To make flooring, oftenuse plywood. This material is suitable for roughing and basic coating. With it, you can quickly enough without spending a lot of money, if necessary, to level the floor. Making the floors of plywood with your own hands, you have to answer natural questions, what type of plywood is most suitable for sex and its foundation? What are the methods of laying this material?  For each type of plywood, there is a different methodlaying the material on the floor. First of all, it is required to determine the type of plywood. The main role here is played by floor covering. For an ordinary apartment one-sided polished plywood is suitable. The most suitable is 12 mm plywood. This layered material is glued together with compounds that do not contain toxic substances. The best option for coating the base floor will be the E1 grade, with a low formaldehyde content. After selecting the material, you should determine the way in which it will be laid. The most economical, not requiring much time is considered to be laying directly on the concrete foundation. It is best to use a material with a thickness exceeding 12 mm. Another popular way was to install a plywood floor directly on the wooden surface, so it turns out the rough floor. Self-tapping screws are used to fix the plywood coating.

For each type of plywood, there is a different methodlaying the material on the floor. First of all, it is required to determine the type of plywood. The main role here is played by floor covering. For an ordinary apartment one-sided polished plywood is suitable. The most suitable is 12 mm plywood. This layered material is glued together with compounds that do not contain toxic substances. The best option for coating the base floor will be the E1 grade, with a low formaldehyde content. After selecting the material, you should determine the way in which it will be laid. The most economical, not requiring much time is considered to be laying directly on the concrete foundation. It is best to use a material with a thickness exceeding 12 mm. Another popular way was to install a plywood floor directly on the wooden surface, so it turns out the rough floor. Self-tapping screws are used to fix the plywood coating.

How to properly lay plywood?

Before you start, you need to make plywoodpassed the period of acclimatization. She is left in the apartment for at least 1 day. If the storage conditions in the warehouse are very different from the apartment ones, the acclimatization of the material should take place within 3 days.  Layout of plywood laying on the floor. The moisture resistance of plywood, when necessary, can be increased. It is impregnated with putty, made on the basis of polyvinyl acetate. First impregnate only one side and wait for the appearance of spots on the opposite. Then the reverse side is also impregnated. This plywood is dried, set horizontally and left for 3 days. The dried plywood is treated with an antiseptic. Before starting to lay the prepared material, it is necessary to measure the moisture content of the substrate. Take the plastic film and put it on 1 m² of the base, the edges are pressed with the load, the middle part should be slightly raised. If there is condensation inside the film within 24 hours, you can not install plywood in this room. If a small condensate was formed after 3 days, a parchment is placed on the main floor, a mounting net is installed and a screed is made. If the appearance of condensate is not found after 5 days, we can safely do plywood floor. Back to contents</a>

Layout of plywood laying on the floor. The moisture resistance of plywood, when necessary, can be increased. It is impregnated with putty, made on the basis of polyvinyl acetate. First impregnate only one side and wait for the appearance of spots on the opposite. Then the reverse side is also impregnated. This plywood is dried, set horizontally and left for 3 days. The dried plywood is treated with an antiseptic. Before starting to lay the prepared material, it is necessary to measure the moisture content of the substrate. Take the plastic film and put it on 1 m² of the base, the edges are pressed with the load, the middle part should be slightly raised. If there is condensation inside the film within 24 hours, you can not install plywood in this room. If a small condensate was formed after 3 days, a parchment is placed on the main floor, a mounting net is installed and a screed is made. If the appearance of condensate is not found after 5 days, we can safely do plywood floor. Back to contents</a>

Features of preparation

Tools for leveling the floor For work you need to have special tools:

Tools for leveling the floor For work you need to have special tools:

- perforator;

- Screwdriver;

- laser level;

- a hammer;

- electric jigsaw;

- long roulette.

First standard sheets are sawn tosquares, with them it will be much easier to work with. The edges of the plywood after sawing must not be chipped. Square sheets need to be adjusted taking into account damping seams. The gap between the sheets should be less than 10 mm. A tight fit to the wall of plywood sheets is not allowed, it is necessary to maintain a clearance of 15 mm. When the sheets are laid out on the floor, they need to be numbered, or draw a sketch of the laying. The next stage is the cleaning of the concrete base. When performing this operation, the concrete base must be protected from any ingress of moisture. It must always be remembered that humidity is the worst enemy of plywood.  Use of plywood as a rough floor. The simplest and most accessible way, which makes it possible to conduct the preparation of the base to put the floor covering, is the leveling of the plywood of the existing wooden floor. This is a kind of option, the most accessible for execution by own hands. There are also several technologies for plywood leveling when used in bulk mixtures. But this work is the most laborious. It is not at all necessary to dismantle the old boards in the apartment in order to prepare the floor and install a new coating. Any person can cope with such work. He does not need to have a great experience of home repair. Before you begin to mount the plywood sheets, you need to remove all defects in the base. All the loosened boards are fastened with screws. The boards that have completely dried out are best replaced, since later the floors will begin to creak. After preparing the rough foundation, you can begin to mount the plywood. The optimum thickness of used plywood sheets is 12 mm. Such a floor will have an even, reliable surface. From the last class of plywood is a rough draft. This material should have an increased moisture resistance. Back to contents</a>

Use of plywood as a rough floor. The simplest and most accessible way, which makes it possible to conduct the preparation of the base to put the floor covering, is the leveling of the plywood of the existing wooden floor. This is a kind of option, the most accessible for execution by own hands. There are also several technologies for plywood leveling when used in bulk mixtures. But this work is the most laborious. It is not at all necessary to dismantle the old boards in the apartment in order to prepare the floor and install a new coating. Any person can cope with such work. He does not need to have a great experience of home repair. Before you begin to mount the plywood sheets, you need to remove all defects in the base. All the loosened boards are fastened with screws. The boards that have completely dried out are best replaced, since later the floors will begin to creak. After preparing the rough foundation, you can begin to mount the plywood. The optimum thickness of used plywood sheets is 12 mm. Such a floor will have an even, reliable surface. From the last class of plywood is a rough draft. This material should have an increased moisture resistance. Back to contents</a>

The technology used for the plywood leveling process

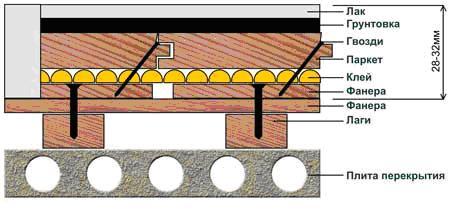

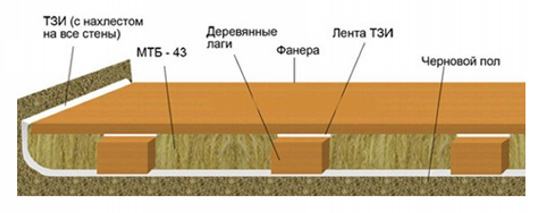

When laying plywood directly on theconcrete screed, because of the lack of a wooden base, it is necessary to find out what is the moisture content of the existing concrete surface. High humidity can spoil the coating. Tighten the top with a waterproofing substrate. How to determine the moisture content of concrete was described above.  The device of a floor from plywood. There is also a technology in which plywood is leveled using lags. For this purpose, a frame made of wooden slats on a special technology is pre-assembled on a concrete floor in advance. After the concrete screed has been carefully dried, the wooden floor is well reinforced, it is necessary to cut the plywood sheets. In stores, sheets of plywood are sold with dimensions of 1.5x1.5 m. It should be noted that it is not advisable to use sheets of large dimensions. To carry out the alignment of plywood, you need to cut it into certain squares. Each sheet is divided into 4 small squares. The cut sheets are laid all over the floor, but they do not attach. This is necessary to determine the amount of material for the entire floor area. On the laid out sheets it is easy to make marks on the plywood, which will need to be pruned. Between the sheets fixed on the floor, small gaps should be maintained. Usually the width of the seam reaches 10 mm. When installing, do not allow the plywood sheets to be mounted directly to the wall. The gap between the wall and the last plywood sheet should reach 2 cm. This makes it possible for the floor to acquire "breath", which will prevent deformations of the overlays depending on the seasonal time. The cooked sheets are fastened according to the type of chess order, similar to brickwork. The installed surface must be polished. After such an operation, the plywood floor becomes an ideal base to put any coating on it.

The device of a floor from plywood. There is also a technology in which plywood is leveled using lags. For this purpose, a frame made of wooden slats on a special technology is pre-assembled on a concrete floor in advance. After the concrete screed has been carefully dried, the wooden floor is well reinforced, it is necessary to cut the plywood sheets. In stores, sheets of plywood are sold with dimensions of 1.5x1.5 m. It should be noted that it is not advisable to use sheets of large dimensions. To carry out the alignment of plywood, you need to cut it into certain squares. Each sheet is divided into 4 small squares. The cut sheets are laid all over the floor, but they do not attach. This is necessary to determine the amount of material for the entire floor area. On the laid out sheets it is easy to make marks on the plywood, which will need to be pruned. Between the sheets fixed on the floor, small gaps should be maintained. Usually the width of the seam reaches 10 mm. When installing, do not allow the plywood sheets to be mounted directly to the wall. The gap between the wall and the last plywood sheet should reach 2 cm. This makes it possible for the floor to acquire "breath", which will prevent deformations of the overlays depending on the seasonal time. The cooked sheets are fastened according to the type of chess order, similar to brickwork. The installed surface must be polished. After such an operation, the plywood floor becomes an ideal base to put any coating on it.