Plastering is a stage of construction,which in most cases is necessary for high-quality wall finishing. In addition to leveling, plaster also strengthens surfaces. And how firmly the solution itself will adhere to them depends on how carefully the . Preparing walls for decorative plaster.

Preparing walls for decorative plaster.

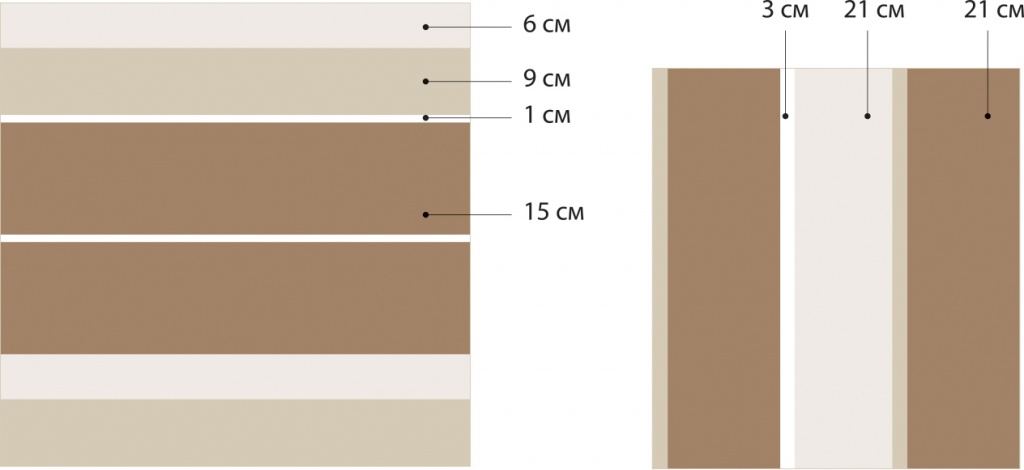

Permissible thickness of plaster

Despite the fact that a high-quality solution afterhardening is a fairly durable material, it should not be applied in a thick layer to the walls, as it will not stick to the surface. Building codes determine how thick the plaster layer should be on the wall if it deviates from the vertical plane. The requirements are as follows: Tools for plastering walls.

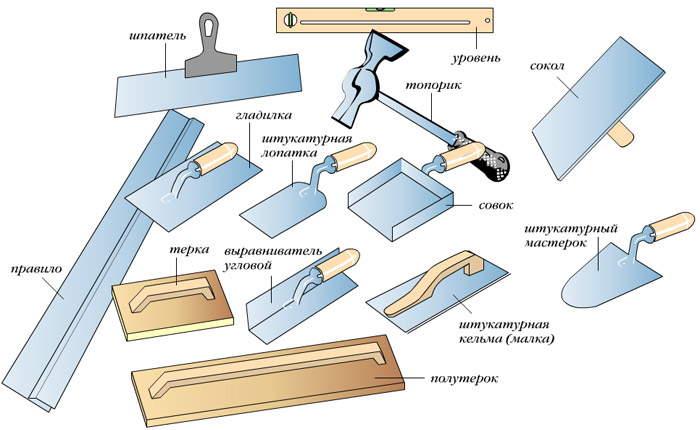

Tools for plastering walls.

- if the deviation of the surface is up to 1.5 cm to the height of the room or not more than 0.3 cm per meter of height, then the thickness of the layer from the ordinary solution can not be more than 1.2 cm;

- the thickness of the improved solution when applied to an uneven wall can be no more than 1.5 cm if the curvature of the wall along the vertical does not exceed 1 cm to the height of the room or 2 mm to each meter thereof;

- high-quality mixtures can be used for wall deflection up to 0.5 cm (for the height of the room) and 1 mm (for each meter), with the layer not exceeding 2 cm in thickness.

It should be noted that with a large curvaturesurfaces will have to take measures to pre-level them. This process can be carried out by applying several layers of cement-sand mortar, although its consumption will increase significantly. Return to contents</a>

Strengthening plaster reinforcement

In addition, to level the wall you will needand a reinforcing mesh that will improve the adhesion of the solution to the surface. For this purpose, a chain-link or other metal mesh with 1 x 1 cm cells can be used. Preparation of wooden surfaces forplaster. Such reinforcement is attached to a surface made of bricks with nails that can be driven into the seams. This method of fastening is less labor-intensive and costly than fastening the mesh with dowel-nails screwed into the masonry. The nails should be driven in with some deviation from the plane perpendicular to the wall. On concrete walls, the grid is attached to the reinforcement outlets. Otherwise, it is screwed to the concrete plane with dowel-nails. The mesh itself is sprayed with cement milk. It creates a film on the wire through which rust will not show through later, and the adhesion of the mesh to the mortar will be better. Metal mesh is used not only for leveling walls, it must also be used when the plaster layer can be more than 4 cm. Return to contents</a>

Preparation of wooden surfaces forplaster. Such reinforcement is attached to a surface made of bricks with nails that can be driven into the seams. This method of fastening is less labor-intensive and costly than fastening the mesh with dowel-nails screwed into the masonry. The nails should be driven in with some deviation from the plane perpendicular to the wall. On concrete walls, the grid is attached to the reinforcement outlets. Otherwise, it is screwed to the concrete plane with dowel-nails. The mesh itself is sprayed with cement milk. It creates a film on the wire through which rust will not show through later, and the adhesion of the mesh to the mortar will be better. Metal mesh is used not only for leveling walls, it must also be used when the plaster layer can be more than 4 cm. Return to contents</a>

How to prepare the wall

However, before grating on the surfaceit is necessary to remove defects: cracks, deep depressions, etc. Before sealing some cracks, it is necessary to make sure that they do not increase. To do this, beacons made of plaster, mortar or paper are installed between the opposite sides of the gaps in the wall, which are monitored for a certain period of time. If the beacons break, it means that the wall or its base needs to be repaired, eliminating the cause of the crack. If no changes are observed on the indicators, the cracks are cut with a chisel. They should take the form of expanding grooves so that the mortar is laid in them as deeply as possible. Before sealing, large holes are treated with a primer. Preparation for plastering:jointing and applying a primer. Remove dirt, traces of old paint, and dust from the walls. The surfaces can also be treated with a 3% HCl solution, after which the remaining dirt and acid are washed off with water. There is another way to clean the walls of grease deposits, in which greasy clay acts as their absorbent. Spread in a thick layer, it interacts well with deposits. After drying, the clay is removed. Perhaps, for high-quality removal of grease, it will be necessary to apply clay several times. It should be said that greasy stains on the walls do not always disappear. They can be so deeply absorbed that over time they will show through the plaster and even through the finishing. To anticipate such a result, it is better to cut out the “fat” fragment with a hammer drill to the required depth, and then seal this place with a solution. Before installing the grate, the wall is impregnated with a primer. So, for preliminary cleaning of the walls for subsequent plastering, you need to prepare:

Preparation for plastering:jointing and applying a primer. Remove dirt, traces of old paint, and dust from the walls. The surfaces can also be treated with a 3% HCl solution, after which the remaining dirt and acid are washed off with water. There is another way to clean the walls of grease deposits, in which greasy clay acts as their absorbent. Spread in a thick layer, it interacts well with deposits. After drying, the clay is removed. Perhaps, for high-quality removal of grease, it will be necessary to apply clay several times. It should be said that greasy stains on the walls do not always disappear. They can be so deeply absorbed that over time they will show through the plaster and even through the finishing. To anticipate such a result, it is better to cut out the “fat” fragment with a hammer drill to the required depth, and then seal this place with a solution. Before installing the grate, the wall is impregnated with a primer. So, for preliminary cleaning of the walls for subsequent plastering, you need to prepare:

- perforator;

- scarlet or chisel;

- a hammer;

- putty knife;

- steel brush;

- capacity with a 3% solution of hydrochloric acid;

- brush or roller;

- a container with water;

- a primer;

- cement for the preparation of cement milk.

Return to Contents</a>Installation of beacons Fastenings for beacons under plaster.Today, it is impossible to imagine leveling the plane of walls for subsequent plastering without beacon profiles. Having installed them, even an average craftsman can do a quality job. When using beacons, more trouble is associated not so much with stretching the mortar along the wall, but with their correct installation. This procedure does not require physical effort, but only patience and accuracy. Before installing the beacons, a plane is built. To do this, 2 cords are pulled vertically in the corners of the wall. Their verticality is checked with a plumb line. The cords are tied to self-tapping screws screwed into dowels driven into the walls. Profiles are attached to the surface with plaster along the cords. Horizontal threads are stretched between them, which will become a guide for the rest of the beacons. The distance between the profiles should be slightly less than the length of the rule for leveling the mortar. Return to the table of contents</a>How to prepare smooth walls Even if the wallsdo not require preliminary leveling and reinforcement, preparation for plastering is carried out on them too. Brickwork made of porous elements (like cinder block) will adhere to the solution better than other surfaces, but even it requires some preparatory procedures.

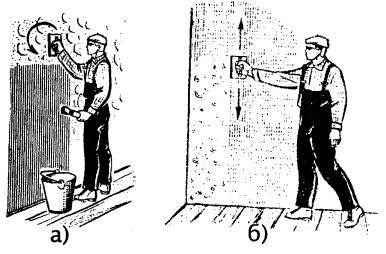

Fastenings for beacons under plaster.Today, it is impossible to imagine leveling the plane of walls for subsequent plastering without beacon profiles. Having installed them, even an average craftsman can do a quality job. When using beacons, more trouble is associated not so much with stretching the mortar along the wall, but with their correct installation. This procedure does not require physical effort, but only patience and accuracy. Before installing the beacons, a plane is built. To do this, 2 cords are pulled vertically in the corners of the wall. Their verticality is checked with a plumb line. The cords are tied to self-tapping screws screwed into dowels driven into the walls. Profiles are attached to the surface with plaster along the cords. Horizontal threads are stretched between them, which will become a guide for the rest of the beacons. The distance between the profiles should be slightly less than the length of the rule for leveling the mortar. Return to the table of contents</a>How to prepare smooth walls Even if the wallsdo not require preliminary leveling and reinforcement, preparation for plastering is carried out on them too. Brickwork made of porous elements (like cinder block) will adhere to the solution better than other surfaces, but even it requires some preparatory procedures. Scheme for grouting plaster:a - in a circle, b - at random. First of all, the seams are cut out (the mortar between the bricks is removed with a chisel to a depth of 1 cm). Then the dirt is removed and a primer is applied. It is more difficult to plaster concrete surfaces and walls made of smooth bricks or blocks. To prepare them for plastering, you need to make many notches directed in different directions. Recesses in the walls are made with a hammer drill, an axe, a chisel or a chisel. Short furrows are cut on the bricks, and on concrete the length of each notch should not be less than 5 cm, and the depth - less than 0.5 cm. Once again, it is worth mentioning the need to remove the paint layer from the surfaces, which is either cut out or heated with a building hair dryer and removed with a spatula. The worst contact with plaster is a plane covered with oil paint. And yet, sometimes it is not possible to completely remove it from the wall. In this case, the maximum number of notches are made on the painted area, and the surface itself is treated with concrete contact. Return to contents</a>

Scheme for grouting plaster:a - in a circle, b - at random. First of all, the seams are cut out (the mortar between the bricks is removed with a chisel to a depth of 1 cm). Then the dirt is removed and a primer is applied. It is more difficult to plaster concrete surfaces and walls made of smooth bricks or blocks. To prepare them for plastering, you need to make many notches directed in different directions. Recesses in the walls are made with a hammer drill, an axe, a chisel or a chisel. Short furrows are cut on the bricks, and on concrete the length of each notch should not be less than 5 cm, and the depth - less than 0.5 cm. Once again, it is worth mentioning the need to remove the paint layer from the surfaces, which is either cut out or heated with a building hair dryer and removed with a spatula. The worst contact with plaster is a plane covered with oil paint. And yet, sometimes it is not possible to completely remove it from the wall. In this case, the maximum number of notches are made on the painted area, and the surface itself is treated with concrete contact. Return to contents</a>

Preparation of wood and clay surfaces

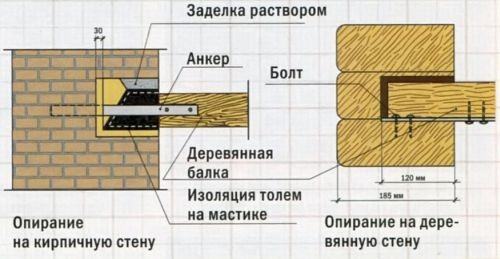

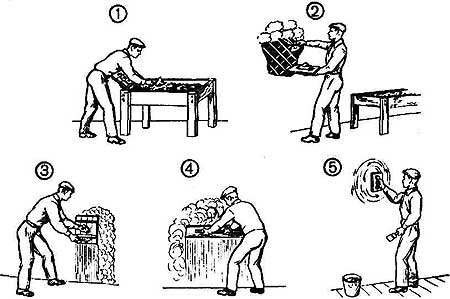

Plastering is carried out not only on concreteor brick walls. The solution is used to cover clay and wooden surfaces. Preparation of wooden walls for plastering is carried out using both reinforcing mesh and shingles. A 2-layer lathing is made from wooden slats, each 1-2 m long. The first layer is filled with forging shingles. For it, planks of at least 3 mm thickness are used. They are nailed to the wall with thin nails up to 4 cm long. The step of the slats is about 5 cm. The planks are located at an angle of 450. There is no need to drive the nails into the planks up to the head; after the next layer is filled, they are pulled out. Wall plastering scheme:1 – collecting the solution on the hawk, 2 – applying to the wall, 3 – leveling with the hawk, 4 – leveling with the float, 5 – rubbing the plaster. The upper (output) shingle consists of even planks 1.5-2 cm wide. It is fixed perpendicular to the elements of the previous layer. First, the slats are nailed along the edges. The nails are driven in at an angle. Their tips are directed towards the ends. This way, the proper tension of the slats is achieved. The remaining nails can be driven in through 2 straightening slats and perpendicular to the wall. Before nailing, the shingle should be wetted so that it does not split during installation. It is necessary to leave a gap between the ends of the slats so that they, changing in size with changes in humidity, do not cause cracks in the plaster. Clay surfaces are prepared in a similar way, but they must first be cleaned of whitewash or other coating. It should be noted that clay does not go well with sand-cement plaster, so the lathing must be firmly bonded to the base. Instead of a lath lattice, it is better to attach a metal mesh to the wall. To install it, you need to use nails 8-10 cm long. They are not driven in all the way: the remaining part is bent so that the nail better presses the reinforcement to the wall. Instead of a reinforcing mesh, you can use wire, which is pulled between the driven nails and wrapped around their heads. In this case, the fasteners are staggered with a step of 50 cm. Return to the table of contents</a>

Wall plastering scheme:1 – collecting the solution on the hawk, 2 – applying to the wall, 3 – leveling with the hawk, 4 – leveling with the float, 5 – rubbing the plaster. The upper (output) shingle consists of even planks 1.5-2 cm wide. It is fixed perpendicular to the elements of the previous layer. First, the slats are nailed along the edges. The nails are driven in at an angle. Their tips are directed towards the ends. This way, the proper tension of the slats is achieved. The remaining nails can be driven in through 2 straightening slats and perpendicular to the wall. Before nailing, the shingle should be wetted so that it does not split during installation. It is necessary to leave a gap between the ends of the slats so that they, changing in size with changes in humidity, do not cause cracks in the plaster. Clay surfaces are prepared in a similar way, but they must first be cleaned of whitewash or other coating. It should be noted that clay does not go well with sand-cement plaster, so the lathing must be firmly bonded to the base. Instead of a lath lattice, it is better to attach a metal mesh to the wall. To install it, you need to use nails 8-10 cm long. They are not driven in all the way: the remaining part is bent so that the nail better presses the reinforcement to the wall. Instead of a reinforcing mesh, you can use wire, which is pulled between the driven nails and wrapped around their heads. In this case, the fasteners are staggered with a step of 50 cm. Return to the table of contents</a>

How to prepare external corners

Special attention in preparation forPlastering should be done on the outer corners of the walls. These are the most problematic areas that need to be strengthened. They are covered with a profile or reinforcing grid. To ensure that the corners are even when finishing, before plastering, a 10 cm wide wooden plank should be nailed to the wall perpendicular to the surface being treated. The rule will rest on it when leveling the mortar, so the protruding part of the plank should be in the same plane as the beacon profiles. After plastering the wall, the plank is removed and attached to the treated surface. Now it serves as a guide for finishing the adjacent surface.