Today, during repairs, specialists prefermake walls from plasterboard, because this material is the most popular. In addition, it is environmentally friendly, lightweight, and its installation is available even to a beginner. It is worth noting that such a wall will have a smooth and even surface. Sound and heat insulation material can be laid between the sheets of plasterboard and the structure, which will significantly improve the quality of the walls. Moreover, you can do everything yourself. Plasterboard walls are fairly easy to install, they are smooth and environmentally friendly.

Plasterboard walls are fairly easy to install, they are smooth and environmentally friendly.

Stages of work: the sequence of actions

Before you start working, you need to prepare the necessary tools and materials:

- roulette and long ruler;

- gypsum board and profiles (if necessary);

- a stationery knife or a special hacksaw;

- self-tapping screws and screwdrivers;

- rails;

- building level;

- Upholstery cord;

- perforator;

- scissors for metal.

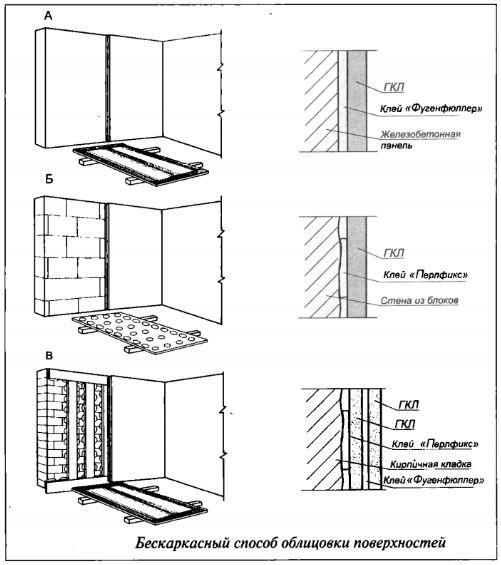

Since plasterboard walls can be made in three waysmethods, you may need various tools. For example, if the material is laid without a structure, you will need glue for plasterboard on the walls. If the frame is made of wood, you will need to buy nails and a wood saw. If metal profiles are installed, you will also have to buy hangers. Tool for working with plasterboard.First of all, the material is calculated: the height of the walls, their width and length are measured. The rough base must be prepared. To do this, all the cracks, crevices and dents are sealed. The surface must be primed to protect the home from fungi and mold. After this, all the corners must be brought out, that is, the horizontal level must be measured with a building level. In this case, the lacing must be pulled onto small nails, thanks to which all the corners and walls will be perfectly even. You need to know that the step between the intermediate slats should be 50-60 cm. This means that a vertical slat is screwed in after each step. With a metal frame, a profile must first be set up, guiding along the entire perimeter, and then the remaining components are attached to it. Return to contents</a>Installation of plasterboard on walls without a frame and onwooden structure This material is intended for fastening to the wall without using any structure. Of course, in this case it is impossible to lay insulating materials, but the installation will be very simple. To do this, check the working surface for evenness, because with this method of installation the walls should be as even as possible. Special glue is diluted in small portions, since it has the property of hardening quickly. It must be applied to both the wall and the working material, after which gluing is done with light tapping. In this case, it is necessary to constantly use a building level so that the evenness is accurate.

Tool for working with plasterboard.First of all, the material is calculated: the height of the walls, their width and length are measured. The rough base must be prepared. To do this, all the cracks, crevices and dents are sealed. The surface must be primed to protect the home from fungi and mold. After this, all the corners must be brought out, that is, the horizontal level must be measured with a building level. In this case, the lacing must be pulled onto small nails, thanks to which all the corners and walls will be perfectly even. You need to know that the step between the intermediate slats should be 50-60 cm. This means that a vertical slat is screwed in after each step. With a metal frame, a profile must first be set up, guiding along the entire perimeter, and then the remaining components are attached to it. Return to contents</a>Installation of plasterboard on walls without a frame and onwooden structure This material is intended for fastening to the wall without using any structure. Of course, in this case it is impossible to lay insulating materials, but the installation will be very simple. To do this, check the working surface for evenness, because with this method of installation the walls should be as even as possible. Special glue is diluted in small portions, since it has the property of hardening quickly. It must be applied to both the wall and the working material, after which gluing is done with light tapping. In this case, it is necessary to constantly use a building level so that the evenness is accurate. Scheme of frameless method of wall finishingplasterboard. To make a wooden frame yourself, you need to stock up on slats that are at least 5 cm wide. First, holes are drilled in the prepared wall for the pistons or wooden plugs, the distance should correspond to the width of the plasterboard sheet. The vertical elements of the frame are installed in these places, then they are checked with a building level and firmly strengthened. Return to the table of contents</a>Installation of metal profiles forplasterboard on the walls The frame made of profiles is the most durable and high-quality, therefore, despite the complexity of installation, unlike the previous methods, it is used most often. First of all, the corners are beaten off using a building level, and an upholstery cord is pulled along them. These are the corners located on the ceiling and floor, opposite each other. Now, along this lacing, guide profiles are mounted on both sides using self-tapping screws. Their heads must be sunk a maximum of 1.5 mm inward. This must be done on each side of the wall. Then you need to install hangers at a distance of 50-60 cm between them. After strengthening them, you need to bend the ends, maintaining a right angle. The remaining profiles are fixed to these hangers, while the heads of the screws must completely enter the profile. After this, the lacing is cut off, the nails are removed, the excess remains of the hangers are removed with a grinder or metal scissors.

Scheme of frameless method of wall finishingplasterboard. To make a wooden frame yourself, you need to stock up on slats that are at least 5 cm wide. First, holes are drilled in the prepared wall for the pistons or wooden plugs, the distance should correspond to the width of the plasterboard sheet. The vertical elements of the frame are installed in these places, then they are checked with a building level and firmly strengthened. Return to the table of contents</a>Installation of metal profiles forplasterboard on the walls The frame made of profiles is the most durable and high-quality, therefore, despite the complexity of installation, unlike the previous methods, it is used most often. First of all, the corners are beaten off using a building level, and an upholstery cord is pulled along them. These are the corners located on the ceiling and floor, opposite each other. Now, along this lacing, guide profiles are mounted on both sides using self-tapping screws. Their heads must be sunk a maximum of 1.5 mm inward. This must be done on each side of the wall. Then you need to install hangers at a distance of 50-60 cm between them. After strengthening them, you need to bend the ends, maintaining a right angle. The remaining profiles are fixed to these hangers, while the heads of the screws must completely enter the profile. After this, the lacing is cut off, the nails are removed, the excess remains of the hangers are removed with a grinder or metal scissors. Scheme of metal frame for wall fromplasterboard. If the height of the ceilings exceeds the length of the profile, then it is joined using special crabs. Remember that all profiles must be secured starting from the bottom. In places where there is a doorway or window, it is necessary to make support posts. The profiles here are located facing the inside of the opening. These posts, made of CW profile, are secured to the guide elements using flea screws. At this stage, the installation of the metal frame from the profiles is considered complete, then you can install the plasterboard. Return to the table of contents</a>Installation of plasterboard sheets is performedThis action is carried out using screws selected depending on the material from which the frame was erected. If it is a metal structure, then those screws are used that are intended for metal, that is, in this case the thread will be fine. If the structure is wooden, then the thread pitch should be much larger. Keep in mind that for wood it is quite acceptable to use screws with fine threads, but not for metal. Remember that in order for the plasterboard walls to be perfectly flat, the screw heads must be sunk into the plasterboard. If this cannot be done, you need to unscrew it and make a larger recess, and then screw the screw back in. These places must be filled with putty. Screw in very carefully, because plasterboard is a fragile material and can crumble at any moment. The first sheet of plasterboard on the wall is laid close to the edge, although some craftsmen, on the contrary, start work from the corner section, since it is easier to install the missing piece near the doorway.

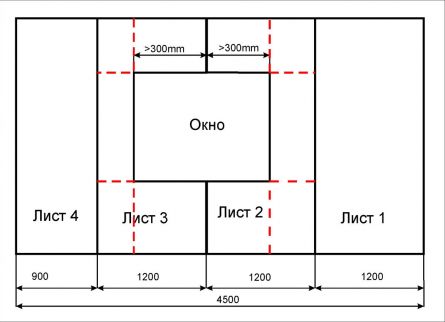

Scheme of metal frame for wall fromplasterboard. If the height of the ceilings exceeds the length of the profile, then it is joined using special crabs. Remember that all profiles must be secured starting from the bottom. In places where there is a doorway or window, it is necessary to make support posts. The profiles here are located facing the inside of the opening. These posts, made of CW profile, are secured to the guide elements using flea screws. At this stage, the installation of the metal frame from the profiles is considered complete, then you can install the plasterboard. Return to the table of contents</a>Installation of plasterboard sheets is performedThis action is carried out using screws selected depending on the material from which the frame was erected. If it is a metal structure, then those screws are used that are intended for metal, that is, in this case the thread will be fine. If the structure is wooden, then the thread pitch should be much larger. Keep in mind that for wood it is quite acceptable to use screws with fine threads, but not for metal. Remember that in order for the plasterboard walls to be perfectly flat, the screw heads must be sunk into the plasterboard. If this cannot be done, you need to unscrew it and make a larger recess, and then screw the screw back in. These places must be filled with putty. Screw in very carefully, because plasterboard is a fragile material and can crumble at any moment. The first sheet of plasterboard on the wall is laid close to the edge, although some craftsmen, on the contrary, start work from the corner section, since it is easier to install the missing piece near the doorway. Example diagram of marking sheets of plasterboard onwalls. But this is done according to individual preferences. Do not forget that you need to conduct electrical wires, which can be placed directly under the plasterboard, that is, in the frame. This will greatly simplify the work. To do this, a hole of the required diameter is made in the rack profile, where the wires are carried out. Make sure that the edges of the holes are not sharp, otherwise they can subsequently damage the electrical wire. To do this, sharp edges can be bent to one side. Of course, all wiring must be installed in a corrugated pipe. To lay the insulating material, you can use mineral wool, this is the easiest way to lay it. It is best to buy mineral wool in rolls, which is laid between the rack profile strips. Try to do this very tightly. The joints are putty and, if desired, laid before this with a mounting mesh. The rest of the surface must be putty first with a starting putty, then with a finishing putty, and then cleaned with fine-grained sandpaper. Next, decorative finishing is done (at your discretion). This can be wallpapering, painting or decorative puttying. Return to contents</a>Recommendations for installing plasterboard on wallsEvery person who installs walls made of such material as plasterboard needs to know how to cut it. One careless movement, and it will cut in the wrong place. Many specialists use a special hacksaw for these purposes, but beginners are better off cutting the material with an ordinary stationery knife, which should be as sharp as possible. In order to carefully cut off the required amount of material, you need to measure the distance with a ruler and draw a straight line. After that, the tip of the stationery knife makes a cut exactly along the line. There is no need to rush here, otherwise the knife may slide to the side. Next, place the support under the plasterboard sheet so that the outlined edge hangs down, then carefully break it off. After breaking, you need to cut off the paper part of the sheet with the same knife. Experts recommend choosing self-tapping screws for fastening to the frame made of metal profiles, having dimensions of 3.5x35 mm. Plasterboard can be used to cover not only walls, but also the ceiling. It can be done in several levels. Think in advance how and what you will sheathe the ceiling part with. If the same material, then all work must be done simultaneously. That is, first install the frame on the walls and ceiling, and then sheathe everything. After the surface is primed, leave it to dry and only then apply the putty. If the sheets are mounted quite evenly, then there is no need to apply a large layer of putty solution. You can make it more liquid and apply it to the surface with a roller. Now you have a unique opportunity to lay drywall on the wall yourself.

Example diagram of marking sheets of plasterboard onwalls. But this is done according to individual preferences. Do not forget that you need to conduct electrical wires, which can be placed directly under the plasterboard, that is, in the frame. This will greatly simplify the work. To do this, a hole of the required diameter is made in the rack profile, where the wires are carried out. Make sure that the edges of the holes are not sharp, otherwise they can subsequently damage the electrical wire. To do this, sharp edges can be bent to one side. Of course, all wiring must be installed in a corrugated pipe. To lay the insulating material, you can use mineral wool, this is the easiest way to lay it. It is best to buy mineral wool in rolls, which is laid between the rack profile strips. Try to do this very tightly. The joints are putty and, if desired, laid before this with a mounting mesh. The rest of the surface must be putty first with a starting putty, then with a finishing putty, and then cleaned with fine-grained sandpaper. Next, decorative finishing is done (at your discretion). This can be wallpapering, painting or decorative puttying. Return to contents</a>Recommendations for installing plasterboard on wallsEvery person who installs walls made of such material as plasterboard needs to know how to cut it. One careless movement, and it will cut in the wrong place. Many specialists use a special hacksaw for these purposes, but beginners are better off cutting the material with an ordinary stationery knife, which should be as sharp as possible. In order to carefully cut off the required amount of material, you need to measure the distance with a ruler and draw a straight line. After that, the tip of the stationery knife makes a cut exactly along the line. There is no need to rush here, otherwise the knife may slide to the side. Next, place the support under the plasterboard sheet so that the outlined edge hangs down, then carefully break it off. After breaking, you need to cut off the paper part of the sheet with the same knife. Experts recommend choosing self-tapping screws for fastening to the frame made of metal profiles, having dimensions of 3.5x35 mm. Plasterboard can be used to cover not only walls, but also the ceiling. It can be done in several levels. Think in advance how and what you will sheathe the ceiling part with. If the same material, then all work must be done simultaneously. That is, first install the frame on the walls and ceiling, and then sheathe everything. After the surface is primed, leave it to dry and only then apply the putty. If the sheets are mounted quite evenly, then there is no need to apply a large layer of putty solution. You can make it more liquid and apply it to the surface with a roller. Now you have a unique opportunity to lay drywall on the wall yourself.