Today there are quite a large numbervarious autonomous heating systems. Each of them has its own advantages and disadvantages. One of the angles that ensures the efficiency and performance of the heating system is the manifold. It is quite easy to assemble such a structure if you know the manifold diagram and understand how it should work. Scheme of a collector for a warm floor. The collector is a unit that includes the following elements:

Scheme of a collector for a warm floor. The collector is a unit that includes the following elements:

- pipes that are made of plastic or metal;

- valves;

- manometers;

- valves;

- fitting;

- other auxiliary nodes.

How does the collector work and what is it for?

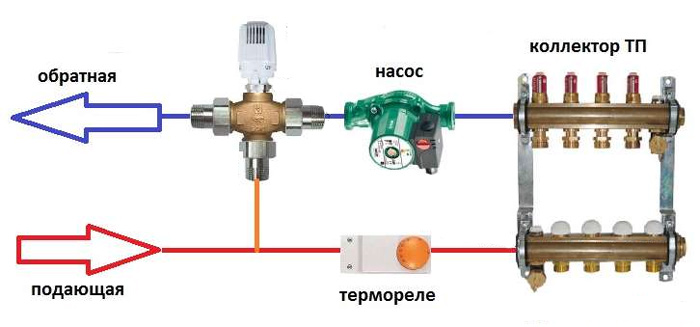

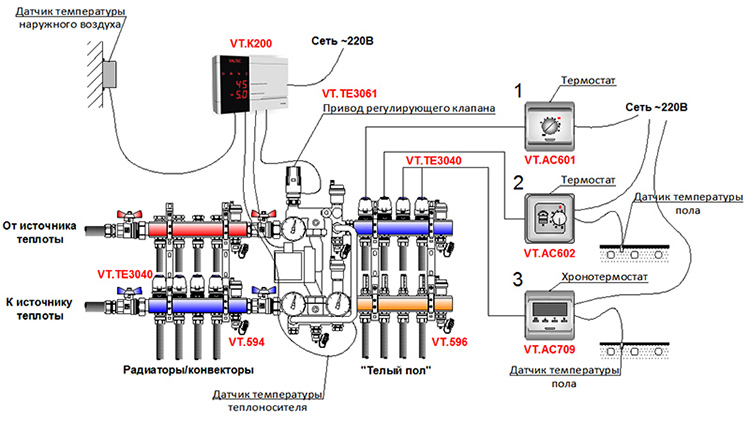

Example of connecting a warm floor manifold.The design is used to mix the coolant coming from different heating circuits. The device then distributes the coolant across these circuits. Due to mixing, the temperature of the liquid will equalize. Therefore, the temperature in the heated rooms will be stable. It should be known that the quality of the underfloor heating system will depend on the correct assembly of the collector design. The operating principle of the heating system is as follows: the hot coolant after passing through the existing circuits and pipes will cool down, and under the action of the pump design or natural circulation will flow back into the collector. In this element, the coolant is mixed through the return pipe. The proportions of the hot and cooled coolant can be adjusted by valves. Temperature control is performed by special heat and pressure sensors. If the heating system is too long or there is no possibility of natural circulation in the house, then a circulation pump will need to be included in the collector design. A standard collector consists of the following elements:

Example of connecting a warm floor manifold.The design is used to mix the coolant coming from different heating circuits. The device then distributes the coolant across these circuits. Due to mixing, the temperature of the liquid will equalize. Therefore, the temperature in the heated rooms will be stable. It should be known that the quality of the underfloor heating system will depend on the correct assembly of the collector design. The operating principle of the heating system is as follows: the hot coolant after passing through the existing circuits and pipes will cool down, and under the action of the pump design or natural circulation will flow back into the collector. In this element, the coolant is mixed through the return pipe. The proportions of the hot and cooled coolant can be adjusted by valves. Temperature control is performed by special heat and pressure sensors. If the heating system is too long or there is no possibility of natural circulation in the house, then a circulation pump will need to be included in the collector design. A standard collector consists of the following elements: Scheme of the device of a water-heated floor.

Scheme of the device of a water-heated floor.

- a two-way or three-way mixing valve;

- check valves;

- balancing valves;

- temperature sensor;

- manometer;

- a pump for circulation;

- element for automatic air discharge;

- fitting;

- tees;

- adapters;

- nipples.

You will also need some other elements forinstallation. The design works as follows: if the temperature exceeds a certain value, the thermal head will close the valve, and the hot heat carrier will be supplied in small quantities. As the heat carrier cools down, the valve will supply more liquid. The heat carrier from the return pipe is supplied with a continuous pressure, and from the supply pipe - if necessary. Therefore, the average temperature of the liquid will remain unchanged. Return to contents</a>

Advantages of the collector circuit of the device of a warm floor

Manifold piping scheme. Underfloor heating with a manifold system has quite a large number of advantages. The main ones are the following:

Manifold piping scheme. Underfloor heating with a manifold system has quite a large number of advantages. The main ones are the following:

Return to Contents</a>

How to choose a collector for underfloor heating?

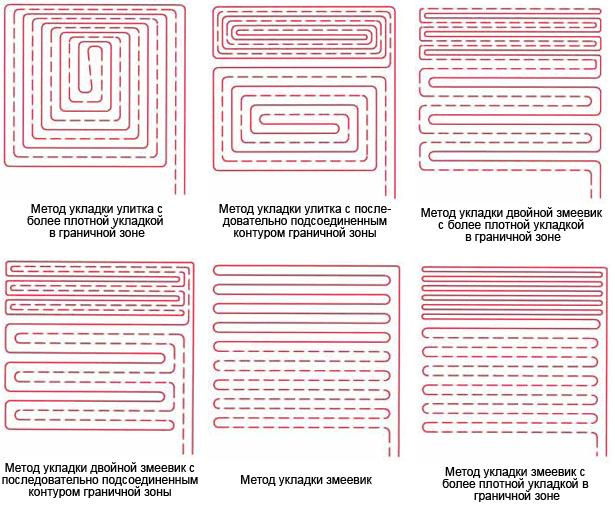

Collector stabilization circuit.Such a design should be selected based on the amount of money that can be spent on its construction. In addition, there is a parameter that must be observed. A similar parameter is the number of outlets on the manifold. This number will depend on how many pipes need to be connected to the manifold structure. It is not always possible to make an absolutely accurate calculation of the number of loops. They differ from each other by the area of the room. In some rooms, it may be necessary to install two loops. An approximate calculation of the number of such elements can be made based on the fact that there are 6.5 m / p of pipe per 1 m². The resulting value must be multiplied by the area of the heated room. The resulting number should be compared with the existing lengths of pipes in the coil. It should be noted that in some cases it is most advisable to make several loops so that there is not a lot of extra pipe left from the coil. You can take a collector for one more circuit, and muffle the extra one. Return to the table of contents</a>

Collector stabilization circuit.Such a design should be selected based on the amount of money that can be spent on its construction. In addition, there is a parameter that must be observed. A similar parameter is the number of outlets on the manifold. This number will depend on how many pipes need to be connected to the manifold structure. It is not always possible to make an absolutely accurate calculation of the number of loops. They differ from each other by the area of the room. In some rooms, it may be necessary to install two loops. An approximate calculation of the number of such elements can be made based on the fact that there are 6.5 m / p of pipe per 1 m². The resulting value must be multiplied by the area of the heated room. The resulting number should be compared with the existing lengths of pipes in the coil. It should be noted that in some cases it is most advisable to make several loops so that there is not a lot of extra pipe left from the coil. You can take a collector for one more circuit, and muffle the extra one. Return to the table of contents</a>

Why do you need to install valves in the collector?

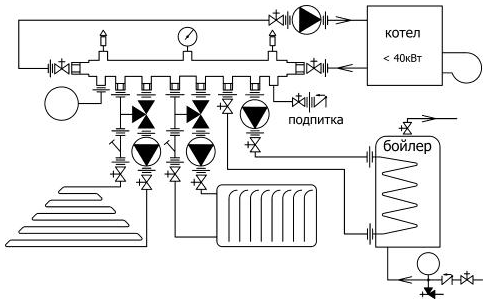

Assembly diagram of the collector and sensors.A two-way valve will let the coolant flow in one direction, but it has a small capacity. The advantage of using a two-way valve is that in this case the coolant will be supplied smoothly and without drops. Such devices have a small capacity, and therefore are used in small rooms. The latest models of valves can be equipped with a servo drive. Such an element is a motor with a valve position sensor. With the help of a servo drive, you can accurately open and close the fluid flow hole. A three-way valve will mix or separate the coolant flows. The body of the structure contains several pipes through which the element is connected to the heating pipes. The valve will receive liquid from the boiler, transfer it to the heating system, and also receive liquid from the return pipe in order to mix the latter with the hot feed. It is recommended to install a three-way valve in autonomous heating systems at the outlet of the collector system, where there is no need to limit the flow during uniform mixing. With prolonged use, the valve may become clogged. In order to easily replace such an element, a detachable coupling should be used in the connection of all elements. If the layout of the heat carrier provides for the installation of several collectors, then at the outlet of each of the elements it will be necessary to install a branch with a structure for air removal.

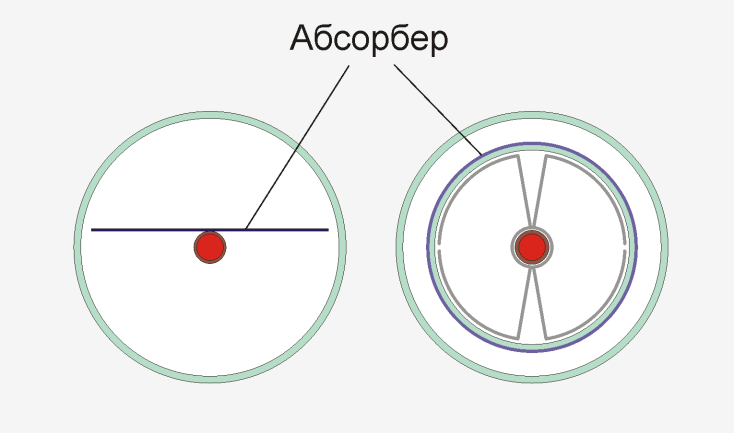

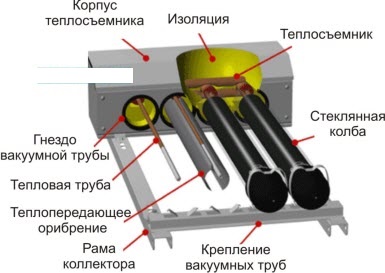

Assembly diagram of the collector and sensors.A two-way valve will let the coolant flow in one direction, but it has a small capacity. The advantage of using a two-way valve is that in this case the coolant will be supplied smoothly and without drops. Such devices have a small capacity, and therefore are used in small rooms. The latest models of valves can be equipped with a servo drive. Such an element is a motor with a valve position sensor. With the help of a servo drive, you can accurately open and close the fluid flow hole. A three-way valve will mix or separate the coolant flows. The body of the structure contains several pipes through which the element is connected to the heating pipes. The valve will receive liquid from the boiler, transfer it to the heating system, and also receive liquid from the return pipe in order to mix the latter with the hot feed. It is recommended to install a three-way valve in autonomous heating systems at the outlet of the collector system, where there is no need to limit the flow during uniform mixing. With prolonged use, the valve may become clogged. In order to easily replace such an element, a detachable coupling should be used in the connection of all elements. If the layout of the heat carrier provides for the installation of several collectors, then at the outlet of each of the elements it will be necessary to install a branch with a structure for air removal. Types of absorbers in vacuum tubescollectors. Air is discharged from the top of the branch pipe. The drain valve should be installed in the lower part of the structure. It will be used to drain the coolant during the repair of the heating system. Some of the heating system schemes do not require mixing of liquids, in such cases the valves can be omitted. To maintain a constant temperature in such systems, it will be necessary to install a circulation pump. Such a structure should be installed directly in the return pipe to eliminate the excess intake of coolant from the heating system. Return to contents</a>

Types of absorbers in vacuum tubescollectors. Air is discharged from the top of the branch pipe. The drain valve should be installed in the lower part of the structure. It will be used to drain the coolant during the repair of the heating system. Some of the heating system schemes do not require mixing of liquids, in such cases the valves can be omitted. To maintain a constant temperature in such systems, it will be necessary to install a circulation pump. Such a structure should be installed directly in the return pipe to eliminate the excess intake of coolant from the heating system. Return to contents</a>

Tips for installing a collector for a warm floor

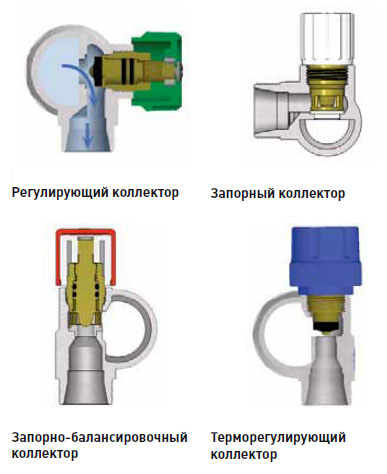

Types of collectors.You can install a similar structure for a warm floor yourself. The distribution manifold is in most cases located in a manifold cabinet or a separate room hidden in the wall. When installing the structure, the following nuances should be taken into account:

Types of collectors.You can install a similar structure for a warm floor yourself. The distribution manifold is in most cases located in a manifold cabinet or a separate room hidden in the wall. When installing the structure, the following nuances should be taken into account:

Return to Contents</a>

Additional accessories that are installed in the collectors

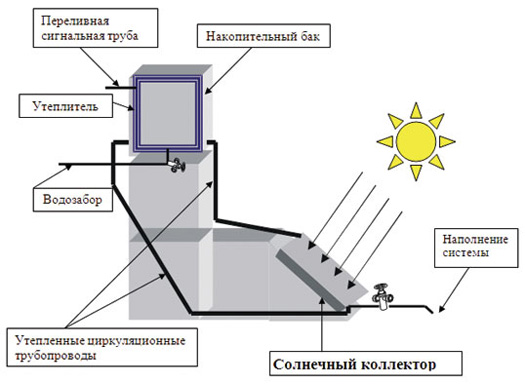

Scheme of the solar collector device.To automatically adjust the underfloor heating system, weather sensors can be installed in the manifold structure. If it gets cold outside, the heating intensity will increase. The weather sensor will send signals to turn the boiler on and off. It is worth noting that manual adjustment is ineffective. Weather-dependent sensors will check the temperature several times a minute. If necessary, servo drives will turn the valve in either direction by 5°. In order to assemble the simplest manifold, you need to prepare the following elements:

Scheme of the solar collector device.To automatically adjust the underfloor heating system, weather sensors can be installed in the manifold structure. If it gets cold outside, the heating intensity will increase. The weather sensor will send signals to turn the boiler on and off. It is worth noting that manual adjustment is ineffective. Weather-dependent sensors will check the temperature several times a minute. If necessary, servo drives will turn the valve in either direction by 5°. In order to assemble the simplest manifold, you need to prepare the following elements:

- mixing valve;

- nipple;

- adapter;

- tee;

- knee;

- coupling;

- a pump for circulation;

- ball valve;

- collector connector;

- collector;

- external and internal connectors;

- air vent.

Vacuum manifold diagram. It is also not very difficult to assemble a multi-circuit manifold for underfloor heating with your own hands. It includes the following elements:

Vacuum manifold diagram. It is also not very difficult to assemble a multi-circuit manifold for underfloor heating with your own hands. It includes the following elements:

- a thermal head with a sensor;

- mixing valve;

- coupling;

- nut;

- tee;

- nipple;

- pump for circulation with connected cranes;

- a stopper;

- collector device;

- Ball Valves;

- fitting;

- union nuts;

- metal-plastic pipes.

If the collector structure is plannedconnect the pipes of the "warm floor" system, then to fix them you should use crimping fittings. Before fixing, you need to make a shallow chamfer on the pipe so that the pipe can fit tightly into the seat. After installing and connecting the manifold structure to the boiler and to the heating system, you will need to pressurize the pipes and check their operability. Pressurization should be carried out for approximately 3-5 hours. In this case, even with a small leak, it will be able to show itself. For several hours, the system will be heated at the maximum level. The entire manifold structure should be placed in a special cabinet, which is installed on the wall near the heating boiler or near the connection point to the warm floor. Standard designs of this type in most cases are designed for 2-12 circuits. Today, in construction supermarkets you can find devices of varying levels of complexity. The simplest device has the form of a pipe, the standard hole diameter is 1 inch, the diameter of the outgoing channel is 0.5 inches. Such elements in this case are supplied with valves. For such a design, you need to buy pumping equipment, an air release valve and a control system. It is not necessary to install servo drives and thermometers. When purchasing or making a design for a warm floor with your own hands, you should be guided by your own financial capabilities. You should also proceed from what type of design you will need. Almost anyone can assemble a collector design. To do this, use one of the existing schemes.