In order for the house to be warmer,carry out a whole range of works aimed at its insulation. The primary goal in this case is the thermal insulation of the floor, but it is important to choose the right material so that the work is effective. As the most common heat insulator is foam, which is due to its many advantages. Before you insulate the floor with foam, you should familiarize yourself with the technology of the work, because only then the master will be able to achieve a positive result.  To insulate the floor with polystyrene, you first need to clean the base, then lay the film with the overlap and secure the edges with adhesive tape.

To insulate the floor with polystyrene, you first need to clean the base, then lay the film with the overlap and secure the edges with adhesive tape.

Thermal insulation of a wooden floor

As a rule, in private houses are equippedwooden floors, as they have minimal load on the floor. Warming of the floor with foam should be done only after the surface can be prepared. It is necessary to clean the base, get rid of cracks and cracks through which parasites can penetrate. Then the film is covered with an overlap, the width of which is 10 cm.  The scheme of warming the wooden floor with foam plastic. After laying the waterproofing edge, it is necessary to strengthen the edges with adhesive tape. On the laid coating, sheets of foam should be laid. From the received joints it is necessary to get rid by a method with a fillet by a mounting staff. Then another layer of film follows, which will exclude the effect of moisture on the material from the side of the room. After all the above steps have been carried out, it is possible to proceed with the installation of the concrete screed and the installation of the finishing coat. The thickness of the mortar layer should be 5 cm. For the work, some tools and materials should be prepared:

The scheme of warming the wooden floor with foam plastic. After laying the waterproofing edge, it is necessary to strengthen the edges with adhesive tape. On the laid coating, sheets of foam should be laid. From the received joints it is necessary to get rid by a method with a fillet by a mounting staff. Then another layer of film follows, which will exclude the effect of moisture on the material from the side of the room. After all the above steps have been carried out, it is possible to proceed with the installation of the concrete screed and the installation of the finishing coat. The thickness of the mortar layer should be 5 cm. For the work, some tools and materials should be prepared:

- film;

- mounting foam;

- Styrofoam;

- cement;

- sand;

- capacity;

- shovel.

Back to contents</a>

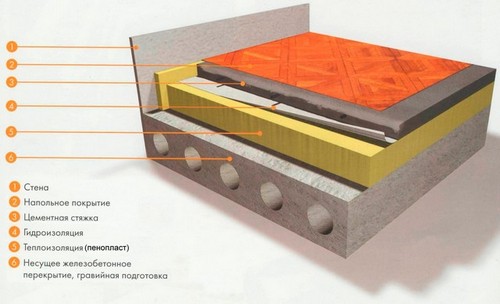

Insulation of concrete floor

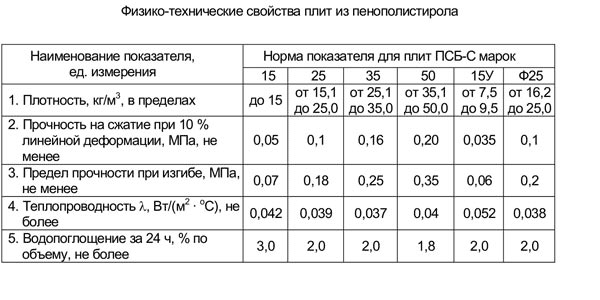

Thermal insulation of concrete floor is carried out in cases of overlap, under which there is a basement, and without it.  Table of characteristics of foam plastic. If there is a basement under the floor, then the concrete overlap may be even colder. If there is access to the basement, then it is preferable to fix the material from the basement side. This allows you to place the plate in a layer of air. In order to insulate the floor, use a foam with a thickness of 5-10 cm. Fix the material to the surface in the basement space with plastic dowels, which have a length of 120-140 mm. It is necessary to start working from the most remote areas of the room. The cloth should be attached to the plate, arrange holes through it using a perforator. Then the sheet must be laid aside, continuing drilling, the diameter of the holes should be equal to the corresponding index of the fasteners. Before insulating the surface with foam plastic by hand, the sheets must be applied with glue, designed to work with a heater. Cloths should be fixed with dowels, filling the obtained seams with mounting foam.

Table of characteristics of foam plastic. If there is a basement under the floor, then the concrete overlap may be even colder. If there is access to the basement, then it is preferable to fix the material from the basement side. This allows you to place the plate in a layer of air. In order to insulate the floor, use a foam with a thickness of 5-10 cm. Fix the material to the surface in the basement space with plastic dowels, which have a length of 120-140 mm. It is necessary to start working from the most remote areas of the room. The cloth should be attached to the plate, arrange holes through it using a perforator. Then the sheet must be laid aside, continuing drilling, the diameter of the holes should be equal to the corresponding index of the fasteners. Before insulating the surface with foam plastic by hand, the sheets must be applied with glue, designed to work with a heater. Cloths should be fixed with dowels, filling the obtained seams with mounting foam.  The scheme of insulation of concrete floor with the help offoam. When carrying out this kind of work from the basement, it can happen that it will not work to use entire sheets. In this case, you can initially prepare a template for cutting the material from the cardboard, through which the insulation sheet of the appropriate size is cut and reinforced in its place. After the insulation of the floor with polystyrene has been completed, leave the surface until the glue dries. Then it is necessary to protect the surface of the insulation, as it is a fuel. Use for this should be plaster. It is permissible to apply the composition to work with ceramics, in this case it is worth using reinforcing mesh. This will allow us to equip a thin, but reliable layer. Back to contents</a>

The scheme of insulation of concrete floor with the help offoam. When carrying out this kind of work from the basement, it can happen that it will not work to use entire sheets. In this case, you can initially prepare a template for cutting the material from the cardboard, through which the insulation sheet of the appropriate size is cut and reinforced in its place. After the insulation of the floor with polystyrene has been completed, leave the surface until the glue dries. Then it is necessary to protect the surface of the insulation, as it is a fuel. Use for this should be plaster. It is permissible to apply the composition to work with ceramics, in this case it is worth using reinforcing mesh. This will allow us to equip a thin, but reliable layer. Back to contents</a>

Thermal insulation of a concrete floor in a building without a basement

If the insulation with foam by own handsIt is supposed to be produced in the area of the floor, under which there is no basement, then it is necessary to initially get rid of the old floor covering. The roughing base should be checked for chips, which can be removed with the help of adhesive for laying ceramic tiles.  Thermal insulation scheme for a concrete floor without a basement.Cracks can be removed by applying a thick mortar applied with a steel trowel. Once the mixture is dry, you can proceed to waterproofing the surface. For this, it is recommended to use bituminous mastic, which can be replaced with roll material. When laying, the material should go to the surface of the walls by 10-15 cm. Next, it is necessary to cover the reinforcement, which can be a masonry mesh. After that, you can start insulating the floor with foam. The optimal thickness of the material is 2-3 cm. Laying should be done as tightly as possible, distributing the mixture over the canvases. The formation of gaps in this case must be avoided. Before the foam, it is worth preparing the glue, which is plugged with a drill with a mixer operating at medium speed. The cakes of the mixture should be removed by 30 cm, which will be enough for a firm attachment. After the laying of the sheets is completed, you should leave the insulation for a while, until the mixture gains strength, then you can start installing the beacons. In order to install the outermost ones, you should make marks on the walls using a water level, while the rest of the elements should be installed using a linear level. For attaching beacons, it is worth using the remnants of glue. Their distance should be equal to 1.4 m. This is necessary for the even laying of the screed, the mixture of which is to be thrown between the marks, eliminating the excess with a rail, which will give the floor an ideal surface. If you intend to choose parquet as a topcoat, after the screed is cured, it is necessary to additionally fill the floor with a self-leveling compound of 2-3 mm. Back to the table of contents</a>

Thermal insulation scheme for a concrete floor without a basement.Cracks can be removed by applying a thick mortar applied with a steel trowel. Once the mixture is dry, you can proceed to waterproofing the surface. For this, it is recommended to use bituminous mastic, which can be replaced with roll material. When laying, the material should go to the surface of the walls by 10-15 cm. Next, it is necessary to cover the reinforcement, which can be a masonry mesh. After that, you can start insulating the floor with foam. The optimal thickness of the material is 2-3 cm. Laying should be done as tightly as possible, distributing the mixture over the canvases. The formation of gaps in this case must be avoided. Before the foam, it is worth preparing the glue, which is plugged with a drill with a mixer operating at medium speed. The cakes of the mixture should be removed by 30 cm, which will be enough for a firm attachment. After the laying of the sheets is completed, you should leave the insulation for a while, until the mixture gains strength, then you can start installing the beacons. In order to install the outermost ones, you should make marks on the walls using a water level, while the rest of the elements should be installed using a linear level. For attaching beacons, it is worth using the remnants of glue. Their distance should be equal to 1.4 m. This is necessary for the even laying of the screed, the mixture of which is to be thrown between the marks, eliminating the excess with a rail, which will give the floor an ideal surface. If you intend to choose parquet as a topcoat, after the screed is cured, it is necessary to additionally fill the floor with a self-leveling compound of 2-3 mm. Back to the table of contents</a>

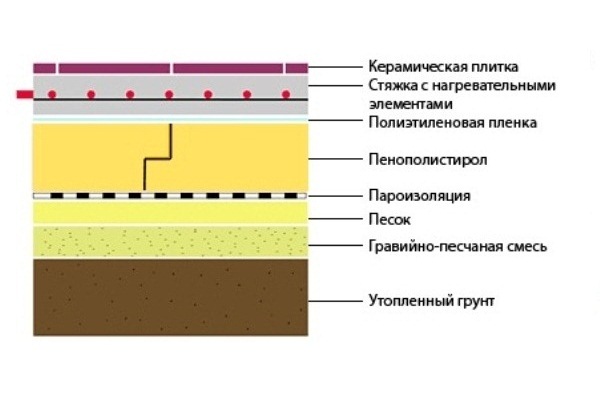

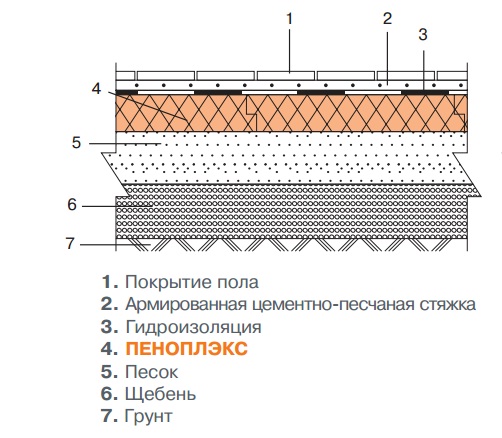

Warming of the floor on the ground

In order to insulate the floor, equipped withsoil, it should be leveled. With loose soil, it should be compacted and allowed to settle within a month. Further, a pillow made of crushed stone 10 cm thick, instead of gravel, can be produced in any case. Then a layer of sand of the same thickness is covered, pressed and covered with a film. The basis for the foam insulation of the floor with its own hands must be dry and clean, as well as devoid of significant unevenness.  Scheme of floor insulation on the ground. As a moisture protection, it is possible to use polyethylene with a thickness of 0.2 mm or roofing material. Strips of the material should be laid with a 10 cm clearance and a 15 cm wall outlet. Heat insulation should be started from the corner, tightly pressing. To ensure the ligation, the next row should be started with ½ plates. Laying is recommended to be carried out in 2 layers, with the aim of removing the seams, in order to avoid the formation of cold bridges. Completely prevent the penetration of cold use of material with milled locks "spike-groove". The last cloths need to be cut a little larger, so that their laying was carried out with effort. After that, the material should be covered with another layer of polyethylene with a thickness equal to 0.2 mm. In exchange, you can use a roofing material, removing its edges up the wall. To obtain a more impressive floor resistance, the screed is recommended to be reinforced with a steel or alkali-resistant mesh. On the covered plates it is necessary to pour out the concrete, which becomes thick. The minimum thickness of the screed should be 4 cm. Warming of the floor is not a difficult task, therefore the work can be done independently.

Scheme of floor insulation on the ground. As a moisture protection, it is possible to use polyethylene with a thickness of 0.2 mm or roofing material. Strips of the material should be laid with a 10 cm clearance and a 15 cm wall outlet. Heat insulation should be started from the corner, tightly pressing. To ensure the ligation, the next row should be started with ½ plates. Laying is recommended to be carried out in 2 layers, with the aim of removing the seams, in order to avoid the formation of cold bridges. Completely prevent the penetration of cold use of material with milled locks "spike-groove". The last cloths need to be cut a little larger, so that their laying was carried out with effort. After that, the material should be covered with another layer of polyethylene with a thickness equal to 0.2 mm. In exchange, you can use a roofing material, removing its edges up the wall. To obtain a more impressive floor resistance, the screed is recommended to be reinforced with a steel or alkali-resistant mesh. On the covered plates it is necessary to pour out the concrete, which becomes thick. The minimum thickness of the screed should be 4 cm. Warming of the floor is not a difficult task, therefore the work can be done independently.