The installation of a heated floor under laminate flooring requires the use of a specific technology. Classification of heated floors. Experts distinguish 3 types of heated floors under laminate:

Classification of heated floors. Experts distinguish 3 types of heated floors under laminate:

- water circuit;

- electrical circuit;

- infra-red film floor.

Water circuit - step by step instructions

Water heated floors allow you to save onheating in the cold season due to the ability to regulate and reduce the water temperature. This is due to the fact that the heat output area is larger than from a conventional battery. Installation of a heated floor under a laminate on a concrete base involves the use of an electric analogue. A similar design is installed in cottages, private houses and apartments in which the floors are not arranged on a floor slab, but on logs. The device of the water circuit is made using the following materials:

- unedged boards, which if necessary lagged before filling the space with a heater;

- fiberglass or mineral wool, the required amount is calculated by multiplying the floor area by 0.1 m, the layer of insulation between the lags should reach 10 cm;

- metal-plastic pipe without a seam with a diameter of 16 mm.

Water heated floor scheme.The space between the joists is filled with a 100 mm layer of insulation, and from below they are hemmed with a thin unedged board of 18-22 mm. The layer of heat insulator can be increased to 150 mm. A rough flooring of boards is prepared in advance. Grooves can be located in the center of the boards or on the edges. In the second case, there will be fewer cuts. Experts recommend using boards 40-50 mm long and up to 100-150 mm wide. The length of each board should be a multiple of the joist pitch. The location of the grooves on all boards should be the same, since the pipe is laid in them. Violation of the pitch of the turns can contribute to uneven heating of the surface of the laminate floor. Then the boards are laid on the joists and fastened with self-tapping screws. An arc-shaped section is sawn in a checkerboard pattern under the bends of the metal-plastic pipe, connecting the grooves so that the pipe passes over the entire floor area without joints and transitions. The structure must be airtight. A straight cut of similar dimensions must be made on the side of the short wall (to ensure the installation of the return pipe). The foil must be cut into strips 20-25 cm wide. The pieces of foil are rolled out along the grooves. The pipe is placed on top of them, which is wrapped in foil on all sides. To fix the foil, clamping strips and a construction stapler are used. Tees with ball valves are cut into the main pipe. The ends of the water circuit pipes will be connected to them. Using the valves, it will be possible to regulate the temperature and heating speed of the laminate. Foamed polyethylene 2-3 mm thick is rolled out on top of the laid pipe. The laminate boards are mounted. In terms of reliability and durability, such a floor structure is not inferior to analogues made of OSB, plywood or solid plank flooring. Return to contents</a>

Water heated floor scheme.The space between the joists is filled with a 100 mm layer of insulation, and from below they are hemmed with a thin unedged board of 18-22 mm. The layer of heat insulator can be increased to 150 mm. A rough flooring of boards is prepared in advance. Grooves can be located in the center of the boards or on the edges. In the second case, there will be fewer cuts. Experts recommend using boards 40-50 mm long and up to 100-150 mm wide. The length of each board should be a multiple of the joist pitch. The location of the grooves on all boards should be the same, since the pipe is laid in them. Violation of the pitch of the turns can contribute to uneven heating of the surface of the laminate floor. Then the boards are laid on the joists and fastened with self-tapping screws. An arc-shaped section is sawn in a checkerboard pattern under the bends of the metal-plastic pipe, connecting the grooves so that the pipe passes over the entire floor area without joints and transitions. The structure must be airtight. A straight cut of similar dimensions must be made on the side of the short wall (to ensure the installation of the return pipe). The foil must be cut into strips 20-25 cm wide. The pieces of foil are rolled out along the grooves. The pipe is placed on top of them, which is wrapped in foil on all sides. To fix the foil, clamping strips and a construction stapler are used. Tees with ball valves are cut into the main pipe. The ends of the water circuit pipes will be connected to them. Using the valves, it will be possible to regulate the temperature and heating speed of the laminate. Foamed polyethylene 2-3 mm thick is rolled out on top of the laid pipe. The laminate boards are mounted. In terms of reliability and durability, such a floor structure is not inferior to analogues made of OSB, plywood or solid plank flooring. Return to contents</a>

Electrical circuit

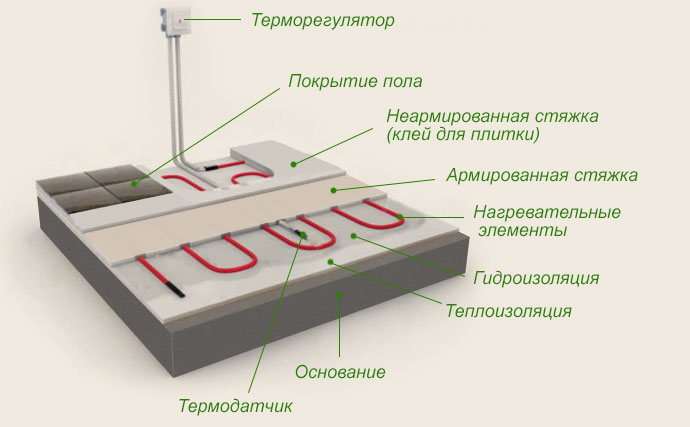

Electric underfloor heating system diagram.The design of a heated floor with an electric circuit is used for additional, local heating of the room. When choosing such a design, the power indicator is taken into account. For the kitchen and living room, this indicator should be within 150 W, and 220 W can be a power source for heating the balcony and rooms with large heat losses. The operation of an electric heated floor occurs due to the heating of the cable, which is powered by the network. Experts include the following as advantages of an electric heated floor:

Electric underfloor heating system diagram.The design of a heated floor with an electric circuit is used for additional, local heating of the room. When choosing such a design, the power indicator is taken into account. For the kitchen and living room, this indicator should be within 150 W, and 220 W can be a power source for heating the balcony and rooms with large heat losses. The operation of an electric heated floor occurs due to the heating of the cable, which is powered by the network. Experts include the following as advantages of an electric heated floor:

- Simplicity of installation, allowing to carry out work independently;

- laying on the finished screed.

A similar design is used foradditional heating due to high energy costs. It is necessary to decide on the arrangement of furniture in advance. It cannot be placed above the electrical wiring. Otherwise, there is a risk of local overheating of the cable and its burnout. Return to the table of contents</a>

Infrared film construction

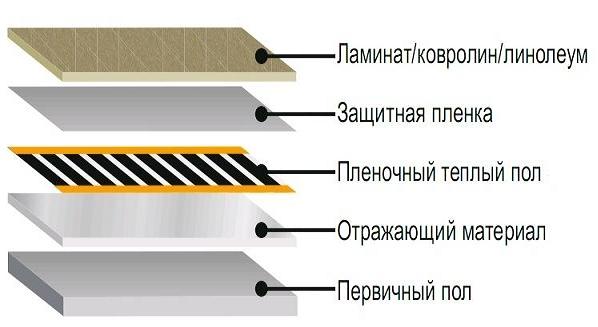

Infrared film promotes uniformheating of the area. The laminate will not deform or crack due to the heating elements of the film, located at intervals of 5 mm. The advantages of this system include: Construction of film heated floor.

Construction of film heated floor.

- rapid warm-up;

- economical power consumption;

- Due to mechanical damage, an exceptionally damaged strip (parallel connection of heating elements) can fail;

- the film is not subject to damage and corrosion;

- the installation of such a structure takes no more than 1-2 hours;

- It is not necessary to make a screed or use adhesives;

- lack of special skills, it is enough to follow the instructions;

- used after laying;

- in a room with similar heating, the microclimate is most favorable for humans;

- The film does not release toxic substances, and its thickness does not affect the useful height in the room;

- service life is not less than 50 years;

- does not require the care and use of additional equipment;

- regulation of the heating mode allows you to save finances.

The cost of infrared film heated floors is an order of magnitude higher than the cost of water and electric circuit designs, but it pays for itself in the first 2-3 years of use.</ ul>