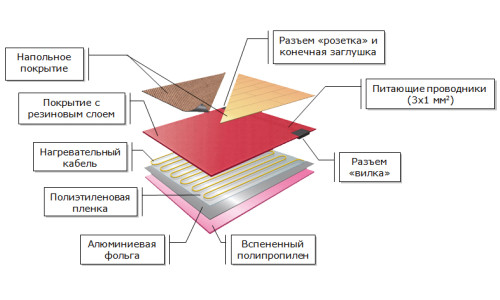

Warm floors, the principle of which is associated withwork of electricity, seem quite elementary, schematically simple and profitable solution of problems related to heating of buildings. They consume less energy, compared to similar options. Anyone can mount a warm floor under the laminate with their own hands. This requires a set of tools, materials and knowledge of the main points of installation.  Scheme of a warm floor under a laminate.

Scheme of a warm floor under a laminate.

Classification of warm floors: the choice of a suitable option

The most popular systems are the following:

- warm floor film infrared;

- rod mats.

Preferring a certain type of film type for a laminate, often take such models:

- budgetary;

- premium.

The latter variety is characterized by rapidityheating, high melting points, some of which are able to improve the quality of airspace and provide an antibacterial effect. Back to contents</a>

Installation of a warm floor of film type

Tools for laying underfloor heating. Materials and tools:

Tools for laying underfloor heating. Materials and tools:

- a set of film floor;

- heat-reflecting material;

- Temperature regulator;

- adhesive tape for installation;

- installation kit;

- electric wires;

- screwdriver;

- Nippers;

- knife;

- dowels;

- a hammer;

- perforator;

- soldering iron;

- film for vapor barrier based on polyethylene;

- plaster mesh made of plastic;

- material for thermal insulation;

- corrugated pipe.

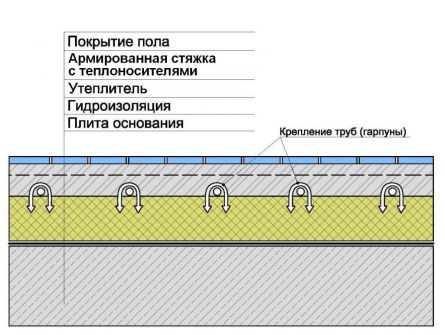

Back to contents</a> Preparatory work To packelectric warm floor, you need to pre-work on leveling the surface and cleaning the base. There should be no depressions and notches. As preliminary work, it is also necessary to thoroughly clean the base. It is entirely possible to wash the floor and allow it to dry well. Back to contents</a> Design features of thermal insulation  Scheme of the device of a water-heated floor withfastening pipes with harpoons to the layer of thermal insulation. To carry out the work on laminate flooring means to provide it with the necessary foundations for high-quality thermal insulation. This layer is very important, because it depends on the preservation of floor heat. The necessary materials for this will be:

Scheme of the device of a water-heated floor withfastening pipes with harpoons to the layer of thermal insulation. To carry out the work on laminate flooring means to provide it with the necessary foundations for high-quality thermal insulation. This layer is very important, because it depends on the preservation of floor heat. The necessary materials for this will be:

- foil;

- reflective elements;

- bung.

Once such material is cut, it is possible to start covering the floor with the metal part facing upwards. Then the insulating elements are attached with an adhesive tape. Back to contents</a>

Installation of a warm floor under a laminate

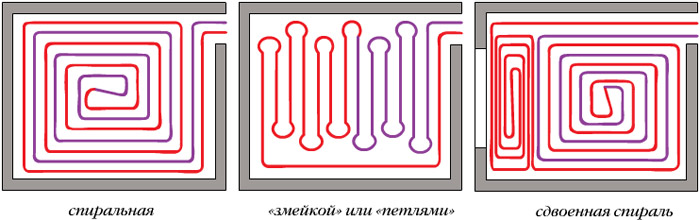

Getting to work, it should be clarified thatIt is not necessary to cover the whole surface of the floor with this system. Avoid areas where heavy furniture will be located. It is important to take care of a distance of 5-10 cm from the walls. When placing the film, it is necessary not to adhere to its parts. At the same time, it is spread over the entire length, which helps to protect against accumulation of wires. After that, the film parts are fixed with the help of a mounting tape. Connecting the wires. To lay a warm floor under the laminate, use crimp terminals. They are fixed in copper strips and fixed. Then wires are inserted here, which are strengthened with the help of pliers. Finish the insulation by gluing the bituminous tape. It should be located above and below. Recommendation. Carrying out similar works, it is necessary to take care of grounding. For this purpose, it will be necessary to glue the film, which is covered with a base, with foil tape. Its edge must be recessed, grounded.  Schemes laying pipes of the warm floor. Eyelets. These parts are characterized by increased safety and a small thickness. To implement their fixation, you can use eyelets, bitumen tape, special purpose stapler. The stacking technique corresponds to the above described method. Also, electric underfloor heating involves connecting the system using a parallel connection method. Formation of thermal insulation. To install a high-quality warm floor under the laminate, it is necessary to provide it with a reliable insulation that can keep the heat as much as possible. Preferring foil as a material, it is necessary to follow the conductivity of electricity. It is best to install a base that does not conduct current. Back to contents</a> Installation of a temperature sensor and a temperature controllerThe "warm floor" must be equipped with a thermal sensor. It goes in a set with a thermoregulator. It must be installed at the end of the work, at a time when the main work on the installation of the coating has already been carried out. The temperature sensor is fixed to the thermal insulation layer. And this will require a small notch. To put it in place, you need to apply the main methods:

Schemes laying pipes of the warm floor. Eyelets. These parts are characterized by increased safety and a small thickness. To implement their fixation, you can use eyelets, bitumen tape, special purpose stapler. The stacking technique corresponds to the above described method. Also, electric underfloor heating involves connecting the system using a parallel connection method. Formation of thermal insulation. To install a high-quality warm floor under the laminate, it is necessary to provide it with a reliable insulation that can keep the heat as much as possible. Preferring foil as a material, it is necessary to follow the conductivity of electricity. It is best to install a base that does not conduct current. Back to contents</a> Installation of a temperature sensor and a temperature controllerThe "warm floor" must be equipped with a thermal sensor. It goes in a set with a thermoregulator. It must be installed at the end of the work, at a time when the main work on the installation of the coating has already been carried out. The temperature sensor is fixed to the thermal insulation layer. And this will require a small notch. To put it in place, you need to apply the main methods:

- outer;

- interior.

The first option consists of mounting the deviceimmediately onto the wall, the other assumes the preparation of the base by cutting the surface. The place should be determined most accurately. Fixation of the protective and finishing layer. Installing the film in the construction, it is necessary to ensure its reliable protection. To do this, a polyethylene film is most often used. It is put in the gap between the film coating itself and the finish base. Then you can finish the finish material. In the present embodiment, such a substrate is a laminate. Back to contents</a>

Recommendations for laying underfloor heating

To ensure that the film warm floor has the maximum safety parameters, you should follow some recommendations:

- Do not place heavy furniture on the base, unless there are holes for ventilation;

- It is forbidden to perform work on the installation of the film without proper grounding;

- Do not cut holes in the film;

- It is not recommended to set the film with a single cloth, the length of which exceeds 15 m;

- It is not possible to install a warm floor near various heating appliances;

- installation work at a temperature below zero is not carried out, and high humidity is also not allowed.

Back to contents</a>

Features of warm floors

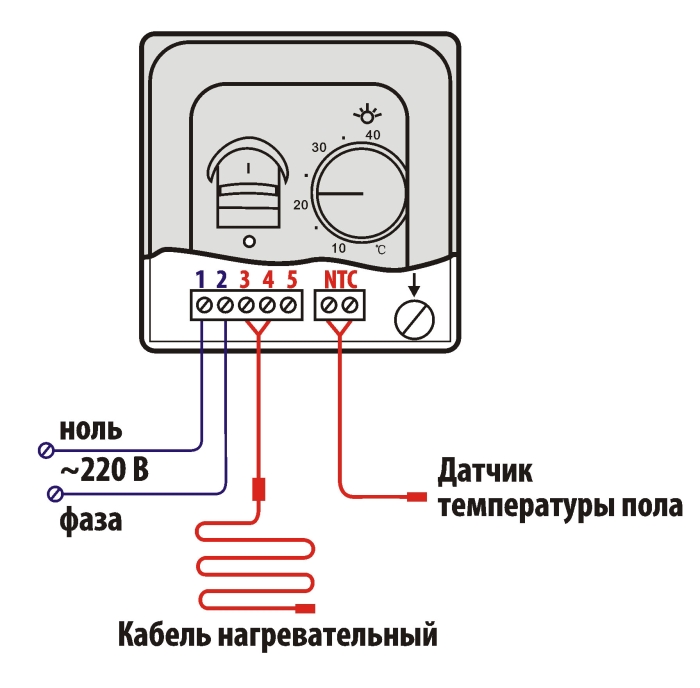

To ensure that the floor surface is warm, different types of bases are used: mats, cables, films. They are united by common signs, you need to know which ones, when you start editing:  Connection scheme for a temperature sensor.

Connection scheme for a temperature sensor.

Back to contents</a>

A few words as a conclusion

Following all of the above recommendations andtechnical arguments, it is quite possible to install a warm floor yourself, without recourse to specialists. The chosen system, installed according to all requirements, will bring comfort, warmth and a pleasant home atmosphere to any room. </ ul>