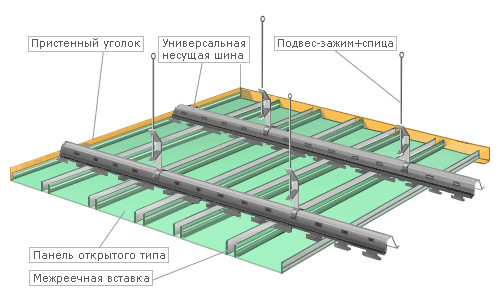

The modern market offers a wide varietybuilding materials for finishing walls and ceilings. The most popular and inexpensive option for finishing are PVC or MDF panels, which can be used for both walls and ceilings. Do-it-yourself ceiling installation from panels is quite simple, therefore, knowing the basic rules for finishing work, you can learn this business in a short time. Scheme of a slatted panel ceiling.PVC panels have one feature, which is their main drawback, fragility. Moreover, PVC ceiling panels are more fragile than wall panels, so they require more careful handling. The variety of colors and textures is very large, so choosing them for a specific interior will not be difficult. There can be both matte and glossy surfaces of panels, or with a decorative ornament. Everything depends on the design of your room, your desires and preferences. The quality of the materials from which the panels are made is very diverse. Therefore, in order to choose a high-quality finishing material, you need to follow the basic rules of selection.

Scheme of a slatted panel ceiling.PVC panels have one feature, which is their main drawback, fragility. Moreover, PVC ceiling panels are more fragile than wall panels, so they require more careful handling. The variety of colors and textures is very large, so choosing them for a specific interior will not be difficult. There can be both matte and glossy surfaces of panels, or with a decorative ornament. Everything depends on the design of your room, your desires and preferences. The quality of the materials from which the panels are made is very diverse. Therefore, in order to choose a high-quality finishing material, you need to follow the basic rules of selection. Scheme of installation of PVC panels on the ceiling.

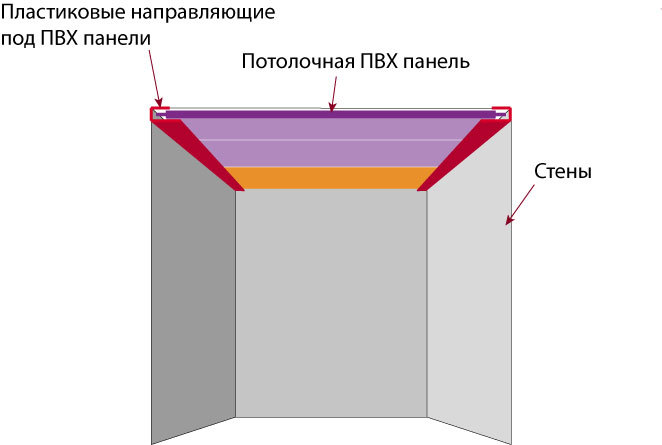

Scheme of installation of PVC panels on the ceiling.

How to calculate the required amount of material?

To install the ceiling yourself,you need to calculate the number of panels you will need. First, you need to measure the area of the ceiling, which is easy to do with a manual or laser tape measure, if you have one. You need to add about 20% to the resulting area. This is done to compensate for the number of panels that will be defective or damaged during installation. To calculate the number of profiles, you need to make a drawing of the ceiling. To do this, draw parallel lines along one side of the wall. The distance between the profiles should be 0.5-0.6 m. Every 0.5 meter of the profile will need to be secured with one dowel. To secure the panels, you will also need one dowel for every 0.5 m. To secure the panels themselves, it is recommended to use special clips or self-tapping screws with a large washer. Return to contents</a>

Required tools for installing the ceiling yourself

Tools for installation of panel ceiling.

Tools for installation of panel ceiling.

- roller for painting works;

- electric drill or perforator;

- small hacksaw;

- level;

- roulette;

- Ruler;

- a hammer;

- hacksaw;

- knife.

Before you start finishing, you need to clean itceiling from various peelings and dirt. If there is whitewash on the ceiling, it should be washed off using a sprayer and spatula. It is important that the surface is dry before installation, so some time should pass after such cleaning. After this, it is necessary to apply a primer antifungal coating to prevent mold from forming in the future. There is no need to worry about the harm of such coatings, since they are completely safe for humans, but the presence of mold can cause a number of pulmonary and bronchial diseases in humans. Return to contents</a>

Panel mounting technology

It is recommended to mount plastic panels onmetal profiles, as wood is too susceptible to moisture. At the very beginning of the work, it is necessary to think about how and where the lighting fixtures will be located, and to conduct electrical wiring, since it is extremely impractical to do it later. First of all, fix the U-shaped profile along all sides of the walls of the room using dowels every 0.5 m. The L-shaped profile must be fixed with screws also along the entire perimeter. This structure will be the frame for the main profile, on which the plastic panels will be attached. The panels should be cut as they are attached to the ceiling, and not all at once, since the length of the ceiling may vary. You need to start the installation from the wall of the room, alternately fixing them to the metal profiles using screws with press washers every 0.5-0.6 m. Please note that the panels themselves have special "tongues" for attaching them to the profile. The first panel must be pressed tightly to the L-shaped profile, and the following ones should not be pressed too hard, so as not to damage the joints. Before installing the last panel, measure the remaining distance to the wall from the last fixed panel, leaving a margin of 3-4 mm, since the walls will most likely definitely diverge. After all the panels are fixed, you can proceed to installing the ceiling plinth. To ensure that the corner joints are even, use a construction miter box, which will allow you to make an angle of exactly 45 degrees. The plinth is attached using polyurethane glue, which is applied directly to the plinth. The technology for installing the ceiling plinth must be fully observed. Fastening panels directly to the wall, without using metal profiles, is highly undesirable, because even if your ceiling is visually completely even, it will be extremely difficult to avoid distortions. In addition, such installation will provoke the appearance of fungi and mold on the ceiling, which will be dangerous to your health.