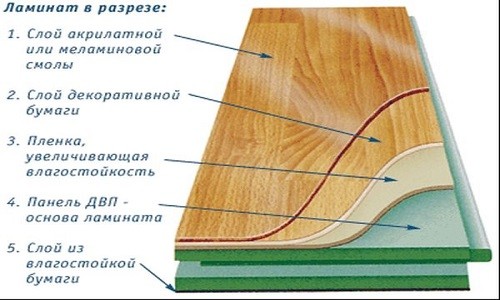

Полы в городских квартирах не отвечают всем requirements for laying the flooring material. They need leveling work, sealing cracks, potholes, and strengthening. And this applies not only to concrete but also to wooden floors. In the latter case, it may be necessary to remove the sheathing boards, replace them with whole ones, and get rid of cracks. Such work is especially important if laminate or linoleum is to be used as the flooring material. How to level the floor for laminate, what should be done? Sectional diagram of laminate.Usually, the lamellas are thin and long, they are made from wood processing products. The panels are fastened together with a special locking connection. The floor for laying such a floor covering must be perfectly flat, otherwise the lamellas will be subject to uneven loads. The locks will be damaged first, then cracks will appear along the boards themselves. If the base is uneven, the laminate will bend under the weight of a person when walking, cracks will appear between the boards, and over time, swelling, strong creaking, and cracks will occur. Using a substrate will not correct the situation, it is necessary to level the base.

Sectional diagram of laminate.Usually, the lamellas are thin and long, they are made from wood processing products. The panels are fastened together with a special locking connection. The floor for laying such a floor covering must be perfectly flat, otherwise the lamellas will be subject to uneven loads. The locks will be damaged first, then cracks will appear along the boards themselves. If the base is uneven, the laminate will bend under the weight of a person when walking, cracks will appear between the boards, and over time, swelling, strong creaking, and cracks will occur. Using a substrate will not correct the situation, it is necessary to level the base.

Leveling with bulk mixes

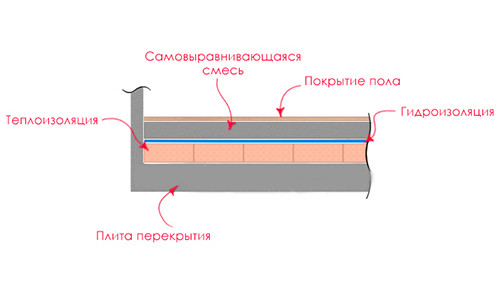

Self-leveling floor installation.- the process is responsible, so it is important to do everything correctly. If the concrete base has small differences in height up to 5 cm, you can use self-leveling mixtures. These are self-leveling leveling solutions, which are convenient and easy to work with. Today, you can find special compositions on sale that involve applying 2 layers:

Self-leveling floor installation.- the process is responsible, so it is important to do everything correctly. If the concrete base has small differences in height up to 5 cm, you can use self-leveling mixtures. These are self-leveling leveling solutions, which are convenient and easy to work with. Today, you can find special compositions on sale that involve applying 2 layers:

The use of such mixtures is extremely simple.It is necessary to dilute the ready dry base with cold water, using a construction mixer for convenience. Marks are made on the surface of the walls, and the pouring will be done according to them. Tools for leveling the floor under the laminate:hammer, ruler, joists, level, pliers, tape measure, brush. Apply leveling mixtures from the far corner. To do this, pour strips of 40-50 cm wide from the container onto the floor, then level them with a wide metal spatula. It is more convenient to do the work together. While one person prepares a new portion of the composition, the second will apply it to the floor and level it. Drying time is short, it is 2-3 days. After this, you can safely begin work on laying the laminate. Return to the table of contents</a>

Tools for leveling the floor under the laminate:hammer, ruler, joists, level, pliers, tape measure, brush. Apply leveling mixtures from the far corner. To do this, pour strips of 40-50 cm wide from the container onto the floor, then level them with a wide metal spatula. It is more convenient to do the work together. While one person prepares a new portion of the composition, the second will apply it to the floor and level it. Drying time is short, it is 2-3 days. After this, you can safely begin work on laying the laminate. Return to the table of contents</a>

Aligning the base with a cement screed

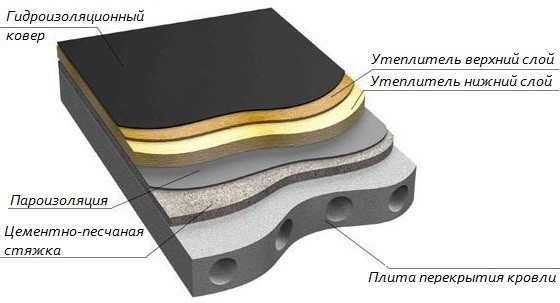

When the differences in the concrete floor exceed 5 cm,then it is necessary to use a cement screed. This process takes a lot of time, but the base is not only perfectly flat, but also durable. How to do the leveling work yourself? First, you need to clean the base from the old coating, determine what difference in height is observed. Scheme of cement-sand floor screed.There are ready-made dry mixes on sale, you only need to dilute them with water. The proportions and consumption are specified by the manufacturer, you must pay attention to the label. The dry mix is poured into a prepared container (from 20 l). Then clean water is poured in at the rate of 1 l of water per 5 kg of dry mix. Using a construction mixer or a metal spatula, the mixture is thoroughly mixed until smooth, after which the solution is given time to settle. This takes 1-2 minutes. Then you should mix the screed mixture again. Marks are applied to the walls in advance, along which the pouring will be carried out. Beacons are placed along the floor area (you can buy ready-made ones).

Scheme of cement-sand floor screed.There are ready-made dry mixes on sale, you only need to dilute them with water. The proportions and consumption are specified by the manufacturer, you must pay attention to the label. The dry mix is poured into a prepared container (from 20 l). Then clean water is poured in at the rate of 1 l of water per 5 kg of dry mix. Using a construction mixer or a metal spatula, the mixture is thoroughly mixed until smooth, after which the solution is given time to settle. This takes 1-2 minutes. Then you should mix the screed mixture again. Marks are applied to the walls in advance, along which the pouring will be carried out. Beacons are placed along the floor area (you can buy ready-made ones). Installation of beacons for floor screed.The first beacon should be placed 2-3 cm from the wall surface at the highest point of the floor to properly level the floor for the laminate. The second will be 60-80 cm, then the same step is observed. It is necessary that the height of the beacons coincides with the marks on the walls. If the difference is large, pieces of plywood or wooden beams are used for lining. Then you can proceed directly to the pouring itself. The solution can be mixed independently, for this you should take 3 parts of dry sifted sand and 1 part of Portland cement. The ingredients are mixed, poured with water in a prepared container. Experts recommend using ready-made mixtures, since in the absence of experience it will be problematic to accurately observe all the proportions, and this will negatively affect the quality. Leveling the floor under the laminate with cement screed is carried out from the far corner. The mixture should be poured in portions, then smoothed with a rule. If the surface is ready, the screed should be left to dry, which can take up to 30 days. At this time, the heating in the room is turned off, the screed is protected from sunlight. Return to the table of contents</a>

Installation of beacons for floor screed.The first beacon should be placed 2-3 cm from the wall surface at the highest point of the floor to properly level the floor for the laminate. The second will be 60-80 cm, then the same step is observed. It is necessary that the height of the beacons coincides with the marks on the walls. If the difference is large, pieces of plywood or wooden beams are used for lining. Then you can proceed directly to the pouring itself. The solution can be mixed independently, for this you should take 3 parts of dry sifted sand and 1 part of Portland cement. The ingredients are mixed, poured with water in a prepared container. Experts recommend using ready-made mixtures, since in the absence of experience it will be problematic to accurately observe all the proportions, and this will negatively affect the quality. Leveling the floor under the laminate with cement screed is carried out from the far corner. The mixture should be poured in portions, then smoothed with a rule. If the surface is ready, the screed should be left to dry, which can take up to 30 days. At this time, the heating in the room is turned off, the screed is protected from sunlight. Return to the table of contents</a>

Leveling of wooden floors

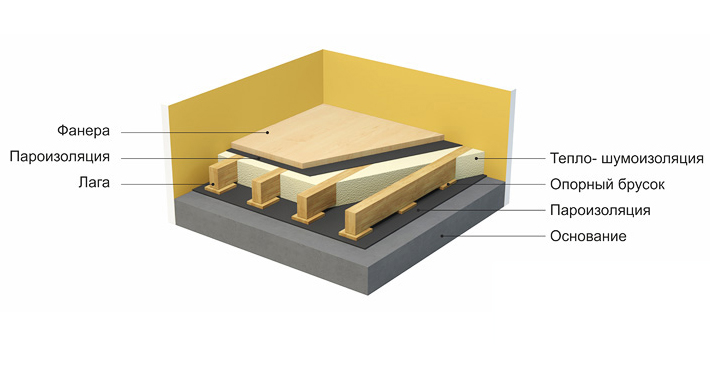

Leveling a wooden floor is a bit of a hasslediffers from work with concrete bases. Plank floors require more attention, since their condition must first be inspected. Often, the entire plank base must be removed for replacement. The order of work for leveling a wooden floor for laminate flooring is as follows: Scheme of leveling a wooden floor on joists.

Scheme of leveling a wooden floor on joists.

How to level the base if the joists are intact and there areonly gaps between the boards? In this case, you can use a special mixture of PVA glue and sawdust. Beacons are installed on the surface of the base, after which the space between them is filled with the prepared mixture. The glue will dry for a long time, so you need to wait until it becomes like plastic. Only after this can you begin to lay the underlay, lay the laminate. Laminate is a beautiful and stylish material. Many people prefer to use it for flooring. But laminate requires a flat and durable base. It needs to be prepared, and leveling work should be carried out if necessary. Only then will the installation be durable and reliable.