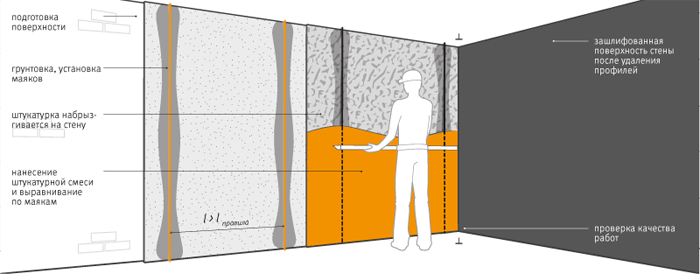

In each room, the walls are leveled. Repairs are rarely done without this procedure. The process of leveling the walls, no matter how it is carried out, is related to finishing works. Scheme of wall alignment using beacons. There are only two ways to align walls:

Scheme of wall alignment using beacons. There are only two ways to align walls:

- drywall;

- building mixtures.

These two methods are also called dry and wet.alignment, each of them has its own characteristics. To identify the most suitable method, the unevenness on the walls must first be measured using a level, a level or an ordinary plumb line. Putty helps to eliminate depressions and potholes that do not exceed 5-6 mm. The building mixture is used when the unevenness reaches 3-5 cm, and if the differences are greater than this value, it is easiest to use plasterboard.

Aligning walls with plaster

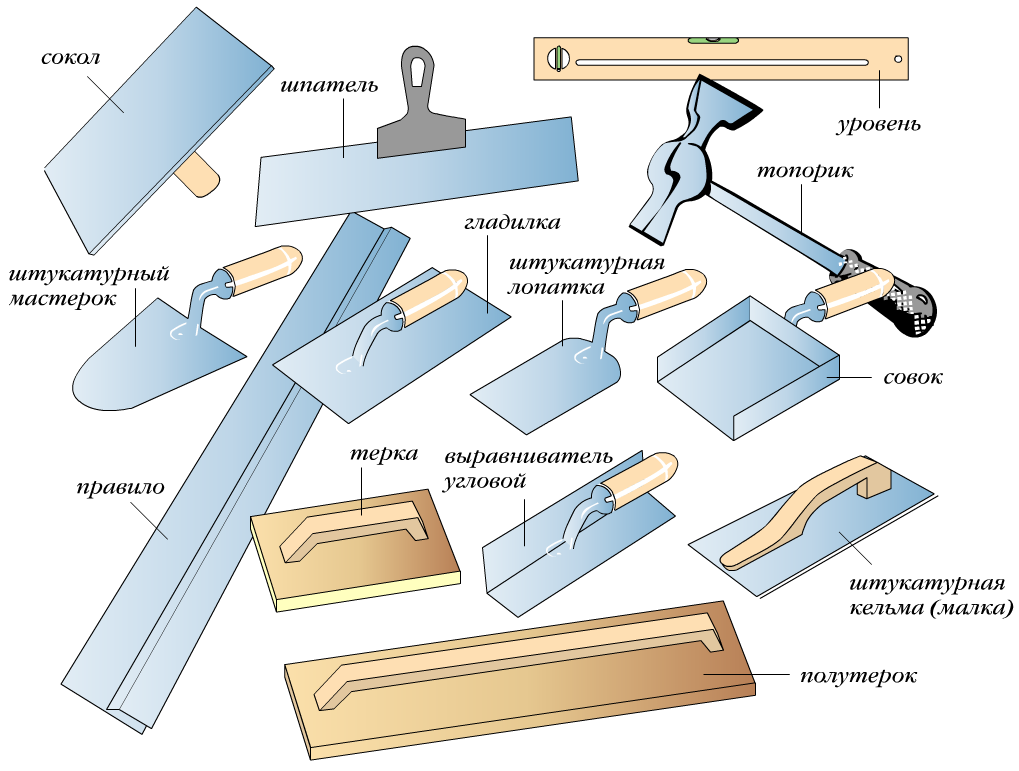

The following materials and tools will be required for the work:

- plaster mixture;

- capacity;

- water;

- reinforcing mesh;

- primer;

- Master OK;

- level;

- rule;

- putty knife;

- lighthouses.

Wall hanging diagram.Before proceeding directly to leveling, it is necessary to carry out preparatory work. If possible, the finishing materials that were on the wall earlier should be dismantled, and then the surface that needs to be plastered should be assessed again. The wall should not crumble or delaminate; such places are cleaned to a solid surface. Often, when using plaster, the drying of its layer reveals exactly such previously invisible defects. Under the influence of moisture, part of the wall loses its solidity and begins to crumble along with the plaster. To avoid this, three conditions must be met:

Wall hanging diagram.Before proceeding directly to leveling, it is necessary to carry out preparatory work. If possible, the finishing materials that were on the wall earlier should be dismantled, and then the surface that needs to be plastered should be assessed again. The wall should not crumble or delaminate; such places are cleaned to a solid surface. Often, when using plaster, the drying of its layer reveals exactly such previously invisible defects. Under the influence of moisture, part of the wall loses its solidity and begins to crumble along with the plaster. To avoid this, three conditions must be met:

- qualitative preparation of the treated surface;

- good building mix;

- accurate beacons.

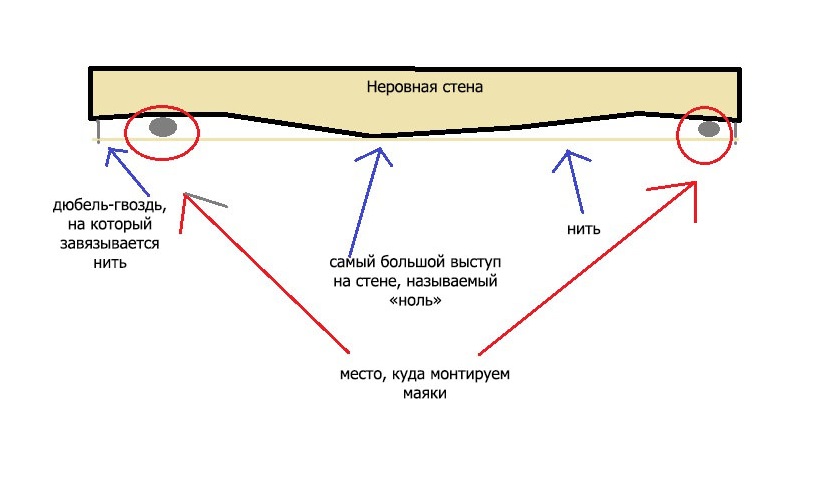

To level a brick wall, it is besta cement-based building mixture will do. Since its cost is low in comparison with others, it will not be difficult to use it. It is also important for brick walls that such mixtures can be applied in a fairly thick layer. You can start using a plaster mesh for reinforcing the composition with a thickness exceeding 2 cm. If you need to plaster a smooth concrete wall, it is best to use a gypsum-based mixture, such mixtures are called leveling. As a rule, these mixtures include small particles of quartz, which makes the wall covered with them rough and improves adhesion. Before starting work, the surface must be primed, and if reinforcement is planned, it is carried out with a special mesh, the cell size of which is 5x5 cm. In order to treat the surface of foam concrete, gypsum mixtures or cement-based compositions are most often used. Such walls must be primed, but there is no need to add quartz to the primer, since foam concrete is quite rough in itself. The tongue and groove slabs used for the construction of partitions are plastered after applying a regular primer with a gypsum mixture. To determine the readiness of the surface for applying the plaster mixture, there is the installation of beacons. Return to the table of contents</a>Beacons and their installation on the wall Scheme of plastering a wall using beacons.In construction, beacons are special guides that help control the alignment of the surface when liquid mixtures are used for this. A perforated profile can serve as a beacon for plaster, and its width will depend on the volume of the mixture applied to the wall. Beginners in this matter are better off using special purchased beacons. Such consumables do not need to be removed after the work is done, and there is no need to mask the depressions that appear after their removal. Beacons are installed on specially applied strips of quick-hardening mortar or mixture, with which plastering will be done. It is necessary to determine the distance between all the beacons. It is determined using a rule and taking into account its dimensions. The edges of the rule should rest, without slipping, on two beacons. Return to the table of contents</a>How should plaster be applied?Using a trowel, an intentionally excessive amount of mixture, called a trowel, is placed in the space between the two beacons. A tool called a falcon is used for this: it has a handle just like the trowel and generally resembles it, but the base is much larger than the trowel base.

Scheme of plastering a wall using beacons.In construction, beacons are special guides that help control the alignment of the surface when liquid mixtures are used for this. A perforated profile can serve as a beacon for plaster, and its width will depend on the volume of the mixture applied to the wall. Beginners in this matter are better off using special purchased beacons. Such consumables do not need to be removed after the work is done, and there is no need to mask the depressions that appear after their removal. Beacons are installed on specially applied strips of quick-hardening mortar or mixture, with which plastering will be done. It is necessary to determine the distance between all the beacons. It is determined using a rule and taking into account its dimensions. The edges of the rule should rest, without slipping, on two beacons. Return to the table of contents</a>How should plaster be applied?Using a trowel, an intentionally excessive amount of mixture, called a trowel, is placed in the space between the two beacons. A tool called a falcon is used for this: it has a handle just like the trowel and generally resembles it, but the base is much larger than the trowel base. Tools for leveling walls.The plaster is collected from the container with a hawk, and then dropped onto the wall between the beacons using a trowel. This tool saves time and increases productivity, since it is not necessary to return to the container with the putty too often. The solution is distributed on the wall in the direction from the bottom up using a rule. If it is necessary to apply a massive layer of plaster at once, the rough coat is not leveled on site. Then, when this rough layer dries, another coat is applied on top of it, this time the finishing version, leveling it in the same way using a rule. Return to the table of contents</a>

Tools for leveling walls.The plaster is collected from the container with a hawk, and then dropped onto the wall between the beacons using a trowel. This tool saves time and increases productivity, since it is not necessary to return to the container with the putty too often. The solution is distributed on the wall in the direction from the bottom up using a rule. If it is necessary to apply a massive layer of plaster at once, the rough coat is not leveled on site. Then, when this rough layer dries, another coat is applied on top of it, this time the finishing version, leveling it in the same way using a rule. Return to the table of contents</a>

Alignment of walls with putty

To putty the walls you will need:

- solution;

- water;

- primer;

- capacity;

- level;

- grinding machine;

- putty knife.

Scheme of correct surface puttying.The surface must also be primed before carrying out this type of repair. This method of leveling walls is not always applicable. It is possible to achieve a smooth surface suitable for painting or further finishing using putty only if the wall was initially quite smooth and the height differences on it were small. Under other repair conditions, putty can be used, but as a finishing touch after all other leveling operations. It is preferable to use several spatulas (wide and narrow), and you will also need a special tray with a narrow bottom. The mixture is mixed to such a consistency that the cone formed in the center of the container when stirred with a stick retains a constant shape. The putty hardens quite quickly, so during the application process it will be necessary to dilute it several times with water or a special primer. The required consistency of the mixture is also determined using a spatula, since it does not slip off it, holding in a vertical position. When the putty for repair is properly prepared and placed in a tray, it needs to be covered, thus preventing it from drying too quickly. A small amount of the mixture is applied to the wall surface with a spatula in small strokes. The putty needs to be leveled so that its layer is 1-2 mm. This is done with movements in a horizontal direction, with great care.

Scheme of correct surface puttying.The surface must also be primed before carrying out this type of repair. This method of leveling walls is not always applicable. It is possible to achieve a smooth surface suitable for painting or further finishing using putty only if the wall was initially quite smooth and the height differences on it were small. Under other repair conditions, putty can be used, but as a finishing touch after all other leveling operations. It is preferable to use several spatulas (wide and narrow), and you will also need a special tray with a narrow bottom. The mixture is mixed to such a consistency that the cone formed in the center of the container when stirred with a stick retains a constant shape. The putty hardens quite quickly, so during the application process it will be necessary to dilute it several times with water or a special primer. The required consistency of the mixture is also determined using a spatula, since it does not slip off it, holding in a vertical position. When the putty for repair is properly prepared and placed in a tray, it needs to be covered, thus preventing it from drying too quickly. A small amount of the mixture is applied to the wall surface with a spatula in small strokes. The putty needs to be leveled so that its layer is 1-2 mm. This is done with movements in a horizontal direction, with great care. Wall alignment diagram.The spatula for repairs must be held at an angle, remembering that the greater the angle of inclination of the spatula to the surface, the thinner the layer remaining on the wall will be. For beginners, it is useful to hold the spatula blade with the other hand for greater convenience. After the mixture has set, it is washed using a primer. This removes irregularities and drips. Leave it to dry for at least a day, and then sand it using zero sandpaper and removing all roughness. A second layer is applied, if necessary, but the putty surface must be primed before this. It is forbidden to apply a second layer without a primer, since even the thinnest layer of putty can cause cracking when moisture is absorbed into the previously applied hardened mixture. Then wait another day and sand the walls, using sandpaper wound on a block or a special grinding wheel. Return to the table of contents</a>

Wall alignment diagram.The spatula for repairs must be held at an angle, remembering that the greater the angle of inclination of the spatula to the surface, the thinner the layer remaining on the wall will be. For beginners, it is useful to hold the spatula blade with the other hand for greater convenience. After the mixture has set, it is washed using a primer. This removes irregularities and drips. Leave it to dry for at least a day, and then sand it using zero sandpaper and removing all roughness. A second layer is applied, if necessary, but the putty surface must be primed before this. It is forbidden to apply a second layer without a primer, since even the thinnest layer of putty can cause cracking when moisture is absorbed into the previously applied hardened mixture. Then wait another day and sand the walls, using sandpaper wound on a block or a special grinding wheel. Return to the table of contents</a>

Repair of walls with plasterboard

Scheme of leveling walls with plasterboard on glue.This method is also called frame and is used in cases where repair of large potholes on walls in another way is impossible or undesirable. This repair option is quite effective and low-budget. It is done in frame and frameless ways. For frame repair of walls you will need:

Scheme of leveling walls with plasterboard on glue.This method is also called frame and is used in cases where repair of large potholes on walls in another way is impossible or undesirable. This repair option is quite effective and low-budget. It is done in frame and frameless ways. For frame repair of walls you will need:

- drywall;

- profile;

- self-tapping screws;

- drill;

- Screwdriver;

- level.

If the frame method is used, then firstA frame is assembled around the walls. Then, plasterboard sheets are attached to it. The frame is assembled from a metal profile and can be of two types: guide or rack. Since a timber frame is considered short-lived, prone to deformation, deterioration from moisture and exposure to microorganisms, a metal profile is more often used for repairs. It is also much easier to install than a wooden one. To construct the frame, guide profiles are attached parallel to each other to the ceiling. Then, guides are installed based on the width of the plasterboard sheet (every 40-60 cm). If necessary, insulation is carried out using mineral wool or any other insulation. When the frame is fully assembled, the plasterboard sheets are attached to the metal profile with self-tapping screws. The screw heads should be flush with the surface and thus hidden in the sheet. The frameless method involves gluing plasterboard sheets directly to the surface that requires repair. To carry it out, only material and glue suitable for the surfaces to be glued are required. This method cannot be used to repair walls with large defects, this is the disadvantage of frameless repair. You can use plywood or plastic panels for this, since the fastening of these materials is no different from the fastening of plasterboard. Even walls are the main condition for an ideal repair, so the choice of repair method should be taken seriously.</ ul>