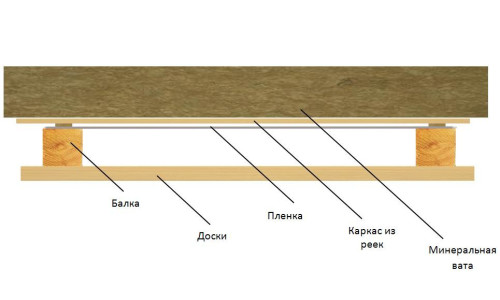

Installation helps to decorate the interior.The most popular are false wooden ceilings. The design got its name due to the way the panels are attached from below to the ceiling. They are installed in rooms with wooden and concrete floors. Scheme of the device of a wooden ceiling.

Scheme of the device of a wooden ceiling.

Basic Techniques

Experts highlight several technologiesmanufacturing of such structures. The most famous are false and coffered ceilings. The first option uses clapboard or Euro lining. The boards are made of linden, coniferous wood or oak. They are attached to the frame of the ceilings and connected with a tongue and groove. The design resembles the cladding of the ceiling with clapboard, but instead of individual boards, whole panels are attached. Decorative ceilings are made of panels. The structures are covered with veneer made of expensive wood and have an attractive appearance. A relief false ceiling is constructed from split timber. A rectangular blank is split lengthwise and attached to the frame with a smooth surface. With the help of visible chips, a unique pattern is formed on the ceiling. Coffered structures are assembled from box-shaped modules, which are called caissons. Their production technology is the most complex, and the appearance of the finished structure is spectacular. Experts highlight the following advantages of such finishing: Ceiling design options.

Ceiling design options.

- Durability in the presence of appropriate care for timber;

- resistance to environmental influences;

- ecological compatibility: in wood and impregnation toxic substances are not contained;

- high degree of sound and heat insulation;

- attractiveness: experts do not recommend painting the wood, it is opened with a colorless varnish.

The disadvantages of the design under consideration include:

- exposure to fungi, woodworm beetles: wooden panels must be treated with special formulations;

- flammability: dry wood easily ignites, it is necessary to apply a fireproof mixture;

- high price.

You can save on the cost of the structure if you do the finishing work yourself. Return to contents</a>

Step-by-step instruction

Before you start installing a wooden ceilingcarry out preparatory work. Since after laying the panels the height of the room will decrease by 10-15 cm, experts recommend taking measurements in advance and making sure that the height of the walls in the room allows for such finishing. You will need an electrical wiring plan, which indicates the locations of the lighting fixtures. To install a wooden ceiling, you will need the following materials and tools: Tools for installing wooden ceilings.

Tools for installing wooden ceilings.

- lining of coniferous wood or imitation of timber;

- screws 2,5х25;

- rails 40x20;

- block-house boarding;

- dowel shock 6x60;

- strap;

- fishing line;

- paints and varnishes.

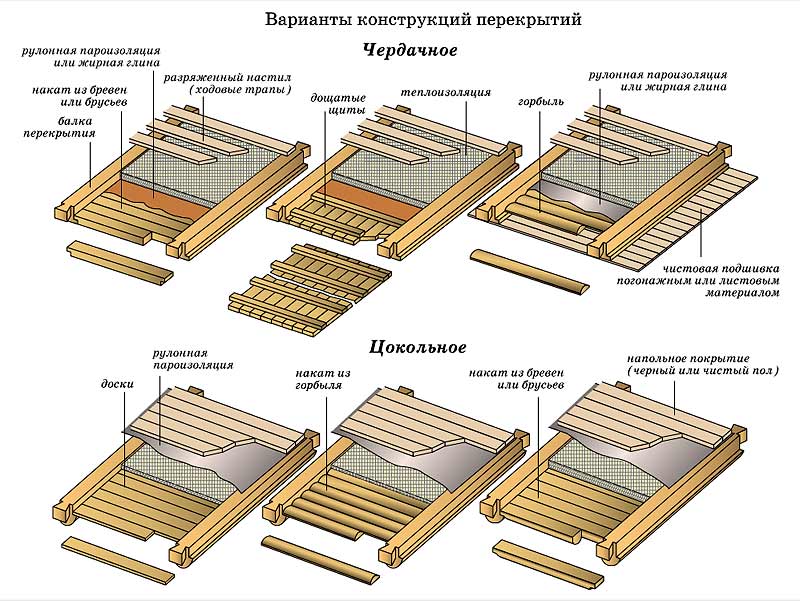

Before finishing work begins, the surfaceis insulated using vapor and waterproofing material, foam, roofing felt or parchment, insulation, slabs, plasterboard or fiberboard and nails. The first stage is to create a vapor barrier layer. Suitable materials for this:

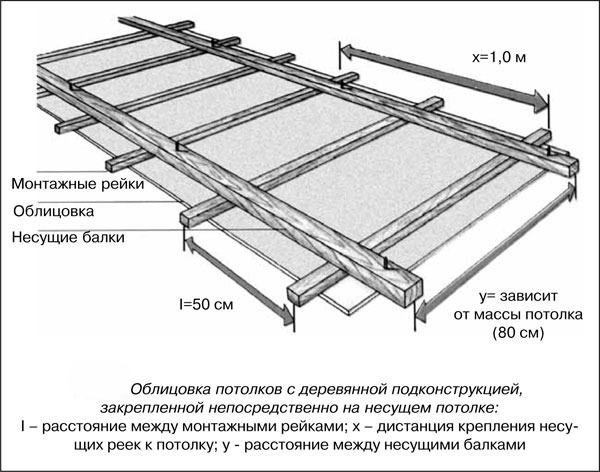

The material is placed between the beams along,overlapping the height of the beam. Fastening is performed with a construction stapler or paper clips. The next step is choosing insulation. For this, you can use glass wool, ecowool, expanded clay, mineral wool and foam. The insulation layer is laid flush with the floor beams. A layer of waterproofing is laid on top. The use of ecowool eliminates the need for a protective film. A board made of slabwood is laid across the beams on the waterproofing layer. Using such a board arrangement allows you to move along it if there is a need to repair the roof, protecting the board from additional loads. Experts advise to insulate the ceiling well in the chimney area if there is no attic, and the chimney duct passes through the attic. It is recommended to use a non-combustible material that can withstand temperatures up to 200 °. The layer of thermal insulation around the entire perimeter of the chimney and at its outlet should be at least 25-30 cm. It is recommended to make an asbestos gasket between the insulation layer and the beams. It is not necessary to lay a layer of insulation if an attic is arranged, but it is recommended to make a layer of sound insulation. For this, dry sand or sawdust mixed with lime are used. Return to contents</a>Lathing and surface finishing SuspendedThe wooden ceiling is attached to a wooden frame. The lathing is mounted with a step between the slats of 30 cm. It is made from a 20x40 mm slat. A fishing line is pulled along the edges and in the center of the ceiling, along which the slats will be attached. Wooden lathing installation diagram.The first plank is placed close to the wall (perpendicular to the boards with standard sheathing across or along the plane). Sheathing at an angle of 45° requires the placement of planks along the entire perimeter. At the points of their attachment, pieces of boards are placed against the joists so that the placement is even. The ceiling is covered after the frame of the slats is installed. It is necessary to determine the length of the boards and cut off the excess. Electrical communications are hidden under the clapboard. Experts advise using a multi-core non-heating copper wire with a power reserve. The structure will be attached to the ceiling panel with an indentation from the walls of 2 mm. Wood is subject to shrinkage, compression and expansion, so the material requires a small space. The clapboard is fixed to the slats with self-tapping screws, which are fastened into its grooves. To avoid protruding nail heads, fastening the cladding to the lathing with high-quality glue helps. To give the interior an unusual look, fastening the paneling with screws with decorative caps helps. After fixing, wooden panels are covered with a layer of paint or varnish. The shade of the paneling is changed with the help of special dyes that give the material a natural shade of walnut, oak or pine, preserving the natural texture of the wood. Experts do not recommend covering the surface with glossy varnishes that make the ceilings shiny, quickly tiring the eyes. The 1st layer of varnish is applied to the surface. After it dries, the coating is treated with fine-grained sandpaper (to eliminate lint and air bubbles). The procedure must be repeated 2-3 times.

Wooden lathing installation diagram.The first plank is placed close to the wall (perpendicular to the boards with standard sheathing across or along the plane). Sheathing at an angle of 45° requires the placement of planks along the entire perimeter. At the points of their attachment, pieces of boards are placed against the joists so that the placement is even. The ceiling is covered after the frame of the slats is installed. It is necessary to determine the length of the boards and cut off the excess. Electrical communications are hidden under the clapboard. Experts advise using a multi-core non-heating copper wire with a power reserve. The structure will be attached to the ceiling panel with an indentation from the walls of 2 mm. Wood is subject to shrinkage, compression and expansion, so the material requires a small space. The clapboard is fixed to the slats with self-tapping screws, which are fastened into its grooves. To avoid protruding nail heads, fastening the cladding to the lathing with high-quality glue helps. To give the interior an unusual look, fastening the paneling with screws with decorative caps helps. After fixing, wooden panels are covered with a layer of paint or varnish. The shade of the paneling is changed with the help of special dyes that give the material a natural shade of walnut, oak or pine, preserving the natural texture of the wood. Experts do not recommend covering the surface with glossy varnishes that make the ceilings shiny, quickly tiring the eyes. The 1st layer of varnish is applied to the surface. After it dries, the coating is treated with fine-grained sandpaper (to eliminate lint and air bubbles). The procedure must be repeated 2-3 times.