Every owner of a city apartment strives forso that the room is always warm, so that the floors are never cold. Heat retention greatly depends on properly done insulation, this also applies to the floors of the room. The coziness and comfort of the home depends on how warm the floor is. If the floors are well insulated, then the costs of heating are sharply reduced and the comfort of the room increases. Comparative characteristics of thicknessthermal insulation. It is quite possible for everyone to insulate floors with their own hands. It does not require particularly professional skills and extensive experience. It is very important to immediately determine the thermal insulation material, select the simplest one. When choosing insulation, its main functional properties are taken into account:

Comparative characteristics of thicknessthermal insulation. It is quite possible for everyone to insulate floors with their own hands. It does not require particularly professional skills and extensive experience. It is very important to immediately determine the thermal insulation material, select the simplest one. When choosing insulation, its main functional properties are taken into account:

- thermal conductivity;

- strength;

- weight;

- fire resistance;

- moisture resistance;

- installation;

- ecological compatibility;

- lifetime.

Very often the following is used as insulating material:

- Styrofoam;

- penoplex;

- mineral wool;

- expanded clay.

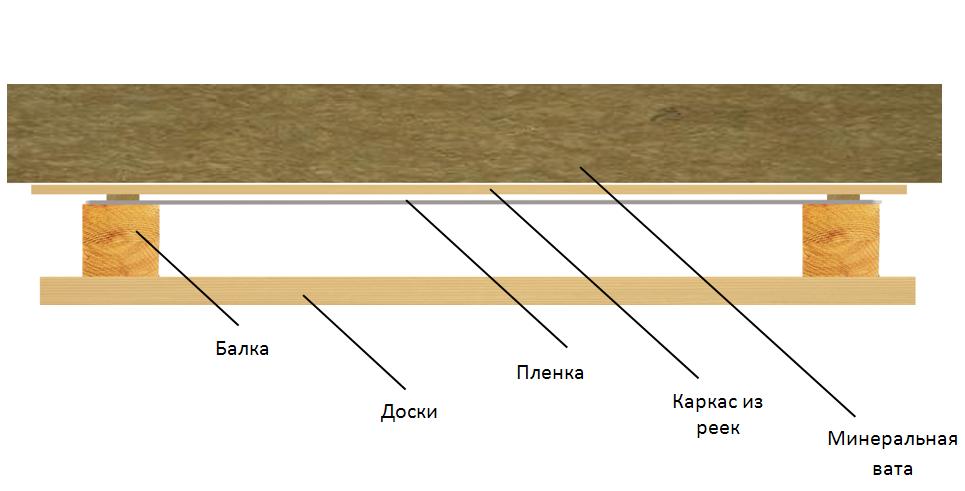

Warming with mineral wool

Scheme of floor insulation with mineral wool.One of the positive characteristics of mineral wool is its excellent thermal insulation. To insulate the floor, use mineral wool rolls, which are most suitable for laying single-layer insulation. Particularly flexible mats, which are distinguished by their high strength, are also used. Very often, mineral wool is used as thermal insulation for installed wooden joists. It is placed under the subfloor. The negative properties of mineral wool are:

Scheme of floor insulation with mineral wool.One of the positive characteristics of mineral wool is its excellent thermal insulation. To insulate the floor, use mineral wool rolls, which are most suitable for laying single-layer insulation. Particularly flexible mats, which are distinguished by their high strength, are also used. Very often, mineral wool is used as thermal insulation for installed wooden joists. It is placed under the subfloor. The negative properties of mineral wool are:

- thickness;

- low strength;

- high water absorption.

A slightly better material than mineral wool is fiberglass, which is not afraid of water. Liquid penetration does not affect the properties of the material. Return to contents</a>

Styrofoam and penoplex

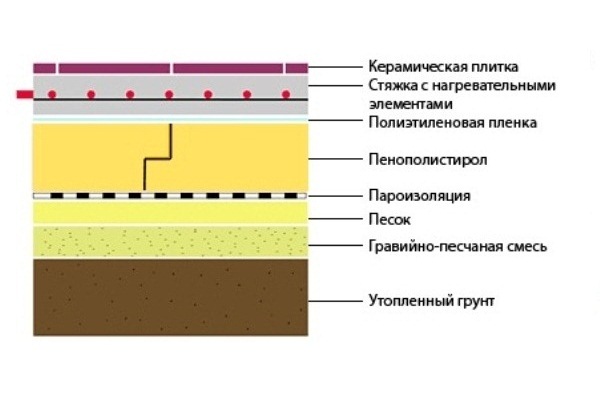

Polystyrene foam.This material has excellent heat-insulating properties. It can be used for a long time, it has a very low cost. It is used to insulate floors with heating. It is laid on the ground and located above the basement. In most cases, such insulation can be laid on: Scheme of insulating a wooden floor with polystyrene foam.

Scheme of insulating a wooden floor with polystyrene foam.

- tree;

- concrete;

- metal;

- ceramics.

Insulation of the floor, filled with concrete, gives a great effect.concrete. Thermal insulation is laid directly on the floor, then polystyrene foam, which is covered with a reinforcing mesh on top. After that, a concrete screed is made. Modern penoplex. This newest material was specially developed for laying thermal insulation in a variety of structures. Basically, the structure of the material is distinguished by the following properties:

- reduced thermal conductivity;

- good sound insulation;

- moisture resistance;

- durability.

With these characteristics, this materialhas become an excellent replacement for polystyrene foam when it is necessary to insulate the floor. Penoplex can be used in any design, it can be used for any, even the most complex base. It is very often installed as an excellent heat insulator for floors with joists. It is also used when insulating floors with preliminary screed. Return to contents</a>

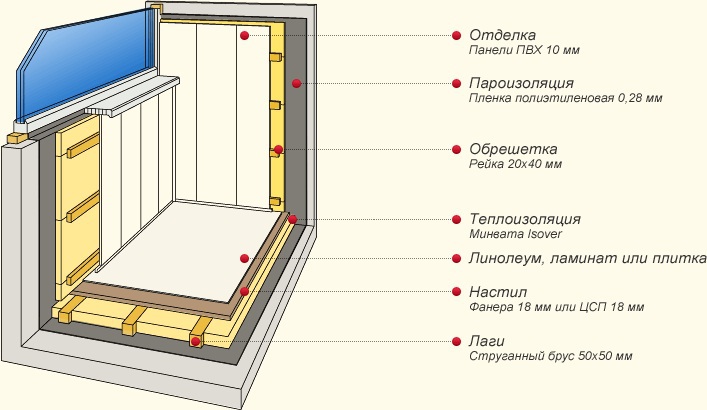

Warming of the loggia: recommendations

Loggia insulation scheme.Any work should begin with preparation, and in order to insulate the floor, it is necessary to make a closed space. Loggias are mostly made open. In other words, they have no protection from precipitation and wind. Of course, it is very difficult to call this comfortable. Therefore, the first thing to do is to completely glaze the loggia. The best option for this will be double-glazed windows, preferably double-chamber. They will provide the best thermal insulation. If you make glazing from a wooden frame in which single-layer glass is installed, then the effect of such thermal insulation will be minimal. When the glazing work is completed, it is necessary to remove all accumulated dirt and dust. The cracks found are filled with polyurethane foam. If the cracks are large, they must be sealed with broken bricks added to the cement mortar. When performing preparatory work, you need to plan the installation of electrical outlets in advance. Especially if you are going to install a heated floor that runs on electricity. When insulating the floor, it must be raised 5 cm up.

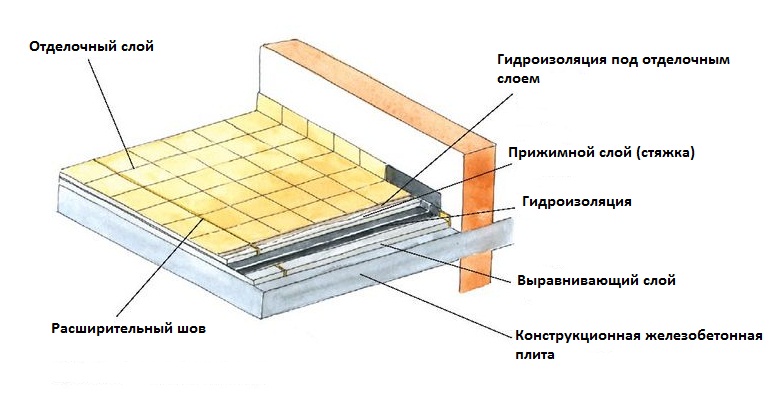

Loggia insulation scheme.Any work should begin with preparation, and in order to insulate the floor, it is necessary to make a closed space. Loggias are mostly made open. In other words, they have no protection from precipitation and wind. Of course, it is very difficult to call this comfortable. Therefore, the first thing to do is to completely glaze the loggia. The best option for this will be double-glazed windows, preferably double-chamber. They will provide the best thermal insulation. If you make glazing from a wooden frame in which single-layer glass is installed, then the effect of such thermal insulation will be minimal. When the glazing work is completed, it is necessary to remove all accumulated dirt and dust. The cracks found are filled with polyurethane foam. If the cracks are large, they must be sealed with broken bricks added to the cement mortar. When performing preparatory work, you need to plan the installation of electrical outlets in advance. Especially if you are going to install a heated floor that runs on electricity. When insulating the floor, it must be raised 5 cm up. Scheme of waterproofing of a balcony or loggia.Naturally, the supply of utility lines must be carried out taking into account such a rise. The first layer to be laid is waterproofing. This is very important for the first floor, when the ground surface is too close and external flooding is possible. For all other cases, the loggia is considered a closed room. Any external impact will be minimal. In this case, when it is necessary to insulate the floor, it is not necessary to lay foam insulation. Return to contents</a>

Scheme of waterproofing of a balcony or loggia.Naturally, the supply of utility lines must be carried out taking into account such a rise. The first layer to be laid is waterproofing. This is very important for the first floor, when the ground surface is too close and external flooding is possible. For all other cases, the loggia is considered a closed room. Any external impact will be minimal. In this case, when it is necessary to insulate the floor, it is not necessary to lay foam insulation. Return to contents</a>

Warming of the floors of a private house

This work only seems very difficult. In fact, anyone can do it on their own. To ensure that everything works out well and reliably, you need to have the following types of tools:

- building level;

- drill;

- a hammer;

- roulette;

- hacksaw;

- gun for sealant;

- building stapler.

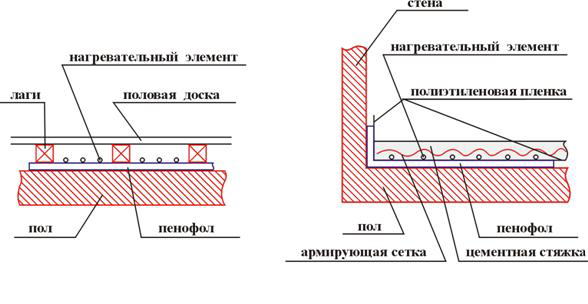

Types of floor insulation using penofol. The technological operation of floor insulation can be performed in two ways:

Types of floor insulation using penofol. The technological operation of floor insulation can be performed in two ways:

- by lags;

- on the ground.

Insulation on joists.Usually, such an operation concerns a wooden house, where the floors are held by joists. To insulate the floor, first the floor covering is dismantled. The condition of the joists is carefully checked. Rotten and cracked ones must be replaced with new ones. After all the replacements, you can start insulating the floor. Mineral wool is considered the most suitable heat-insulating material for a wooden house. The fact is that parasites never appear in it. The subfloor is covered with a layer of vapor barrier, on which the insulation is then laid. The mineral wool must be laid very tightly, there should be no free space left. If cracks are left, cold air may enter the room. The insulation is covered from above with polyethylene film, which is attached with special staples directly to the joists. Thus, an excellent hydraulic barrier is obtained. After that, the floor is sheathed with wooden boards. Insulation on the base. Thermal insulation is attached directly to the surface of the base of the house, then it is reinforced. After that, a concrete screed is made. The use of liquid materials in this case gives a very high heat-insulating effect. When the screed has completely hardened, a decorative coating is laid. The most suitable materials for this are:

- laminate;

- parquet;

- carpet.

Return to Contents</a>

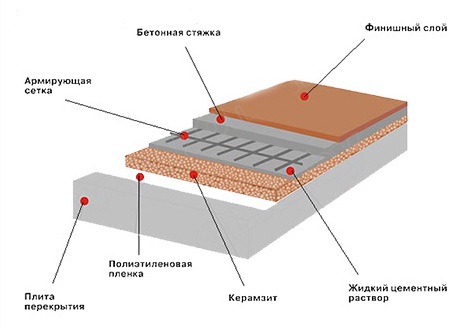

Expanded clay for thermal insulation of floors

At a very low cost, expanded clayinsulation gives the maximum effect. It is always warm in such an apartment. To get good thermal insulation, it is better to use expanded clay blocks of different sizes. The range of dimensions can vary from 5 mm to 20 mm. This combination of different dimensions allows you to get an excellent concrete bond, and there is no shrinkage of the floor surface. Scheme of floor insulation with expanded clay.Expanded clay is lightweight. However, it and concrete screed create some load on the base. In this regard, before starting work, it is necessary to calculate the strength of the concrete slab, inspect its condition. Floors that have expanded clay as insulation are best covered with wood. Before backfilling the insulation, waterproofing is first laid. It is made of thick polyethylene film. When laying, the edges of the film should protrude beyond the edges of the formwork walls in which the pouring is done. The joints are covered with construction tape. If the work was done correctly, an absolutely flat, sealed surface should be obtained. Then beacons are mounted. They help to speed up the work time and make the floor absolutely flat. The best material for such guides can be any durable metal with increased resistance. The best option would be metal pipes. The first pipe is laid with a small indentation from the wall. The second is laid parallel to the first, against the opposite wall. The evenness of the laying is measured with a level. After this, expanded clay is backfilled. The evenness of the surface and the thickness of the layer are determined by the beacons. The insulation layer should be more than 10 cm high. This value has a great impact on the strength of the structure. To prevent the expanded clay grains from moving, they are filled with liquid cement mortar. A reinforcing mesh is laid on the cement mortar. It prevents possible deformation of the structure if heavy loads appear. Pouring the concrete screed begins from the farthest corner of the room, slowly moving towards the exit. To prevent cracks from appearing, the concrete screed must be watered for about a week. When everything is finished, the base has acquired a massive appearance, the floor is covered with a decorative coating.

Scheme of floor insulation with expanded clay.Expanded clay is lightweight. However, it and concrete screed create some load on the base. In this regard, before starting work, it is necessary to calculate the strength of the concrete slab, inspect its condition. Floors that have expanded clay as insulation are best covered with wood. Before backfilling the insulation, waterproofing is first laid. It is made of thick polyethylene film. When laying, the edges of the film should protrude beyond the edges of the formwork walls in which the pouring is done. The joints are covered with construction tape. If the work was done correctly, an absolutely flat, sealed surface should be obtained. Then beacons are mounted. They help to speed up the work time and make the floor absolutely flat. The best material for such guides can be any durable metal with increased resistance. The best option would be metal pipes. The first pipe is laid with a small indentation from the wall. The second is laid parallel to the first, against the opposite wall. The evenness of the laying is measured with a level. After this, expanded clay is backfilled. The evenness of the surface and the thickness of the layer are determined by the beacons. The insulation layer should be more than 10 cm high. This value has a great impact on the strength of the structure. To prevent the expanded clay grains from moving, they are filled with liquid cement mortar. A reinforcing mesh is laid on the cement mortar. It prevents possible deformation of the structure if heavy loads appear. Pouring the concrete screed begins from the farthest corner of the room, slowly moving towards the exit. To prevent cracks from appearing, the concrete screed must be watered for about a week. When everything is finished, the base has acquired a massive appearance, the floor is covered with a decorative coating.