Various types of alignment are used for alignment.materials. Chipboards are considered inexpensive and practical, you can lay them on the floor yourself. This material consists of a wood-chip base, made from wood processing waste. Sheets are used for various jobs, they are indispensable for wall, floor and ceiling cladding. Most often, chipboard is used to level and insulate the floor surface. The material is great for concrete or wood bases, you can do cladding on logs. The work is simple, does not require special experience, but the process should be done step by step. Chipboard is used for leveling floors.

Chipboard is used for leveling floors.

Tools and materials for styling

The device of a floor from chipboard slabs isa simple process. Before starting work, you should prepare all the materials. Chipboard is an excellent option for cladding, since this material has the following advantages:

Tools for installing chipboard floors.Chipboard cannot be laid when there is constant humidity in the room. It has a negative effect on the quality of the lining, the boards will be destroyed in the shortest time. The humidity level should not exceed 60% at an ambient temperature of 10°C. The following materials and tools are required for the work:

Tools for installing chipboard floors.Chipboard cannot be laid when there is constant humidity in the room. It has a negative effect on the quality of the lining, the boards will be destroyed in the shortest time. The humidity level should not exceed 60% at an ambient temperature of 10°C. The following materials and tools are required for the work:

- building level;

- roulette;

- a simple pencil;

- gon;

- Circular Saw;

- electric jigsaw;

- Screwdriver;

- perforator;

- waterproofing membrane;

- chipboard plates;

- self-tapping screws;

- dowels;

- putty.

Return to Contents</a>

Preparation before laying the plates

Before you start laying chipboard on the floor, you need to do some preparatory work. The order of actions in this case is as follows: Scheme of laying chipboard on the floor.

Scheme of laying chipboard on the floor.

Return to Contents</a>

Laying of chipboard on the base

Fastening chipboard to the floor using self-tapping screws.After the preparation is complete, you can begin leveling the base. The chipboard floor is laid from the far corner, it will be much more convenient. You should move towards the exit of the room. Temperature gaps should be provided between the slabs and the wall surface. In the first case, gaps of 10 mm should be left, and a joint of only a couple of millimeters is needed between the slabs. To level the base, you may need not 1 layer of chipboard, but two, if the unevenness is too large. For the floor on the logs, alignment is carried out at the stage of installing the timber. Self-tapping screws are used for fastening, they are mounted along the perimeter of each slab. The screws themselves must be installed in such a way that they move away from the edge by at least 1 cm, otherwise the slab may be damaged. The step of the screws for fastening is 30 cm, this will be quite enough. If the installation is carried out on a floor with logs, then the fastening points should fall on the timber. The same rule applies to the joints of individual slabs. After the floor repair is finished, it is necessary to start finishing the surface. To do this, all joints and fastening points are filled with putty. The heads of the screws should be slightly recessed into the wood, not protruding above the surface. But this must be done so that the sheet is not covered with cracks. To decorate the fastening points, a special wood putty is used, it is applied in a thin layer. When the material dries, the surface of the base is sanded, and further finishing work can begin. Return to contents</a>

Fastening chipboard to the floor using self-tapping screws.After the preparation is complete, you can begin leveling the base. The chipboard floor is laid from the far corner, it will be much more convenient. You should move towards the exit of the room. Temperature gaps should be provided between the slabs and the wall surface. In the first case, gaps of 10 mm should be left, and a joint of only a couple of millimeters is needed between the slabs. To level the base, you may need not 1 layer of chipboard, but two, if the unevenness is too large. For the floor on the logs, alignment is carried out at the stage of installing the timber. Self-tapping screws are used for fastening, they are mounted along the perimeter of each slab. The screws themselves must be installed in such a way that they move away from the edge by at least 1 cm, otherwise the slab may be damaged. The step of the screws for fastening is 30 cm, this will be quite enough. If the installation is carried out on a floor with logs, then the fastening points should fall on the timber. The same rule applies to the joints of individual slabs. After the floor repair is finished, it is necessary to start finishing the surface. To do this, all joints and fastening points are filled with putty. The heads of the screws should be slightly recessed into the wood, not protruding above the surface. But this must be done so that the sheet is not covered with cracks. To decorate the fastening points, a special wood putty is used, it is applied in a thin layer. When the material dries, the surface of the base is sanded, and further finishing work can begin. Return to contents</a>

Features of laying of particle board on concrete

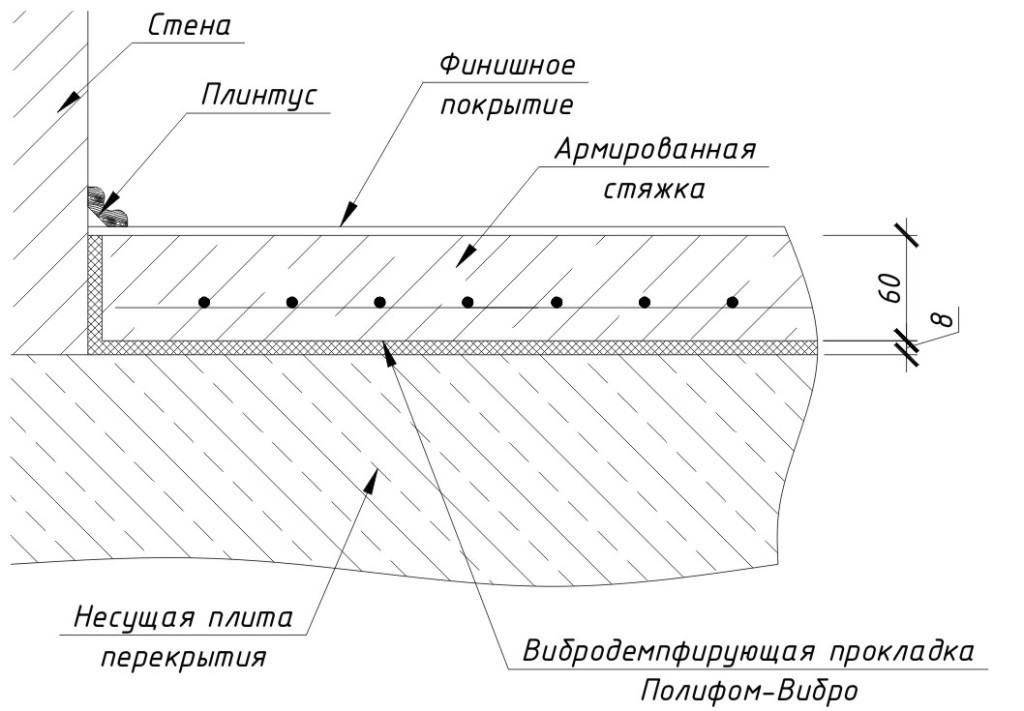

Floor screed diagram.The above installation is perfect for wooden floors, although it can also be used for concrete. However, in the latter case, it is better to use special dowels instead of screws. If the concrete floor has large irregularities, then a screed must be made first. Before laying, the slabs should be covered with drying oil to ensure their protection. Markings are made on the base that will correspond to the fastening points. Holes are made in the material with a hammer drill, after which you can begin laying and fastening the panels to the surface. If the unevenness of the concrete base is not too large, then more than one layer may be required for repair. This method is not the best, so experts advise laying logs or using a special adjustment system. The slabs are laid on special dowels, the height of which can be set independently. This is convenient, such a floor is durable and reliable. When using slats as logs, the base can be immediately insulated. This option is most similar to installation on logs. A layer of waterproofing membrane is laid on the concrete in advance during repairs.</ ul>

Floor screed diagram.The above installation is perfect for wooden floors, although it can also be used for concrete. However, in the latter case, it is better to use special dowels instead of screws. If the concrete floor has large irregularities, then a screed must be made first. Before laying, the slabs should be covered with drying oil to ensure their protection. Markings are made on the base that will correspond to the fastening points. Holes are made in the material with a hammer drill, after which you can begin laying and fastening the panels to the surface. If the unevenness of the concrete base is not too large, then more than one layer may be required for repair. This method is not the best, so experts advise laying logs or using a special adjustment system. The slabs are laid on special dowels, the height of which can be set independently. This is convenient, such a floor is durable and reliable. When using slats as logs, the base can be immediately insulated. This option is most similar to installation on logs. A layer of waterproofing membrane is laid on the concrete in advance during repairs.</ ul>