As a material for interior finishing worksplasterboard has long and firmly won the leading position. Plasterboard systems can act not only as an alternative to plaster or suspended ceilings, but also as interior partitions. Installation of such systems, although requiring some skills and dexterity, can be done on your own if you have the time and desire. Construction of a partition made of plasterboard.

Construction of a partition made of plasterboard.

Preparation of tools and materials

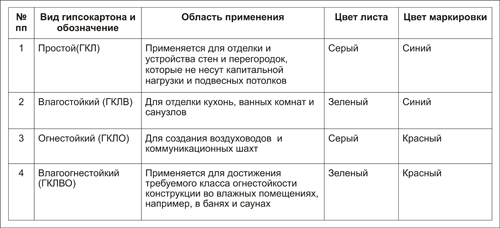

In order to begin the actual installation, you need to purchase the necessary materials and prepare the working tool. Gypsum plasterboard sheets (GKL) have several standard sizes and thicknesses, the most popular of them are 1200 x 2500 mm with a thickness of 12.5 mm. The material can be purchased in other dimensions if this allows you to save money, but the thickness is better to take 12.5 mm, thin sheets are not used for partitions. According to the purpose, the material is of 3 types:

Types of plasterboard, area of application and theircolor marking. The cost of materials for various purposes increases in the same order as presented in the list. Plasterboard sheets will need to be attached to a frame, which consists of special profiles. The latter are made of galvanized steel with a thickness of 0.4-0.7 mm, have a U-shape and come in different widths. This size in this case determines the thickness of the future partition, so it is selected individually. One of the most popular is a profile with a width of 75 mm. Since an interior partition is rarely found without doors, then to strengthen the doorway you will need a dry wooden beam of the same width as the U-shaped profile, since it will be inserted inside it. To install a plasterboard partition, you will need additional and consumable materials:

Types of plasterboard, area of application and theircolor marking. The cost of materials for various purposes increases in the same order as presented in the list. Plasterboard sheets will need to be attached to a frame, which consists of special profiles. The latter are made of galvanized steel with a thickness of 0.4-0.7 mm, have a U-shape and come in different widths. This size in this case determines the thickness of the future partition, so it is selected individually. One of the most popular is a profile with a width of 75 mm. Since an interior partition is rarely found without doors, then to strengthen the doorway you will need a dry wooden beam of the same width as the U-shaped profile, since it will be inserted inside it. To install a plasterboard partition, you will need additional and consumable materials:

In order to assemble a plasterboard partition, you need to have the following basic power tools and devices: Tool for working with plasterboard.

Tool for working with plasterboard.

- electric screwdriver;

- Special knife for cutting GKL;

- gon 90 °;

- building level;

- plumb bob;

- scissors for cutting metal;

- a hammer;

- roulette.

Ideal option when availablea construction laser level that can replace a regular level and plumb line. It is much more convenient to work with such a device, and the quality of measurements is much higher. Return to contents</a>

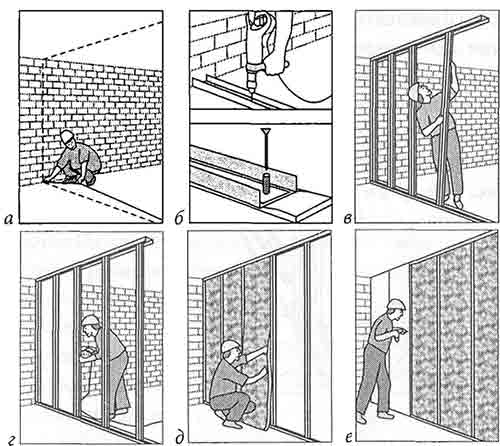

Assembling the frame from galvanized profiles

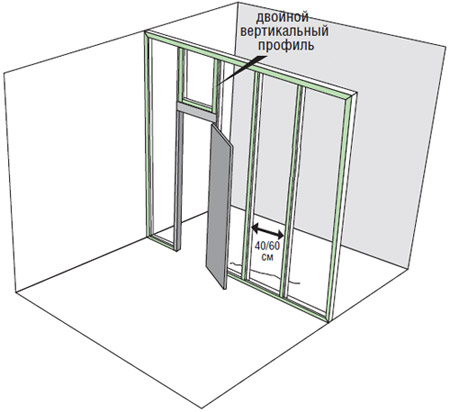

Installation of plasterboard partition beginswith the assembly of a metal frame to which the gypsum boards will be attached. To do this, it is necessary to determine the location of the partition and mark it on the floor of the room in the form of a line, observing perpendicularity to the existing walls. The exception is partitions specially turned at a certain angle. Next, a galvanized U-shaped profile is attached to the floor along the drawn line with the shelf down. The fastening method depends on the floor material, self-tapping screws or dowels are screwed in at intervals of 150 mm. Using a level and a plumb line, we make markings on the walls and ceiling, after which we attach the profiles to them in the same way. The latter are produced in standard lengths of 3 and 4 m, so you need to measure and prepare the profiles of the required length in advance, cutting off the excess with metal scissors. At the joints and junctions of the floor and walls, the products are inserted into each other, fixed together on the sides with short self-tapping screws for metal (10 mm long). As a result, the entire contour of the future plasterboard partition must be edged with a profile. Scheme of metal frame for partition fromdrywall. The next step is to install vertical support posts. Their ends are inserted into the profile laid on the floor and attached to the ceiling, the post is aligned vertically using a level and fixed on the sides with short screws at the bottom and top. The distance between two posts depends on the width of the drywall sheet. The calculation is as follows: each sheet should rest on 3 posts, 2 at the edges and 1 in the middle of the sheet. In this case, its edge should go exactly halfway along the side surface of the profile, leaving room for fastening the next sheet. To tighten the structure, horizontal spacers are fixed between the vertical posts. Their number depends on the height of the ceilings, under standard conditions it is 2-3 pcs. To do this, measure the distance from the inner surface of the U-shaped profile of the first post to the outer end of the next one. Having cut a piece of the profile to this size, one end of it is cut. To do this, make 2 cuts with scissors at the corners for a length equal to the side surface of the U-shaped profile. After this, the wide shelf is bent outward at an angle of 90⁰ and the part is installed in place. One end of it is traditionally inserted inside the rack, the second connection will be of the "tongue and groove" type. The spacer is fixed to the racks with short screws, screwing them on the sides. Return to the table of contents</a>Forming a doorway VerticalThe posts to which the door frame will be attached must be reinforced with wooden blocks inserted inside the profiles. Here, all connections are made with self-tapping screws 35-40 mm long so that they securely fasten the metal to the wood. The upper horizontal lintel of the doorway must be installed in the same way as the spacers, only insert a wooden block into it. To connect the wooden reinforcing structures together, 2 long screws (100-120 mm) must be screwed in from the outside of the vertical post so that they enter the block located in the horizontal lintel.

Scheme of metal frame for partition fromdrywall. The next step is to install vertical support posts. Their ends are inserted into the profile laid on the floor and attached to the ceiling, the post is aligned vertically using a level and fixed on the sides with short screws at the bottom and top. The distance between two posts depends on the width of the drywall sheet. The calculation is as follows: each sheet should rest on 3 posts, 2 at the edges and 1 in the middle of the sheet. In this case, its edge should go exactly halfway along the side surface of the profile, leaving room for fastening the next sheet. To tighten the structure, horizontal spacers are fixed between the vertical posts. Their number depends on the height of the ceilings, under standard conditions it is 2-3 pcs. To do this, measure the distance from the inner surface of the U-shaped profile of the first post to the outer end of the next one. Having cut a piece of the profile to this size, one end of it is cut. To do this, make 2 cuts with scissors at the corners for a length equal to the side surface of the U-shaped profile. After this, the wide shelf is bent outward at an angle of 90⁰ and the part is installed in place. One end of it is traditionally inserted inside the rack, the second connection will be of the "tongue and groove" type. The spacer is fixed to the racks with short screws, screwing them on the sides. Return to the table of contents</a>Forming a doorway VerticalThe posts to which the door frame will be attached must be reinforced with wooden blocks inserted inside the profiles. Here, all connections are made with self-tapping screws 35-40 mm long so that they securely fasten the metal to the wood. The upper horizontal lintel of the doorway must be installed in the same way as the spacers, only insert a wooden block into it. To connect the wooden reinforcing structures together, 2 long screws (100-120 mm) must be screwed in from the outside of the vertical post so that they enter the block located in the horizontal lintel. If you take the right approach, you shoulddetermine in advance the places where shelves or other interior details will be attached to the partition. In order not to test the strength of the plasterboard sheet later by hanging a shelf directly to it, it is better to install additional horizontal struts made of wooden beams in this place. The installation technology is the same as when installing a horizontal crossbar of a doorway. Now the metal frame is ready, and before continuing to install the partition, you need to lay the electric lighting wires inside it, if necessary. You should know that inside such a partition, the wires must be laid in a fireproof insulating tube. For this purpose, special holes are provided in good quality U-shaped profiles. Return to contents</a>

If you take the right approach, you shoulddetermine in advance the places where shelves or other interior details will be attached to the partition. In order not to test the strength of the plasterboard sheet later by hanging a shelf directly to it, it is better to install additional horizontal struts made of wooden beams in this place. The installation technology is the same as when installing a horizontal crossbar of a doorway. Now the metal frame is ready, and before continuing to install the partition, you need to lay the electric lighting wires inside it, if necessary. You should know that inside such a partition, the wires must be laid in a fireproof insulating tube. For this purpose, special holes are provided in good quality U-shaped profiles. Return to contents</a>

Instructions for finishing the frame in sheets

Solid sheets are attached to the frame profilesvertical position. A gap of 3-5 mm is maintained between the product and the floor surface using stands, after which the sheet is screwed with 35 mm long self-tapping screws to the side surfaces of the profiles. The tightening force of the screwdriver should be adjusted so that the head of the screw after tightening is flush with the plane of the gypsum board. The distance between the screws is 150 mm. It is impossible to sew up the entire plane with whole sheets, so they will have to be marked according to measurements and cut into pieces. There are 2 methods for this. In the first case, the plasterboard sheet is placed on a flat surface and the cutting line is marked with a pencil. A building level or the same U-shaped profile is applied to it and a deep cut is made with a special knife, at least half the thickness of the plaster. After that, the material is turned over and folded along the cutting line, the cardboard lining is cut along the fold with a knife. The procedure for installing the partition.This method is convenient if you have an assistant, otherwise it is very difficult to turn over and bend a solid sheet alone. When there is no assistant, you need to act in the second way, that is, cut the sheet along the line to the very end. It is strongly recommended not to do this work with an angle grinder with a cutting wheel. The entire space of the room will be filled with gypsum dust in a matter of seconds, which will harm your health. Before fixing the drywall parts with your own hands, you will need to make chamfers on them using a knife. If you carefully study the design of solid gypsum boards, you can see that such chamfers are initially made on the sides of the sheet. This is necessary for the convenience of further finishing of the wall. The cut pieces are screwed to the metal frame in the same way as solid sheets, using self-tapping screws. When all the sheets are screwed on one side of the frame, you need to make openings for installing sockets, switches and lighting distribution boxes. Taking advantage of the temporary convenience, you can install the switches themselves or other lighting fixtures. The next step is filling the space with soundproofing material. It must be cut for each opening so that it fits tightly. After this, you can sew up the second side of the partition. After completing the assembly of the plasterboard partition with your own hands, you need to fill all the gaps between the material and the existing structures of the walls and ceiling with polyurethane foam. After polymerization, cut off the excess foam with a knife, now you can proceed to the final finishing. To do this, take the putty, mix it according to the instructions on the package and apply it to all the joints of the sheets and other irregularities. For example, on deeply seated screw heads or the junction of the new partition with the wall. After hardening, the putty layer is processed with sandpaper. Further finishing can be whatever you wish. The advantage of plasterboard systems is that they are easy and quick to install, can be painted or tiled, or covered with vinyl wallpaper.

The procedure for installing the partition.This method is convenient if you have an assistant, otherwise it is very difficult to turn over and bend a solid sheet alone. When there is no assistant, you need to act in the second way, that is, cut the sheet along the line to the very end. It is strongly recommended not to do this work with an angle grinder with a cutting wheel. The entire space of the room will be filled with gypsum dust in a matter of seconds, which will harm your health. Before fixing the drywall parts with your own hands, you will need to make chamfers on them using a knife. If you carefully study the design of solid gypsum boards, you can see that such chamfers are initially made on the sides of the sheet. This is necessary for the convenience of further finishing of the wall. The cut pieces are screwed to the metal frame in the same way as solid sheets, using self-tapping screws. When all the sheets are screwed on one side of the frame, you need to make openings for installing sockets, switches and lighting distribution boxes. Taking advantage of the temporary convenience, you can install the switches themselves or other lighting fixtures. The next step is filling the space with soundproofing material. It must be cut for each opening so that it fits tightly. After this, you can sew up the second side of the partition. After completing the assembly of the plasterboard partition with your own hands, you need to fill all the gaps between the material and the existing structures of the walls and ceiling with polyurethane foam. After polymerization, cut off the excess foam with a knife, now you can proceed to the final finishing. To do this, take the putty, mix it according to the instructions on the package and apply it to all the joints of the sheets and other irregularities. For example, on deeply seated screw heads or the junction of the new partition with the wall. After hardening, the putty layer is processed with sandpaper. Further finishing can be whatever you wish. The advantage of plasterboard systems is that they are easy and quick to install, can be painted or tiled, or covered with vinyl wallpaper.