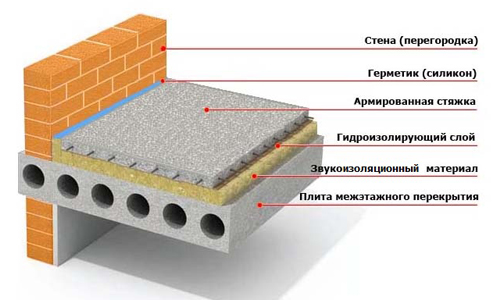

How to make a floor screed with your own hands? The floor tie is a common way of leveling the floor. It is suitable for any type of finish coat. In it you can install a system of floor heating. Despite the fact that pouring the floor is a time-consuming process, it can be done by yourself. How to make a floor screed by yourself?  Scheme of floor screed device. Concrete screed is a wet method of leveling the floor. Before starting work, it is necessary to prepare the surface of the substrate. With this solution, the joints and other deformations of the slabs are sealed. Before pouring cement screed, waterproofing of the basement is sometimes performed. The thickness of the cement screed is not less than 50 mm. This allows for good strength. To improve strength it can be reinforced. To do this, use a metal mesh. It is placed closer to the surface, since there will be the greatest loads. To reduce the amount of the mixture, it is possible to use a filler when pouring. As a filler, claydite is most often used. It is added to the mixture and creates an underlayer. Then it is poured on the main layer of concrete without claydite. Thanks to this, you can save cement mortar and lighten the weight of the coating.

Scheme of floor screed device. Concrete screed is a wet method of leveling the floor. Before starting work, it is necessary to prepare the surface of the substrate. With this solution, the joints and other deformations of the slabs are sealed. Before pouring cement screed, waterproofing of the basement is sometimes performed. The thickness of the cement screed is not less than 50 mm. This allows for good strength. To improve strength it can be reinforced. To do this, use a metal mesh. It is placed closer to the surface, since there will be the greatest loads. To reduce the amount of the mixture, it is possible to use a filler when pouring. As a filler, claydite is most often used. It is added to the mixture and creates an underlayer. Then it is poured on the main layer of concrete without claydite. Thanks to this, you can save cement mortar and lighten the weight of the coating.

Laying floor screed with your own hands

Materials and tools:  Tools for floor screed.

Tools for floor screed.

- finished cement mixture;

- building level;

- beacons;

- waterproofing;

- rule;

- self-tapping screws;

- perforator with a nozzle mixer;

- concrete mixer;

- grater.

First of all, it is necessary to prepare a basis forpouring cement mortar. To do this, it is necessary to clean the floor of the dirt and perform its priming. Then you need to seal all the seams overlapping slabs and connecting them to the walls with a cement solution. This is necessary to prevent leakage. For these purposes, you can also make a waterproofing. Then the floor surface is measured using a construction or laser level, revealing the highest base location. It is a guide for placing beacons and choosing the thickness of the screed. Then the beacons are installed. They are needed for leveling cement. Without their installation it is impossible to create a flat surface. Lighthouses - this guides, which move the rule when leveling concrete. They are installed arbitrarily. They should be located at a distance of 20 cm from the wall. The distance between them should be 30 cm less than the length of the rule, by which the concrete will be leveled. The guides can be made of metal or made of a solution. Solvent guides are installed as follows. In that place where there should be a beacon, it is necessary to lay cement. Then, with the help of the rule, it is necessary to form a special area corresponding to the floor level on the mixture. Then remove excess cement.  Installation of beacons for floor screed. To simplify the installation of solution beacons, perform the following steps. First you need to install the self-tapping screw 2 in the base of the beacon placement. They are wrapped so that the top of the self-tapping screw is at the surface level. Then, the solution beacons are installed. In this case, self-tapping screws are used as restraints that do not allow setting the beacon lower than necessary. After solidification of concrete proceed to pouring. Back to contents</a>

Installation of beacons for floor screed. To simplify the installation of solution beacons, perform the following steps. First you need to install the self-tapping screw 2 in the base of the beacon placement. They are wrapped so that the top of the self-tapping screw is at the surface level. Then, the solution beacons are installed. In this case, self-tapping screws are used as restraints that do not allow setting the beacon lower than necessary. After solidification of concrete proceed to pouring. Back to contents</a>

How to install beacons

Metal beacons are moretechnological. When installing them, the quality of the coating increases. They are 10 mm and 6 mm thick. To create a screed, usually 10 mm beacons are used. They are established as follows. First, screw the screws and throw the mixture in the same way as when creating beacons. Then a metal beacon is placed over it. After this, using the rule, the concrete is pressed until it comes into contact with the screws. Then remove excess solution. The lighthouse is pressed into the cement in such a way that the mixture does not get onto its surface. At the same time, during the pressing of the lighthouse, it can be bent, which will reduce the quality of the laying of cement. There is another way to install metal beacons. Together with the beacon, a fastening element is used. With its help, the beacon is set according to the level. Then, to increase the rigidity of the beacon, a cement mixture is applied under its base. Thus, the beacon is smeared into the cement. When the cement solidifies, the lighthouse can be used. Back to contents</a>

Pouring cement floor screed with your own hands

First you need to prepare a cement slurry. It can be stirred right on the floor or use a mixer. Concrete needs to be poured into a large bucket. As a mixer, a perforator with a nozzle-mixer is used. This nozzle is placed in the punch through a special adapter with a cartridge. Also for the preparation of the mixture you can use a concrete mixer. Preparation of concrete. Usually use a ready-made solution. It has special additives that increase strength, pour point and coating quality. When using the finished solution, there will be no cracking of the mixture or its shrinkage. With independent selection of all components of the mixture it is difficult to withstand the necessary proportions, so the quality of the screed will decrease. The price of the finished mixture and homemade is almost the same.  Installation diagram of a concrete floor screed.When making a mortar on your own, you need to maintain the proportion of cement, sand and water in a ratio of 1: 3: 0.5. The sand should be used without impurities and dry. First, the cement is mixed with sand, and then water is added. When using ready-mixed concrete, add the required amount of water according to the instructions and mix the components. The finished solution must be evenly distributed over the base and leveled using a rule that is moved along the beacons. In those places where there is little mixture or pits appear, you need to add it and level the surface. The cement must fill the entire surface evenly. There should be no air pockets. An indicator of the quality of laying the cement slurry is the flow of cement laitance to the surface. This means that the cement is laid with good quality and the floor screed will be very strong. This method is used to fill the entire surface of the base. When the concrete hardens, after about 3 hours, it is sanded with a float. Then the surface will become smoother, without roughness. In order for the surface to completely solidify and acquire the necessary strength, it is necessary that about 25 days have passed. In the first 7 days, it should not be affected by drafts. , made according to this technology, will provide a high-quality solid foundation that can withstand heavy loads.

Installation diagram of a concrete floor screed.When making a mortar on your own, you need to maintain the proportion of cement, sand and water in a ratio of 1: 3: 0.5. The sand should be used without impurities and dry. First, the cement is mixed with sand, and then water is added. When using ready-mixed concrete, add the required amount of water according to the instructions and mix the components. The finished solution must be evenly distributed over the base and leveled using a rule that is moved along the beacons. In those places where there is little mixture or pits appear, you need to add it and level the surface. The cement must fill the entire surface evenly. There should be no air pockets. An indicator of the quality of laying the cement slurry is the flow of cement laitance to the surface. This means that the cement is laid with good quality and the floor screed will be very strong. This method is used to fill the entire surface of the base. When the concrete hardens, after about 3 hours, it is sanded with a float. Then the surface will become smoother, without roughness. In order for the surface to completely solidify and acquire the necessary strength, it is necessary that about 25 days have passed. In the first 7 days, it should not be affected by drafts. , made according to this technology, will provide a high-quality solid foundation that can withstand heavy loads.