One of the most durable, reliable and inexpensiveoptions for arranging the floor is to use a concrete screed. Due to the advantages of this coating, many people choose a concrete screed for arranging the floor in a house or garage, and therefore they often have a question: how do they do it with their own hands?  Screed floor concrete mix is the most qualitative and lasting option.

Screed floor concrete mix is the most qualitative and lasting option.

Preparatory work

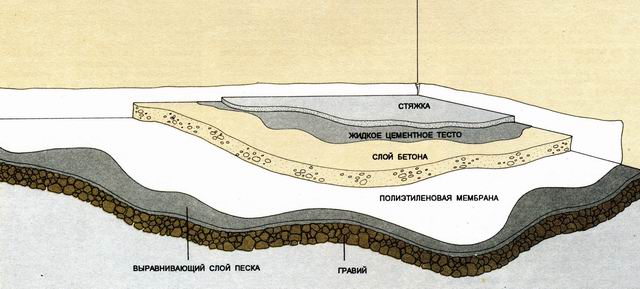

For pouring concrete with your own handsconcrete is used, for the preparation of which cement M 75 and more is used. Such a coating is laid on a cushion of rubble, its fraction should not exceed 15 mm, it is often used to create a warm floor in the house.  Constructive scheme of concrete floor. Solving the question of how to pour concrete, scares many people, but in this process there is nothing complicated. You just have to make considerable physical efforts, and all the technology of work is reduced to the correct preparation of the solution and installation of lighthouses. At the first stage of the work, the floor must be freed from the old covering. If the quality of the old screed is normal, then the new screed can be laid on top without removing the old coating. To remove the old concrete coating, which began to crumble, you can use a puncher or a jackhammer. Before you fill the floor with a mortar, you need to determine the highest point of the floor in the room, for which you have to use a water level or level. There are times when between rooms there is a very large difference in heights, and then to lay a concrete warm floor, choose the option when it is performed in each room separately. Although this method results in differences in the height of the floor between the rooms, but they can be hidden with a decor, but the layer of the screed will not be too thick, the warm floor will work efficiently and it will not get very high load. Back to contents</a>

Constructive scheme of concrete floor. Solving the question of how to pour concrete, scares many people, but in this process there is nothing complicated. You just have to make considerable physical efforts, and all the technology of work is reduced to the correct preparation of the solution and installation of lighthouses. At the first stage of the work, the floor must be freed from the old covering. If the quality of the old screed is normal, then the new screed can be laid on top without removing the old coating. To remove the old concrete coating, which began to crumble, you can use a puncher or a jackhammer. Before you fill the floor with a mortar, you need to determine the highest point of the floor in the room, for which you have to use a water level or level. There are times when between rooms there is a very large difference in heights, and then to lay a concrete warm floor, choose the option when it is performed in each room separately. Although this method results in differences in the height of the floor between the rooms, but they can be hidden with a decor, but the layer of the screed will not be too thick, the warm floor will work efficiently and it will not get very high load. Back to contents</a>

Proper use of beacons

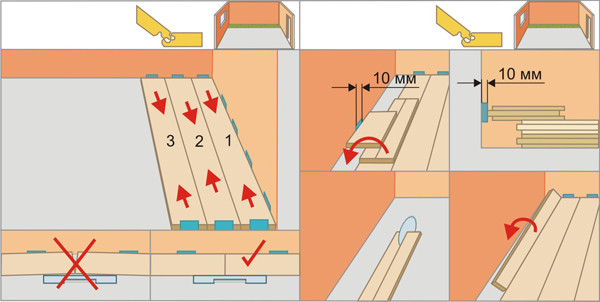

The scheme of setting the lighthouses. The work begins at the highest point. For making beacons, special T-shaped guides are best, but if they are not, other materials can be used, and wooden beacons can only be used in extreme cases. In order for the screed to have sufficient strength, its minimum thickness should be greater than 7 mm. Lighthouses are placed on the surface of the floor in the form of sections, but the dimensions of these sections should not be greater than the length of the rule that will be used in the work. For aligning beacons, a lining material is used. The distance between the lining should not be more than 30 cm, to control the position of the beacon the building level is used. To fix beacons, you need to use the material from which the screed will be made, but most often use alabaster, as it quickly seizes and fixes the beacons in the desired position. It is clear that the pouring of the floor with concrete is a moist process, therefore, as a lining, you can not use chipboard or cardboard, because under the influence of moisture they can change shape, so that the beacons will shift. For pads, it is best to use metal or plastic plates. Back to contents</a>

The scheme of setting the lighthouses. The work begins at the highest point. For making beacons, special T-shaped guides are best, but if they are not, other materials can be used, and wooden beacons can only be used in extreme cases. In order for the screed to have sufficient strength, its minimum thickness should be greater than 7 mm. Lighthouses are placed on the surface of the floor in the form of sections, but the dimensions of these sections should not be greater than the length of the rule that will be used in the work. For aligning beacons, a lining material is used. The distance between the lining should not be more than 30 cm, to control the position of the beacon the building level is used. To fix beacons, you need to use the material from which the screed will be made, but most often use alabaster, as it quickly seizes and fixes the beacons in the desired position. It is clear that the pouring of the floor with concrete is a moist process, therefore, as a lining, you can not use chipboard or cardboard, because under the influence of moisture they can change shape, so that the beacons will shift. For pads, it is best to use metal or plastic plates. Back to contents</a>

Preparation of the floor surface

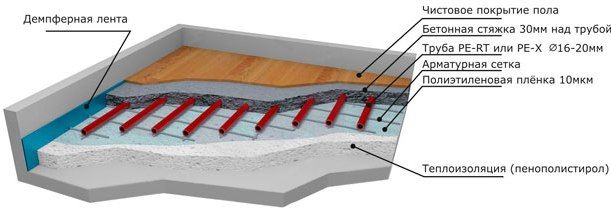

Tools and materials for the work:  Scheme of pouring a warm concrete floor.

Scheme of pouring a warm concrete floor.

- perforator;

- jackhammer;

- water level

- level;

- rule;

- building level;

- mixer;

- cement

- sand;

- plasticizer.

Before pouring a warm floor, it is necessarylay pipes or cable. If you just make a concrete screed, then the surface of the floor is wetted with water, for this you can use a roller, otherwise the concrete will exfoliate. Examine the room, and if there are gaps between the floor and the wall, they must be filled in, using a mounting foam. To make the solution, cement and sand are used in a proportion of 1: 3, after which they are mixed until a homogeneous mass is obtained. To make the solution homogeneous, it is better to mix it not with a shovel, but with a mixer. The quality of the mortar is important in any case, especially when the floor is poured and tiles will be laid. 5 kg of cement-sand mixture requires 1 liter of water. Add the mixture to the water, not vice versa. After the preparation of the solution, it should stand for 1-2 minutes, and then it must be mixed again.  Pouring cement mortar along the lighthouses is carried outrule. To simplify your work, you can buy a ready-made solution. If you want to get a perfectly flat surface, you can use a self-leveling screed, this option is chosen when laying tiles, linoleum or laminate. The composition of the self-leveling screed includes cement, gypsum and anhydrite. If you need a small thickness of screed, up to 5 cm, that is special solutions with microfibers, which reinforce the screed and make it more durable. You can purchase both a dry screed and a completely ready-to-use solution. Back to contents</a>

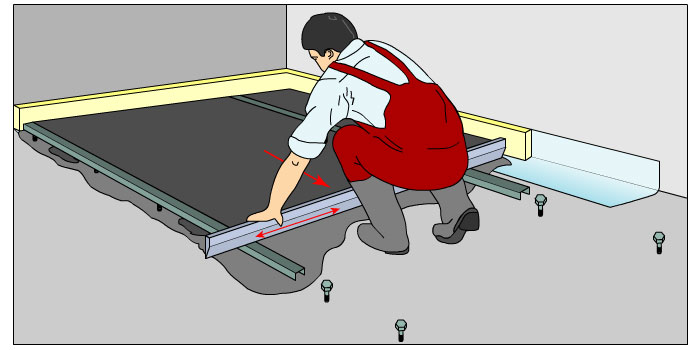

Pouring cement mortar along the lighthouses is carried outrule. To simplify your work, you can buy a ready-made solution. If you want to get a perfectly flat surface, you can use a self-leveling screed, this option is chosen when laying tiles, linoleum or laminate. The composition of the self-leveling screed includes cement, gypsum and anhydrite. If you need a small thickness of screed, up to 5 cm, that is special solutions with microfibers, which reinforce the screed and make it more durable. You can purchase both a dry screed and a completely ready-to-use solution. Back to contents</a>

Casting mortar

Scheme of a three-stage cement floor. Start this stage of work from the corner, which is farthest from the doors. If you work together, then one person prepares the solution, and the second pours it. The solution is poured onto the floor, then adjusted with a trowel and tightened with the rule, moving towards the exit from the room. The rule is moved to the lighthouses, making them oval movements, such as when carrying out grouting walls. The room should be tried to pour in at a time, only in this case you will be able to get a monolithic and durable floor. Once the solution has hardened and will retain its shape, the guides need to be removed. When the floor can be moved, it is necessary to seal the seams from the guides. If you use beacons, you do not need to remove them from the screed, so the work is greatly accelerated and simplified. Although the coupler will harden after a day, this does not mean that it is ready for use. For gaining strength characteristics of the floor, he should stay unloaded for at least 7 days, but better 21 days. In order not to crack the concrete, twice a day, it is necessary to wet the screed with water. To make the concrete stronger and harden faster, you can use a plasticizer when preparing it. Back to contents</a>

Scheme of a three-stage cement floor. Start this stage of work from the corner, which is farthest from the doors. If you work together, then one person prepares the solution, and the second pours it. The solution is poured onto the floor, then adjusted with a trowel and tightened with the rule, moving towards the exit from the room. The rule is moved to the lighthouses, making them oval movements, such as when carrying out grouting walls. The room should be tried to pour in at a time, only in this case you will be able to get a monolithic and durable floor. Once the solution has hardened and will retain its shape, the guides need to be removed. When the floor can be moved, it is necessary to seal the seams from the guides. If you use beacons, you do not need to remove them from the screed, so the work is greatly accelerated and simplified. Although the coupler will harden after a day, this does not mean that it is ready for use. For gaining strength characteristics of the floor, he should stay unloaded for at least 7 days, but better 21 days. In order not to crack the concrete, twice a day, it is necessary to wet the screed with water. To make the concrete stronger and harden faster, you can use a plasticizer when preparing it. Back to contents</a>

We estimate the quality of the work performed

Spend an external inspection of the floor, it should behomogeneous in appearance and have a gray color. To determine how smooth the floor has turned out, it is necessary to take a rule, preferably a length of 2 m, and attach it to the floor surface. Normal is considered when the gaps between the rule and the floor will not exceed 4 mm. To determine the hardness of the coating on it, it is necessary to strike the tangent with a hammer, while the trace should be practically invisible. In order to cover 7-8 square meters of floor, you will need up to 10 bags of cement, it all depends on the thickness of the screed. To save money, you can first make a black screed, while using less quality materials, and then carry out the final screed. The use of reinforcement, although it increases the cost of work, but significantly increases the life of the coating. Screed foam concrete is considered a more economical option, but you can not lay it on the ground, first you need to make a rough screed with ordinary concrete.