How to make If the area of the apartment is small andWhen buying new furniture, difficulties arise with choosing a place, then items with multifunctional characteristics are indispensable in such a situation. Transformer products are very popular now.  The coffee table transformer will help savethe useful space of the room. On sale there are such models, but they are very expensive. Therefore, you can make a transformer table by yourself. This piece of furniture in a folded form is a coffee table, and in the unfolded turns into a large dining table.

The coffee table transformer will help savethe useful space of the room. On sale there are such models, but they are very expensive. Therefore, you can make a transformer table by yourself. This piece of furniture in a folded form is a coffee table, and in the unfolded turns into a large dining table.

Technology of manufacturing the table transformer

Materials and tools:  Scheme of the table transformer.

Scheme of the table transformer.

- sheets of particle board;

- the mechanism of transformation;

- pipes 20x20 mm;

- bolts 8x60 mm;

- metal corner;

- building level;

- nuts;

- washers;

- self-tapping screws;

- loops.

How to make a table transformer magazine? First of all, you need to purchase a product transformation mechanism in the store. Now on sale there are various versions of such devices from different manufacturers. The choice is big enough. The device has in its design a special gas lift or springs, through which the model is transformed. These elements provide a sufficiently soft and smooth course of the product. A device based on a spring is more simple. This option is more durable and reliable. In the finished product, it will look more aesthetic, since the spring is inside the body of the mechanism and it is not visible when the table transformer will be assembled in a magazine or lunch version. Back to contents</a>

Development of the table design

To make the project of the future product it is possible inspecialized computer program. This work can be done by anyone who is familiar with the computer. In this case, you can execute a copy of the instance in a three-dimensional image.  Possible dimensions of the table transformer. Knowing the dimensions of the transformation mechanism, they choose the sizes of the future model in both variants. When the project is ready, you need to purchase the necessary materials. To perform the model you need the sheets of chipboard. Cut sheets of the necessary size can be made to order in a specialized workshop. When sheets of the appropriate size are ready, they need to be placed on a flat surface, you can on the floor. The thickness of the chipboard for making the design is better to choose 22 mm. From this sheet will be made the table top of the lunch copy. It is on such loads that the mechanism of transformation is calculated. The case of the model can be made from a sheet of chipboard with a thickness of 16 mm. In the workshop, the edges of the chipboard sheets are processed. Then you need to purchase the tools to build the model. Back to contents</a>

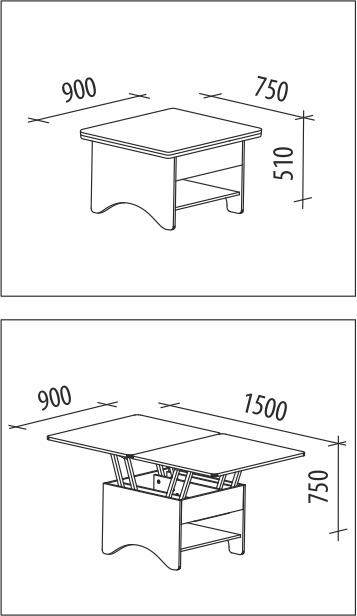

Possible dimensions of the table transformer. Knowing the dimensions of the transformation mechanism, they choose the sizes of the future model in both variants. When the project is ready, you need to purchase the necessary materials. To perform the model you need the sheets of chipboard. Cut sheets of the necessary size can be made to order in a specialized workshop. When sheets of the appropriate size are ready, they need to be placed on a flat surface, you can on the floor. The thickness of the chipboard for making the design is better to choose 22 mm. From this sheet will be made the table top of the lunch copy. It is on such loads that the mechanism of transformation is calculated. The case of the model can be made from a sheet of chipboard with a thickness of 16 mm. In the workshop, the edges of the chipboard sheets are processed. Then you need to purchase the tools to build the model. Back to contents</a>

Assembly of the table construction

First, assembling the frame is performed. The frame of the product is mounted on confirmats. A strong drill is used for this. Then, markers are made on the sheets of chipboard using a marker. After this, the mechanism of transformation is established in the framework. Preliminary it is necessary to install springs, with which the model will be decomposed and its soft movement will be ensured. The mechanism of transformation must be established through the method. The weight of the device is large enough, so the structure should be strong. After this, the device is fixed. To ensure that the fasteners of the product are not visible, the installation of overhead legs is provided, which will hide all the additional parts. After that, mark the places where the fasteners will be installed. Then, in the required places, drill holes for the installation of bolts. After this a strong drill is prepared for a special place, where the bolt heads will be hidden. The device is fixed to the frame of the model using bolted connections. Using the bolts connect the walls of the product with each other. After installing the device proceed to fixing the legs of the product. The legs must support the weight of the entire structure, which is 40-50 kg. In addition, they must withstand the weight of objects that will be on the table. Therefore, the legs are fastened together with ties. After this, the legs are screwed to the structure. Preliminary for correct installation of legs it is necessary to make appropriate marks. The horizontal structure and observance of right angles should be controlled with the help of a building level. Drill holes to install the legs. They need to be installed on the bushings of metal. Then proceed to install the countertop. It must be assembled very carefully, since the mechanism of transformation of the table top should be reliable and perform an even unfolding of the countertop. Then make notes for the holes. The fasteners will be installed in these holes. After that, the product is installed. Adjust the mechanism of unfolding countertops. Drill holes for the installation of countertops. Using screws, a small table top is attached to the structure. Then, holes for fastenings are made in the same way and a large table top is placed in its place. The transformer table is a journal lunch table ready. This design should be very strong to withstand all the loads. After manufacturing the model, it is necessary to check how the transformation mechanism works. If there are any errors in the operation of the mechanism, then you can adjust it. The log table of the transformer, manufactured using such technology, will ensure the creation of a solid and reliable construction with a long service life.