. That is why it is still often used in construction. It can be laid on a base prepared in the manner described above, and then filled with a leveling screed. The thickness of the expanded clay backfill can be from 5 to 15 cm. It is leveled along the surface and carefully tamped. After that, beacons are installed on the expanded clay, and the solution is poured. After it hardens, the floor is ready for laying plywood, fiberboard, linoleum or pouring a self-leveling floor. On this base, you can also arrange a warm floor. Expanded clay is often used as insulation for a floor on logs. If the logs are to be laid on a leveling screed, then a waterproofing membrane is laid on it. After installing the support beams, expanded clay is poured between them. After the insulation work is completed, the joists are covered with boards or wood slabs, which also make the floor warmer. Recently, the technology of adjustable joists has been used often. They are installed on supports, the height of which can be changed. With this method of installation, preliminary leveling of the base is not necessary. In this case, expanded clay is poured after leveling the beams and evenly distributed over the entire surface of the base. It is worth adding that expanded polystyrene granules can be used instead of expanded clay. It is poured between the beams in exactly the same way. Return to the table of contents</a>

Insulation of the floor with expanded clay.Expanded clay is not only a high-quality insulator, but also a good sound insulator. That is why it is still often used in construction. It can be laid on a base prepared in the manner described above, and then filled with a leveling screed. The thickness of the expanded clay backfill can be from 5 to 15 cm. It is leveled along the surface and carefully tamped. After that, beacons are installed on the expanded clay, and the solution is poured. After it hardens, the floor is ready for laying plywood, fiberboard, linoleum or pouring a self-leveling floor. On this base, you can also arrange a warm floor. Expanded clay is often used as insulation for a floor on logs. If the logs are to be laid on a leveling screed, then a waterproofing membrane is laid on it. After installing the support beams, expanded clay is poured between them. After the insulation work is completed, the joists are covered with boards or wood slabs, which also make the floor warmer. Recently, the technology of adjustable joists has been used often. They are installed on supports, the height of which can be changed. With this method of installation, preliminary leveling of the base is not necessary. In this case, expanded clay is poured after leveling the beams and evenly distributed over the entire surface of the base. It is worth adding that expanded polystyrene granules can be used instead of expanded clay. It is poured between the beams in exactly the same way. Return to the table of contents</a>

Warming with expanded polystyrene

Scheme of insulation of the floor of the first floor usingfoam plastic. Now about how it is possible. Like expanded clay, they can be laid under the leveling screed or between the joists. In the first case, it is better to lay slabs of extruded material (penoplex). They are more durable, in addition, the EPS will be covered with a screed and finishing materials on top, so its use is harmless to health. The slabs are laid as tightly as possible to each other, and possible gaps between them are filled with polystyrene foam or glue. The panels are laid in a checkerboard pattern. They are covered with a primer on top. Before pouring the solution, reinforcement is laid on the EPS, which will strengthen the screed. The metal reinforcing grid consists of 10x10 cm cells. The thickness of the wire should be at least 8 mm. It is necessary to leave a gap of 1-1.5 cm between the EPS and the reinforcement so that the latter is in the thickness of the screed. When installing a floor on joists, it is better to use foamed polystyrene foam (foam plastic). It is more fragile than extruded EPS, but the strength characteristics of the foamed material when laid between the beams play a secondary role. It is important that the slabs are laid without gaps. Possible cracks between them are sealed in the same way as described above. Return to contents</a>

Scheme of insulation of the floor of the first floor usingfoam plastic. Now about how it is possible. Like expanded clay, they can be laid under the leveling screed or between the joists. In the first case, it is better to lay slabs of extruded material (penoplex). They are more durable, in addition, the EPS will be covered with a screed and finishing materials on top, so its use is harmless to health. The slabs are laid as tightly as possible to each other, and possible gaps between them are filled with polystyrene foam or glue. The panels are laid in a checkerboard pattern. They are covered with a primer on top. Before pouring the solution, reinforcement is laid on the EPS, which will strengthen the screed. The metal reinforcing grid consists of 10x10 cm cells. The thickness of the wire should be at least 8 mm. It is necessary to leave a gap of 1-1.5 cm between the EPS and the reinforcement so that the latter is in the thickness of the screed. When installing a floor on joists, it is better to use foamed polystyrene foam (foam plastic). It is more fragile than extruded EPS, but the strength characteristics of the foamed material when laid between the beams play a secondary role. It is important that the slabs are laid without gaps. Possible cracks between them are sealed in the same way as described above. Return to contents</a>

Filling of mineral wool

Mineral wool is very effectiveinsulation, but it can only be used to fill voids. Because of its looseness, it cannot serve as a base for a screed, so mineral wool is laid only when installing floors on logs. In addition, the material strongly absorbs moisture. To prevent its contact with steam and water, it is necessary to take care of enhanced waterproofing. Roll mineral wool and basalt slabs are used for thermal insulation. The dimensions of the insulator should be slightly larger than the distance between the logs, then there will be no gaps in the insulation. First, whole sheets or slabs should be laid, and then fragments of the material are laid. If 2 (or more) layers of thermal insulation are arranged, then the joints at the next levels should not coincide with the joints of the sheets at the previous ones. Before laying the floor, a waterproofing agent is laid on the mineral wool. Return to the table of contents</a>

Warming of the floor on a columnar foundation

Some buildings stand on a columnar foundationfoundation. Double floors are used to insulate them. A waterproofing layer is laid on the lower (rough, raised floor) floor treated with an antiseptic. Expanded clay is poured between the joists or mineral wool is laid. A membrane is laid on them, and the finishing coating is laid on top.</ ul>