Each repair is accompanied by its own workersnuances that should always be foreseen in advance. High-quality wall covering with plastic with your own hands is carried out quite quickly, but the process must be approached with all attention and scrupulousness. Plastic panels are a cheap and durable material that can easily withstand wet cleaning.

Plastic panels are a cheap and durable material that can easily withstand wet cleaning.

Surface preparation

Tools and materials:

- level;

- putty knife;

- roulette;

- profile directing;

- profile U-shaped;

- plastic wedges;

- corner connecting elements.

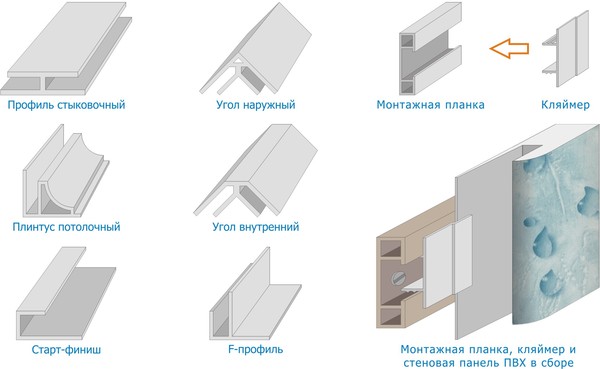

To begin with, you need to clear the walls of claddingexcess construction waste. This is done not so much out of necessity as to prevent further destruction. Usually, a simple metal spatula is used for cleaning, which removes everything that does not hold well. Now you need to form the lathing on the walls. This will require special plastic profiles that are mounted horizontally to the walls on screws with dowels. The step between the profiles is 40 cm, due to which the installation will be accompanied by maximum reliability without the slightest overspending. During installation, a hole is first drilled in the selected place, after which a dowel is driven into it, and only at the very end is the screw tightened. Materials for working with plastic panels.During installation, it is necessary to pay attention to the fact that the walls are often uneven, so it will be necessary to artificially align the lathing. For this, a mounting level and special plastic wedges are used. It is not necessary to drill the wedges themselves during work, since the drill is quite easily beveled, but many craftsmen prefer to achieve maximum quality. At this stage, each step is checked with a long mounting level not only for ideal horizontal and vertical alignment, but also for their mutual parallelism. Special vertical elements are screwed to the corners of the room, which allow the material to be perfectly joined together to form visual integrity. In addition, the U-shaped profile levels out all the imperfections of the surface and material. Return to contents</a>

Materials for working with plastic panels.During installation, it is necessary to pay attention to the fact that the walls are often uneven, so it will be necessary to artificially align the lathing. For this, a mounting level and special plastic wedges are used. It is not necessary to drill the wedges themselves during work, since the drill is quite easily beveled, but many craftsmen prefer to achieve maximum quality. At this stage, each step is checked with a long mounting level not only for ideal horizontal and vertical alignment, but also for their mutual parallelism. Special vertical elements are screwed to the corners of the room, which allow the material to be perfectly joined together to form visual integrity. In addition, the U-shaped profile levels out all the imperfections of the surface and material. Return to contents</a>

Installation work

Tools and materials:

- electric jigsaw;

- Screwdriver;

- roulette;

- level;

- plastic panels;

- plinth.

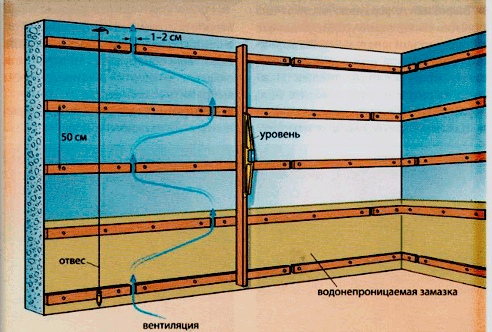

Before covering the walls with plastic, you need toMake sure for the last time that the surface has been prepared and carefully inspect the U-shaped profiles. They should be positioned so that the opposite ones “look” at each other. Installation diagram of the lathing.A plastic panel is fixed between the profiles, which rests against the corner strip, and on the reverse side it is fixed with self-tapping screws (only those with a washer under the head are used, since ordinary ones can crack) to the lathing. Fixation is carried out at all points of contact in order to achieve the maximum effect. Each subsequent panel is initially fixed with a tooth for the previous one (there is a groove on the reverse side), after which it is manually brought to the desired position. Some difficulty arises when installing the last panel, since its width usually exceeds the required parameters. To do this, you need to use a jigsaw and a blade with fine teeth to make a longitudinal cut. Small holes are made at the places of future joints, and after the panel is installed, screws are screwed through the holes. Working with the ceiling is a little more difficult, but the principle is the same. The main difference is that you will have to fix it with 1 hand, since the other one holds the material in the desired position. After finishing the wall and ceiling paneling, you need to proceed to the last stage - installing the baseboards. They are simply laid under the ceiling in the corners, and when pressed, they snap into place. Glue or any other fastening material is not required. Return to contents</a>

Installation diagram of the lathing.A plastic panel is fixed between the profiles, which rests against the corner strip, and on the reverse side it is fixed with self-tapping screws (only those with a washer under the head are used, since ordinary ones can crack) to the lathing. Fixation is carried out at all points of contact in order to achieve the maximum effect. Each subsequent panel is initially fixed with a tooth for the previous one (there is a groove on the reverse side), after which it is manually brought to the desired position. Some difficulty arises when installing the last panel, since its width usually exceeds the required parameters. To do this, you need to use a jigsaw and a blade with fine teeth to make a longitudinal cut. Small holes are made at the places of future joints, and after the panel is installed, screws are screwed through the holes. Working with the ceiling is a little more difficult, but the principle is the same. The main difference is that you will have to fix it with 1 hand, since the other one holds the material in the desired position. After finishing the wall and ceiling paneling, you need to proceed to the last stage - installing the baseboards. They are simply laid under the ceiling in the corners, and when pressed, they snap into place. Glue or any other fastening material is not required. Return to contents</a>

Summarizing

In order to properly cover with plasticwalls, it will not take much effort and time, because this finishing material is not without reason called the simplest of all existing ones. Its versatility allows it to compete even with plasterboard, because the external result is in no way inferior, and does not require additional finishing. Even if you have never had experience in construction and installation activities, this procedure can be performed safely. The only thing that is important to consider is the correct choice of a high-quality tool that will not fail at a crucial moment.</ ul>