An integral part of the interior is the ceiling.Its design not only supports the chosen style of the room, but can also transform and visually change the geometric dimensions of the room. The huge selection of materials for finishing the ceiling causes confusion among consumers. However, it is the installation of suspended ceilings that makes it possible to implement even the most daring design proposals. Suspended plasterboard ceilings deservedlyoccupy leading positions. Due to plasterboard, it is possible to create a wide variety of structures. Suspended ceilings are divided into several types: stretch ceilings, plasterboard, slatted, made of plastic or wooden panels. Among the listed types of ceiling coverings, the plasterboard ceiling has gained the greatest popularity. This is largely due to the fact that it is quite possible to install suspended plasterboard ceilings with your own hands.

Suspended plasterboard ceilings deservedlyoccupy leading positions. Due to plasterboard, it is possible to create a wide variety of structures. Suspended ceilings are divided into several types: stretch ceilings, plasterboard, slatted, made of plastic or wooden panels. Among the listed types of ceiling coverings, the plasterboard ceiling has gained the greatest popularity. This is largely due to the fact that it is quite possible to install suspended plasterboard ceilings with your own hands.

Necessary materials and tools

In order to install a suspended ceiling fromplasterboard sheets, first of all, a drawing or sketch of the future ceiling is needed, if it is a multi-tiered structure, according to which the calculation of the required material will be performed. If it is supposed to install a single-tier plasterboard ceiling, then the calculation of the number of slabs and other materials comes down to the correct measurement of the ceiling. It should be noted that the sheets can have different moisture resistance characteristics. This should be paid attention to if the room where this ceiling is planned to be installed has high humidity (bathroom). In this case, you should choose moisture-resistant plasterboard. The outer layer of a moisture-resistant plasterboard sheet is painted green. Tools for installing a suspended plasterboard ceiling. In addition to the plasterboard sheets themselves, which should lie on a flat surface in a horizontal position, the following are required for assembly:

Tools for installing a suspended plasterboard ceiling. In addition to the plasterboard sheets themselves, which should lie on a flat surface in a horizontal position, the following are required for assembly:

- metal profiles of various shapes and hangers that are attached to them;

- dowels, self-tapping screws;

- electric drill, suitable and punch, screwdriver;

- scissors for cutting metal;

- building water long level (laser level is also suitable), gon;

- A hacksaw and several canvases for her or a construction knife;

- colored building cord, bright color marker, stepladder.

Since gypsum plasterboards havesignificant weight, as well as a very large size, it is desirable to have an assistant. If there is no such person, then with the help of a mop and a stepladder, the assembly can be done independently. Return to the table of contents</a>

Framework: practical recommendations

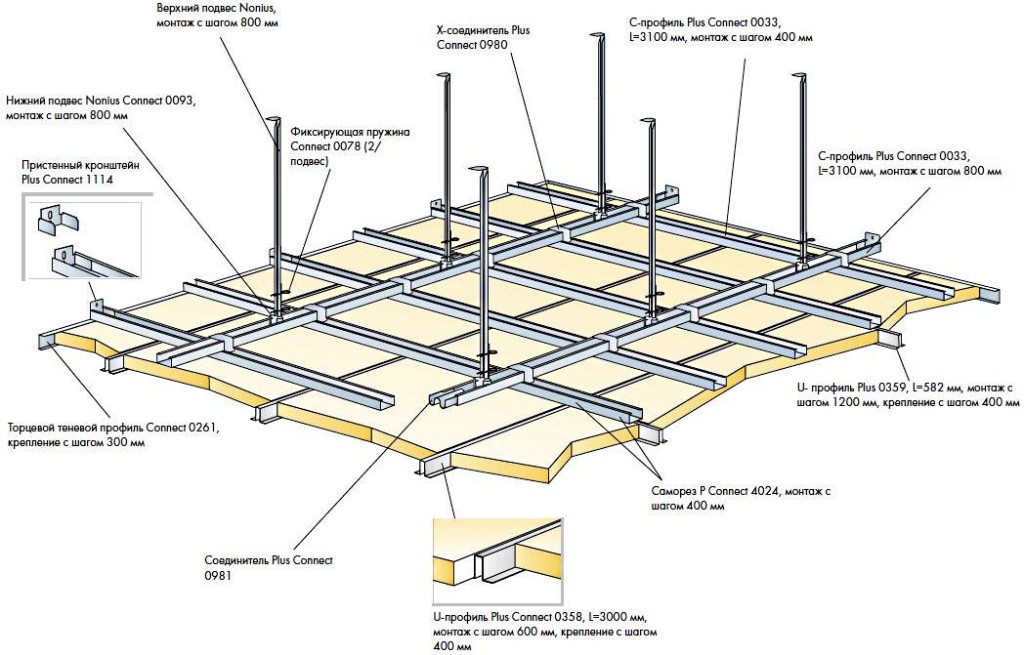

Frame diagram for suspended ceiling.The suspended ceiling is located at a distance from the existing one, which is equal to the sum of the heights of the plasterboard sheet, suspension and profile. When installing built-in lighting fixtures in the future ceiling, it can be additionally lowered by approximately 10 cm or more, depending on the height of the lamps. Installation of the frame should begin with marking the places where the profiles are attached. In addition, the size of the plasterboard sheets should be taken into account, that is, its edges should be on the center line of the profiles, both longitudinal and transverse. If the ceiling cannot be taken as a reference point due to its curvature, then the floor is taken as the zero mark for marking. After marking the corner markings, a horizontal line is beaten off along the entire perimeter using a cord. Then, all fastening of the profiles is carried out along this line. Installation of the profiles begins with drilling holes in the walls, where the profiles will be attached with dowels. To mark the fastening of the profile itself to the ceiling, parallel lines are drawn on it with a step of 50-60 cm. The frame in the form of suspensions will be attached along these lines. The distance between the hangers is 50 cm.

Frame diagram for suspended ceiling.The suspended ceiling is located at a distance from the existing one, which is equal to the sum of the heights of the plasterboard sheet, suspension and profile. When installing built-in lighting fixtures in the future ceiling, it can be additionally lowered by approximately 10 cm or more, depending on the height of the lamps. Installation of the frame should begin with marking the places where the profiles are attached. In addition, the size of the plasterboard sheets should be taken into account, that is, its edges should be on the center line of the profiles, both longitudinal and transverse. If the ceiling cannot be taken as a reference point due to its curvature, then the floor is taken as the zero mark for marking. After marking the corner markings, a horizontal line is beaten off along the entire perimeter using a cord. Then, all fastening of the profiles is carried out along this line. Installation of the profiles begins with drilling holes in the walls, where the profiles will be attached with dowels. To mark the fastening of the profile itself to the ceiling, parallel lines are drawn on it with a step of 50-60 cm. The frame in the form of suspensions will be attached along these lines. The distance between the hangers is 50 cm. Scheme of fastening the profile to the hangers.To drill holes in the ceiling, you will need a drill and a drill bit that matches the ceiling material. The profile is attached to the hangers, checking the horizontal using a building level. The ends of the profile that is attached to the ceiling must be inserted into the profiles fixed to the walls. After fixing, the hanging ends of the hangers are bent towards the old ceiling. The crossbars that connect the parallel profiles give the overall frame structure the necessary rigidity and reliability. The distance between the crossbars is 50-60 cm. As a result of the work performed, a frame of profiles with a square structure is formed on the ceiling. If in the future it is planned to connect lamps, built-in or in the form of central lighting, the laying of the corresponding cables is carried out at this stage. The wires are laid in special metal boxes or pipes for additional insulation. These structures can be attached to the frame with insignificant weight in order to prevent deflections, or to the old ceiling using dowel clamps. The ends of the wires left for connecting the lighting fixtures must be securely insulated. Return to Contents</a>

Scheme of fastening the profile to the hangers.To drill holes in the ceiling, you will need a drill and a drill bit that matches the ceiling material. The profile is attached to the hangers, checking the horizontal using a building level. The ends of the profile that is attached to the ceiling must be inserted into the profiles fixed to the walls. After fixing, the hanging ends of the hangers are bent towards the old ceiling. The crossbars that connect the parallel profiles give the overall frame structure the necessary rigidity and reliability. The distance between the crossbars is 50-60 cm. As a result of the work performed, a frame of profiles with a square structure is formed on the ceiling. If in the future it is planned to connect lamps, built-in or in the form of central lighting, the laying of the corresponding cables is carried out at this stage. The wires are laid in special metal boxes or pipes for additional insulation. These structures can be attached to the frame with insignificant weight in order to prevent deflections, or to the old ceiling using dowel clamps. The ends of the wires left for connecting the lighting fixtures must be securely insulated. Return to Contents</a>

Installation of a suspended ceiling from plasterboard with own hands

Construction of a single-level ceiling made of plasterboard.With the correct calculation of the frame and its installation, the edges of the plasterboard sheets are attached to the middle of the profiles: longitudinal and transverse. If the ceiling configuration requires cutting sheets to non-standard sizes, this can be done with a sharp construction knife, i.e. a cut is made along the applied cutting line. Then the sheet is placed on a flat surface of the table, broken by pressing along the cut, then cut if necessary. You can also use a hacksaw for this, but there will be a lot of gypsum dust when cutting. Fastening of sheets begins from the corner of the room. Self-tapping screws, with which the installation is carried out, are slightly deepened into the sheet. They cannot be deepened too much. Self-tapping screws are screwed in using a screwdriver with a stiffness limiter, it is advisable not to miss the profile. The step between the screws is no more than 20 cm. Fastening is carried out both on longitudinal profiles and on transverse ones. The gaps between the sheets of plasterboard are 2 mm. After finishing the installation of plasterboard sheets, it is necessary to seal the seams and finally putty the ceiling. First, the sheets are treated with a primer. It is applied with a roller and allowed to soak in completely. You can cover the primer several times, tightening the screws if necessary. Then sticky reinforcing tape is glued to the joints, on top of which a special gypsum mixture is applied. It is sold dry and needs to be diluted with water in the proportion indicated on the package. The gypsum putty is applied with a spatula and leveled, preventing the formation of bumps or indentations. After complete hardening, the putty areas are treated with sandpaper, removing all the resulting irregularities. The gaps between the wall and the plasterboard sheet are sealed and treated in the same way. Next, a thin layer of putty is applied to the entire ceiling. After this, it is cleaned with fine sandpaper, bringing the surface of the ceiling to a perfectly smooth condition. After this, the plasterboard ceiling made by yourself is ready for final finishing. Any material can be used as finishing materials - it all depends on the interior style and the purpose of the room. Start the process, and you will definitely succeed. The installation will be quick. Good luck!

Construction of a single-level ceiling made of plasterboard.With the correct calculation of the frame and its installation, the edges of the plasterboard sheets are attached to the middle of the profiles: longitudinal and transverse. If the ceiling configuration requires cutting sheets to non-standard sizes, this can be done with a sharp construction knife, i.e. a cut is made along the applied cutting line. Then the sheet is placed on a flat surface of the table, broken by pressing along the cut, then cut if necessary. You can also use a hacksaw for this, but there will be a lot of gypsum dust when cutting. Fastening of sheets begins from the corner of the room. Self-tapping screws, with which the installation is carried out, are slightly deepened into the sheet. They cannot be deepened too much. Self-tapping screws are screwed in using a screwdriver with a stiffness limiter, it is advisable not to miss the profile. The step between the screws is no more than 20 cm. Fastening is carried out both on longitudinal profiles and on transverse ones. The gaps between the sheets of plasterboard are 2 mm. After finishing the installation of plasterboard sheets, it is necessary to seal the seams and finally putty the ceiling. First, the sheets are treated with a primer. It is applied with a roller and allowed to soak in completely. You can cover the primer several times, tightening the screws if necessary. Then sticky reinforcing tape is glued to the joints, on top of which a special gypsum mixture is applied. It is sold dry and needs to be diluted with water in the proportion indicated on the package. The gypsum putty is applied with a spatula and leveled, preventing the formation of bumps or indentations. After complete hardening, the putty areas are treated with sandpaper, removing all the resulting irregularities. The gaps between the wall and the plasterboard sheet are sealed and treated in the same way. Next, a thin layer of putty is applied to the entire ceiling. After this, it is cleaned with fine sandpaper, bringing the surface of the ceiling to a perfectly smooth condition. After this, the plasterboard ceiling made by yourself is ready for final finishing. Any material can be used as finishing materials - it all depends on the interior style and the purpose of the room. Start the process, and you will definitely succeed. The installation will be quick. Good luck!