Plasterboard ceilings are becoming more and more popularis relevant, because such a system is able to hide all the unevenness of the ceiling, even if they are quite impressive. In addition, the appearance of such ceilings can be very diverse, the master is able to implement different design solutions: it is permissible to mount a flat base or a multi-level structure, which will have a complex shape. As an additional advantage of the plasterboard ceiling, it is possible to supplement it with built-in lighting fixtures and decorative lighting. Under the thickness of the material, in the hollow space of the plasterboard ceiling, heat-insulating boards can be laid, which will perform an additional role of sound insulation. The system is installed quite simply, and not so much money will be spent on it. A suspended ceiling made of plasterboard can hide all the unevenness of the ceiling, even if they are quite impressive.

A suspended ceiling made of plasterboard can hide all the unevenness of the ceiling, even if they are quite impressive.

Preparing before starting the installation

Before starting the installation of a plasterboard ceilingyou should measure the room, which will allow you to design the frame scheme and understand how to correctly arrange the sheets of material. The step between the sheets of gypsum board and the main ceiling will be determined by the unevenness and dimensions of the built-in lighting fixtures. To carry out the work, you need to prepare the following materials and tools: Fastening plasterboard.

Fastening plasterboard.

- GCR;

- guide and bearing profiles;

- a primer;

- screws intended for work on metal;

- hangers and connectors;

- reinforcing sickle;

- dowel-screws;

- screws for working with plasterboard;

- finishing putty;

- roulette.

- the Bulgarian;

- water level;

- cutter for profiles;

- Pull out cord;

- perforator;

- screwdriver.

- rule;

- scissors for work on metal;

- a hammer;

- drill;

- knife for drywall;

- putty knife;

- grinding grater.

Return to Contents</a>

Technology of work

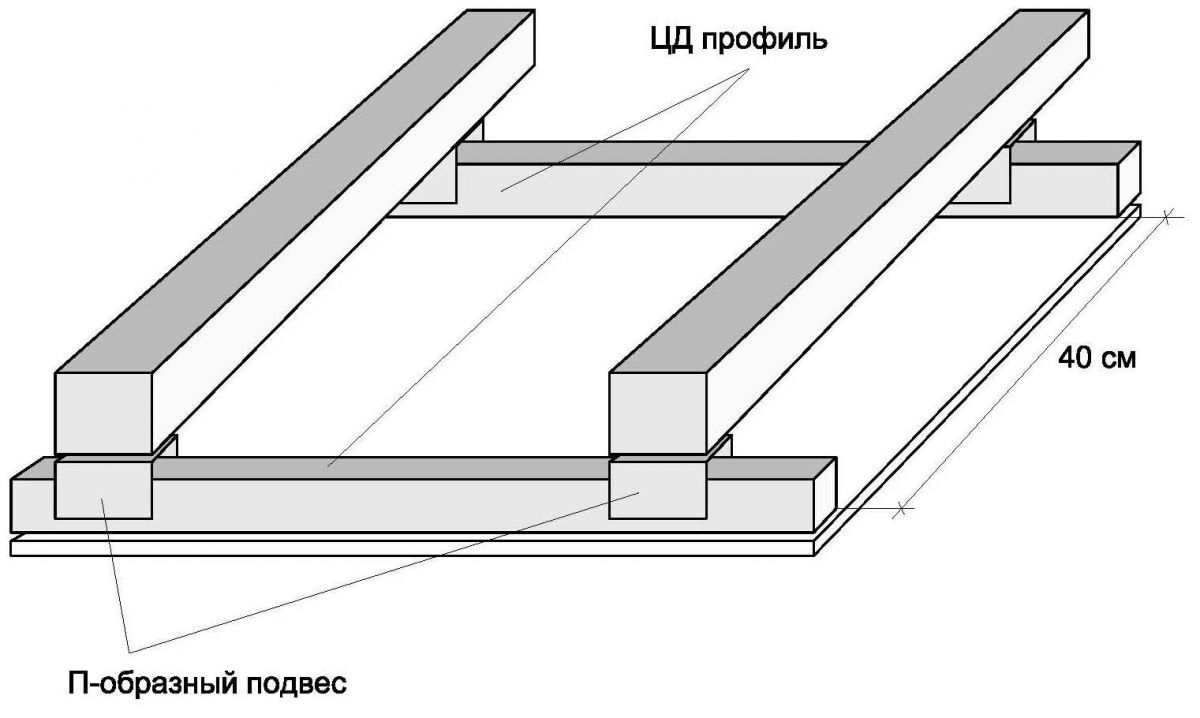

Simple suspended ceiling diagramplasterboard with backlighting. Stretch ceilings are also able to hide communications and uneven surfaces, but their installation is carried out exclusively by professionals who have the appropriate equipment in their arsenal. Therefore, if you have not yet decided which system to choose for arranging ceilings, then the above-mentioned circumstance should be taken into account. To begin with, a guide profile should be fixed on each wall along the perimeter of the room. In order to ensure its strictly horizontal position, a water level should be used for work. A chalk line will allow you to lay a straight line along the marks made. The required distance from the base ceiling should be set aside at the lowest corner of the room. After that, the chalk line should be pulled as tight as possible between the marks, slightly removed from the wall and released, at the moment of impact a clear mark will remain on the surface. This line will be useful for installing the guide profile. It must be fixed to the wall using "quick installation". To do this, holes need to be made in the wall body using a hammer drill, the distance between them should be 40 cm. The bearing profiles should be attached to the fixed guide profiles, and their installation points should be marked with a marker.

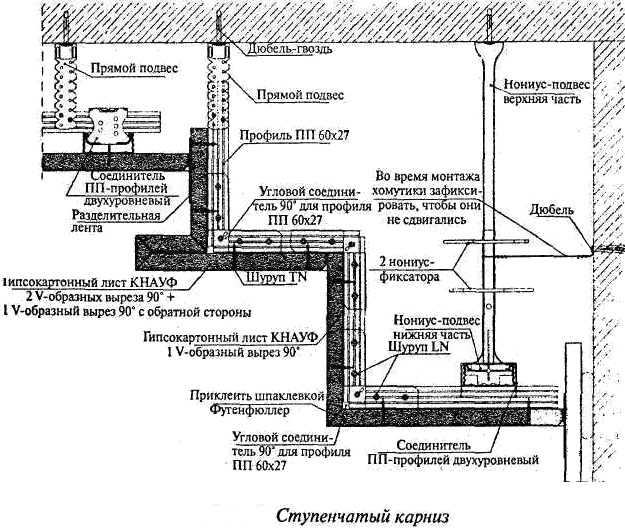

Simple suspended ceiling diagramplasterboard with backlighting. Stretch ceilings are also able to hide communications and uneven surfaces, but their installation is carried out exclusively by professionals who have the appropriate equipment in their arsenal. Therefore, if you have not yet decided which system to choose for arranging ceilings, then the above-mentioned circumstance should be taken into account. To begin with, a guide profile should be fixed on each wall along the perimeter of the room. In order to ensure its strictly horizontal position, a water level should be used for work. A chalk line will allow you to lay a straight line along the marks made. The required distance from the base ceiling should be set aside at the lowest corner of the room. After that, the chalk line should be pulled as tight as possible between the marks, slightly removed from the wall and released, at the moment of impact a clear mark will remain on the surface. This line will be useful for installing the guide profile. It must be fixed to the wall using "quick installation". To do this, holes need to be made in the wall body using a hammer drill, the distance between them should be 40 cm. The bearing profiles should be attached to the fixed guide profiles, and their installation points should be marked with a marker. The device of a suspended ceiling located inthree levels. When installing a suspended plasterboard ceiling, it should be taken into account that the sheets should be joined in the central longitudinal line of the supporting profiles, this will ensure reliable fastening of the system. The central longitudinal lines of the supporting profiles should be removed from each other at a distance of 60 cm, this is due to the width of the covering sheet, which is 120 cm. Installation of the starting supporting profile should be carried out, stepping back 60 cm from the wall. On the surface in the center of the supporting profiles, it is necessary to install hangers, they must be located at a distance of 80 cm, using the "quick installation" technique described above. For each hanger, it is necessary to arrange two holes in the ceiling, using a hammer drill for this. When installing a suspended ceiling, you will be faced with the need to cut the profiles. This should be done using a grinder. After the element is installed in its place, it should be secured with self-tapping screws to the guide profiles, as well as hangers. To make screwing in the fasteners easier, use punches, having prepared holes in the steel profiles in advance. The effect of the bearing profiles sagging can be avoided by using a thread that needs to be pulled across the center of the room, placing it at an angle of 90° to the profiles. All remaining bearing profiles are installed using the technology already described. The area where the chandelier is to be fixed should be reinforced by installing crossbars made of bearing profiles. If the system assumes the presence of a ceiling cornice intended for curtains, then the areas of future fixation of the named element require similar reinforcement.

The device of a suspended ceiling located inthree levels. When installing a suspended plasterboard ceiling, it should be taken into account that the sheets should be joined in the central longitudinal line of the supporting profiles, this will ensure reliable fastening of the system. The central longitudinal lines of the supporting profiles should be removed from each other at a distance of 60 cm, this is due to the width of the covering sheet, which is 120 cm. Installation of the starting supporting profile should be carried out, stepping back 60 cm from the wall. On the surface in the center of the supporting profiles, it is necessary to install hangers, they must be located at a distance of 80 cm, using the "quick installation" technique described above. For each hanger, it is necessary to arrange two holes in the ceiling, using a hammer drill for this. When installing a suspended ceiling, you will be faced with the need to cut the profiles. This should be done using a grinder. After the element is installed in its place, it should be secured with self-tapping screws to the guide profiles, as well as hangers. To make screwing in the fasteners easier, use punches, having prepared holes in the steel profiles in advance. The effect of the bearing profiles sagging can be avoided by using a thread that needs to be pulled across the center of the room, placing it at an angle of 90° to the profiles. All remaining bearing profiles are installed using the technology already described. The area where the chandelier is to be fixed should be reinforced by installing crossbars made of bearing profiles. If the system assumes the presence of a ceiling cornice intended for curtains, then the areas of future fixation of the named element require similar reinforcement. Scheme of a two-level plasterboard ceiling.When installing a suspended ceiling, some craftsmen face a problem expressed by the insufficient length of the sheets for the width of the room. In this case, in the places where the sheets are connected, it is necessary to install crossbars from the supporting profile, which are fixed with self-tapping screws using single-level crab-type connectors. should be installed in such a way that the sheets of material are located "staggered" or, in other words, in a checkerboard pattern. At this stage, it can be considered that the frame is ready for further work. Return to the table of contents</a>

Scheme of a two-level plasterboard ceiling.When installing a suspended ceiling, some craftsmen face a problem expressed by the insufficient length of the sheets for the width of the room. In this case, in the places where the sheets are connected, it is necessary to install crossbars from the supporting profile, which are fixed with self-tapping screws using single-level crab-type connectors. should be installed in such a way that the sheets of material are located "staggered" or, in other words, in a checkerboard pattern. At this stage, it can be considered that the frame is ready for further work. Return to the table of contents</a>

Installation of gypsum boards

Ceiling with lighting at the stage of fixing sheetsmaterial involves the use of self-tapping screws designed for working with plasterboard. You can use a method that involves marking the location of the self-tapping screws, this must be done on one side. In order for the fastener head not to break the canvas at the time of screwing in, only slightly immersed in it, you should correctly adjust the screwdriver tool or use a specially designed nozzle that has a limiter. You can see an illustration showing how to correctly position the fastener when fixing drywall to the profile. Cutting of sheets is carried out using a knife and an aluminum rule. In this case, you need to use a special cutting technology. With a knife next to the attached rule, you need to cut a layer of material on one side, then turn the sheet over and hit it a little so that the cut breaks, then the canvas must be slightly bent and the second layer of the canvas should be cut along the resulting bend. After the sheets are installed, the joints where there are special chamfers should be glued with "serpyanka", while it is worth using a putty mixture and a spatula. The holes left from the fasteners are also subject to processing, they should be covered with putty. After the putty gains strength, the entire base of the material should be puttyed, while using a float. If necessary, the mixture can be applied in several layers, this will allow you to get an ideal surface. The completion of the final grinding should be accompanied by the beginning of priming, but in advance it is necessary to remove dust from the surface with a dry brush. Return to the table of contents</a>

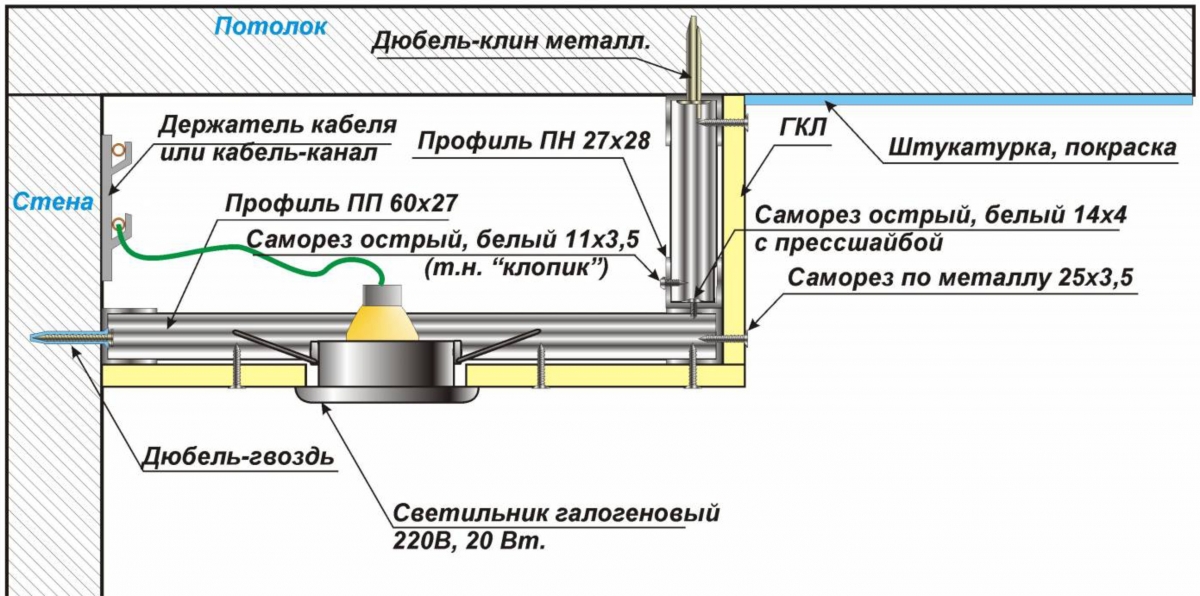

Installation of lighting equipment

In order for the ceiling to have lighting,Built-in equipment must be connected in advance by laying electrical wiring. In the places where the devices are supposed to be located, it is necessary to arrange holes of the required diameter, the last of which must correspond to the dimensions of the lamp. You need to use a drill with a crown. Partially remove the laid wire through the hole, to which the device is connected via connecting contacts. If 12 V bulbs are used, a step-down transformer will need to be installed. The mounting strip of the lighting device must be reinforced with self-tapping screws through the drywall to the installed profiles. If you plan to install a multi-level system with backlighting, then its installation should be carried out using adjustable hangers of different lengths, which will allow you to adjust the height of the levels. Return to contents</a>

Features of LED strip installation

Ceiling lighting can also be presentedLED strip. It can be cut only in special places, which are marked by the manufacturer. To connect several strips, you can connect them using LED connectors. But you can also solder the strip with a soldering iron. The described backlight should be selected in such a way that its power supply has a reserve of 30% of power, otherwise its premature burnout cannot be avoided. The backlight is attached exclusively to the insulating material.