Any type of finishing, be it tiles, wallpaper orpainting the walls requires leveling the base. This is necessary so that the decorative material looks smooth and beautiful. To level the surface, plastering and puttying of the walls is performed. Scheme of applying plaster and primer to the wall.Not everyone knows the difference between these two types of work and sometimes they are confused. And in this regard, in order to have an idea of what the difference is, you need to consider each material and type of work separately. So, putty and plaster.

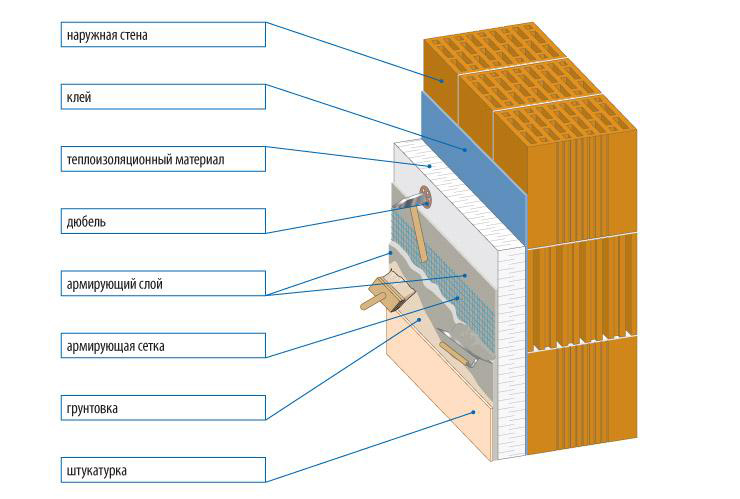

Scheme of applying plaster and primer to the wall.Not everyone knows the difference between these two types of work and sometimes they are confused. And in this regard, in order to have an idea of what the difference is, you need to consider each material and type of work separately. So, putty and plaster.

Wall plastering: features

Plastering walls is quite a labor-intensive taskprocess. Plastering of walls and ceilings is done with gypsum or cement-based solutions. Before starting work, it is necessary to prepare the surface. If the walls are covered with wallpaper, they are removed. Wallpaper can be easily removed if it is moistened with water and then scraped off with a spatula or a special brush. Also . Tools for applying plaster.If there were cracks under the wallpaper, they need to be widened and covered with mortar. For better adhesion of the plaster in places where there were cracks, serpyanka or construction mesh is glued. Stone, brick or concrete walls are knocked down to a depth of 1 cm before applying plaster, this is necessary for a strong fixation of the mortar on the walls. An axe or chisel is used for knocking down. It is necessary to make as many notches as possible, the quality of the plastered surface depends on this. But for finishing wooden walls, you will have to make shingles, which are necessary for the plaster to adhere firmly to the base. Shingles are, if you figure it out, wood chips that are stuffed in the form of a mesh. Currently, there is an alternative to shingles - this is a metal mesh. It is also stuffed onto a wooden base. Before use, the metal mesh is covered with paint and dried. This procedure is necessary so that the mesh is not subject to rust. To ensure that the surface is level after plastering, beacons are installed during work. To install beacons, a long level or plumb line is used to check the verticality of the walls. Dowels are driven into the corners of the wall at the top and bottom, to which the twine is attached, and its verticality is checked with a water level.

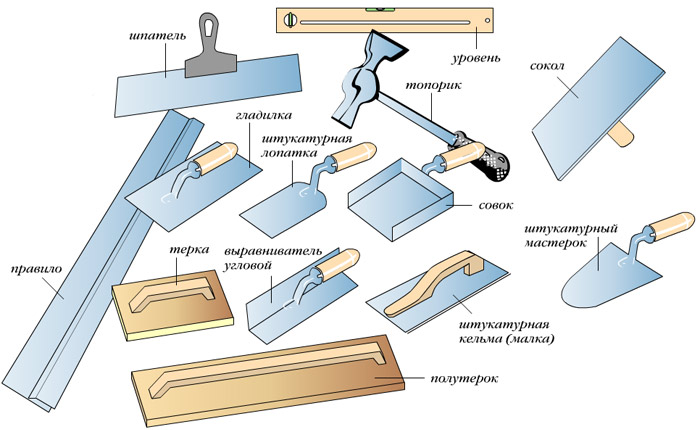

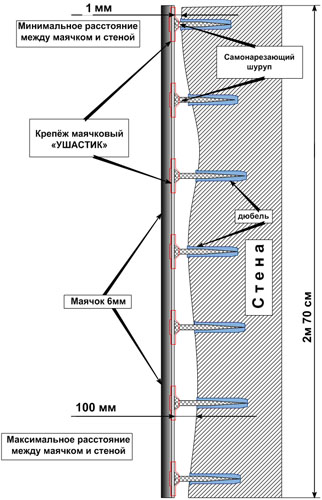

Tools for applying plaster.If there were cracks under the wallpaper, they need to be widened and covered with mortar. For better adhesion of the plaster in places where there were cracks, serpyanka or construction mesh is glued. Stone, brick or concrete walls are knocked down to a depth of 1 cm before applying plaster, this is necessary for a strong fixation of the mortar on the walls. An axe or chisel is used for knocking down. It is necessary to make as many notches as possible, the quality of the plastered surface depends on this. But for finishing wooden walls, you will have to make shingles, which are necessary for the plaster to adhere firmly to the base. Shingles are, if you figure it out, wood chips that are stuffed in the form of a mesh. Currently, there is an alternative to shingles - this is a metal mesh. It is also stuffed onto a wooden base. Before use, the metal mesh is covered with paint and dried. This procedure is necessary so that the mesh is not subject to rust. To ensure that the surface is level after plastering, beacons are installed during work. To install beacons, a long level or plumb line is used to check the verticality of the walls. Dowels are driven into the corners of the wall at the top and bottom, to which the twine is attached, and its verticality is checked with a water level. Scheme of installation of beacons.The horizontal twine is stretched according to the same principle. For rooms with a small ceiling, four horizontals will be enough. The stretched twine will be a guide for the beacons from the profile. They are installed on the solution, which is applied under the fishing line in the form of slides and into which the profile is subsequently pressed. When installing beacons, it is necessary to take into account that the profile should touch the twine, but in no case should it be moved away. First, vertical beacons are installed, and then - horizontal ones, according to the same principle. The evenness of the beacons is also checked with a level, their location should be in the same plane. Once the surface with beacons is ready, the plastering proceeds to the next stage - preparing the solution. Return to the table of contents</a>

Scheme of installation of beacons.The horizontal twine is stretched according to the same principle. For rooms with a small ceiling, four horizontals will be enough. The stretched twine will be a guide for the beacons from the profile. They are installed on the solution, which is applied under the fishing line in the form of slides and into which the profile is subsequently pressed. When installing beacons, it is necessary to take into account that the profile should touch the twine, but in no case should it be moved away. First, vertical beacons are installed, and then - horizontal ones, according to the same principle. The evenness of the beacons is also checked with a level, their location should be in the same plane. Once the surface with beacons is ready, the plastering proceeds to the next stage - preparing the solution. Return to the table of contents</a>

Mortar and plaster technology

Plastering of walls is usually done in three layers:

Preparing the wall for plastering.Once the finishing layer dries a little, you need to do the grouting. The grouting is done with a wet float, which should be pressed firmly against the surface. Finishing grouting is also done, for which felt or felt is nailed to the float. For plastering walls and ceilings, cement, lime or gypsum are used to prepare the solution. A particularly strong solution is made on the basis of cement, and a lime solution is the opposite. It is important to remember that the cement solution sets very quickly, and therefore after preparation it must be used within an hour. But as for the gypsum-based solution, it must be prepared in small portions, since gypsum has the ability to harden quickly. And when using ready-made mixtures, you must follow the instructions for use indicated on the packaging. To perform the work, you will need the following tools:

Preparing the wall for plastering.Once the finishing layer dries a little, you need to do the grouting. The grouting is done with a wet float, which should be pressed firmly against the surface. Finishing grouting is also done, for which felt or felt is nailed to the float. For plastering walls and ceilings, cement, lime or gypsum are used to prepare the solution. A particularly strong solution is made on the basis of cement, and a lime solution is the opposite. It is important to remember that the cement solution sets very quickly, and therefore after preparation it must be used within an hour. But as for the gypsum-based solution, it must be prepared in small portions, since gypsum has the ability to harden quickly. And when using ready-made mixtures, you must follow the instructions for use indicated on the packaging. To perform the work, you will need the following tools:

- guide rails;

- water level;

- Master OK;

- rule;

- a set of putty knives;

- latex gloves;

- solution tank.

Return to Contents</a>

Wall plastering: recommendations

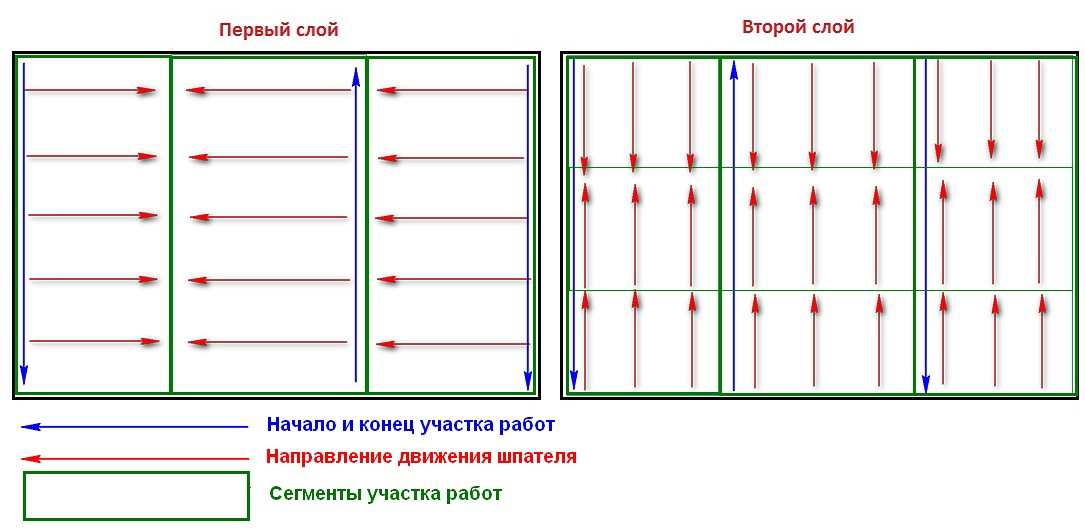

Wall puttying scheme.Wall puttying is considered the final stage before wallpapering, painting or tiling. There are plaster mixes that can give a perfectly smooth surface, but such work is expensive, and for this reason puttying is not abandoned. The tools used for puttying are the same as for plastering. But there are some nuances. For example, putty spatulas should be used much thinner so that they can bend when pressed, which helps to apply a thinner, more even layer. When performing puttying, it is necessary that the blade of the spatula is flawless, that is, completely smooth, but with rounded edges. When sanding the walls after puttingtying, a mesh grater with clamps is needed. It is not recommended to sand the putty coating with sandpaper, especially for gypsum surfaces, since the lumps that will be removed from the putty can damage the surface. For puttying work, the tools must be kept separate and clean, since the adhering solution dries and is difficult to remove, and dried particles will not allow you to achieve an ideal base. Before starting work, you need to select a suitable composition for leveling the walls. There are several types of material, and which one is better can be found out by studying each in detail. Return to the table of contents</a>

Wall puttying scheme.Wall puttying is considered the final stage before wallpapering, painting or tiling. There are plaster mixes that can give a perfectly smooth surface, but such work is expensive, and for this reason puttying is not abandoned. The tools used for puttying are the same as for plastering. But there are some nuances. For example, putty spatulas should be used much thinner so that they can bend when pressed, which helps to apply a thinner, more even layer. When performing puttying, it is necessary that the blade of the spatula is flawless, that is, completely smooth, but with rounded edges. When sanding the walls after puttingtying, a mesh grater with clamps is needed. It is not recommended to sand the putty coating with sandpaper, especially for gypsum surfaces, since the lumps that will be removed from the putty can damage the surface. For puttying work, the tools must be kept separate and clean, since the adhering solution dries and is difficult to remove, and dried particles will not allow you to achieve an ideal base. Before starting work, you need to select a suitable composition for leveling the walls. There are several types of material, and which one is better can be found out by studying each in detail. Return to the table of contents</a>

Putty on an oil-based adhesive

This type of material is the cheapest, soas they contain drying oil. This material has sunk into oblivion due to the fact that drying oil is a kind of oil composition and after gluing wallpaper it comes out. It can also come through paint and be absorbed into concrete walls. But it is still used today. It has a beneficial effect on waterproofing and protects the plastered surface from destruction by moisture. It has found its application in finishing basements and utility rooms, bathrooms - in general, those places where the walls are painted with oil paint. It is also indispensable for plastered walls on shingles. It performs a protective function for shingle sheathing and gaskets from mold, decay, and metal elements - from rust. And thanks to drying oil, the service life of wooden walls under the plaster will be extended. Return to contents</a>

Gypsum cement putty

Gypsum cement material is much more expensive, butit can be used for any finishing work. This putty has the form of a dry mixture, which is diluted with water. It has different grades and is divided into a material for finishing residential premises and for premises with high humidity. It is mainly used for leveling walls under wallpaper. In turn, it is divided into:

- water-dispersive;

- acrylic.

Water-dispersed putty is produced inliquid form. It is mixed with a water-polymer emulsion and packed in buckets. Its price exceeds the cost of dry mixes, but working with it is simplified by the fact that it does not need to be diluted. There is only one requirement for the master - do not forget to close the container with the solution, otherwise the composition will lose its properties, and the mixture will not set well. Such putty, made in industrial conditions, has viscosity, strength and smoothness. It is easy to work with, since it is easy to apply and when sanding the surface, the jointer does not make holes. Even a non-professional can work with water-polymer materials. To get a good surface for painting, it is necessary to putty three times. Acrylic composition has the best qualities, but it also has one drawback. The surface of the wall after puttying is perfectly smooth. And cheap paint rolls off it, so you can not use low-quality paints. So. Puttying and plastering walls is a rather labor-intensive process and is used on the same surface, but the process of execution is different. But the connecting link is that only by combining these two types of work can you achieve an ideal base for finishing.