I really want to protect my home from outside noise,to feel calm. Do-it-yourself soundproofing of walls can give you this. The main thing is that the materials meet your needs and are of high quality. Soundproofing a brick wall.Soundproofing walls using regular partitions is almost impossible. But today there are several ways to soundproof and insulate walls. They will take away a few centimeters from the total area of the entire room, but in the end it will be worth it. Let's look at the most popular methods of insulation.

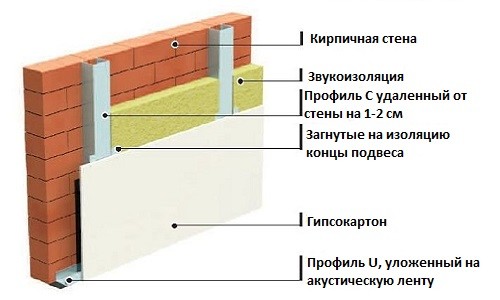

Soundproofing a brick wall.Soundproofing walls using regular partitions is almost impossible. But today there are several ways to soundproof and insulate walls. They will take away a few centimeters from the total area of the entire room, but in the end it will be worth it. Let's look at the most popular methods of insulation.

Wall Preparation

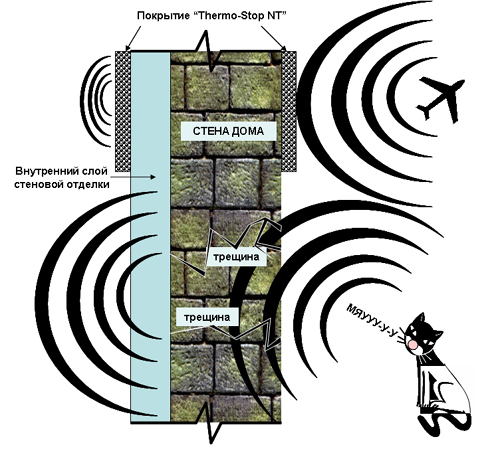

The principle of soundproofing a wall.Before any soundproofing, you need to prepare the walls. You need to clear the room of all furniture, remove all the lamps. Then remove the old wallpaper from the walls and carefully inspect each wall. Existing cracks and holes must be well filled and primed. Next, soundproof all the sockets, it is through them that extraneous sounds from neighbors are very often heard. To do this, first of all, you need to de-energize the room, unscrew the socket and carefully remove it. Fill the hole for the socket with soundproofing material, such as foam rubber, polystyrene foam or fiberglass. Insert the socket and seal it in the wall with alabaster or plaster, screw on the lid. Do the same procedure with the mounting boxes in which the wires are hidden. It is best if all work related to electricity is carried out by a specialist.

The principle of soundproofing a wall.Before any soundproofing, you need to prepare the walls. You need to clear the room of all furniture, remove all the lamps. Then remove the old wallpaper from the walls and carefully inspect each wall. Existing cracks and holes must be well filled and primed. Next, soundproof all the sockets, it is through them that extraneous sounds from neighbors are very often heard. To do this, first of all, you need to de-energize the room, unscrew the socket and carefully remove it. Fill the hole for the socket with soundproofing material, such as foam rubber, polystyrene foam or fiberglass. Insert the socket and seal it in the wall with alabaster or plaster, screw on the lid. Do the same procedure with the mounting boxes in which the wires are hidden. It is best if all work related to electricity is carried out by a specialist. Soundproofing walls with mineral wool andplasterboard. The joints of heating or water pipes with the wall must be sealed with silicone or elastic sealant. The space near the pipe is cleaned of old mortar and sealed with new cement mortar. And it is advisable to additionally seal the joints with silicone sealant to prevent cracks from appearing in the mortar when the temperature changes. Carefully seal the joints between the walls, between the wall and the ceiling, between the wall and the floor. All detected voids can be eliminated with cement mortar or gypsum putty. If necessary, seal the gaps around the door frame and window frames. Return to the table of contents</a>

Soundproofing walls with mineral wool andplasterboard. The joints of heating or water pipes with the wall must be sealed with silicone or elastic sealant. The space near the pipe is cleaned of old mortar and sealed with new cement mortar. And it is advisable to additionally seal the joints with silicone sealant to prevent cracks from appearing in the mortar when the temperature changes. Carefully seal the joints between the walls, between the wall and the ceiling, between the wall and the floor. All detected voids can be eliminated with cement mortar or gypsum putty. If necessary, seal the gaps around the door frame and window frames. Return to the table of contents</a>

Use of soundproof panels

You can soundproof walls usingmultilayer panels, which consist of dense sheets and light layers of fiberglass or mineral wool. The peculiarity of such panels is that they can be attached to walls without a frame. The thickness of such panels can be from 40 to 120 mm. The panels already have special holes through which they are attached to the wall. There are also tongue and groove joints, which facilitate fastening. First, we glue two layers of a special gasket to the walls using acoustic sealant. Then we proceed to the direct fastening of the panels. This must be done from the bottom up using dowels. For additional strength, the joint grooves are pulled together with self-tapping screws. Upon completion of installation, the joints of the panels are sanded with an emery board and sealed with sealant. After this, the panels can be puttied and decorative finishing can begin. This method of soundproofing is considered quite simple and affordable. Return to contents</a>

Soundproofing based on carcass

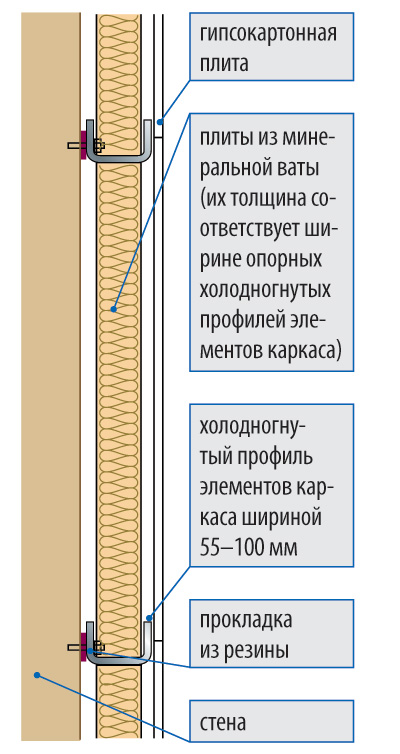

Return to Contents</a>Preparation of tools and materials Tool for working with plasterboard.This method requires preliminary installation of the frame on which the soundproofing material will be attached. Then the entire structure is covered with plasterboard. Today, this method is the most reliable. This is explained not only by the fastening, but also by good air circulation between the insulating material and the final finish. The disadvantages are considered to be the relative complexity of the fastening and the fence of more usable area of the room than in the case of gluing the material. There are two methods of frame soundproofing: based on a wooden frame and a metal one. Working with metal is very similar to the device of a frame made of plasterboard. With wood, everything is a little more complicated, since there are no ready-made places for fastenings. It is more susceptible to deformation and requires good pre-treatment to protect against pests and moisture. Therefore, let's consider in more detail working with a metal frame. Such do-it-yourself wall soundproofing is very reliable, since the absence of glue will ensure a longer service life of the panels and resistance to moisture and steam. To perform the labor-intensive work of installing the frame, you need to prepare the tools:

Tool for working with plasterboard.This method requires preliminary installation of the frame on which the soundproofing material will be attached. Then the entire structure is covered with plasterboard. Today, this method is the most reliable. This is explained not only by the fastening, but also by good air circulation between the insulating material and the final finish. The disadvantages are considered to be the relative complexity of the fastening and the fence of more usable area of the room than in the case of gluing the material. There are two methods of frame soundproofing: based on a wooden frame and a metal one. Working with metal is very similar to the device of a frame made of plasterboard. With wood, everything is a little more complicated, since there are no ready-made places for fastenings. It is more susceptible to deformation and requires good pre-treatment to protect against pests and moisture. Therefore, let's consider in more detail working with a metal frame. Such do-it-yourself wall soundproofing is very reliable, since the absence of glue will ensure a longer service life of the panels and resistance to moisture and steam. To perform the labor-intensive work of installing the frame, you need to prepare the tools: An example diagram of marking plasterboard sheets on walls.

An example diagram of marking plasterboard sheets on walls.

- building level and roulette;

- drill and screwdriver;

- sharp construction knife and hacksaw;

- a hammer;

- Furniture stapler;

- The container in which the glue will be mixed;

- set of screws;

- a simple pencil for markings;

- putty knife.

You still need to choose the material that will beused for soundproofing a room. Mostly mineral wool is used, which absorbs all sounds well and is easily inserted into the frame. This is achieved due to the air bubbles inside the material. Basalt slabs can be considered an analogue of mineral wool, which are also quite light and easy to install. Construction of a metal frameplasterboard. Egg trays have long been considered the most budget-friendly and oldest option for isolating a room from extraneous sounds. Here we do not mean plastic trays, but special paper ones, which have been used since Soviet times for packing eggs. They absorb sound very well, which is why they are installed even in sound recording rooms. However, attaching such material to walls is quite a difficult and time-consuming job. And they are not particularly resistant to moisture. Before buying, carefully measure all the walls to correctly determine the required amount of material. You should always take it with a margin to ensure a minimum distance between the joints. This is extremely important, since in the process of inserting the material into the frame, it will be significantly compressed. Return to contents</a>Fastening the frame to the wall

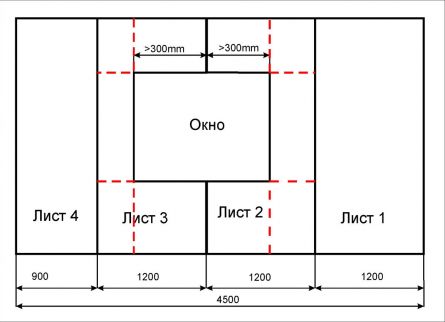

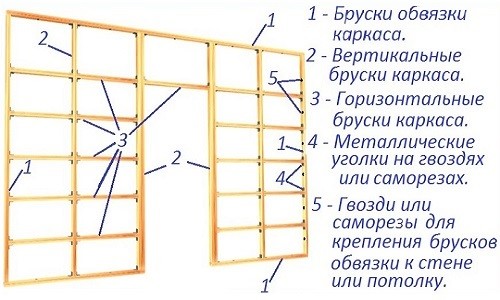

Construction of a metal frameplasterboard. Egg trays have long been considered the most budget-friendly and oldest option for isolating a room from extraneous sounds. Here we do not mean plastic trays, but special paper ones, which have been used since Soviet times for packing eggs. They absorb sound very well, which is why they are installed even in sound recording rooms. However, attaching such material to walls is quite a difficult and time-consuming job. And they are not particularly resistant to moisture. Before buying, carefully measure all the walls to correctly determine the required amount of material. You should always take it with a margin to ensure a minimum distance between the joints. This is extremely important, since in the process of inserting the material into the frame, it will be significantly compressed. Return to contents</a>Fastening the frame to the wall Construction of a wooden frame.So, first we make a metal frame. It should be noted that for such work you need the most even wall possible. Then everything will hold much more reliably. How to prepare the wall has already been described above. In general, this process is no different from preparing the wall before gluing the soundproofing material. Now we proceed to the installation of the frame. First, we mark the wall. Along the perimeter, using a tape measure and a pencil, it is necessary to draw straight lines where the guide profiles will be installed. Particular attention should be paid to the corners. Correct and maximally tight connection of the joints of horizontal and vertical strips will ensure good fixation of the soundproofing. When the marking along the perimeter is finished, start marking for the internal strips. Particular attention should be paid to the distance between them. You must always remember that the resulting space between the internal strips should be slightly smaller than the pieces of soundproofing material that will be laid there. You need to make metal squares. To do this, measure the dimensions of the insulation boards, subtract approximately 20-25 cm from each side. You will get the size of the squares. The wall must be marked in accordance with these dimensions. It often happens that the edges of the wall cannot be provided with such clear squares. Then you just need to divide the remaining area into two or three parts. When the markings are done, start fastening the frame. It is necessary to fasten from one edge of the wall to the other. You need to use self-tapping screws and a screwdriver. But, if the walls in the room are panel, one screwdriver will not do. Then you will have to first drill the wall with a hammer drill, hammer dowels into the holes, and only then fasten the frame there with self-tapping screws. The distance between the fasteners should be approximately 20 cm. Return to the table of contents</a>Fastening insulating sheets to the frame What is it?When it comes to installing soundproofing boards, everything is simple. The main thing is to follow simple rules, compliance with which will make it possible to do everything as efficiently as possible in a short time:

Construction of a wooden frame.So, first we make a metal frame. It should be noted that for such work you need the most even wall possible. Then everything will hold much more reliably. How to prepare the wall has already been described above. In general, this process is no different from preparing the wall before gluing the soundproofing material. Now we proceed to the installation of the frame. First, we mark the wall. Along the perimeter, using a tape measure and a pencil, it is necessary to draw straight lines where the guide profiles will be installed. Particular attention should be paid to the corners. Correct and maximally tight connection of the joints of horizontal and vertical strips will ensure good fixation of the soundproofing. When the marking along the perimeter is finished, start marking for the internal strips. Particular attention should be paid to the distance between them. You must always remember that the resulting space between the internal strips should be slightly smaller than the pieces of soundproofing material that will be laid there. You need to make metal squares. To do this, measure the dimensions of the insulation boards, subtract approximately 20-25 cm from each side. You will get the size of the squares. The wall must be marked in accordance with these dimensions. It often happens that the edges of the wall cannot be provided with such clear squares. Then you just need to divide the remaining area into two or three parts. When the markings are done, start fastening the frame. It is necessary to fasten from one edge of the wall to the other. You need to use self-tapping screws and a screwdriver. But, if the walls in the room are panel, one screwdriver will not do. Then you will have to first drill the wall with a hammer drill, hammer dowels into the holes, and only then fasten the frame there with self-tapping screws. The distance between the fasteners should be approximately 20 cm. Return to the table of contents</a>Fastening insulating sheets to the frame What is it?When it comes to installing soundproofing boards, everything is simple. The main thing is to follow simple rules, compliance with which will make it possible to do everything as efficiently as possible in a short time: Types of metal profiles.

Types of metal profiles.

So, after this, all you have to do is sew it upwall with plasterboard, fill the joints between the sheets with putty and finish with the desired method. When covering, use a level so that the wall does not turn out crooked. When fastening, try to countersink the screw heads so that they do not disturb the smoothness of the surface. When sealing the joints, do not neglect a sufficient amount of putty. Features of soundproofing walls with your own hands using frame and frameless methods are considered. Now you can safely get to work. If you follow the above sequence of work and simple advice, the insulation will be quite reliable and will protect the room from noise.