If you choose the material to replace the floor, leaningon the criteria of affordable price, durability, ease of care and the possibility of self-assembly, then this description is best suited for laminate coating. A reliable and sturdy construction will decorate any dwelling, and laying a laminate with your own hands will not be difficult even for a person unfamiliar with repair work. But to get a good result you need to choose the right laminate, carefully prepare for its packing and take into account some rules that will help you not make mistakes while performing this process.  With the help of laminate it is possible to create a strong, beautiful and reliable floor covering.

With the help of laminate it is possible to create a strong, beautiful and reliable floor covering.

Classification of laminated flooring

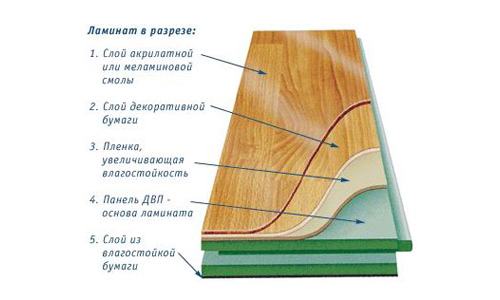

Before buying a laminate it will be useful toread some information about this kind of flooring. The price of the products is different and depends not only on the manufacturer, but also on its type and class.  Laminate varieties. All of it is made by practically one technology, implying the soldering of high-density fiberboard with decorative and stabilizing layers. This occurs under conditions of high temperature and pressure, and as a result, a board is produced, famous for its high functional characteristics and excellent aesthetic performance. Depending on the components used and the features of the production process, the laminate acquires specific strength and wear resistance characteristics. This leads to subdivision of it into classes from 31 to 34. Higher values allow the use of the coating in premises with a high load on the surface, but the price for such material differs in a larger direction. If you plan a floor of laminate in an apartment or a house, it does not make sense to buy high-end goods. For this purpose, 31 or 32 markings by classification are sufficient. Back to contents</a>

Laminate varieties. All of it is made by practically one technology, implying the soldering of high-density fiberboard with decorative and stabilizing layers. This occurs under conditions of high temperature and pressure, and as a result, a board is produced, famous for its high functional characteristics and excellent aesthetic performance. Depending on the components used and the features of the production process, the laminate acquires specific strength and wear resistance characteristics. This leads to subdivision of it into classes from 31 to 34. Higher values allow the use of the coating in premises with a high load on the surface, but the price for such material differs in a larger direction. If you plan a floor of laminate in an apartment or a house, it does not make sense to buy high-end goods. For this purpose, 31 or 32 markings by classification are sufficient. Back to contents</a>

Choose a laminate cover

Layout of the laminate.An exception can be made if planned in the kitchen or bathroom. These rooms are very humid, and only waterproof floors will be able to withstand constant contact with water and frequent cleaning. It should be noted that the water resistance and moisture resistance of a laminated coating are two different concepts. The latter type is able to survive only high humidity and a very short-term presence of water on the surface. The waterproof material also does not have absolute resistance to liquid, but it easily tolerates flooding with water for several hours, after which it can be dried without losing its shape and appearance. When buying a laminate, you should pay attention to the manufacturer of the product. Well-known companies value their reputation, their products comply with European standards and have a high, and sometimes even a lifetime warranty period. Full control of the production process and the use of environmentally friendly components allow the floor to have decent quality and complete safety for human health. Laminate flooring made without following the rules and regulations can be identified by the pungent smell of formaldehyde. A prohibited and hazardous to health drug can only be contained in a low-quality laminate. Back to the table of contents</a>

Layout of the laminate.An exception can be made if planned in the kitchen or bathroom. These rooms are very humid, and only waterproof floors will be able to withstand constant contact with water and frequent cleaning. It should be noted that the water resistance and moisture resistance of a laminated coating are two different concepts. The latter type is able to survive only high humidity and a very short-term presence of water on the surface. The waterproof material also does not have absolute resistance to liquid, but it easily tolerates flooding with water for several hours, after which it can be dried without losing its shape and appearance. When buying a laminate, you should pay attention to the manufacturer of the product. Well-known companies value their reputation, their products comply with European standards and have a high, and sometimes even a lifetime warranty period. Full control of the production process and the use of environmentally friendly components allow the floor to have decent quality and complete safety for human health. Laminate flooring made without following the rules and regulations can be identified by the pungent smell of formaldehyde. A prohibited and hazardous to health drug can only be contained in a low-quality laminate. Back to the table of contents</a>

Preparing the floor for laying

The main condition that must be strictly observed when laying the laminate with your own hands, concerns the preparation of the foundation.  Tools for laying laminate. For the installation of the coating, any kind of surface is suitable, except that the carpet is too soft. The basic requirements for the condition of the rough floor can be identified in several points:

Tools for laying laminate. For the installation of the coating, any kind of surface is suitable, except that the carpet is too soft. The basic requirements for the condition of the rough floor can be identified in several points:

If these requirements do not matchconcrete foundation and its restoration will not lead to the necessary indicators of a horizontal level, in this case it will not be possible to do without the cement screed. The old boardwalk can be strengthened by fixing the boards to the logs with screws or nails, and cover wide cracks with small chips and putty. The main thing is that the boards are not rotten and keep the shape. Linoleum is examined from the back side, and if there are traces of mold on it, ground on as far as possible from the edge. The fallen off ceramic tile is glued in place, and chips and cracks are shpatlyuyut or treated with tile glue. Back to contents</a>

Substrate for laying the laminate with your own hands

Technology of laying laminate. Urgent recommendations from manufacturers to use a substrate when installing a laminate coating is not an advertising move, but a way to prolong the life of a laminate and make its operation more comfortable. This material is not so expensive, but it has very important properties:

Technology of laying laminate. Urgent recommendations from manufacturers to use a substrate when installing a laminate coating is not an advertising move, but a way to prolong the life of a laminate and make its operation more comfortable. This material is not so expensive, but it has very important properties:

- ability to hide small surface irregularities;

- waterproofing;

- soundproofing;

- prevention of the appearance of insects and microorganisms;

- shock absorption during walking.

Different kinds of substrates are designed foruse in specific conditions of premises. The most inexpensive option is a single-layer foamed polyethylene. It does not have a long service life due to high crushing. Good properties have a substrate consisting of polystyrene and aluminum foil. Its antiseptic and moisture-proof properties correspond to the cost and make it the most suitable for laying the laminate. There are several more varieties of this material: cork, bitumen-cork, composite and extruded polystyrene foam. They are distinguished by different functional features, but the price of this product is higher than that of ordinary species. Back to contents</a>

Tools for laying laminate

Laying patterns for laminate in various ways. It is impossible to proceed with the laying of laminated boards immediately after delivery. Packings must be placed in the room where the floor will be installed and allow the material to adapt to new conditions of humidity and temperature for 2-3 days. During this time, you can prepare the tools you need:

Laying patterns for laminate in various ways. It is impossible to proceed with the laying of laminated boards immediately after delivery. Packings must be placed in the room where the floor will be installed and allow the material to adapt to new conditions of humidity and temperature for 2-3 days. During this time, you can prepare the tools you need:

- electric jigsaw;

- drill with feather drills on wood;

- pencil with soft lead;

- ruler, gon and roulette;

- a hammer;

- podbivochny wooden bar;

- wooden wedges;

- clamp.

There is a special device - machinefor cutting laminate. But the expediency of its acquisition casts doubt on two facts. Firstly, he knows how to cut panels just across, so to reduce the width of boards the extreme rows do not fit, you still have to use a jigsaw. And secondly, is it worth to spend money on the device, which is extremely rarely used on the farm. If there is no electric jigsaw at hand, it can be replaced with a hacksaw, but the teeth must be very small, otherwise the film on the surface of the laminate will get damaged. Back to contents</a>

The process of installing a laminate coating

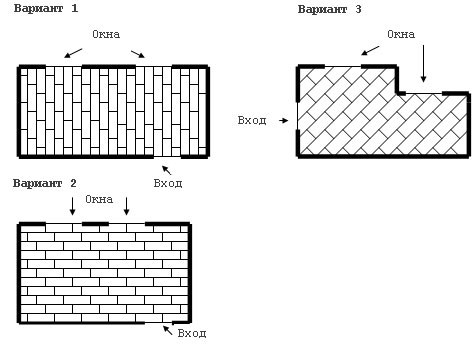

Sequence laying the laminate. Before you begin to lay laminated panels, you need to carefully spread out the substrate on a clean and dry substrate. In this case, the strips should go to each other by 6-10 cm, and their edges should be fixed with adhesive tape, so that they do not get lost during operation. Between all walls and a laminated covering there should be a gap of at least 1 cm. It will perform the function of a compensation gap when the panels change naturally under the influence of climatic changes at different times of the year. The layout of the laminate floor has three options: longitudinal, transverse and diagonal. The first method is the simplest and can be performed by the classical method or in checkerboard order. The classical arrangement of the panels is virtually non-wasteful due to the fact that the remainder of the first row will serve as the start of the second. Therefore, for the first experiment, it is better to use a simple option.

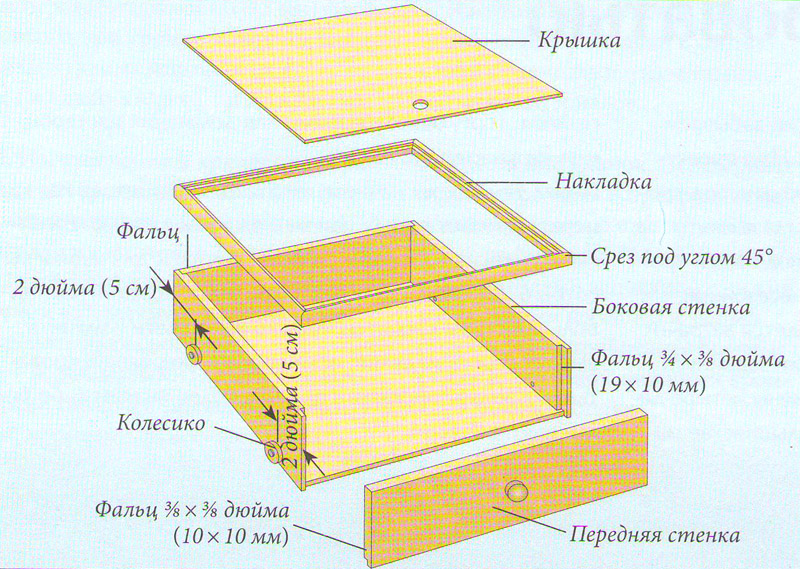

Sequence laying the laminate. Before you begin to lay laminated panels, you need to carefully spread out the substrate on a clean and dry substrate. In this case, the strips should go to each other by 6-10 cm, and their edges should be fixed with adhesive tape, so that they do not get lost during operation. Between all walls and a laminated covering there should be a gap of at least 1 cm. It will perform the function of a compensation gap when the panels change naturally under the influence of climatic changes at different times of the year. The layout of the laminate floor has three options: longitudinal, transverse and diagonal. The first method is the simplest and can be performed by the classical method or in checkerboard order. The classical arrangement of the panels is virtually non-wasteful due to the fact that the remainder of the first row will serve as the start of the second. Therefore, for the first experiment, it is better to use a simple option.  Rules for laying a laminate near the door jambs andpipes. The first row of planks should be facing the groove to the wall. Select its direction can be experienced by placing the panels alternately along or across the room. The light falling from the window will show how the joints on their butt-end will look better. Additionally, take into account the interior features and the arrangement of furniture in the room. In order not to face the fact that the last row turns out to be too narrow, it is worth to count the number of bands and, if necessary, cut the first boards in width. Then the width of the extreme rows becomes proportional. Lamellae are easily interconnected by means of a lock method. They are brought with their butts facing each other, making sure that the ridge on the other is turned to the groove on one board. The connection occurs at an angle of 45 ° and is considered to be successfully performed if a characteristic click is heard, indicating a qualitative contact. The last board is brought to the desired size with an electric jigsaw, and the second row is assembled from its remainder. For a good density, the strips are knocked down with light tapping of the hammer, placing a wooden block under it. Installation of the last row is carried out with the help of wooden wedges and clamps. Holes for heating pipes are most conveniently carried out with a drill equipped with feather drills for wood. The final stage of work will be the installation of skirting boards and doors. These parts are better to buy at the same time with a laminated coating, in order to be able to perfectly match the appropriate shade and texture. Mount skirting can only be to the wall, and not to the floor covering. If you screw the skirting board to the laminate, it will lose the ability to freely change the dimensions with varying temperature and humidity. A glutinous method of fastening will deprive the material of one of its main advantages - the possibility of dismantling and transferring to another room if necessary. </ ul>

Rules for laying a laminate near the door jambs andpipes. The first row of planks should be facing the groove to the wall. Select its direction can be experienced by placing the panels alternately along or across the room. The light falling from the window will show how the joints on their butt-end will look better. Additionally, take into account the interior features and the arrangement of furniture in the room. In order not to face the fact that the last row turns out to be too narrow, it is worth to count the number of bands and, if necessary, cut the first boards in width. Then the width of the extreme rows becomes proportional. Lamellae are easily interconnected by means of a lock method. They are brought with their butts facing each other, making sure that the ridge on the other is turned to the groove on one board. The connection occurs at an angle of 45 ° and is considered to be successfully performed if a characteristic click is heard, indicating a qualitative contact. The last board is brought to the desired size with an electric jigsaw, and the second row is assembled from its remainder. For a good density, the strips are knocked down with light tapping of the hammer, placing a wooden block under it. Installation of the last row is carried out with the help of wooden wedges and clamps. Holes for heating pipes are most conveniently carried out with a drill equipped with feather drills for wood. The final stage of work will be the installation of skirting boards and doors. These parts are better to buy at the same time with a laminated coating, in order to be able to perfectly match the appropriate shade and texture. Mount skirting can only be to the wall, and not to the floor covering. If you screw the skirting board to the laminate, it will lose the ability to freely change the dimensions with varying temperature and humidity. A glutinous method of fastening will deprive the material of one of its main advantages - the possibility of dismantling and transferring to another room if necessary. </ ul>