Any floor in modern conditions, finishedlaminate, can be heated. For this, a warm water floor system is installed. The outer layer of such a coating made in a short period of time will provide a pleasant microclimate in the room throughout the year. Having prepared the necessary materials and studied the basic scheme of the work, you can install a water one. This can be done without significant material costs, without pouring a concrete screed. A water heated floor will provide a warm, pleasant microclimate in the room. In order for the work to go smoothly and in an organized manner, you should prepare a number of devices:

A water heated floor will provide a warm, pleasant microclimate in the room. In order for the work to go smoothly and in an organized manner, you should prepare a number of devices:

- lining material that promotes heat reflection: isospane, megasole;

- infrared carbon film with a carbonaceous base;

- coating for installation of waterproofing;

- Scotch tape for installation and electrical work;

- copper wire;

- soldering iron;

- temperature sensor and floor temperature controller.

Compatibility of laminate and water insulation

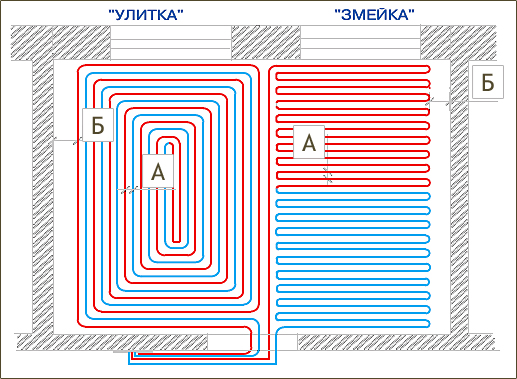

Before installing such insulation, it is worth finding out whether these components are compatible: Scheme of laying pipes on the floor in a snake and snail pattern.

Scheme of laying pipes on the floor in a snake and snail pattern.

Disadvantages of warm water floors:

- installation work is associated with significant material costs;

- the need to recruit specialists;

- installation is not only associated with mechanicallaying the material on the floor, but also requires the connection to the heating system of the building, connection with the boiler, pump, filter, radiators, piping and bypass.

These water-based floors helpinsulation of the laminate. At the same time, it retains its strength indicators. A concrete base, even with a high-quality waterproofing layer, will not be able to perform such functions. Compared to electric varieties, water coatings will cost much more, which cannot be said about further maintenance of the system. The funds spent on installation pay off within the first six months of use. Return to contents</a>

Preparatory work

The principle of heating a warm floor.The installation of the selected floor heating system can be carried out independently. In order for the screed prepared for laying to acquire the specified humidity indicators, it is necessary to warm up and dry the surface. To achieve the desired indicators, it is necessary to connect the floor heating, gradually increasing the temperature of the floor surface. The day before laying the laminate, it is necessary to check the quality of the completed screed, monitor the drying level of its base. Usually, manufacturers of such a coating indicate these values. Regardless of whether a concrete screed will be erected or not, the laminate necessarily requires protection from moisture. For this purpose, a polyethylene film with a thickness of 200 microns is laid on top of the finished surface. To protect against extraneous sounds, the screed is insulated with any soundproofing material. This can be foamed polyethylene, the thickness of which is 2-3 mm. The substrate is determined over the entire area of the room by joining layers. Return to the table of contents</a>

The principle of heating a warm floor.The installation of the selected floor heating system can be carried out independently. In order for the screed prepared for laying to acquire the specified humidity indicators, it is necessary to warm up and dry the surface. To achieve the desired indicators, it is necessary to connect the floor heating, gradually increasing the temperature of the floor surface. The day before laying the laminate, it is necessary to check the quality of the completed screed, monitor the drying level of its base. Usually, manufacturers of such a coating indicate these values. Regardless of whether a concrete screed will be erected or not, the laminate necessarily requires protection from moisture. For this purpose, a polyethylene film with a thickness of 200 microns is laid on top of the finished surface. To protect against extraneous sounds, the screed is insulated with any soundproofing material. This can be foamed polyethylene, the thickness of which is 2-3 mm. The substrate is determined over the entire area of the room by joining layers. Return to the table of contents</a>

Basic mounting options

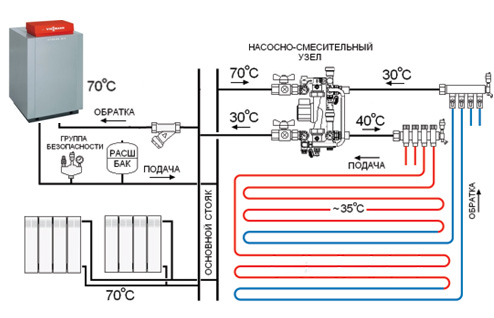

The most commonly used method of installation is to lay the laminate on top of the finished flooring. The following options for laying out the device exist: Connecting the floor to the battery.

Connecting the floor to the battery.

It is impossible to imagine a water-heated floor without some elements that do not depend on the type of finishing flooring used:

- distributing the collector, a number of such parts are taken for heating;

- the main collector, which allows to connect the warm floor to the common device of the heating system;

- integrated collector;

- pump that allows you to pump water.

Recommendation!Laminate under water heated floors has one drawback: it has insufficient heat transfer indicators. To get out of this difficult situation, you should take thinner slats for the flooring, 2-3 mm high. Return to contents</a>

Heating system installation

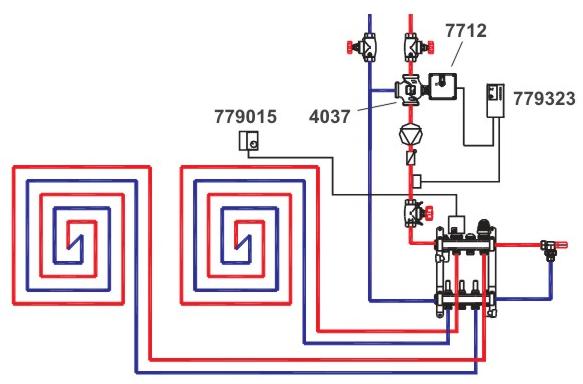

Before carrying out the main work, you should decide on the method of placing the pipes, taking into account some points: General diagram of connection of heated floors in a private house.

General diagram of connection of heated floors in a private house.

Pipes for underfloor heating can be installed in the following ways:

- snake;

- double snake;

- angular snake;

- snail.

Give preference to a certain methodis worth it, based on personal views and work experience. It should be noted that the efficiency of all four methods with equal length of contours gives similar results. Return to contents</a>

Sequence of the installation

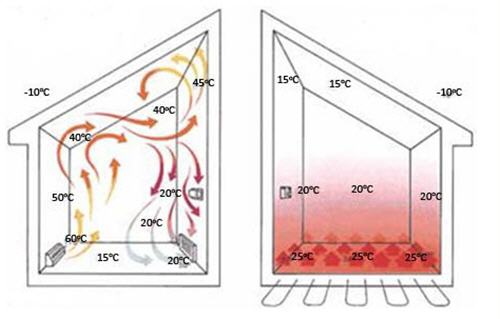

is laid out according to a certain system: Temperature distribution diagram for radiator heating and underfloor heating.

Temperature distribution diagram for radiator heating and underfloor heating.

Return to Contents</a>

A few words in conclusion

Taking into account the funds spent andfurther support of the device, it is worth noting that the combination of "laminate and warm floor" seems to be the most effective in terms of the results of the system. If there is a need for repairs, any of the planks of the selected material can be lifted, and at any point of the coating. It is easy to fix it in the right place. does not imply mandatory installation of warm floors, while the water device needs to be covered with this type of material.</ ul>