Coffee tables are just as relevant today,as many years ago, they can be purchased separately from the upholstered furniture or as a set, however, like all other pieces of furniture, the described one has a high cost, despite its small size. That is why you can make it yourself. Coffee tables have relatively high prices in furniture stores, but, unlike other pieces of furniture, they are quite easy to make yourself.

Coffee tables have relatively high prices in furniture stores, but, unlike other pieces of furniture, they are quite easy to make yourself.

Preparatory work

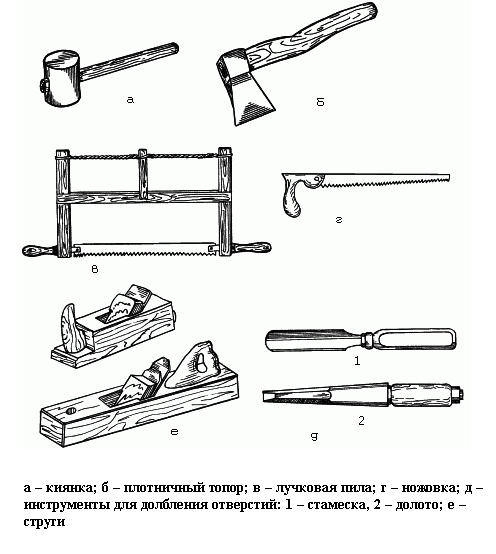

In order to make a wooden table yourself, you need to stock up on the following tools and materials:

- an array of pine;

- varnish on a water basis;

- white spirit;

- acrylic paint;

- brush;

- self-tapping screws;

- electric jigsaw;

- screwdriver;

- radial grinding machine;

- a milling cutter;

- drill.

As for the pine massif, it is necessarypurchase a material with a thickness of 25 mm. The dimensions of the blank for this table are 1500x500 mm. This model does not require separate legs. In order to cover the table, you will need 300 g of water-based varnish. Acrylic paint must be purchased with gloss, which will give the product a tone, about 100 g of this product will be spent. To apply the composition, you need to purchase a brush or take the one that is available, it is worth considering only that after the work has been carried out, it will have to be disposed of, since it will be impossible to get rid of the glitter. Tools for making magazinetable. The coffee table should be assembled using self-tapping screws of two sizes: 4x60 and 4x40 mm. To process the wood, you will need to use an electric jigsaw, which comes with a set of saws designed for clean cutting of wood. It is preferable to use a self-clamping chuck, it is more convenient for the master when carrying out work. In any case, it should be possible to install a drill with a diameter of 10 mm in the chuck. The radial grinder can be replaced with a conventional screwdriver, which has an appropriate attachment. You can also refuse a hand router in favor of a traditional plane, since not every master has the first version of the tool. It will be necessary to remove more impressive chamfers. The drills should have the following sizes: 10 and 5 mm, the first option should be used instead of a separate countersink. A set of bits with an extension will also be useful in the work. When cutting the material, you can not try to calculate the size of the radius, for this you can use a traditional steel hula hoop as a template. Return to the table of contents</a>

Tools for making magazinetable. The coffee table should be assembled using self-tapping screws of two sizes: 4x60 and 4x40 mm. To process the wood, you will need to use an electric jigsaw, which comes with a set of saws designed for clean cutting of wood. It is preferable to use a self-clamping chuck, it is more convenient for the master when carrying out work. In any case, it should be possible to install a drill with a diameter of 10 mm in the chuck. The radial grinder can be replaced with a conventional screwdriver, which has an appropriate attachment. You can also refuse a hand router in favor of a traditional plane, since not every master has the first version of the tool. It will be necessary to remove more impressive chamfers. The drills should have the following sizes: 10 and 5 mm, the first option should be used instead of a separate countersink. A set of bits with an extension will also be useful in the work. When cutting the material, you can not try to calculate the size of the radius, for this you can use a traditional steel hula hoop as a template. Return to the table of contents</a>

Preparing for the Build Process

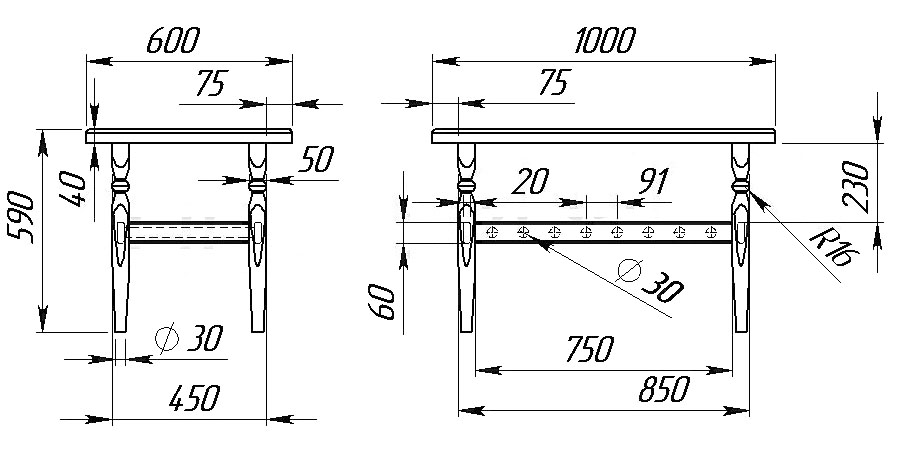

When making a coffee table, you will have toperform two stages of product processing: preliminary and final. The first stage includes cutting, beveling and grinding. The bevel should be removed approximately 5 mm, it looks aesthetically pleasing and will not “eat up” the thickness of the countertop externally. Even before the moment of covering the elements with tone, grinding should be done in three approaches in the area of the ends. Coffee table drawing.Such work should be carried out using the technology below. After you have managed to sand the cuts, you should cover them with a layer of varnish. You should be prepared for the fact that the structure of the wood will stick out under the coating. After drying, you should re-sand and varnish, this should be done until you manage to achieve a smooth cut. In this case, you must ensure that you do not damage the plane. Return to the table of contents</a>

Coffee table drawing.Such work should be carried out using the technology below. After you have managed to sand the cuts, you should cover them with a layer of varnish. You should be prepared for the fact that the structure of the wood will stick out under the coating. After drying, you should re-sand and varnish, this should be done until you manage to achieve a smooth cut. In this case, you must ensure that you do not damage the plane. Return to the table of contents</a>

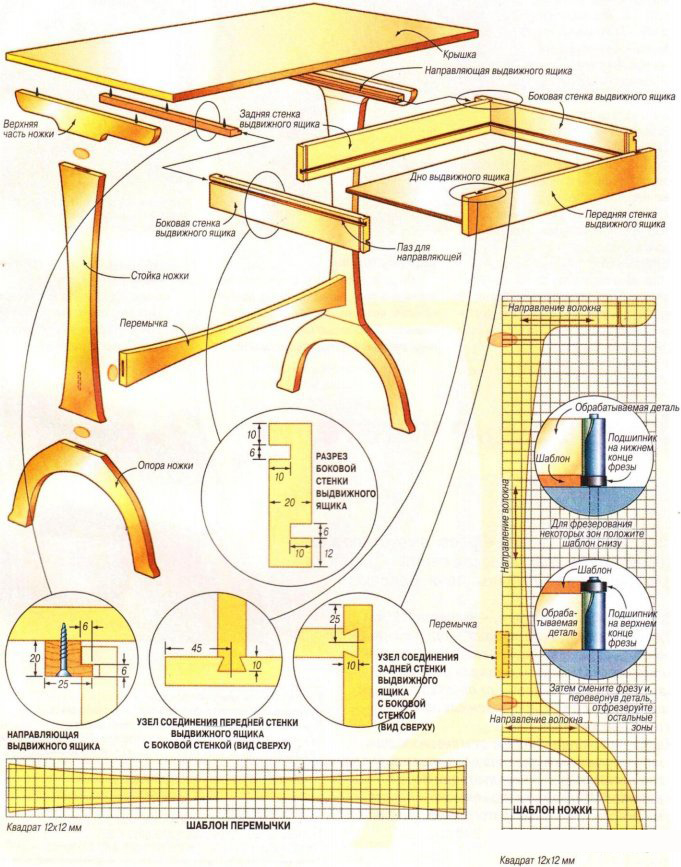

The technology of mounting a wooden table

When making a coffee table, beforeto start gluing the elements together, it is necessary to prime the joints with PVA, which can be replaced with wood glue, then the surface should be left to dry. The planks with legs should be joined with self-tapping screws with dimensions of 4x40, while when fixing to the table top, fasteners with dimensions of 4x60 should be used. The coffee table should not have a resinous surface, in order to get rid of it, you should use white spirit and a large amount of rags. It is advisable to carry out such work in an open space. Otherwise, the smell will remain in the apartment for a long time. The varnish must be mixed with glossy paint and cover the surface of the table. You can experiment a little with the remains of acrylic, depicting patterns under the final layer of varnish, they will not be very noticeable and intrusive, they can only be seen in reflected light. Return to the table of contents</a>

Coffee table made of wood on legs

Assembly diagram of a coffee table.A coffee table can be made similar to the one described above, but its design can also include legs. To do this, you will need to use a blank made of solid wood of the required size. It is necessary to saw off material from four sides of the element (not two). The size of the tabletop of such a table can be 950x650 mm. In this case, the solid wood should be 35-40 mm thick. The blank for this table will be a material with dimensions of 1280x980 mm. Ready-made balusters can serve as legs, which can be purchased in the construction department, their top should be square, the side of which can be limited to 60 mm. The blanks for the legs can be sawed off so that the table is the required height. If you saw off the tabletop radially from 4 sides, then instead of the elements that in the first case served as legs, you will be able to get a ready-made base for the table made of four parts. To fasten them together, they must be pulled together with 5x90 mm confirmats. In this case, the blanks must form a rectangle, which should be screwed to the tabletop using corners. Do not forget that the elements of the "box" part must be sawn off along the length, this will allow you to get a structure of the correct shape after assembling the table. When installing the legs, self-tapping screws should be used, mounting them from the inside. The reliability of the base box will be achieved by the fact that the wood structure on the long elements is horizontal. Thus, the model will acquire legs. If desired, such a table can be turned into a dining table at the installation stage, for this it will be necessary to cut the legs, leaving a more impressive length. When making cuts with a jigsaw, you can make curly movements. Return to the table of contents</a>

Assembly diagram of a coffee table.A coffee table can be made similar to the one described above, but its design can also include legs. To do this, you will need to use a blank made of solid wood of the required size. It is necessary to saw off material from four sides of the element (not two). The size of the tabletop of such a table can be 950x650 mm. In this case, the solid wood should be 35-40 mm thick. The blank for this table will be a material with dimensions of 1280x980 mm. Ready-made balusters can serve as legs, which can be purchased in the construction department, their top should be square, the side of which can be limited to 60 mm. The blanks for the legs can be sawed off so that the table is the required height. If you saw off the tabletop radially from 4 sides, then instead of the elements that in the first case served as legs, you will be able to get a ready-made base for the table made of four parts. To fasten them together, they must be pulled together with 5x90 mm confirmats. In this case, the blanks must form a rectangle, which should be screwed to the tabletop using corners. Do not forget that the elements of the "box" part must be sawn off along the length, this will allow you to get a structure of the correct shape after assembling the table. When installing the legs, self-tapping screws should be used, mounting them from the inside. The reliability of the base box will be achieved by the fact that the wood structure on the long elements is horizontal. Thus, the model will acquire legs. If desired, such a table can be turned into a dining table at the installation stage, for this it will be necessary to cut the legs, leaving a more impressive length. When making cuts with a jigsaw, you can make curly movements. Return to the table of contents</a>

Table with own hands from boxes

You can also make a table from several wooden ones.drawers. However, it should be remembered that the plywood of the products is very thin. When screwing in the screws, it can break lengthwise. For this reason, it is initially necessary to make a hole for installing the fasteners. If you make two holes in the board on different sides, this will guarantee that the crack will not appear at all. For the work, you will need to prepare a sheet of plywood so as not to weigh down the structure. The drawers will not allow you to get an ideal square, so before cutting the sheet, you need to lay them on the workpiece and draw a contour. The plywood needs to be covered with stain. For the table, you should buy wheels that are not very high. They need to be strengthened at the corners with some indentation from the edges. The drawers should be fixed to the lower tabletop. At this point, you can consider the table ready, its surface is recommended to be varnished in several layers. It is permissible to decorate the table in an antique style, covering its surface with a special varnish, which is covered with cracks during drying.