Over time, any furniture loses itsoriginal beauty, deteriorates and begins to distort the interior rather than decorate it. But what if your favorite comfortable sofa has become unusable and you don’t want to search for and buy a new one? Old torn upholstery of the sofa is notreason for throwing it away. High-quality restoration will give it a second life. There is a way out: you just need to remake the sofa yourself. This will require less financial costs, will allow you to save your favorite thing, and will also give you the opportunity to use your imagination and make the item truly unique.

Old torn upholstery of the sofa is notreason for throwing it away. High-quality restoration will give it a second life. There is a way out: you just need to remake the sofa yourself. This will require less financial costs, will allow you to save your favorite thing, and will also give you the opportunity to use your imagination and make the item truly unique.

Preparation for self-alteration of the sofa

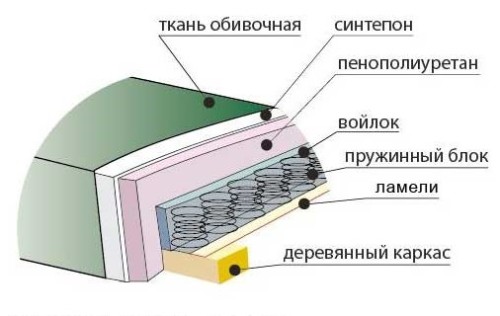

Most often, the sofa is in useit is not the frame that is damaged, but the upholstery. It wears out, loses its original colors, gets stains or snags. In this case, there are two options for getting out of the situation: take the sofa to a furniture repair shop and order a replacement of the upholstery there, or, which is much more interesting and economical, do the re-upholstery yourself. Scheme of a soft sofa in section. In fact, it is not so difficult to remake. To replace the upholstery, you will need to prepare the following tools:

Scheme of a soft sofa in section. In fact, it is not so difficult to remake. To replace the upholstery, you will need to prepare the following tools:

- foam with high density;

- silicate adhesive;

- chalk for fabric;

- destepler;

- building stapler;

- staples;

- Roulette or measuring tape (centimeter);

- fabric for lining and upholstery of the sofa.

Return to Contents</a>

Fabrics for the constriction of the sofa

The following fabrics are most often used for sofa upholstery: An example of re-upholstering an old sofa with new upholstery.

An example of re-upholstering an old sofa with new upholstery.

Return to Contents</a>

Material measurements

The process of taking measurements from a sofa:1 – sofa length with hem allowance, 2 – sofa width with seam and hem allowance, 3 – depth (thickness). It is very important to take all measurements correctly before buying fabric. It is better to buy a little more fabric, with a reserve. You also need to buy fabric for the sofa lining (cotton). To take the correct measurements of the sofa, you need to follow these tips:

The process of taking measurements from a sofa:1 – sofa length with hem allowance, 2 – sofa width with seam and hem allowance, 3 – depth (thickness). It is very important to take all measurements correctly before buying fabric. It is better to buy a little more fabric, with a reserve. You also need to buy fabric for the sofa lining (cotton). To take the correct measurements of the sofa, you need to follow these tips:

Return to Contents</a>

Elimination of defects on the case of the sofa

Before you start removing the old upholstery andupholstery, you should inspect the external wooden parts of the sofa. If any damage or defects have formed on them, they must be eliminated. Moreover, when minor damage has been caused, this can be done without even disassembling the furniture. Sofa body diagram. Minor damage can be repaired in the following ways:

Sofa body diagram. Minor damage can be repaired in the following ways:

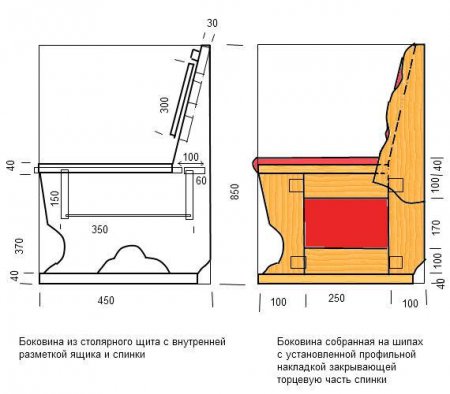

For more serious damage such aschips and cracks, you will need to purchase wood filler in a hardware store that matches the tone of the furniture and carefully apply it in small portions to the damaged area. After the crack or chip is filled with filler, all that remains is to go over it with a spatula and smooth out the surface. Scheme of the sofa side.When the wooden parts of the sofa are very badly damaged, you can’t do without removing them and disassembling the sofa. Elements that have become completely unusable (for example, those that have been gnawed by animals) will have to be replaced by ordering new ones from a furniture company. In the case where you need to remake the damaged coating of an entire part, the first thing you need to do is remove the layer of varnish and paint. When this is impossible, you will just have to sand the surface. A special primer for wood is applied to the element, and paint or drying oil is applied to the part. If necessary, it is additionally coated with varnish. After the coating dries, all that remains is to put it back in place and proceed to further work on remaking the sofa with your own hands. Remaking is a creative process, so you can show your imagination and hide existing flaws in the wood with decorative elements, such as mosaics or other decorations. Return to contents</a>

Scheme of the sofa side.When the wooden parts of the sofa are very badly damaged, you can’t do without removing them and disassembling the sofa. Elements that have become completely unusable (for example, those that have been gnawed by animals) will have to be replaced by ordering new ones from a furniture company. In the case where you need to remake the damaged coating of an entire part, the first thing you need to do is remove the layer of varnish and paint. When this is impossible, you will just have to sand the surface. A special primer for wood is applied to the element, and paint or drying oil is applied to the part. If necessary, it is additionally coated with varnish. After the coating dries, all that remains is to put it back in place and proceed to further work on remaking the sofa with your own hands. Remaking is a creative process, so you can show your imagination and hide existing flaws in the wood with decorative elements, such as mosaics or other decorations. Return to contents</a>

Dismantling of old coating and cutting of material

The next step that needs to be taken isdo-it-yourself sofa remodeling, remove the worn-out upholstery. To do this, you should disassemble the sofa, and it is important to remember which parts were where. To simplify the task, you can use a video camera. When disassembling, you just need to film each stage. Then, reassembling the furniture after the remodeling is complete will not be difficult. A camera is also great for this purpose. First of all, the armrests are removed from the sofa, which in some cases can be combined with the legs. Next, the sides of the sofa, the transformation mechanism, the seat and the back are removed. The sofa is disassembled until only the frame remains. After this, you need to remove the upholstery material, using, if necessary, a destapler and prying the fabric with a knife or scissors. When all the parts of the sofa are freed from the old material, you should also get rid of the filler. With long-term use, it usually becomes unusable, especially if the filler of the sofa is foam rubber or synthetic padding. Sofa upholstery pattern.First of all, remove the easily detached pieces of foam rubber from the frame. Scrape off small upholstery parts with a spatula, but do so carefully so as not to damage the wood. Do not try to remove the stuck pieces of foam rubber or synthetic padding with your hands. It is better to do this with a tool. If you cannot remove the upholstery even with a spatula, soak the remaining pieces in warm water and repeat the action. Before proceeding with further alteration of the sofa, it is important to make sure that all upholstery parts are completely removed. Use a wet sponge to remove small loose pieces from the frame, and then wait until the wood dries. In no case should you continue working until the frame is completely dry: this is fraught with fungus, rotting of both wood and upholstery. The next thing that is necessary in order to is to cut and prepare the upholstery fabric. It is better to cut out all the elements at once. It is convenient to do this with a special chalk (if there is no chalk for fabric, then it can be replaced with a piece of ordinary dry soap). The pattern is made on the removed, old material or on the furniture parts themselves. Before further work, the cut fabric must be processed on a sewing machine: hem the edge of the material so that it does not unravel. The lining material is also measured and processed. After the fabric is ready, the foam lining is cut out. It is cut to the size of the sofa, while the lining also leaves allowances of 5 cm. For alteration, it is worth using only good, very dense foam rubber, since material with a low density deforms extremely quickly, and, therefore, such upholstery will not last long. Then the lining should be tried on to the parts of the sofa and, having made sure that all the patterns correspond to the parts, you can safely proceed to the main stage of alteration - the direct upholstery of the sofa. Return to the table of contents</a>

Sofa upholstery pattern.First of all, remove the easily detached pieces of foam rubber from the frame. Scrape off small upholstery parts with a spatula, but do so carefully so as not to damage the wood. Do not try to remove the stuck pieces of foam rubber or synthetic padding with your hands. It is better to do this with a tool. If you cannot remove the upholstery even with a spatula, soak the remaining pieces in warm water and repeat the action. Before proceeding with further alteration of the sofa, it is important to make sure that all upholstery parts are completely removed. Use a wet sponge to remove small loose pieces from the frame, and then wait until the wood dries. In no case should you continue working until the frame is completely dry: this is fraught with fungus, rotting of both wood and upholstery. The next thing that is necessary in order to is to cut and prepare the upholstery fabric. It is better to cut out all the elements at once. It is convenient to do this with a special chalk (if there is no chalk for fabric, then it can be replaced with a piece of ordinary dry soap). The pattern is made on the removed, old material or on the furniture parts themselves. Before further work, the cut fabric must be processed on a sewing machine: hem the edge of the material so that it does not unravel. The lining material is also measured and processed. After the fabric is ready, the foam lining is cut out. It is cut to the size of the sofa, while the lining also leaves allowances of 5 cm. For alteration, it is worth using only good, very dense foam rubber, since material with a low density deforms extremely quickly, and, therefore, such upholstery will not last long. Then the lining should be tried on to the parts of the sofa and, having made sure that all the patterns correspond to the parts, you can safely proceed to the main stage of alteration - the direct upholstery of the sofa. Return to the table of contents</a>

Stretching the sofa

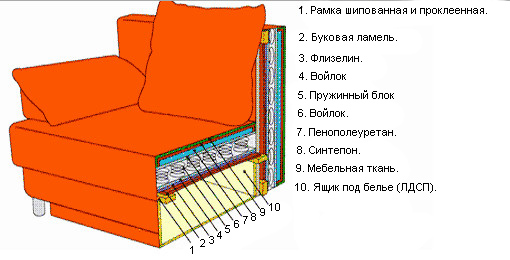

Sofa re-upholstery scheme.When all the parts of the lining are ready, they can be glued to the sofa parts. The foam pattern is applied to the sofa. Then the silicate glue is split and applied to the edges of the material in a narrow strip (no more than 1.5 cm). Then the side coated with glue must be applied to the sofa and pressed for 3 minutes. So, side by side, the entire sofa is glued with lining. But glue alone is not enough. It is also necessary to properly fix the foam rubber with a stapler. Moving away from the edge a couple of millimeters, you need to pierce the foam rubber with staples, keeping a distance of 10 cm between them. Then, in the process of alteration, the lining is pulled onto the sofa. This is done so that the foam rubber does not crumble on the upholstery and does not start to crawl out through it in small pieces, using cotton fabric. The upholstery with lining material occurs as follows:

Sofa re-upholstery scheme.When all the parts of the lining are ready, they can be glued to the sofa parts. The foam pattern is applied to the sofa. Then the silicate glue is split and applied to the edges of the material in a narrow strip (no more than 1.5 cm). Then the side coated with glue must be applied to the sofa and pressed for 3 minutes. So, side by side, the entire sofa is glued with lining. But glue alone is not enough. It is also necessary to properly fix the foam rubber with a stapler. Moving away from the edge a couple of millimeters, you need to pierce the foam rubber with staples, keeping a distance of 10 cm between them. Then, in the process of alteration, the lining is pulled onto the sofa. This is done so that the foam rubber does not crumble on the upholstery and does not start to crawl out through it in small pieces, using cotton fabric. The upholstery with lining material occurs as follows:

The sofa is covered in the same wayupholstery fabric. After the sofa is covered with the main fabric, all that remains is to carefully assemble it. The alteration is complete. If you are concerned that you will not be able to alter the sofa yourself, then you should not cover the entire sofa at once, but try out just one element. You need to stretch the foam rubber, upholstery and main fabrics onto the selected part (preferably the side one). After making sure that all alteration steps are performed correctly: the seams are positioned correctly, the foam rubber is not skewed and is taken in sufficient quantity, you can proceed to further manufacturing with your own hands.