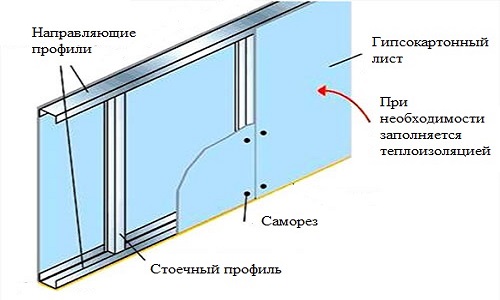

In the process of arranging living space, it is oftenthere is a need to supplement it with a new wall. The simplest option for an apartment in a multi-story building is to use plasterboard installed on a frame system based on steel profiles. The device involves the use of guides and self-tapping screws, which provide high-quality fastening. Scheme of the device of a wall from plasterboard.

Scheme of the device of a wall from plasterboard.

Preparation before the beginning of the formation of the frame

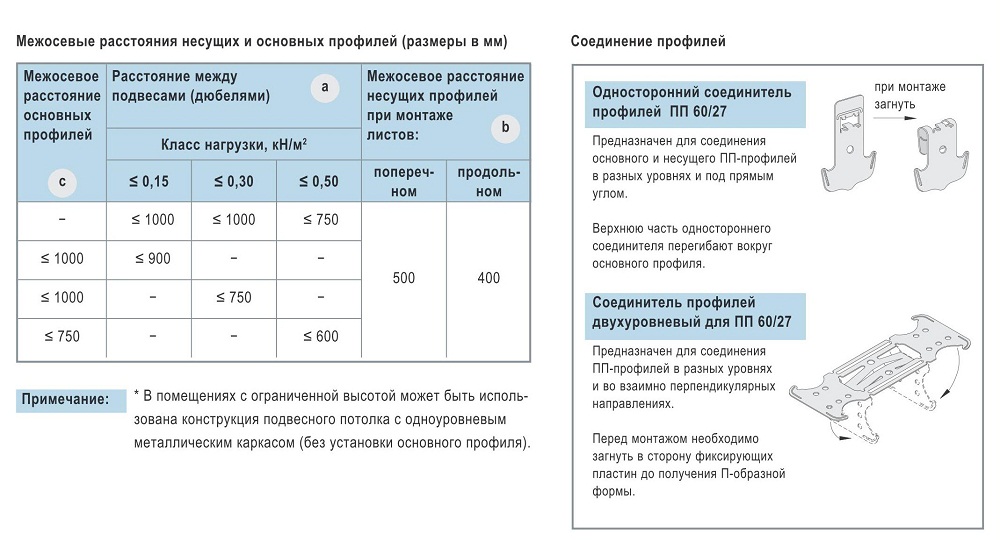

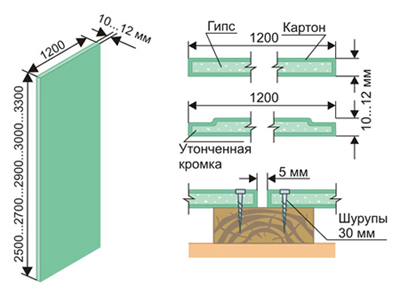

The device of a partition, the width of whichvaries from 50 to 100 mm, involves the use of CW and UW profiles exclusively, while the installation of walls with a more impressive thickness involves the use of CD and UD, while it is fixed on each side of two parallel guides. In order to fix the profile in the frame, a direct hanger and a universal connector should be used. The components must be mated with flea screws and self-tapping screws for metal, designed for fixing gypsum boards. When installing the frame to the main walls, plastic dowels with impact screws should be used. Scheme of the center distance of the bearing and mainprofiles for plasterboard. The principle of the device of walls involves the use of plasterboard, the thickness of which is 12.5 mm, you should choose the material that has an impressive chamfer on the sides. If the work is supposed to be carried out in the space of the kitchen or bathroom, it is necessary to purchase moisture-resistant canvases. They are distinguished by a green tint. To carry out work on the arrangement of walls, it is necessary to prepare:

Scheme of the center distance of the bearing and mainprofiles for plasterboard. The principle of the device of walls involves the use of plasterboard, the thickness of which is 12.5 mm, you should choose the material that has an impressive chamfer on the sides. If the work is supposed to be carried out in the space of the kitchen or bathroom, it is necessary to purchase moisture-resistant canvases. They are distinguished by a green tint. To carry out work on the arrangement of walls, it is necessary to prepare:

- dowels;

- self-tapping screws;

- drywall;

- profiles;

- cant;

- sealing tape;

- minivat;

- steel corner;

- roulette;

- level;

- rule;

- rope;

- plumb bob;

- fishing line;

- Screwdriver;

- perforator;

- scissors for work on metal;

- knife;

- grater for gypsum board.

Return to Contents</a>

Mounting of the frame of the wall

The process of installing plasterboard wallsrequires preliminary preparation. The floor should be covered with a screed, the walls - plastered. In the example, UW, CW profiles will be taken as a basis. On the floor surface, it is necessary to mark the future wall. The following thicknesses should be added to the mark for installing the profile: gypsum board, putty layer and finishing. The line drawn on the floor can be transferred to the ceiling and walls. For this, it is recommended to use a weight on a fishing line. Scheme of fastening of metal frame underplasterboard. All profiles are fixed using sealing tape. The UW guide profiles on the floor and ceiling surfaces should be fixed first. They are installed using dowels and impact screws, which must be removed by 0.5 m. They must also be installed along the edges. Support posts based on the CW profile should be mounted along the edges of the guides. In addition, the posts should be located in places where openings are supposed to be formed. It is preferable to initially fix the profiles on the lower guide. They should be facing the inner space of the opening with their front surface. The posts and guides are fastened together with flea screws. The support profiles along the perimeter of the openings should be reinforced with wooden blocks installed inside the profile, they are fixed with self-tapping screws. At the next stage of wall arrangement, you can start installing the CW-shaped support profiles along the length of the frame, they must be positioned vertically. The first element should be removed from the adjacent wall by 550 mm, all subsequent elements are removed by 600 mm, the measurement should be made from the central point of the elements. To mark the upper level of the door opening and horizontal edges of the windows, a UW-shaped guide profile should be used. Return to contents</a>

Scheme of fastening of metal frame underplasterboard. All profiles are fixed using sealing tape. The UW guide profiles on the floor and ceiling surfaces should be fixed first. They are installed using dowels and impact screws, which must be removed by 0.5 m. They must also be installed along the edges. Support posts based on the CW profile should be mounted along the edges of the guides. In addition, the posts should be located in places where openings are supposed to be formed. It is preferable to initially fix the profiles on the lower guide. They should be facing the inner space of the opening with their front surface. The posts and guides are fastened together with flea screws. The support profiles along the perimeter of the openings should be reinforced with wooden blocks installed inside the profile, they are fixed with self-tapping screws. At the next stage of wall arrangement, you can start installing the CW-shaped support profiles along the length of the frame, they must be positioned vertically. The first element should be removed from the adjacent wall by 550 mm, all subsequent elements are removed by 600 mm, the measurement should be made from the central point of the elements. To mark the upper level of the door opening and horizontal edges of the windows, a UW-shaped guide profile should be used. Return to contents</a>

Preparation of plasterboard sheets

Scheme of fastening plasterboard sheet to the frame.When fixing drywall in height, as a rule, one sheet is not enough, this involves adding small strips of material. The starting sheet, mounted close to the surface of the adjacent wall, should be freed from the chamfer located on the side. To do this, a strip 50 mm wide should be cut along the length of the sheet on one side. You can use a construction knife for this. Before this, the drywall sheet is located on a flat base. In the place where the cut should be made, you need to draw a line with a pencil, cutting the top layer of the material. Then the cladding should be shifted to the edge of the work surface and carefully broken. Now the drywall must be turned over to its original position, bending it. On the reverse side, the cardboard should not be completely cut, after which the sheet can be finally broken. At the stage of fastening the material, the walls should be formed with a gap, a bevel-chamfer on the edge of the sheet will help to arrange it. To do this, a cut of 22.5 ° must be made on the cut edge. To carry out this type of work, you can use a special plane designed for plasterboard. The sheet will need to be chamfered in those places where other sheets located above or below will be adjacent to it. Return to contents</a>

Scheme of fastening plasterboard sheet to the frame.When fixing drywall in height, as a rule, one sheet is not enough, this involves adding small strips of material. The starting sheet, mounted close to the surface of the adjacent wall, should be freed from the chamfer located on the side. To do this, a strip 50 mm wide should be cut along the length of the sheet on one side. You can use a construction knife for this. Before this, the drywall sheet is located on a flat base. In the place where the cut should be made, you need to draw a line with a pencil, cutting the top layer of the material. Then the cladding should be shifted to the edge of the work surface and carefully broken. Now the drywall must be turned over to its original position, bending it. On the reverse side, the cardboard should not be completely cut, after which the sheet can be finally broken. At the stage of fastening the material, the walls should be formed with a gap, a bevel-chamfer on the edge of the sheet will help to arrange it. To do this, a cut of 22.5 ° must be made on the cut edge. To carry out this type of work, you can use a special plane designed for plasterboard. The sheet will need to be chamfered in those places where other sheets located above or below will be adjacent to it. Return to contents</a>

Installation of drywall sheets

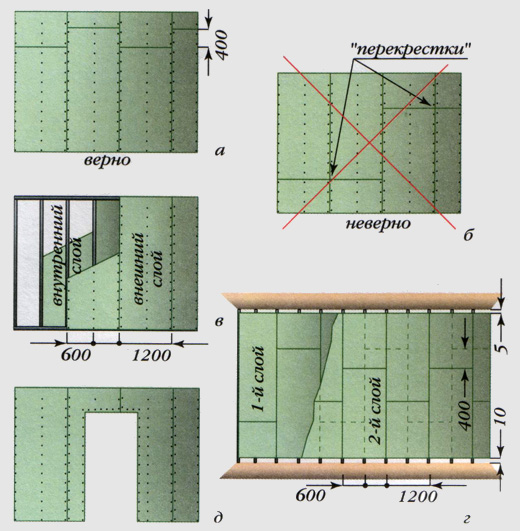

When forming at the stage of fixing the canvases toThe frame system should use 3.5x35 mm screws. First, you need to fix the edges of the canvas, then strengthen the sheet in the remaining parts. To do this, use the marking of the screw installation positions every 250 mm. The screws should be countersunk so that the heads are not visible above the surface. Scheme of correct joining of plasterboard sheets.When forming a plasterboard partition, the sheets must be fixed by removing the fasteners in increments of 10-15 mm from the floor surface. This is required to ensure the integrity of the system during operation. After the plasterboard is secured in the first row, the resulting distance to the base of the ceiling should be measured, this will allow the material to be cut correctly. Subsequent sheets should be mounted whole without chamfering and in a staggered pattern. That is, after the first row has been installed, the whole sheet should be mounted under the ceiling, while the trimmed element will be attached from below. One side of the wall is sheathed in this way. Before proceeding with sheathing the second side, communications should be laid. The wires should be mounted in a corrugated pipe. At this stage, if necessary, a sound insulator should be laid in the hollow space. For reasons of convenience, it is preferable to use material in a roll version, its width can be 600 or 1200 mm. In the case of the latter option, it must be cut lengthwise. The cotton wool should be laid between the rack profiles without creating gaps. There is no need to additionally fix the material. To increase reliability, it is permissible to install elements based on a wooden beam along the width of the partition. In any case, it is necessary to ensure good ventilation of the interior space by installing spacers. Now the plasterboard can be fixed to the second surface of the walls. Completion of this process indicates the need to fill the end surfaces. There is a distance of 100 mm between the sheets of plasterboard, which was formed by chamfers. Due to this circumstance, the surface of the walls must be leveled so that the finishing can be done without any particular difficulties. It is necessary to glue the mounting mesh serpyanka to the joints, leveling it with the general surface of the wall, applying a layer of starting putty to the wall. After that, it is time to work with the finishing putty, which will allow you to cope with the alignment of all the places where the fasteners are installed, which is especially true for the case when the surface is supposed to be painted or pasted over with paper wallpaper. Finally, the surface is treated with an abrasive material and a float, which will finally allow the putty to be leveled. After that, the wall can be considered ready for facing work with any material.

Scheme of correct joining of plasterboard sheets.When forming a plasterboard partition, the sheets must be fixed by removing the fasteners in increments of 10-15 mm from the floor surface. This is required to ensure the integrity of the system during operation. After the plasterboard is secured in the first row, the resulting distance to the base of the ceiling should be measured, this will allow the material to be cut correctly. Subsequent sheets should be mounted whole without chamfering and in a staggered pattern. That is, after the first row has been installed, the whole sheet should be mounted under the ceiling, while the trimmed element will be attached from below. One side of the wall is sheathed in this way. Before proceeding with sheathing the second side, communications should be laid. The wires should be mounted in a corrugated pipe. At this stage, if necessary, a sound insulator should be laid in the hollow space. For reasons of convenience, it is preferable to use material in a roll version, its width can be 600 or 1200 mm. In the case of the latter option, it must be cut lengthwise. The cotton wool should be laid between the rack profiles without creating gaps. There is no need to additionally fix the material. To increase reliability, it is permissible to install elements based on a wooden beam along the width of the partition. In any case, it is necessary to ensure good ventilation of the interior space by installing spacers. Now the plasterboard can be fixed to the second surface of the walls. Completion of this process indicates the need to fill the end surfaces. There is a distance of 100 mm between the sheets of plasterboard, which was formed by chamfers. Due to this circumstance, the surface of the walls must be leveled so that the finishing can be done without any particular difficulties. It is necessary to glue the mounting mesh serpyanka to the joints, leveling it with the general surface of the wall, applying a layer of starting putty to the wall. After that, it is time to work with the finishing putty, which will allow you to cope with the alignment of all the places where the fasteners are installed, which is especially true for the case when the surface is supposed to be painted or pasted over with paper wallpaper. Finally, the surface is treated with an abrasive material and a float, which will finally allow the putty to be leveled. After that, the wall can be considered ready for facing work with any material.