Plywood as a finishing material optionis in great demand among consumers. It provides not only a stable base, but also an excellent soundproofing plane, while pleasing with absolute cleanliness from an environmental point of view and a smooth surface. For this reason, this type of material will always be popular. It will complement the appearance of any room and become its decoration. Plywood is an environmentally friendly material.It is used both for soundproofing and for decorating ceilings. Plywood is distinguished by its affordable price and high degree of decoration, which allows it to compete with any expensive materials. Covering plywood ceilings with your own hands is not as difficult as it may seem. Taking into account the technical characteristics of this raw material, it is quite possible to compare it with plasterboard panels. Plywood has many advantages, among which the following can be highlighted:

Plywood is an environmentally friendly material.It is used both for soundproofing and for decorating ceilings. Plywood is distinguished by its affordable price and high degree of decoration, which allows it to compete with any expensive materials. Covering plywood ceilings with your own hands is not as difficult as it may seem. Taking into account the technical characteristics of this raw material, it is quite possible to compare it with plasterboard panels. Plywood has many advantages, among which the following can be highlighted:

Very often it is difficult for consumersdecide on the dimensions of the finished plywood sheets. This material is produced in square or rectangular sheets. The maximum figures will be 3600-1500 mm.

Varieties of plywood for moisture resistance

It is important to know that plywood is distinguished not only bydimensions, but also technical and physical indicators. An important property is resistance to moisture. Taking into account the latter characteristic, the following categories can be distinguished: Types of plywood.

Types of plywood.

So, for the arrangement of the ceiling in the room the ideal option will be plywood FK, for the construction of furniture - FOF. Return to the table of contents</a>

Types of plywood by type of materials

Plywood can be made from materials such as:

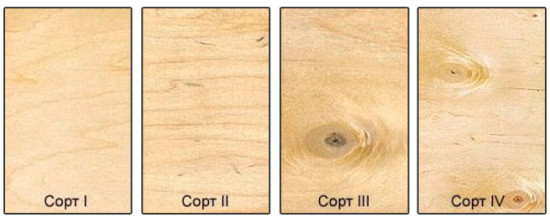

Plywood grades. Each of the presented categories has its own characteristics, which are taken into account when choosing a material:

Plywood grades. Each of the presented categories has its own characteristics, which are taken into account when choosing a material:

- birch has a very strong base and an incredibly attractive appearance, pleasant colors and original structure;

- it does not appear fungi, mold, insect pests.

Return to Contents</a>

Facing the ceiling with plywood

In order to construct a plywood ceiling, a number of preliminary procedures must be completed:

- prepare the plane;

- to estimate the location of strata on the ceiling;

- count the parameters of cutting elements;

- appoint a procedure for conducting cases for the construction and installation of a crate;

- decide on the plywood seams.

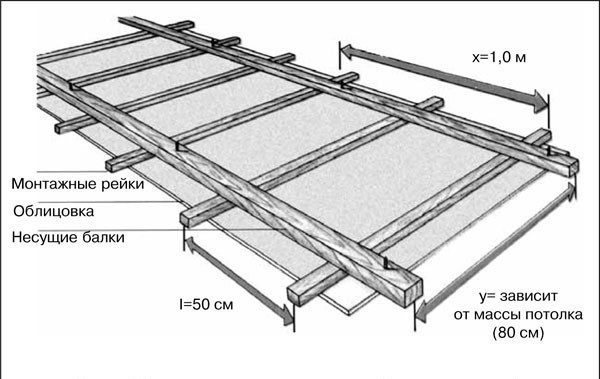

You can finish the ceiling with plywood only if you have a supply of the necessary tools and materials: Scheme of ceiling sheathing with plywood: I – distance between mounting rails; x – distance of fastening of supporting rails to the ceiling; y – distance between supporting beams.

Scheme of ceiling sheathing with plywood: I – distance between mounting rails; x – distance of fastening of supporting rails to the ceiling; y – distance between supporting beams.

Before starting any work, you should carefullycalculate the amount of the source consumed. To avoid problems with changing the appearance of the structure in the future, it is securely fastened to the lathing. In this way, bending and delamination of the base can be avoided. Here, the following facts must be taken into account:

- Single parts are fixed in the central area of the ceiling;

- edges make out parts of plywood.

The lathing is installed in the following order:

Return to Contents</a>

Installation of plywood sheets

Before the main eventsit is necessary to install plywood layers on the ceiling. This activity should be done slowly - otherwise the surface will be unsightly, with an uneven surface. All actions are carried out according to the following scheme: It is recommended to lay the plywood sheets slowly so that the ceiling turns out beautiful and even.

It is recommended to lay the plywood sheets slowly so that the ceiling turns out beautiful and even.

As soon as all the listed works are completedcarried out, it is necessary to paint the surface. Using a relatively inexpensive material, such as plywood, in your work, you can get a perfectly smooth base with a natural and representative appearance. Plywood harmonizes perfectly with any environment, complementing and decorating the interior. This type of coating allows any method of further finishing.</ ul>