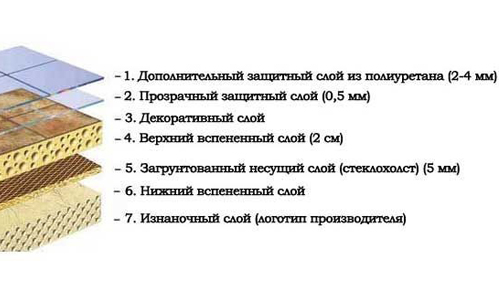

Commercial linoleum is a widely available material on construction markets. Scheme of linoleum composition. Laying commercial linoleum is a special technological process, since it is used intensively in public spaces:

Scheme of linoleum composition. Laying commercial linoleum is a special technological process, since it is used intensively in public spaces:

- in production premises;

- in places of public catering;

- in offices;

- in schools.

Laying commercial linoleum involves performing certain types of work.

Tools and materials for styling

When laying commercial linoleum, you will need the following materials: Tools for laying linoleum.

Tools for laying linoleum.

- linoleum;

- slats for joints;

- putty;

- glue;

- Scotch tape bilateral;

- Screws;

- trailing edge;

- nails;

- cold welding.

In order to carry out the work efficiently, the following tools are required:

- equipment for hot welding;

- standard small spatula;

- a hammer;

- wall marker;

- notched trowel;

- special ice rink;

- marker for marking;

- knife for flooring;

- ruler.

Return to Contents</a>

Preparation for laying commercial linoleum

Once the type of linoleum has been selected, it is necessaryBefore laying it, prepare the surface. If linoleum is laid on a base with defects, this will significantly reduce the service life of the material. On a flat surface, linoleum will last about 25 years, and on a defective one - no more than 5. Thus, in order to increase the service life of the coating, it is necessary to level the surface. To do this, cracks and dents are puttied, and elevations are knocked down. Preparing the subfloor before layinglinoleum. The technology of laying commercial linoleum involves gluing it to the floor surface. In order to ensure high-quality fixation, it is treated in 2 layers with a primer, which is characterized by deep penetration. This procedure will provide increased adhesion of the surface. As a rule, commercial linoleum is laid on a concrete base. However, it can also be laid on tiles or parquet. In addition, laying on a wooden floor is permissible, but it must first be covered with chipboard. Regardless of the base, it must be:

Preparing the subfloor before layinglinoleum. The technology of laying commercial linoleum involves gluing it to the floor surface. In order to ensure high-quality fixation, it is treated in 2 layers with a primer, which is characterized by deep penetration. This procedure will provide increased adhesion of the surface. As a rule, commercial linoleum is laid on a concrete base. However, it can also be laid on tiles or parquet. In addition, laying on a wooden floor is permissible, but it must first be covered with chipboard. Regardless of the base, it must be:

- clean;

- dry;

- smooth.

Only if these conditions are met will the linoleum lie flat and firmly and last for decades. Return to contents</a>

Roll-out, trimming and fixing

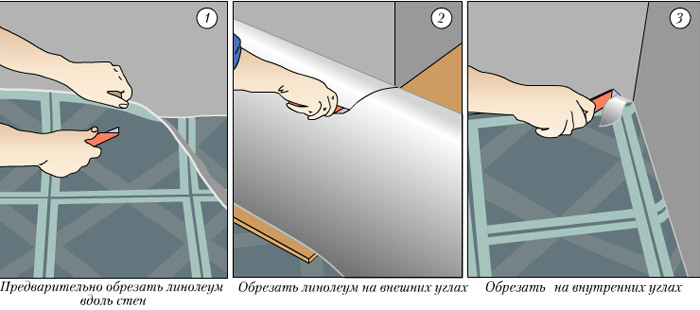

Before you start rolling out the canvases,It is necessary to keep the rolls on the prepared base for 24 hours. After this, the canvas is spread over the entire surface and overlaps are made on the walls of 5-6 cm, and at the joints - 1-2 cm. The material must be allowed to lie down so that the waves that arise due to the tension in the roll of material are smoothed out. The linoleum is finally cut after it is completely straightened. Trimming linoleum.The strips should be cut only at the angle between the floor and the wall. Both layers are cut at the joints of the strips along a straight ruler so that there are no gaps. Then make vertical cuts along the corners of the walls to the floor and align the resulting tongues. Laying requires accuracy and constant checking of the correct position of the linoleum. If you cut off an extra 2 cm, it will be impossible to hide such a defect; a new strip will be needed. Next, you need to bend the trimmed strips in the longitudinal direction by half. A special fixing glue is applied to the freed space on the floor surface. The use of other adhesives will entail poor gluing, which will lead to the formation of air bubbles between the linoleum and the floor. It is best to apply the glue with a spatula (step size - 1-2.5 mm). Its use allows you to distribute the glue evenly and use it economically. The glue should be applied in semicircular movements, holding the spatula at an angle of 30 °. After the fixing compound has been applied, it is left for some time for technical maturation and evaporation of excess moisture for about 15-30 minutes. After the glue has acquired the required consistency, the linoleum is rolled out sequentially, starting from the middle.

Trimming linoleum.The strips should be cut only at the angle between the floor and the wall. Both layers are cut at the joints of the strips along a straight ruler so that there are no gaps. Then make vertical cuts along the corners of the walls to the floor and align the resulting tongues. Laying requires accuracy and constant checking of the correct position of the linoleum. If you cut off an extra 2 cm, it will be impossible to hide such a defect; a new strip will be needed. Next, you need to bend the trimmed strips in the longitudinal direction by half. A special fixing glue is applied to the freed space on the floor surface. The use of other adhesives will entail poor gluing, which will lead to the formation of air bubbles between the linoleum and the floor. It is best to apply the glue with a spatula (step size - 1-2.5 mm). Its use allows you to distribute the glue evenly and use it economically. The glue should be applied in semicircular movements, holding the spatula at an angle of 30 °. After the fixing compound has been applied, it is left for some time for technical maturation and evaporation of excess moisture for about 15-30 minutes. After the glue has acquired the required consistency, the linoleum is rolled out sequentially, starting from the middle. Linoleum laying scheme.The strip of material, which is on the fixing glue, is rolled with rollers (weight 50-68 kg) to press it well to the floor and squeeze out air bubbles. The rollers are passed across, starting from the center to the edge. After this, the unglued strip is bent back and the work is repeated. After gluing the linoleum, it is trimmed along the perimeter to provide a thermal gap (1-2 mm). It provides compensation for the thermal expansion of the coating. Return to the table of contents</a>

Linoleum laying scheme.The strip of material, which is on the fixing glue, is rolled with rollers (weight 50-68 kg) to press it well to the floor and squeeze out air bubbles. The rollers are passed across, starting from the center to the edge. After this, the unglued strip is bent back and the work is repeated. After gluing the linoleum, it is trimmed along the perimeter to provide a thermal gap (1-2 mm). It provides compensation for the thermal expansion of the coating. Return to the table of contents</a>

Welding seams of commercial linoleum

requires complete insulation of the seams. For this purpose, they resort to welding the joints. It can be:

- cold;

- hot.

The choice of welding method depends on:

- complexity of the seam;

- type linoleum.

Return to Contents</a>Hot welding of seams Hot welding of jointsis used quite often in the process of laying linoleum, as it provides the strongest mechanical joint. In addition, this method is used if the sheets will subsequently be subject to intensive use. In the process of laying with hot welding, the following are used:

- A special compressor that pumps air into the heating elements;

- filler rods;

- welding torch.

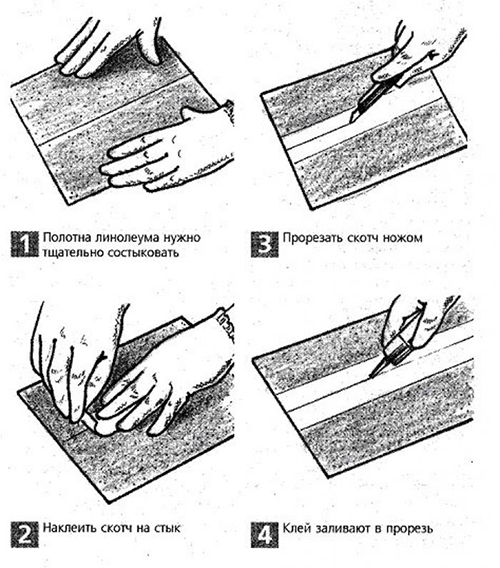

Welding of joints is carried out after high-qualitylaying linoleum on the base. Hot welding with a filler rod is more like soldering, since hot air cannot melt the natural coating. Filler rods are a melting polymer that fills the pores of the linoleum in a molten state and seals them after hardening. The edges of the linoleum melt along with the rods, becoming a single whole. Return to contents</a>Cold welding of seams Scheme of cold welding of linoleum.Quite often, cold welding is used in the process of laying the coating. Its main advantage is that you can do it yourself, while hot welding requires the help of specialists. The following types of glue are used for welding:

Scheme of cold welding of linoleum.Quite often, cold welding is used in the process of laying the coating. Its main advantage is that you can do it yourself, while hot welding requires the help of specialists. The following types of glue are used for welding:

- Type A - ideal for processing joints of newly laid linoleum;

- Type C is suitable for joints of coverings that have been in place in the room for some time.

The difference between the types of glue lies in their consistency.So, the action of glue A is similar to welding the coating - it melts the edges of the linoleum and fastens them. Glue C is thick, pouring between the sheets, it fixes them, filling the gap. The procedure for cold welding type A:

- Wear gloves;

- Clean the seam from the dirt, dry it if there is moisture in it;

- On the edges of the sheets, a single-sided adhesive tape is glued to the joint;

- adhesive tape is cut with a sharp blade in the seam areas;

- apply glue (to collect excess glue the tip turns into a cotton swab), the glue band should protrude about 4 mm from the surface of the strip;

- After 10 minutes, the scotch is removed.

Cold welding procedure type C:

- Wear gloves;

- the joint is cleaned;

- glue is applied, after 30 minutes you can use the coating.

Commercial linoleum does not require special treatment.care, but some rules must be followed. To avoid cracking and fading of the surface, do not use active cleaning agents. In order to avoid having to re-lay commercial linoleum, it is advisable to put special caps on the furniture legs that will not scratch, press or tear it. Thus, the technology of laying commercial linoleum consists of certain sequential procedures. It is best to seek help from professionals who know all the nuances of laying commercial linoleum.