Arrangement of a warm floor is no longer considered somethingawesome. Today it is not even necessary to apply for such a request to specialists. It is possible to equip the heated floor with your own hands, guided by detailed instructions.  A warm floor is a system of room heating,which provides for heating the air from the bottom. First of all, it is necessary to find out what the principle of the electric and water device of the floor with heating is. Knowing this will significantly minimize the financial costs of repair and eliminate some mistakes when laying the system of the warm floor.

A warm floor is a system of room heating,which provides for heating the air from the bottom. First of all, it is necessary to find out what the principle of the electric and water device of the floor with heating is. Knowing this will significantly minimize the financial costs of repair and eliminate some mistakes when laying the system of the warm floor.

Some of the history of floor heating systems

An ancient view of the warm floor. Heat largely determines the comfort and coziness of the atmosphere in the house. Low temperature conditions of life not only cause discomfort to a person, but also are dangerous to health. The development of floor heating systems has its roots in a centuries-old history. For example, even in ancient Rome, there was a similar to the work of the floor heating principle of heating the floor in a bath. Through special channels under the floor covering, smoke from the furnace passed through, heating the room. In addition, the stones retained heat for a long time, which provided an opportunity for economical consumption of combustible fuel. When there was steam (water) heating, it quickly became a common way of heating the floor. A warm floor, heated by water, is quite popular today. Back to contents</a>

An ancient view of the warm floor. Heat largely determines the comfort and coziness of the atmosphere in the house. Low temperature conditions of life not only cause discomfort to a person, but also are dangerous to health. The development of floor heating systems has its roots in a centuries-old history. For example, even in ancient Rome, there was a similar to the work of the floor heating principle of heating the floor in a bath. Through special channels under the floor covering, smoke from the furnace passed through, heating the room. In addition, the stones retained heat for a long time, which provided an opportunity for economical consumption of combustible fuel. When there was steam (water) heating, it quickly became a common way of heating the floor. A warm floor, heated by water, is quite popular today. Back to contents</a>

Advantages of using floor heating systems

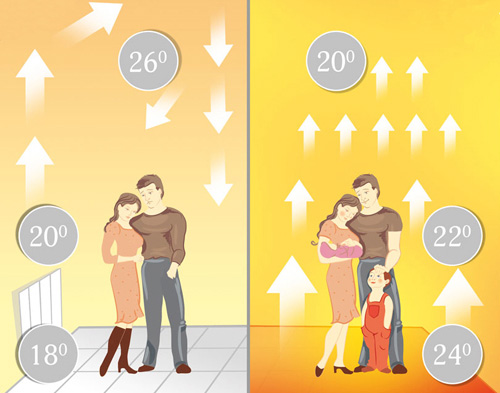

Advantage of the warm floor in comparison withradiators is that the heating of the house occurs evenly. In the past 40 years, electric heated floor is widely used. And it has a lot of reasons: from simple installation and maintenance to durability and a relatively low cost of electricity. In conditions of severe climate (Scandinavia, the Far North of Russia, etc.), the electric warm floor becomes simply irreplaceable for the heating of dwellings. Now no less popular are combined heating systems: a warm floor plus standard heating. By combining it is possible to reduce energy costs during the heating season. Let's consider, in what the basic difference of heating "a warm floor" consists from classical water heating consists. Naturally, in comfort. Recall the principle of the operation of conventional heating: the radiator is located on one of the walls and in most cases under the window, since it is here that the maximum heat loss occurs. Heated air is directed upward, displacing cold air masses there. The most comfortable temperature is 1.5 to 2 meters from the radiator. The heating of room air in the classical version of heating is not the same. The principle of the "warm floor" system is somewhat different from it. The heated area in the room is several times larger than the area heated by the heating radiator, since the heating element is laid under the entire floor surface. No other type of heating will give the same degree of comfort for the feet as the warm floor. Despite this, there are some disadvantages here. They are explained by the fact that the temperature range in which a person feels cozy is not very high: from + 23 ° C to + 28 ° C.

Advantage of the warm floor in comparison withradiators is that the heating of the house occurs evenly. In the past 40 years, electric heated floor is widely used. And it has a lot of reasons: from simple installation and maintenance to durability and a relatively low cost of electricity. In conditions of severe climate (Scandinavia, the Far North of Russia, etc.), the electric warm floor becomes simply irreplaceable for the heating of dwellings. Now no less popular are combined heating systems: a warm floor plus standard heating. By combining it is possible to reduce energy costs during the heating season. Let's consider, in what the basic difference of heating "a warm floor" consists from classical water heating consists. Naturally, in comfort. Recall the principle of the operation of conventional heating: the radiator is located on one of the walls and in most cases under the window, since it is here that the maximum heat loss occurs. Heated air is directed upward, displacing cold air masses there. The most comfortable temperature is 1.5 to 2 meters from the radiator. The heating of room air in the classical version of heating is not the same. The principle of the "warm floor" system is somewhat different from it. The heated area in the room is several times larger than the area heated by the heating radiator, since the heating element is laid under the entire floor surface. No other type of heating will give the same degree of comfort for the feet as the warm floor. Despite this, there are some disadvantages here. They are explained by the fact that the temperature range in which a person feels cozy is not very high: from + 23 ° C to + 28 ° C.  Pros of the warm floor. The comfortable zone in the room is somewhat displaced and becomes located not at some distance from the heating appliance, but at a certain height along the perimeter of the room, depending on the layout of the heating cable. The area of comfortable temperature is located at the bottom of the room, reaching a height of not more than 1 meter from the floor surface. At the top of the room are the cooler air layers. However, human physiology allows us not to consider such distribution of air as uncomfortable. Moreover, the floor provides the opportunity to easily change the temperature level in a heated room. To do this, just rotate the handle once or set the command in the Smart Home system. Note that this is peculiar only for electric heating system. In a situation where a heated floor, made by own hands, is represented by a water or combined system, this possibility becomes simply inaccessible. Still we will notice, that on functioning of system of heating of a floor furniture in a room and a carpet covering influences. This is due to the fact that each type of material is endowed with its own thermal conductivity, which is measured in W / m * K. This value becomes especially important when choosing a heat insulator and a floor covering itself, which will have to be walked barefoot (parquet board, linoleum, laminate, tile, etc.). Back to contents</a>

Pros of the warm floor. The comfortable zone in the room is somewhat displaced and becomes located not at some distance from the heating appliance, but at a certain height along the perimeter of the room, depending on the layout of the heating cable. The area of comfortable temperature is located at the bottom of the room, reaching a height of not more than 1 meter from the floor surface. At the top of the room are the cooler air layers. However, human physiology allows us not to consider such distribution of air as uncomfortable. Moreover, the floor provides the opportunity to easily change the temperature level in a heated room. To do this, just rotate the handle once or set the command in the Smart Home system. Note that this is peculiar only for electric heating system. In a situation where a heated floor, made by own hands, is represented by a water or combined system, this possibility becomes simply inaccessible. Still we will notice, that on functioning of system of heating of a floor furniture in a room and a carpet covering influences. This is due to the fact that each type of material is endowed with its own thermal conductivity, which is measured in W / m * K. This value becomes especially important when choosing a heat insulator and a floor covering itself, which will have to be walked barefoot (parquet board, linoleum, laminate, tile, etc.). Back to contents</a>

Arrangement of a floor heating system

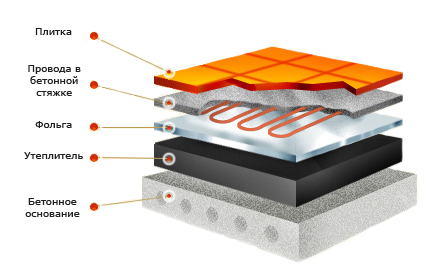

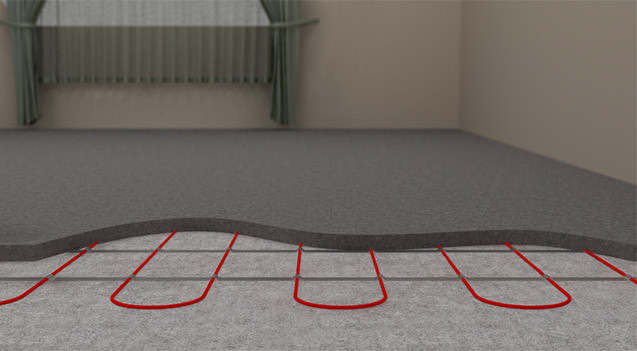

When installing a warm floor, a specialheating cable. Many are wondering how. In fact, the structure of such a system is very simple. Both water and electric floors are laid on a special heat-insulating material. After that, the cement screed is poured, on top of which the topcoat is laid. The heat carrier is water or a special electrical cable. We will tell you about the installation of the latter in more detail. The appearance of the underfloor heating system cable is very similar to the antenna cable. The first differs from the second only in its purpose: it is not intended to send a signal at a distance, but converts the energy of electricity into heat. An important criterion that characterizes the underfloor heating system is specific heat generation. For various manufacturers, this parameter varies in the range of 15-25 W / m. Please note that the thickness of the insulation covering the heating element allows it to withstand temperatures above 100 ° C. This is very important, since the cable is often hidden in a cement screed. The cable must give off heat without damaging the insulation layer.

When installing a warm floor, a specialheating cable. Many are wondering how. In fact, the structure of such a system is very simple. Both water and electric floors are laid on a special heat-insulating material. After that, the cement screed is poured, on top of which the topcoat is laid. The heat carrier is water or a special electrical cable. We will tell you about the installation of the latter in more detail. The appearance of the underfloor heating system cable is very similar to the antenna cable. The first differs from the second only in its purpose: it is not intended to send a signal at a distance, but converts the energy of electricity into heat. An important criterion that characterizes the underfloor heating system is specific heat generation. For various manufacturers, this parameter varies in the range of 15-25 W / m. Please note that the thickness of the insulation covering the heating element allows it to withstand temperatures above 100 ° C. This is very important, since the cable is often hidden in a cement screed. The cable must give off heat without damaging the insulation layer.  Construction of heating cable. If the cable overheats, the insulation layer breaks, then a short circuit will occur. Repairing the heated floor is quite troublesome and expensive, since it is not possible to accurately locate the defect of the cable. Therefore, do not buy a cable that has too high specific heat. When laying the cable, the recommended distance between the threads should be maintained. This fact can also cause overheating and subsequent short circuit of the heating cable. Such breakdowns are not possible with the use of a floor heating system. However, the latter also have their own difficulties. For example, cracking of pipes or fittings with subsequent leakage of coolant. Such an accident would not be so dangerous if it happened in your own home. Since it is only a matter of damage to your property. But when such a trouble happens in a multi-storey residential building with several apartments, then one of the possible consequences is compensation to the neighbors of the material damage caused as a result of flooding their apartments. A thorough waterproofing can reduce the unpleasant consequences in an accident situation. But when the water floor system is connected to centralized heating with high water pressure, waterproofing does not help. Back to contents</a>

Construction of heating cable. If the cable overheats, the insulation layer breaks, then a short circuit will occur. Repairing the heated floor is quite troublesome and expensive, since it is not possible to accurately locate the defect of the cable. Therefore, do not buy a cable that has too high specific heat. When laying the cable, the recommended distance between the threads should be maintained. This fact can also cause overheating and subsequent short circuit of the heating cable. Such breakdowns are not possible with the use of a floor heating system. However, the latter also have their own difficulties. For example, cracking of pipes or fittings with subsequent leakage of coolant. Such an accident would not be so dangerous if it happened in your own home. Since it is only a matter of damage to your property. But when such a trouble happens in a multi-storey residential building with several apartments, then one of the possible consequences is compensation to the neighbors of the material damage caused as a result of flooding their apartments. A thorough waterproofing can reduce the unpleasant consequences in an accident situation. But when the water floor system is connected to centralized heating with high water pressure, waterproofing does not help. Back to contents</a>

Installation and features of the installation of electric underfloor heating

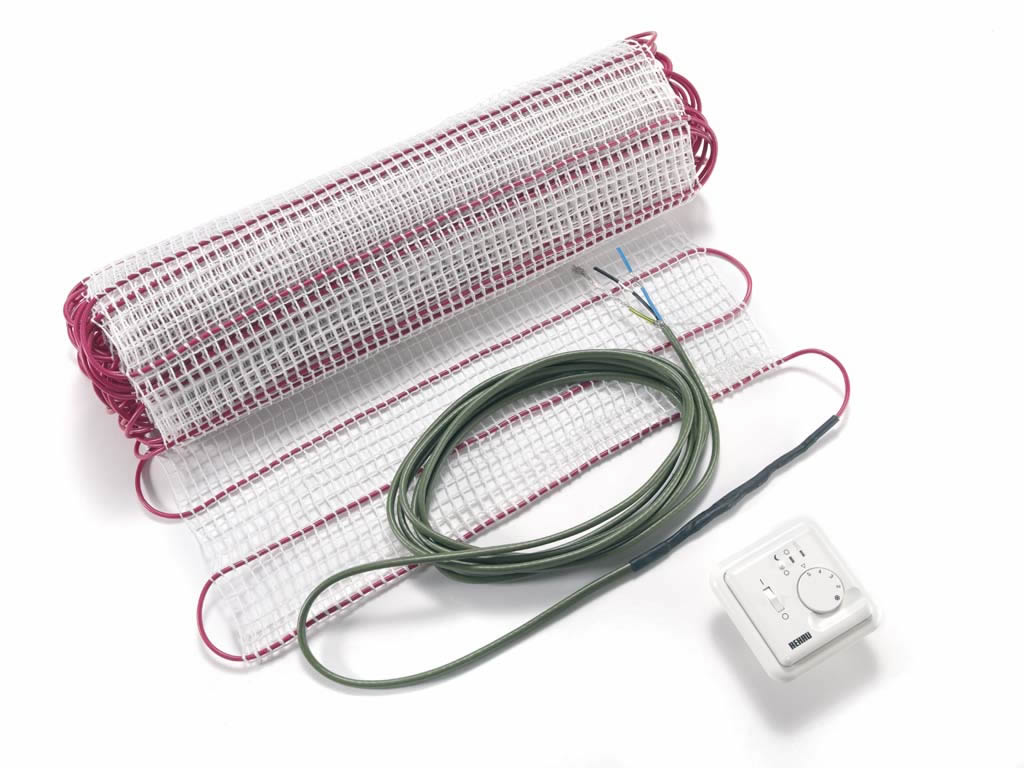

Scheme of electric underfloor heating. In order to equip the heated floor with your own hands, you need to know some features and the correct sequence of actions. First of all, it is necessary to determine the purpose, that is, for the sake of which the warm floor is installed: for additional heating of the home or as a full-fledged heating (for example, on a heated balcony). We will describe the procedure for installing a warm floor system as an additional element of heating the apartment. Often, this kind of system is installed in the kitchen or in the bathroom, since it is there that it is possible to lay the heating elements under the tile. This is considered the best method for installing a warm floor. For the additional system will be enough and 100-120 watts per square meter of area, while that will certainly employ a super heat insulator. For a kitchen area of 10 m² it will take about 45-50 meters of cable. The length of the last element can be clarified by the seller, since he knows the power of the heating element. He also should find out and the minimum possible gap between the heating cable strands-the gap will help to avoid local overheating of the cable. If you plan to perform finishing works in a room where there will be a warm floor, then remember that the cable should be laid before gluing the wallpaper. Before laying the heating element, the space is released from the furnishings, remove the previous floor covering and thoroughly prepare the floor surface (level, remove the formed garbage, as necessary, cement the thin screed).

Scheme of electric underfloor heating. In order to equip the heated floor with your own hands, you need to know some features and the correct sequence of actions. First of all, it is necessary to determine the purpose, that is, for the sake of which the warm floor is installed: for additional heating of the home or as a full-fledged heating (for example, on a heated balcony). We will describe the procedure for installing a warm floor system as an additional element of heating the apartment. Often, this kind of system is installed in the kitchen or in the bathroom, since it is there that it is possible to lay the heating elements under the tile. This is considered the best method for installing a warm floor. For the additional system will be enough and 100-120 watts per square meter of area, while that will certainly employ a super heat insulator. For a kitchen area of 10 m² it will take about 45-50 meters of cable. The length of the last element can be clarified by the seller, since he knows the power of the heating element. He also should find out and the minimum possible gap between the heating cable strands-the gap will help to avoid local overheating of the cable. If you plan to perform finishing works in a room where there will be a warm floor, then remember that the cable should be laid before gluing the wallpaper. Before laying the heating element, the space is released from the furnishings, remove the previous floor covering and thoroughly prepare the floor surface (level, remove the formed garbage, as necessary, cement the thin screed).  Connection of electric underfloor heating. After that, a place is prepared on the wall for the installation of a specially designed electric thermostat, by means of which the heating of the heated floor will be regulated. As necessary, they are equipped with separate wiring for switching on the floor heating system. After these preparatory measures are taken for the device of thermal insulation and directly for the installation of the heating cable. Some experts recommend that in addition to the heat insulator, they also put a waterproofing device in order to avoid condensation in the area of the heating elements. Waterproofing can act as a polyethylene film. Innovative technologies in materials make it possible to reduce losses of useful area (note that the heat insulator, cable, screed - all these layers together reduce the useful living space). Often in the role of a heat insulator using penofol - a modern type of insulation, equipped with a special foil layer (thickness - 14 microns) and foam polyethylene with a gluing side. This kind of material is light enough and thin. The coefficient of thermal conductivity of penofol is equal to 0.049 W / mK. Penofol is produced in a roll version. After installing penofol (foil side up), the joints between the sheets are glued with adhesive tape. After the entire area is covered with a heater, the finest reinforcing mesh is placed on top of the latter. The main purpose of the latter is:

Connection of electric underfloor heating. After that, a place is prepared on the wall for the installation of a specially designed electric thermostat, by means of which the heating of the heated floor will be regulated. As necessary, they are equipped with separate wiring for switching on the floor heating system. After these preparatory measures are taken for the device of thermal insulation and directly for the installation of the heating cable. Some experts recommend that in addition to the heat insulator, they also put a waterproofing device in order to avoid condensation in the area of the heating elements. Waterproofing can act as a polyethylene film. Innovative technologies in materials make it possible to reduce losses of useful area (note that the heat insulator, cable, screed - all these layers together reduce the useful living space). Often in the role of a heat insulator using penofol - a modern type of insulation, equipped with a special foil layer (thickness - 14 microns) and foam polyethylene with a gluing side. This kind of material is light enough and thin. The coefficient of thermal conductivity of penofol is equal to 0.049 W / mK. Penofol is produced in a roll version. After installing penofol (foil side up), the joints between the sheets are glued with adhesive tape. After the entire area is covered with a heater, the finest reinforcing mesh is placed on top of the latter. The main purpose of the latter is:

- protection from overheating of the cable in contact with thermal insulation;

- Strengthening of sand-cement mortar, poured on the floor.

The cable is laid using a mountingfoam fixed on the floor. The tape provides an opportunity to avoid kinks and create the necessary gaps between the cable loops. The heating element is put in place for a step of 20-25 cm. It is not possible to operate the underfloor heating systems normally without the use of a special temperature sensor. It is important to install it so that you do not have to destroy the concrete screed in the future to replace it. To do this, the temperature sensor is placed in the tube, which is filled with the cement screed.  Before filling the heating cable carefullycheck that all connections are correct. Before pouring the stacked heating element, it is checked for correctness of the entire installation and for the strength of the joints. It is important not to make mistakes at this stage, as they can be very expensive in the future (for example, it is necessary to open a cement screed). The readiness of the floor heating system is checked by applying voltage to the cable, and also by measuring the cable resistance by the tester. All specified parameters are available in the manufacturer's data sheet. After the inspection, lay a cement screed (3-4 cm thick). Pouring is carried out evenly, and it is especially ensured that when filling, there are no voids, which can lead to a malfunction of the cable. After the floor is poured with cement, it is expected to completely solidify it. To work on the flooring finish the work begins after 4-5 days, the test for readiness for the work of the warm floor is performed no earlier than a month. The reason here is absolutely not in the dampness of the screed. Many materials become more wide with the influence of high temperature, and when compressed, they shrink. Each kind of material is endowed with its own coefficient of thermal expansion. If you turn on the warm floor before concrete becomes absolutely hard, then the solution will dry unevenly, in the screed there will emerge emptiness and cracking, which was so avoided during the pouring process. This will increase the risk of early failure of the heating element. It makes sense to take into account the layout of furnishing items in the room, so as not to lay the cable in the areas where they will be delivered. Back to contents</a>

Before filling the heating cable carefullycheck that all connections are correct. Before pouring the stacked heating element, it is checked for correctness of the entire installation and for the strength of the joints. It is important not to make mistakes at this stage, as they can be very expensive in the future (for example, it is necessary to open a cement screed). The readiness of the floor heating system is checked by applying voltage to the cable, and also by measuring the cable resistance by the tester. All specified parameters are available in the manufacturer's data sheet. After the inspection, lay a cement screed (3-4 cm thick). Pouring is carried out evenly, and it is especially ensured that when filling, there are no voids, which can lead to a malfunction of the cable. After the floor is poured with cement, it is expected to completely solidify it. To work on the flooring finish the work begins after 4-5 days, the test for readiness for the work of the warm floor is performed no earlier than a month. The reason here is absolutely not in the dampness of the screed. Many materials become more wide with the influence of high temperature, and when compressed, they shrink. Each kind of material is endowed with its own coefficient of thermal expansion. If you turn on the warm floor before concrete becomes absolutely hard, then the solution will dry unevenly, in the screed there will emerge emptiness and cracking, which was so avoided during the pouring process. This will increase the risk of early failure of the heating element. It makes sense to take into account the layout of furnishing items in the room, so as not to lay the cable in the areas where they will be delivered. Back to contents</a>

Installation and features of the installation of a water-heated floor

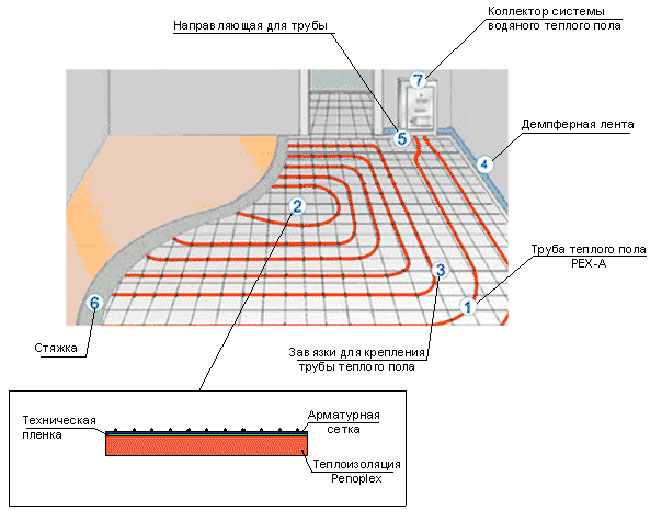

Installation and installation of a warm water floor. Mount the water system in approximately the same order as when laying the electrical product. But consider that electric and water types of heating are guided by different laws of physics. The electric heating element is heated equally on its entire surface (or almost the same), and the water floor is different in this. The maximum temperature level is set immediately after the water enters the heating system from the boiler's heating chamber. Circulating water in the system will give up heat gradually and return to the boiler already in the cooled state. This means that the coolant circulating at the beginning and at the end of the system has different temperatures. If the installation is done illiterately, then do not expect the effective performance of the warm floor with water. As the space starts to warm up is not the same. Back to contents</a> Stacking options

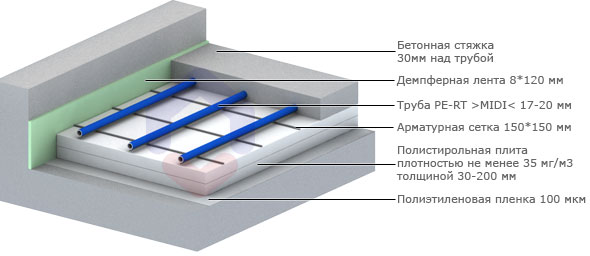

Installation and installation of a warm water floor. Mount the water system in approximately the same order as when laying the electrical product. But consider that electric and water types of heating are guided by different laws of physics. The electric heating element is heated equally on its entire surface (or almost the same), and the water floor is different in this. The maximum temperature level is set immediately after the water enters the heating system from the boiler's heating chamber. Circulating water in the system will give up heat gradually and return to the boiler already in the cooled state. This means that the coolant circulating at the beginning and at the end of the system has different temperatures. If the installation is done illiterately, then do not expect the effective performance of the warm floor with water. As the space starts to warm up is not the same. Back to contents</a> Stacking options  Scheme of a water-heated floor with concreting. There are several options for laying water underfloor heating:

Scheme of a water-heated floor with concreting. There are several options for laying water underfloor heating:

- Concreting system (today the most common);

- flooring system.

The floor heating is also divided into:

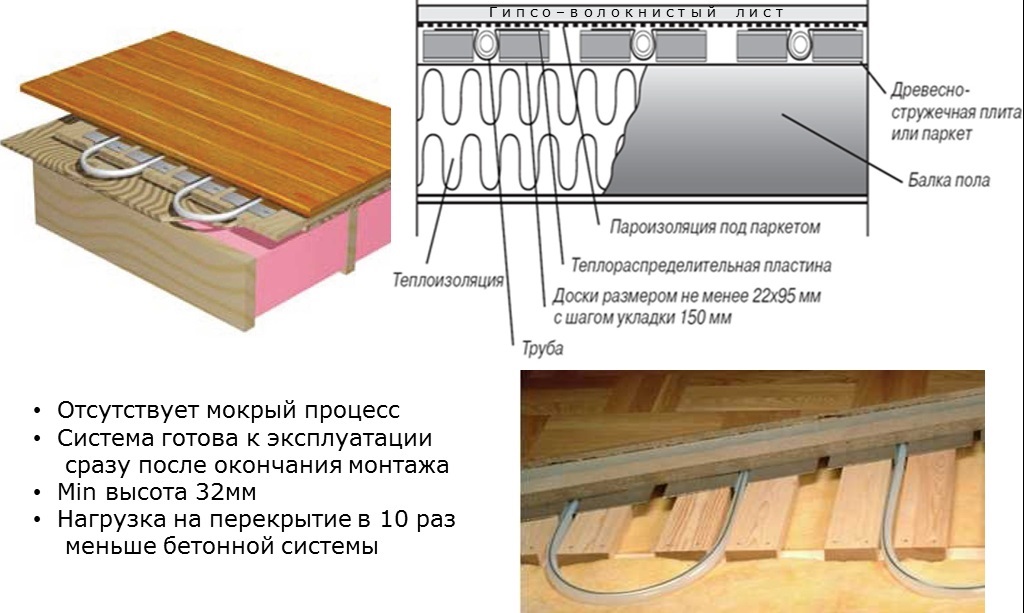

- expanded polystyrene varieties;

- wooden mounting.

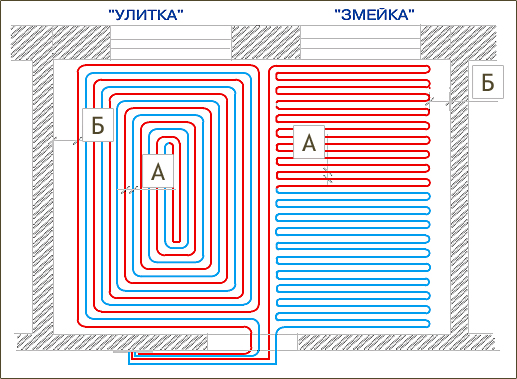

The floor heating system with concreting water, similar to the above described installation of the electric heating system, has become more in demand due to cheap installation. Back to contents</a> Sequence of work All procedures forlaying water floor heating are held in several receptions. The change of procedures and the materials used are used exactly the same as in the arrangement of the electric heating system. But the pipes of the water system, unlike the electric cable, do not overheat. However, they should be stacked neatly, without bending or breaking too hard, observing a strictly defined scheme. A lightweight reinforcing mesh for this situation will be of little use, it will be necessary to stock up a diameter of 4-5 mm with a cell size of about 15 cm. This is determined by the substantial mass of water pipes. The pace of their laying is different. Pipes with water overheating is not terrible. However, more than 400 mm of the gap between the pipes should not be left, since this will significantly reduce the efficiency of the floor heating system and contribute to the appearance of "cold stripes" on the floor surface - segments with a reduced temperature. Fastening of pipes to a floor surface is carried out by means of collars with dowels.  Scheme laying pipes on the floor with a snake and a snail. In practice, it is common to distinguish between several options for installing pipes of a water heating system:

Scheme laying pipes on the floor with a snake and a snail. In practice, it is common to distinguish between several options for installing pipes of a water heating system:

- spiral-shaped;

- Spiral with a center shift;

- snake (parallel version);

- meander (double snake).

To select a specific installation optionIt is worth taking into account a lot of factors, among which are the outside surfaces, and the presence of openings with windows, and others. It is in the designated sections of the pipe with the heat-transfer agent that the temperature should be somewhat hotter than usual. The length of one loop of pipes with water from the inlet to the outlet should not exceed 100 m. This is due to the fact that large hydraulic losses are possible, which reduces the efficiency of the system. For an area of 1 m², about 6-7 running meters of pipes are required. Both ends of the pipe are taken out to the collector cabinet. Such a cabinet is installed in a niche cut in the wall or made in an overhead way. The location of the manifold is determined solely by the capabilities of the owner, since the manufacture of a niche is an expensive type of work. In the manifold there are also pipes connecting the device of the warm floor to the main heating circuit, and a valve that allows to cover the water and set the desired temperature for the floor surface in the room. The valve may have a manual principle of operation, it can be an electronic one, which catches the signals of the temperature sensor. In the second case, the system will be more expensive, but also more convenient. Before the manufacture of a concrete screed, the system is pressurized to eliminate the possibility of leakage of the coolant. The system of water floor heating by the flooring allows to do without installation with concrete without pouring. That not only brings the system commissioning time closer, but also reduces the cost of possible repairs in the future. In addition, such a system is much lighter than a standard warm floor, which significantly reduces the load on the slabs of the bearing parts of the building. Compare: the mass of the standard system of floor water heating is 250-350 kg, while the mass of the water floor by the method of flooring is only 35-50 kg, depending on its variety. However, there is a "NO": to connect the water system of the warm floor to the central heating system without prior agreement with the heat supply organizations and utilities can not. The presented stacking technologies and recommendations are intended to help clarify the process of installing the underfloor heating system by one's own hands.