Any front door should protect the room fromunwanted guests and penetrations inside. In addition, it should be an excellent protection against cold and various noises that can be heard from the entrance or from the street. Also, high-quality soundproofing will leave all family conversations in the room, and none of those passing by the apartment or house will hear a single word. Modern products already have high technical qualities, but sometimes there is a need to increase them. Soundproofing the doors with your own hands is a process that can be easily accomplished. To do this, use modern materials that will meet all the requirements.  A quality front door should protect not only the penetration of unwanted guests, but also from street noise.

A quality front door should protect not only the penetration of unwanted guests, but also from street noise.

Main characteristics

Today in the market of entrance and interior doorssufficiently large model range. Among all the options are models that have very high heat and sound insulation characteristics. It should be noted immediately that such products will cost significantly more. As for cheaper options, then, respectively, and technical qualities are reduced. If you want to install the cheapest and most practical option, use a steel sheet, around which the corner is welded. In order to make the construction more durable, install additional stiffeners. Soundproofing of such a product must be carried out necessarily. Sound insulation of the room can be performed in several ways:

The last two options require additional labor and financial costs. Therefore, the best option will be the insulation of the first door leaf. Back to contents</a>

Sound insulation of doors: practical advice

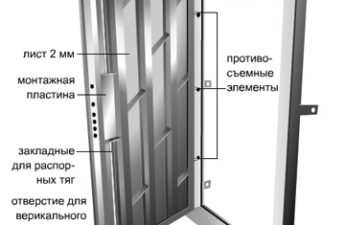

The construction of a door leaf with soundproofing. For noise isolation it is necessary to use modern sound-absorbing materials, which are presented today in a huge assortment. A significant increase in the volume of the canvas allows you to store more heat in the room. Performing such work, you can completely change the appearance of the door. It depends on personal preferences and selected isolators. The first thing that begins work is the removal of the upholstery from the canvas. This is acceptable in case the door has a frame lined with sheets of fiberboard covered with a decorative layer - dermatine or laminated film. If the product is metal, it is worthwhile to disassemble the structure, and it is very important to control that the cutting site is very accurate, since in the future it will be necessary to connect the elements by welding. Preliminary it is necessary to check the parameters of the skeleton and its geometry. In order to make the product more reliable and durable, it is possible to install additional stiffeners inside the structure. The whole inner area must be treated with degreasing agent, for example, acetone. When working with it, you should always wear protective gloves. As a heat insulator, a mounting foam can be used to fill the internal cavity of the structure.

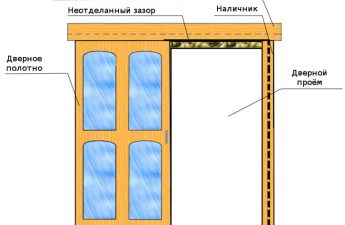

The construction of a door leaf with soundproofing. For noise isolation it is necessary to use modern sound-absorbing materials, which are presented today in a huge assortment. A significant increase in the volume of the canvas allows you to store more heat in the room. Performing such work, you can completely change the appearance of the door. It depends on personal preferences and selected isolators. The first thing that begins work is the removal of the upholstery from the canvas. This is acceptable in case the door has a frame lined with sheets of fiberboard covered with a decorative layer - dermatine or laminated film. If the product is metal, it is worthwhile to disassemble the structure, and it is very important to control that the cutting site is very accurate, since in the future it will be necessary to connect the elements by welding. Preliminary it is necessary to check the parameters of the skeleton and its geometry. In order to make the product more reliable and durable, it is possible to install additional stiffeners inside the structure. The whole inner area must be treated with degreasing agent, for example, acetone. When working with it, you should always wear protective gloves. As a heat insulator, a mounting foam can be used to fill the internal cavity of the structure.  Soundproofing of the door box with a sealant. Mounting foam is used to seal the slots that are formed during installation. As for soundproofing using this material, it will be quite low. Sound insulation of the canvas can be done with the help of bitumen self-adhesive insulators. Among them is worth noting self-adhesive vibroisolators - bimast, vizomat, or self-adhesive noise isolators - vibroplast, splen. In order to qualitatively perform insulation, you need to use three layers of each of the two types of insulator. In order to cut vibration isolation and sound insulation, you will need a conventional construction knife or large scissors. It is also worth using a tape measure, ruler and pencil or chalk for basting. Sometimes it is recommended to use an additional glue composition for better adhesion. Back to contents</a>

Soundproofing of the door box with a sealant. Mounting foam is used to seal the slots that are formed during installation. As for soundproofing using this material, it will be quite low. Sound insulation of the canvas can be done with the help of bitumen self-adhesive insulators. Among them is worth noting self-adhesive vibroisolators - bimast, vizomat, or self-adhesive noise isolators - vibroplast, splen. In order to qualitatively perform insulation, you need to use three layers of each of the two types of insulator. In order to cut vibration isolation and sound insulation, you will need a conventional construction knife or large scissors. It is also worth using a tape measure, ruler and pencil or chalk for basting. Sometimes it is recommended to use an additional glue composition for better adhesion. Back to contents</a>

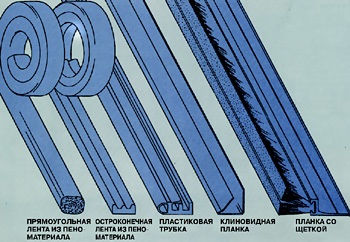

Pasting soundproof material

Types of soundproof sealing tape. After the surface is degreased, it is necessary to give it time to dry completely and only then proceed to the gluing of the materials. The first layer must be laid vibration damping bitumen. Such material is a rather heavy sheet with a sealant-glue. Such a material can be glued in two layers. On top of it you need to lay several layers of noise insulation. This material is more light and looks like a thin foam. The installation of such material must be done with strips, the process resembles the wallpapering on the wall. The protective film, which protects the adhesive layer, is not necessary to tear off at once, its removal is carried out gradually, during the process of gluing to the door. At the same time, it is necessary to smooth the surface so that there are no air spaces left. It is very important to overlap each layer. To do this, all the strips must be glued in staggered order, so that each joint is blocked by a new strip of noise insulation. In order to remove the remnants of the material, you must use an ordinary knife. It is recommended to glue these materials in the warm season, when the air temperature exceeds the mark of + 20 ° С and even + 25 ° С. If the procedure is carried out in the winter, it is necessary to warm the surface of the metal door with a fan heater. When laying insulating materials, you need to be careful in places of lock systems, you can not block access to them, and after the completion of the work the whole system should work without difficulties. Back to contents</a>

Types of soundproof sealing tape. After the surface is degreased, it is necessary to give it time to dry completely and only then proceed to the gluing of the materials. The first layer must be laid vibration damping bitumen. Such material is a rather heavy sheet with a sealant-glue. Such a material can be glued in two layers. On top of it you need to lay several layers of noise insulation. This material is more light and looks like a thin foam. The installation of such material must be done with strips, the process resembles the wallpapering on the wall. The protective film, which protects the adhesive layer, is not necessary to tear off at once, its removal is carried out gradually, during the process of gluing to the door. At the same time, it is necessary to smooth the surface so that there are no air spaces left. It is very important to overlap each layer. To do this, all the strips must be glued in staggered order, so that each joint is blocked by a new strip of noise insulation. In order to remove the remnants of the material, you must use an ordinary knife. It is recommended to glue these materials in the warm season, when the air temperature exceeds the mark of + 20 ° С and even + 25 ° С. If the procedure is carried out in the winter, it is necessary to warm the surface of the metal door with a fan heater. When laying insulating materials, you need to be careful in places of lock systems, you can not block access to them, and after the completion of the work the whole system should work without difficulties. Back to contents</a>

Additional points

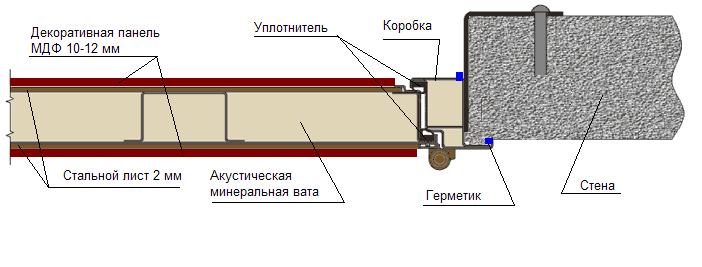

Sound insulation and thermal insulation are different processes,for the implementation of which completely different materials are used. It is not necessary to perform heat insulation, if you only need to protect the room from extraneous sounds, but still it is recommended to perform all the actions simultaneously. For this, after the soundproofing is laid, it is necessary to lay foam rubber or mineral wool in the space between the frame. In order to fix it, you can use a fishing line, which stretches in the form of a grid.  During the soundproofing of the door, you cancompletely change its appearance with the help of modern finishing materials. During the warming and soundproofing of the canvas, it is possible to make the appearance of the door completely different. To do this, it is necessary to choose the finishing material that best fits into the overall interior of the room and you will have to taste it. To finish the entrance door, it is best to use MDF panels, they are much stronger and, in contrast to PVC panels, do not deform with time. You must start the panels from the hinges. Mount wooden panels to the metal frame can be using self-tapping screws or liquid nails. The advantage of the second option is the absence of damage to the panels, the surface is completely flat. It is very important to plan the location of the door eyelet and immediately make holes for it. For this it is necessary to use a drill with a suitable drill. If the door is not covered with new material, and a sheet of steel, which was previously removed, is installed on top, a welding machine should be used. Along the entire perimeter, two parts must be connected carefully. It is necessary to control the welding seam so that it does not interfere with opening and closing the doors. In the end, it is very important to glue the sealant around the entire perimeter of the door. This is a strip of foamed rubber, which has one adhesive side. The thickness of this material is selected depending on the features of the door. Noise as a result of such insulation will not penetrate into the room.

During the soundproofing of the door, you cancompletely change its appearance with the help of modern finishing materials. During the warming and soundproofing of the canvas, it is possible to make the appearance of the door completely different. To do this, it is necessary to choose the finishing material that best fits into the overall interior of the room and you will have to taste it. To finish the entrance door, it is best to use MDF panels, they are much stronger and, in contrast to PVC panels, do not deform with time. You must start the panels from the hinges. Mount wooden panels to the metal frame can be using self-tapping screws or liquid nails. The advantage of the second option is the absence of damage to the panels, the surface is completely flat. It is very important to plan the location of the door eyelet and immediately make holes for it. For this it is necessary to use a drill with a suitable drill. If the door is not covered with new material, and a sheet of steel, which was previously removed, is installed on top, a welding machine should be used. Along the entire perimeter, two parts must be connected carefully. It is necessary to control the welding seam so that it does not interfere with opening and closing the doors. In the end, it is very important to glue the sealant around the entire perimeter of the door. This is a strip of foamed rubber, which has one adhesive side. The thickness of this material is selected depending on the features of the door. Noise as a result of such insulation will not penetrate into the room.