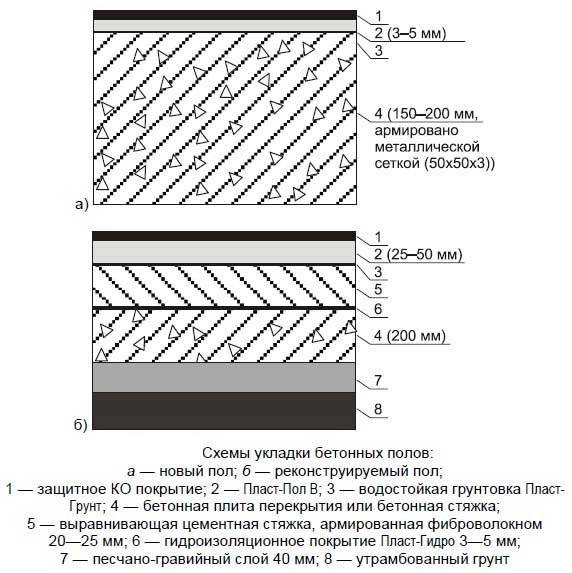

Long-term operation of the floor is impossible withoutcapital foundation. Any decorative coating requires a flat surface, so it is necessary to pour a concrete floor in your own home before starting the finishing work. This information is also important for those who want to install a "warm floor" system in their apartment. Scheme of the device of a concrete floor. It is not difficult to make a concrete floor with your own hands. It is important to prepare the surface before you start pouring. The stages of installation include the following:

Scheme of the device of a concrete floor. It is not difficult to make a concrete floor with your own hands. It is important to prepare the surface before you start pouring. The stages of installation include the following:

What can be required for work?

The ratio between the components in the concrete mixture. Tools:

The ratio between the components in the concrete mixture. Tools:

- perforator;

- a vacuum cleaner;

- level;

- saw-hacksaw;

- building mixer;

- Plank or board for leveling the fill.

It won't be difficult to use them. Now, based on the type of room, you need to decide what materials you will need. Concrete floor in the apartment:

- reinforced mesh;

- concrete mixture;

- boards for formwork.

Scheme of concrete floor screed. Concrete floor on the ground (private houses):

Scheme of concrete floor screed. Concrete floor on the ground (private houses):

- sand;

- crushed stone;

- steam and waterproofing;

- heater;

- reinforced mesh;

- boards for formwork;

- concrete mixture.

Judging by the amount of material, laying a concrete floor in your own home on the ground floor is somewhat more difficult than in an apartment, but this is only due to the multi-layered nature of the material. Return to Contents</a>

Stages of installation of a floor in an apartment

To mark the floor, a zero level is used.To do this, a mark is placed at a level of 1 m from the base of the doorway, and using a level, such beacons are placed along the perimeter of the room. From them, the distance to the floor is also measured at 1 m. The line connecting all the points will be the "zero" level. It is up to this level that the concrete mixture must be poured so as not to change the height of the room. Next comes the work directly with the floor. Concrete floor laying scheme.Having freed the floor from boards and joists, the old covering is removed using a hammer drill. This is done if the concrete base has major damage, holes, cracks, etc. Simple leveling will not help here - the new concrete fill will crack in the same place where the old damage was. Working with a tool, the screed is removed to the very base, that is, to the slab. The work is dirty, so if the apartment is not vacated during the renovation, all cracks and gaps leading to other rooms should be carefully closed. The worker himself must use personal protective equipment - glasses and a respirator. After complete cleaning, you should go over the floor with a vacuum cleaner - it will clean everything to the crumbs. Perhaps the slab will also be damaged, so all chips and cracks are sealed with concrete mortar. After this, a reinforced screed is placed on the slab. It is a sector of reinforcement, serving for additional strength of the coating. The metal will be wire or reinforcing rod, the severity of the reinforcement depends on the purpose of the room. The greater the load it will bear, the more powerful the section of the steel rod should be. The purpose of the reinforcement is to better adhere the concrete to the slab. You can buy a mesh in the store, but it is not difficult to weld it yourself. Then comes the installation of the formwork. It is done if the work will stretch out for more than one day, and the area of the room is significant. What is it? This is the division of the floor into zones with boards. The formwork is not fastened with nails or anything else. For this purpose, guides in the form of metal pipes are used, the height of which is equal to the zero level from the slab to the line, they are placed on a thick cement mortar. The board is placed on top of the pipe, and thus its lower surface will be a guide. When the pouring is finished, the boards are not removed immediately, but only after they have completely hardened. Therefore, to make it easier, they are lubricated with oil.

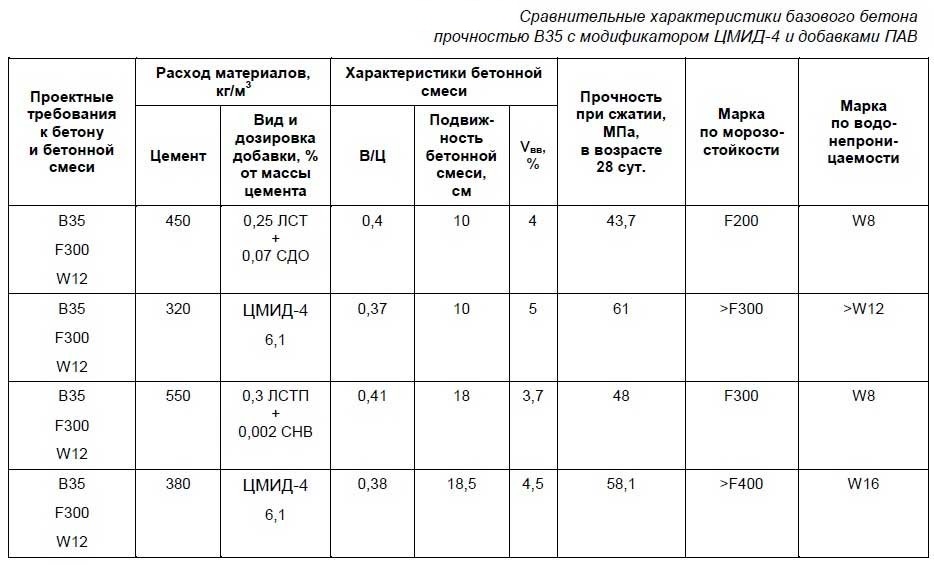

Concrete floor laying scheme.Having freed the floor from boards and joists, the old covering is removed using a hammer drill. This is done if the concrete base has major damage, holes, cracks, etc. Simple leveling will not help here - the new concrete fill will crack in the same place where the old damage was. Working with a tool, the screed is removed to the very base, that is, to the slab. The work is dirty, so if the apartment is not vacated during the renovation, all cracks and gaps leading to other rooms should be carefully closed. The worker himself must use personal protective equipment - glasses and a respirator. After complete cleaning, you should go over the floor with a vacuum cleaner - it will clean everything to the crumbs. Perhaps the slab will also be damaged, so all chips and cracks are sealed with concrete mortar. After this, a reinforced screed is placed on the slab. It is a sector of reinforcement, serving for additional strength of the coating. The metal will be wire or reinforcing rod, the severity of the reinforcement depends on the purpose of the room. The greater the load it will bear, the more powerful the section of the steel rod should be. The purpose of the reinforcement is to better adhere the concrete to the slab. You can buy a mesh in the store, but it is not difficult to weld it yourself. Then comes the installation of the formwork. It is done if the work will stretch out for more than one day, and the area of the room is significant. What is it? This is the division of the floor into zones with boards. The formwork is not fastened with nails or anything else. For this purpose, guides in the form of metal pipes are used, the height of which is equal to the zero level from the slab to the line, they are placed on a thick cement mortar. The board is placed on top of the pipe, and thus its lower surface will be a guide. When the pouring is finished, the boards are not removed immediately, but only after they have completely hardened. Therefore, to make it easier, they are lubricated with oil. Comparative characteristics of base concrete.If the owners prefer to install a "warm floor" system in the apartment, the pouring thickness is made half the size so that all layers can be laid to the zero level. How to mount the system on the floor is a separate story that requires a detailed analysis. We can only say that when pouring the next layer, you need to wait at least a week, and the system can be put into operation only after a month, having previously allowed it to dry and evaporate moisture. To pour the floor, a solution is prepared using a construction mixer so that there are no lumps of sand and cement left in the coating. Pouring occurs from the end of the room to the doors. There is no need to spare the material. When everything is done wisely, there is no need to mix unnecessary things, and if there are differences, the amount of solution must be increased to get a perfectly flat surface. The proportions of correct concrete are as follows - 1 part cement, 2 parts sand, 4 parts crushed stone and 0.5 parts water. The work should be done slowly, using a special leveling bar, and controlling the level. After pouring one sector, the bar is used to settle the concrete until the concrete "milk" appears, then it should be allowed to harden completely. If there are no complaints, then the final field is poured in the same way. The period of complete hardening can be read in the instructions on the package and add another 3 days to this period for reliability. That's it, it's finished. You can move on to the decorative coating. Return to the table of contents</a>

Comparative characteristics of base concrete.If the owners prefer to install a "warm floor" system in the apartment, the pouring thickness is made half the size so that all layers can be laid to the zero level. How to mount the system on the floor is a separate story that requires a detailed analysis. We can only say that when pouring the next layer, you need to wait at least a week, and the system can be put into operation only after a month, having previously allowed it to dry and evaporate moisture. To pour the floor, a solution is prepared using a construction mixer so that there are no lumps of sand and cement left in the coating. Pouring occurs from the end of the room to the doors. There is no need to spare the material. When everything is done wisely, there is no need to mix unnecessary things, and if there are differences, the amount of solution must be increased to get a perfectly flat surface. The proportions of correct concrete are as follows - 1 part cement, 2 parts sand, 4 parts crushed stone and 0.5 parts water. The work should be done slowly, using a special leveling bar, and controlling the level. After pouring one sector, the bar is used to settle the concrete until the concrete "milk" appears, then it should be allowed to harden completely. If there are no complaints, then the final field is poured in the same way. The period of complete hardening can be read in the instructions on the package and add another 3 days to this period for reliability. That's it, it's finished. You can move on to the decorative coating. Return to the table of contents</a>

Stages of installation of a floor on the ground basis

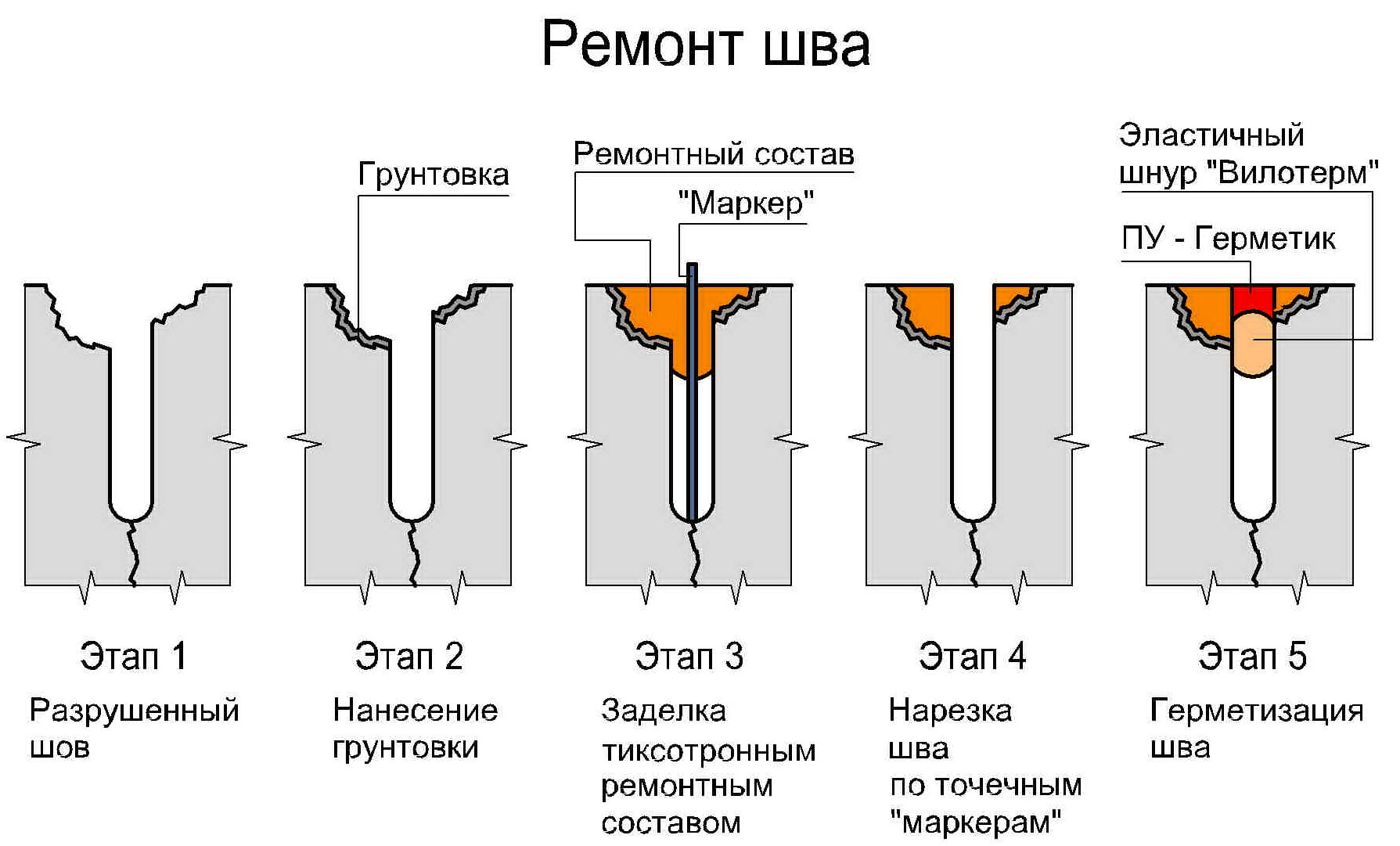

Scheme of sealing a joint in concrete.As in the first case, the floor is freed from the boards. If the house is just being built, this stage can be skipped. The soil covering must be removed to a depth of 25 cm, then leveled and compacted. Then comes a layer of crushed stone, which is thoroughly poured with water and compacted. The next layer will be sand, which also needs to be moistened and passed with a log. So the layers of crushed stone and sand alternate with each other to a height of 15 cm. It is important that the communications running under the floor are enclosed in special waterproof boxes. After the layers are laid, they are poured with the prepared concrete mixture, controlling the process with a level. But the work is far from over. You need to wait until the concrete hardens a little, and proceed to the installation of vapor and waterproofing, and then to insulation. Vapor barrier is an important point in the construction of the floor. Indoor life can cause condensation, which will inevitably settle on the structures and help them rot. To do this, any roll material is laid on top of the concrete base. If it is membrane foil, then the shiny side should be on the surface. You can fasten it with anything, even glue it. Then comes the turn of insulation. Expanded clay can be used in this capacity. You just need to make sure that its granules are of the same size. Thermal insulation can be different, foam plastic, styrene and other things that are affordable for the wallet. After thermal insulation, hydroisol or any film is placed on top - it will perform the task and will not allow moisture to reach the inner layers. When all the functional layers are laid, you can lay the reinforced mesh, divide the area into sectors, using formwork and finally. You can level it with the same bar, fixing the level to it. That's it, the base is ready for finishing. Concrete flooring is a traditional way to level the floor in your own home. In addition, the most budget-friendly. But you can't forget about quality, when buying bags of cement, you should make sure that only the value with a high coefficient (M500 or M400) will go to concrete, because this is the base, which should be the strongest layer in the house. Ready-made building mixtures are available for sale, but they are only suitable as an auxiliary coating, you need to make the concrete yourself. Having applied all the recommendations, you can make a concrete floor yourself, but you should know that this is not a job that allows for "rough drafts" - everything must be high-quality the first time. In addition, spending money on spoiled materials again will be very ruinous.</ ul>

Scheme of sealing a joint in concrete.As in the first case, the floor is freed from the boards. If the house is just being built, this stage can be skipped. The soil covering must be removed to a depth of 25 cm, then leveled and compacted. Then comes a layer of crushed stone, which is thoroughly poured with water and compacted. The next layer will be sand, which also needs to be moistened and passed with a log. So the layers of crushed stone and sand alternate with each other to a height of 15 cm. It is important that the communications running under the floor are enclosed in special waterproof boxes. After the layers are laid, they are poured with the prepared concrete mixture, controlling the process with a level. But the work is far from over. You need to wait until the concrete hardens a little, and proceed to the installation of vapor and waterproofing, and then to insulation. Vapor barrier is an important point in the construction of the floor. Indoor life can cause condensation, which will inevitably settle on the structures and help them rot. To do this, any roll material is laid on top of the concrete base. If it is membrane foil, then the shiny side should be on the surface. You can fasten it with anything, even glue it. Then comes the turn of insulation. Expanded clay can be used in this capacity. You just need to make sure that its granules are of the same size. Thermal insulation can be different, foam plastic, styrene and other things that are affordable for the wallet. After thermal insulation, hydroisol or any film is placed on top - it will perform the task and will not allow moisture to reach the inner layers. When all the functional layers are laid, you can lay the reinforced mesh, divide the area into sectors, using formwork and finally. You can level it with the same bar, fixing the level to it. That's it, the base is ready for finishing. Concrete flooring is a traditional way to level the floor in your own home. In addition, the most budget-friendly. But you can't forget about quality, when buying bags of cement, you should make sure that only the value with a high coefficient (M500 or M400) will go to concrete, because this is the base, which should be the strongest layer in the house. Ready-made building mixtures are available for sale, but they are only suitable as an auxiliary coating, you need to make the concrete yourself. Having applied all the recommendations, you can make a concrete floor yourself, but you should know that this is not a job that allows for "rough drafts" - everything must be high-quality the first time. In addition, spending money on spoiled materials again will be very ruinous.</ ul>