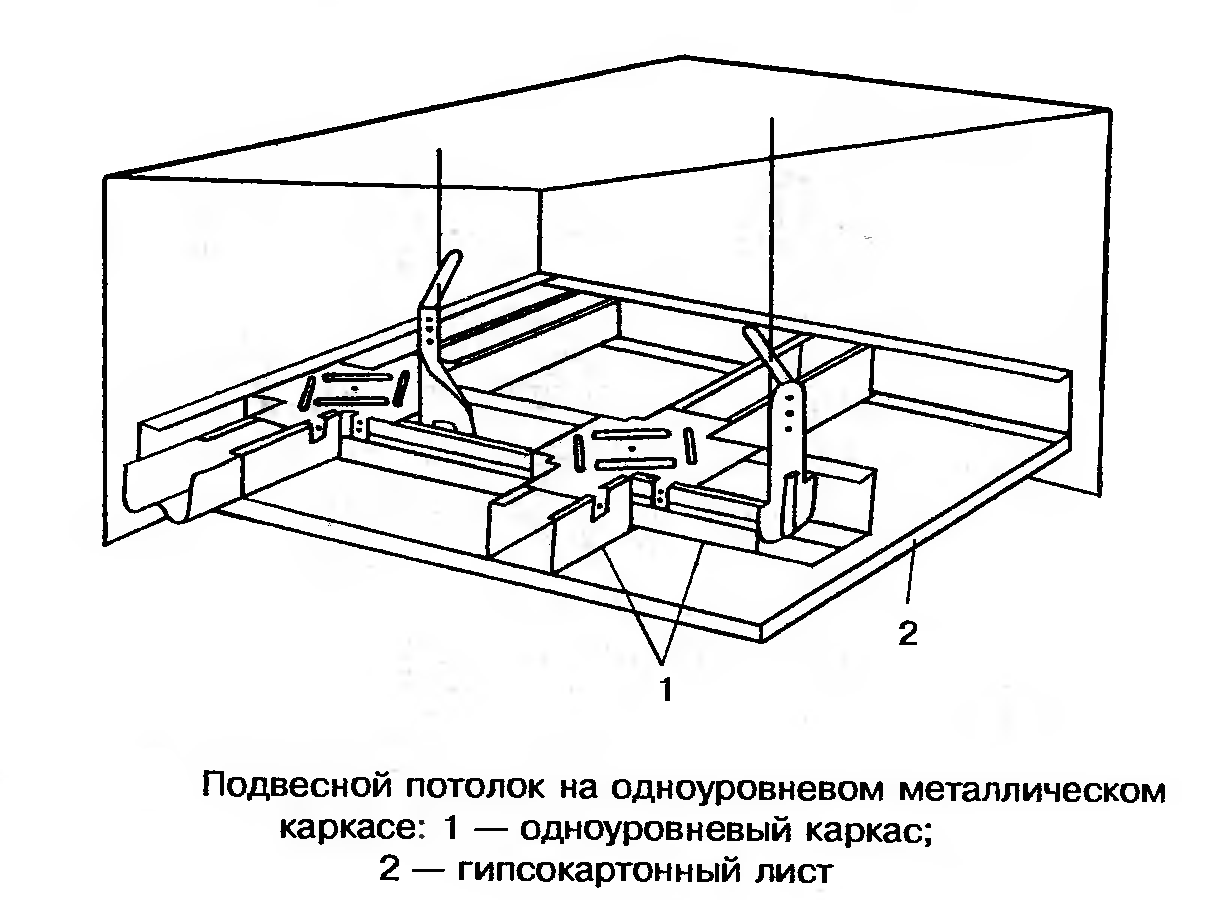

The ceiling is the most visible partpremises, and it cannot be ignored during repairs. Paint, suspension systems and much more can be used as a finishing coat. It is possible, this does not require careful surface preparation. However, you need to be prepared for the fact that in order to arrange such a system, it will be necessary to mount a frame system. Scheme of the device of a single-level suspendedceiling on a metal frame. The guide profile must be installed perfectly level, which is why you should use a level when installing it, it will also allow you to make precise markings of the installation location of the profile, it will be more convenient to work with a laser level, but its cost is much higher. Using a two-meter level, you can determine the evenness of the installation of drywall sheets on the frame. In the process of work, you will have to arrange holes for dowels, for this you should use a hammer drill. A drill will allow you to fix the position of the profile and drywall, which can be replaced with a screwdriver. You need to stock up on a grinder equipped with a circle designed for working with metal, you can also cut the metal with a hand saw.

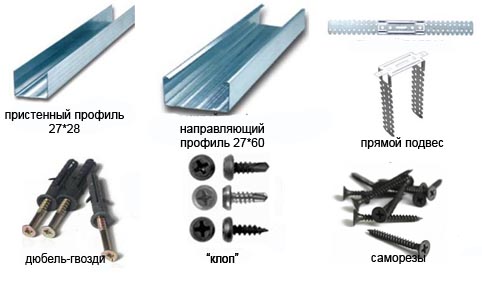

Scheme of the device of a single-level suspendedceiling on a metal frame. The guide profile must be installed perfectly level, which is why you should use a level when installing it, it will also allow you to make precise markings of the installation location of the profile, it will be more convenient to work with a laser level, but its cost is much higher. Using a two-meter level, you can determine the evenness of the installation of drywall sheets on the frame. In the process of work, you will have to arrange holes for dowels, for this you should use a hammer drill. A drill will allow you to fix the position of the profile and drywall, which can be replaced with a screwdriver. You need to stock up on a grinder equipped with a circle designed for working with metal, you can also cut the metal with a hand saw. Suspended plasterboard ceiling with lighting.You need to install a plasterboard ceiling with your own hands after installing the frame, which is based on the profile. The profile can be a guide or a ceiling one; both will be needed to install the frame. The first one is fixed along the perimeter of the room. Before purchasing the frame elements, you should calculate their required number. The guide profile should be calculated along the perimeter of the room. So, if the area of the room is 20 m2, and the length of the walls is 5 and 4 m, then with a standard profile length of 3 and 4 m, a profile 3 m long will be needed in the amount of 7 pieces. In addition to the specified quantity, you need to purchase another profile as a reserve, this is necessary, since during sawing during the work, a defect may occur. In addition, you will need a profile 4 m long in the amount of 5 pieces. Thus, the perimeter must be divided by the length of one profile. Plasterboard ceilings are often installed on two levels, while the number of the required profile will be increased, for the calculation, the length of the additional elements should be added to the above quantity. The fastening of the plasterboard ceiling is also carried out using a C-shaped profile, the calculation of its quantity can be done as follows. Due to the fact that the plasterboard sheet has a width of 1250 mm, under ideal conditions it is fixed at a distance of 600 mm. So, for the above example, it is preferable to use a profile whose standard length is 4 m, this will allow you to get less waste. The wall length of 5 m should be divided by 60 cm, which will allow you to get 8 ceiling profiles.

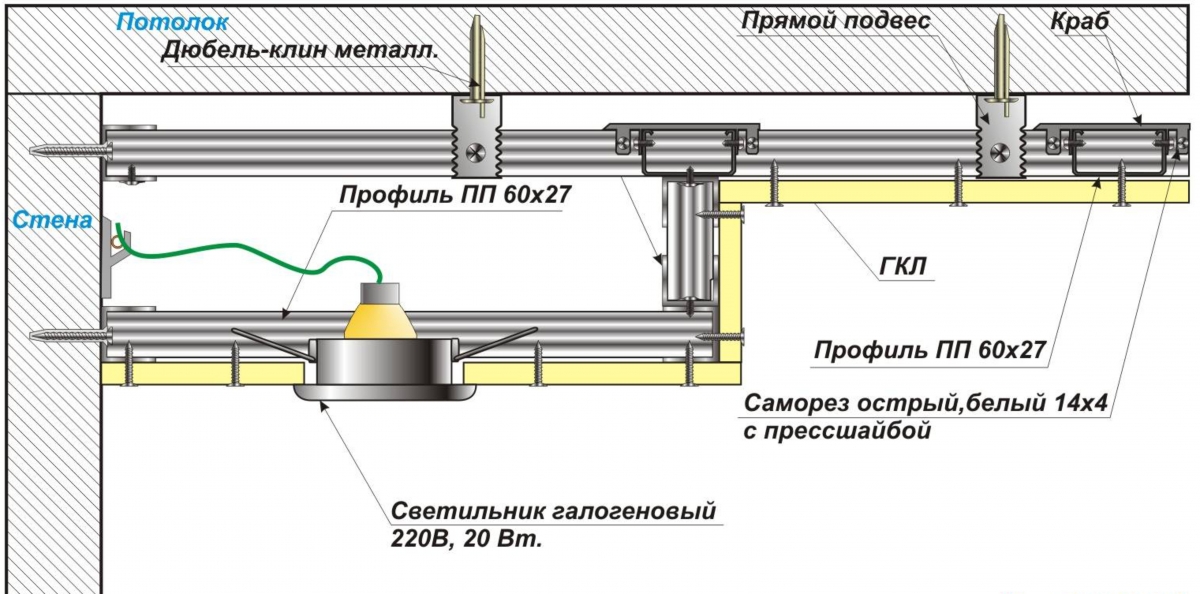

Suspended plasterboard ceiling with lighting.You need to install a plasterboard ceiling with your own hands after installing the frame, which is based on the profile. The profile can be a guide or a ceiling one; both will be needed to install the frame. The first one is fixed along the perimeter of the room. Before purchasing the frame elements, you should calculate their required number. The guide profile should be calculated along the perimeter of the room. So, if the area of the room is 20 m2, and the length of the walls is 5 and 4 m, then with a standard profile length of 3 and 4 m, a profile 3 m long will be needed in the amount of 7 pieces. In addition to the specified quantity, you need to purchase another profile as a reserve, this is necessary, since during sawing during the work, a defect may occur. In addition, you will need a profile 4 m long in the amount of 5 pieces. Thus, the perimeter must be divided by the length of one profile. Plasterboard ceilings are often installed on two levels, while the number of the required profile will be increased, for the calculation, the length of the additional elements should be added to the above quantity. The fastening of the plasterboard ceiling is also carried out using a C-shaped profile, the calculation of its quantity can be done as follows. Due to the fact that the plasterboard sheet has a width of 1250 mm, under ideal conditions it is fixed at a distance of 600 mm. So, for the above example, it is preferable to use a profile whose standard length is 4 m, this will allow you to get less waste. The wall length of 5 m should be divided by 60 cm, which will allow you to get 8 ceiling profiles. Fastening plasterboard.Before starting the installation of the ceiling, it is important to choose the right plasterboard, which can be ordinary, moisture-resistant, and fireproof. If the work is supposed to be carried out in an ordinary room, the conditions of which are not characterized by high humidity, you can use an ordinary sheet, which costs less than a moisture-resistant one. For the installation of the ceiling system, you should not use a material whose thickness exceeds 8-10 mm. With thicker sheets, the weight of the structure will be greater, and there will be no practical benefit from this. In addition, sheets with a greater thickness will complicate the work. The ceiling can be arranged with less material consumption if it is calculated correctly, for this you need to use the following formula: a / b = c, where a is the area of the ceiling, b is the area of one sheet of plasterboard, c is the required number of sheets. A direct hanger will be needed for fastening. For an area of 20 m2, 50 pieces of such hangers will be needed. With a more complex ceiling design and sheets of greater thickness, more hangers will be needed. During the fastening process, it is necessary to ensure a distance of 700 mm between them.

Fastening plasterboard.Before starting the installation of the ceiling, it is important to choose the right plasterboard, which can be ordinary, moisture-resistant, and fireproof. If the work is supposed to be carried out in an ordinary room, the conditions of which are not characterized by high humidity, you can use an ordinary sheet, which costs less than a moisture-resistant one. For the installation of the ceiling system, you should not use a material whose thickness exceeds 8-10 mm. With thicker sheets, the weight of the structure will be greater, and there will be no practical benefit from this. In addition, sheets with a greater thickness will complicate the work. The ceiling can be arranged with less material consumption if it is calculated correctly, for this you need to use the following formula: a / b = c, where a is the area of the ceiling, b is the area of one sheet of plasterboard, c is the required number of sheets. A direct hanger will be needed for fastening. For an area of 20 m2, 50 pieces of such hangers will be needed. With a more complex ceiling design and sheets of greater thickness, more hangers will be needed. During the fastening process, it is necessary to ensure a distance of 700 mm between them.

Tools and materials

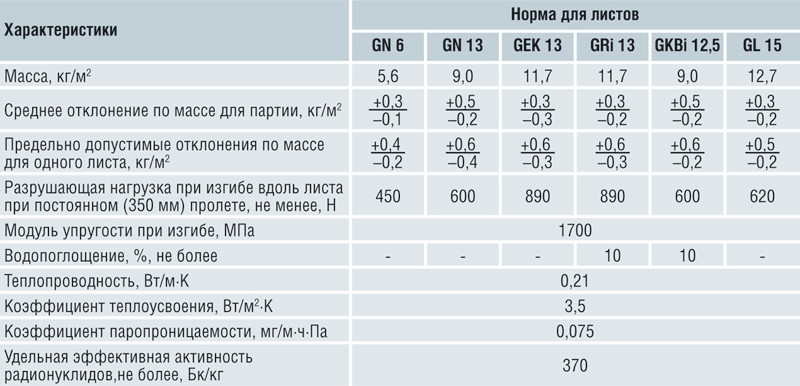

Physical and technical characteristics of gypsum plasterboard sheets.

Physical and technical characteristics of gypsum plasterboard sheets.

- Finishing plaster;

- gypsum plaster;

- Adhesive mesh;

- self-tapping screws;

- dowels;

- water level;

- perforator;

- drill;

- roulette;

- a cutting knife;

- pencil;

- Bulgarian;

- scissors for metal;

- GCR;

- profile.

Return to Contents</a>

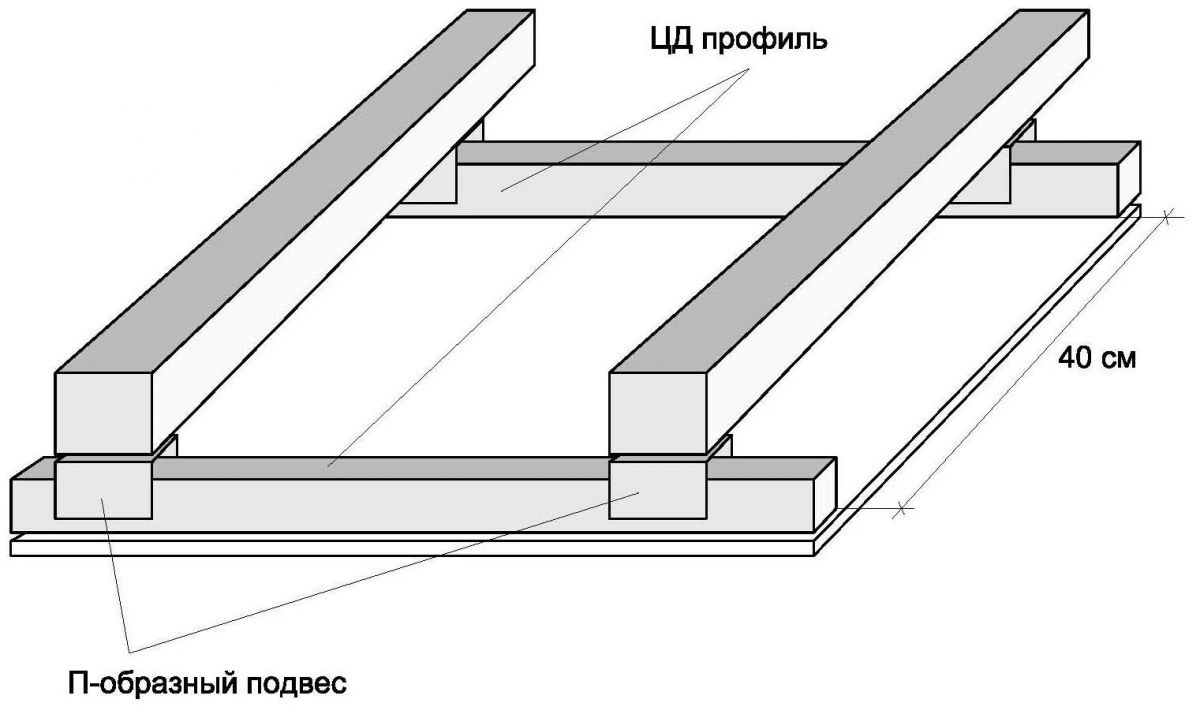

Mounting the frame

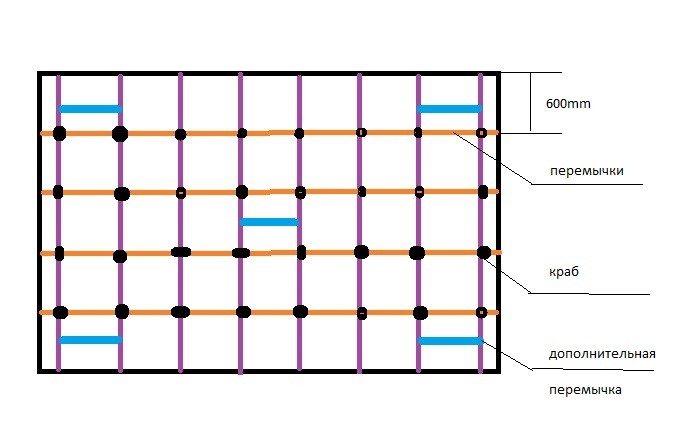

Installation of lintels in a frame made of profiles forplasterboard ceiling. When installing ceilings with your own hands, you will first need to make markings for the installation of the guide profile, using a water level. The distance at which the system will be located can be determined independently, but for the convenience of installing the structure, which especially concerns the installation of heat insulators or spotlights, it is worth ensuring a 10 cm indentation from the ceiling. As soon as the markings on the four walls are ready, you can start drilling holes for the dowels using a hammer drill. The guide profile must be installed to the wall with a step of 40 cm, this distance in the corners should be equal to 15 cm. Having installed the guide profile, you need to make marks on the wall with a tape measure along the perimeter with a step of 60 cm. This is how the marking of the installation locations of the ceiling profile is made. To arrange a simple single-level structure, you will need to install a C-shaped profile in two directions. Thus, the markings should be made on two opposite walls. Then you can start fixing the suspension to the ceiling. If you arrange them at a distance of 70 cm, it will be easier to lay the heat insulator. After installing the direct suspensions, you can start fixing the ceiling profile.

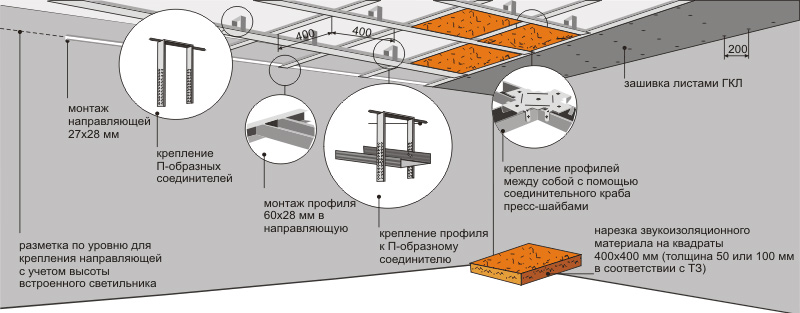

Installation of lintels in a frame made of profiles forplasterboard ceiling. When installing ceilings with your own hands, you will first need to make markings for the installation of the guide profile, using a water level. The distance at which the system will be located can be determined independently, but for the convenience of installing the structure, which especially concerns the installation of heat insulators or spotlights, it is worth ensuring a 10 cm indentation from the ceiling. As soon as the markings on the four walls are ready, you can start drilling holes for the dowels using a hammer drill. The guide profile must be installed to the wall with a step of 40 cm, this distance in the corners should be equal to 15 cm. Having installed the guide profile, you need to make marks on the wall with a tape measure along the perimeter with a step of 60 cm. This is how the marking of the installation locations of the ceiling profile is made. To arrange a simple single-level structure, you will need to install a C-shaped profile in two directions. Thus, the markings should be made on two opposite walls. Then you can start fixing the suspension to the ceiling. If you arrange them at a distance of 70 cm, it will be easier to lay the heat insulator. After installing the direct suspensions, you can start fixing the ceiling profile. Installation of plasterboard ceiling.When installing ceilings in a room with the same parameters as the room in the example, you will not have to join a profile that is 4 m long, since the length of the ceiling is exactly equivalent to 4 m. If you need to join a profile, you need to mount two additional hangers to the ceiling at the junction points. Using a hanger or longitudinal connector, screw the elements together. Use a drill or screwdriver to connect the junction points of the profile with the guides, as well as the hangers and the C-shaped profile. When joining the hanger and the ceiling profile, using a two-meter level, you need to ensure that the profile is fixed evenly, without forming deflections or sagging. If you neglect this rule, the installed plasterboard sheets will have a wavy surface. When installing the ceiling at the stage of completing the frame fastening, you need to carry out communications and lay the insulation, which can be mineral wool. Return to the table of contents</a>

Installation of plasterboard ceiling.When installing ceilings in a room with the same parameters as the room in the example, you will not have to join a profile that is 4 m long, since the length of the ceiling is exactly equivalent to 4 m. If you need to join a profile, you need to mount two additional hangers to the ceiling at the junction points. Using a hanger or longitudinal connector, screw the elements together. Use a drill or screwdriver to connect the junction points of the profile with the guides, as well as the hangers and the C-shaped profile. When joining the hanger and the ceiling profile, using a two-meter level, you need to ensure that the profile is fixed evenly, without forming deflections or sagging. If you neglect this rule, the installed plasterboard sheets will have a wavy surface. When installing the ceiling at the stage of completing the frame fastening, you need to carry out communications and lay the insulation, which can be mineral wool. Return to the table of contents</a>

Carrying out of a covering of a skeleton and шпаклевочные works

Materials for installing plasterboard ceilings.A single-level ceiling should be mounted by fastening the plasterboard to the frame with screws. The distance between the fasteners should be 10-15 cm, this will ensure a reliable structure. Fasteners should be placed along the perimeter of the sheet. The sheets have rounded ends. This is necessary to prevent cracks from forming at the joints after puttying, because in these places the layer will be thicker. If the ceiling is to be arranged using whole sheets or pieces, then using a knife it will be necessary to create minor indentations along the edges where there are none. When installing the ceiling, it will be necessary to countersink the screw heads by about 1 mm. With protruding fasteners, it will be impossible to perform the puttying process qualitatively. Moreover, the final finishing of the plasterboard will not look as aesthetically pleasing as we would like with fastener heads protruding above the surface. Such ceilings are necessarily equipped with lighting systems, for which holes must be formed in the cavity of the sheet, which is done with a knife. Ceilings will be easier to arrange if you cut holes using a special attachment on a hammer drill, which can be replaced with a drill. Using power tools will allow you to get neater holes for lighting fixtures.

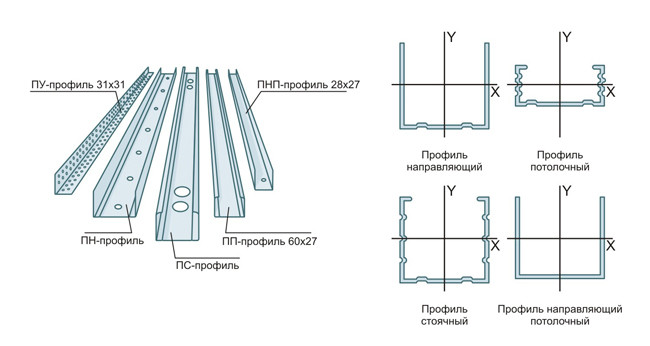

Materials for installing plasterboard ceilings.A single-level ceiling should be mounted by fastening the plasterboard to the frame with screws. The distance between the fasteners should be 10-15 cm, this will ensure a reliable structure. Fasteners should be placed along the perimeter of the sheet. The sheets have rounded ends. This is necessary to prevent cracks from forming at the joints after puttying, because in these places the layer will be thicker. If the ceiling is to be arranged using whole sheets or pieces, then using a knife it will be necessary to create minor indentations along the edges where there are none. When installing the ceiling, it will be necessary to countersink the screw heads by about 1 mm. With protruding fasteners, it will be impossible to perform the puttying process qualitatively. Moreover, the final finishing of the plasterboard will not look as aesthetically pleasing as we would like with fastener heads protruding above the surface. Such ceilings are necessarily equipped with lighting systems, for which holes must be formed in the cavity of the sheet, which is done with a knife. Ceilings will be easier to arrange if you cut holes using a special attachment on a hammer drill, which can be replaced with a drill. Using power tools will allow you to get neater holes for lighting fixtures. Assembly diagram of the frame using the installation method of galvanizedprofiles for plasterboard. If the sheets are fitted tightly enough, the joints are prepared for the puttying process, and the holes for the lamps are cut out, it is permissible to proceed with finishing. The ceilings should be treated with gypsum plaster and reinforced with adhesive mesh at the joints of the gypsum boards. Such work should begin with the joints. It is necessary to apply a thin layer of the mixture to the joint, and then the mesh should be laid on the composition. The latter should be pressed into the plaster a little, and then another layer of the composition should be applied. This will eliminate the likelihood of cracks appearing at the joints of the plasterboard sheets. They need to be allowed to dry a little after applying the mixture, only then can you begin to putty the entire surface using finishing plaster. The walls should dry well, which will take a day or two, then you can start processing the surface with 100/120 sandpaper, the base should be not only even, but also smooth. Now the ceiling surface can be used for decoration. Return to the table of contents</a>

Assembly diagram of the frame using the installation method of galvanizedprofiles for plasterboard. If the sheets are fitted tightly enough, the joints are prepared for the puttying process, and the holes for the lamps are cut out, it is permissible to proceed with finishing. The ceilings should be treated with gypsum plaster and reinforced with adhesive mesh at the joints of the gypsum boards. Such work should begin with the joints. It is necessary to apply a thin layer of the mixture to the joint, and then the mesh should be laid on the composition. The latter should be pressed into the plaster a little, and then another layer of the composition should be applied. This will eliminate the likelihood of cracks appearing at the joints of the plasterboard sheets. They need to be allowed to dry a little after applying the mixture, only then can you begin to putty the entire surface using finishing plaster. The walls should dry well, which will take a day or two, then you can start processing the surface with 100/120 sandpaper, the base should be not only even, but also smooth. Now the ceiling surface can be used for decoration. Return to the table of contents</a>

Decoration of plasterboard ceiling

The decoration of the base can be doneby means of plaster molding, as a simpler and more elegant option will be baguettes made of foam. The surface of the ceiling can be decorated with a pattern, but it is worth considering that such a design will cost much more than all the others, since you will have to involve a professional artist. Wallpaper, which can be painted in any color, changing the shade from time to time, fits perfectly on the surface of plasterboard sheets, which will allow you to update the interior without changing the finish. In addition, gluing wallpaper will not be an excessively labor-intensive task. It is preferable to start such work after you have acquired some knowledge and skills in this area. It is better not to start arranging a multi-level ceiling right away, a simple option will also look good. Over time, you can model a more complex design and bring it to life.