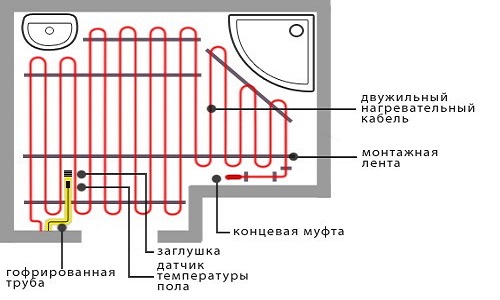

It is difficult to imagine modern life withoutthe benefits of civilization. Every person wants his home to always be warm and cozy. There are several ways to achieve this, but perhaps the most suitable option for insulating a house or apartment is a heated floor. Electric flooring is easy to make. Its installation will not take much time if you follow some recommendations. Scheme for installation of electric underfloor heating.

Scheme for installation of electric underfloor heating.

Varieties of the warm floor and the principle of their operation

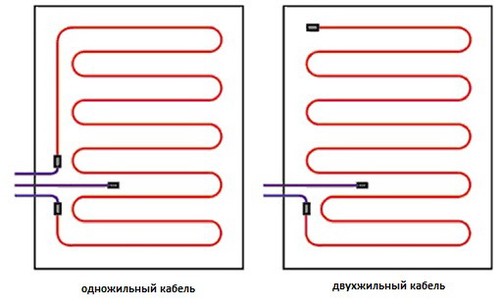

Today, there are 2 types of underfloor heating, which are heated using supplied electric current: Options for laying underfloor heating cables.

Options for laying underfloor heating cables.

Almost all underfloor heating systems,powered by electricity, are made in the form of a constructor, which allows them to be assembled independently and quickly. Regardless of the type chosen, the system is designed the same. It consists of:

- heating element (cable);

- heating mat;

- temperature sensor;

- thermostat.

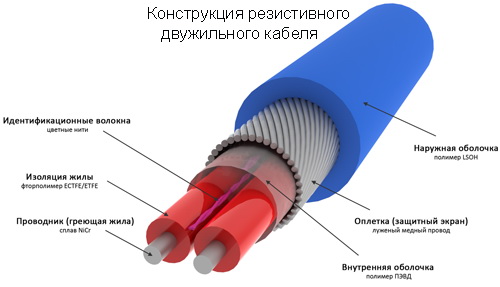

The heating mat serves as the mainheater. Externally, it looks like a grid with a cable on top. The standard size of such a mat reaches 25 m in length and 0.5 m in width, but there are other sizes. When buying such a warm floor system, special attention is paid to the area of the room that needs to be equipped. Professional builders do not recommend laying heating mats in places where furniture will be located. Therefore, before buying, you should clearly define the layout. In order not to make a mistake when choosing, you need to show your room calculation in the store. Based on it, the seller will select the required size of the mat and its power. Construction of a resistive twin-core cable.The thermal sensor allows you to control the floor temperature using a thermostat. Its installation is necessary, since the sensor allows you to track the heating temperature of the cable, thereby ensuring safety. The control unit or thermostat has several modes. With its help, you can program the heating system at your discretion. On the central control panel, you can set hourly, daily or weekly temperature control. The thermostat will turn on and off depending on the set mode. Cheaper models of the control unit do not have programming functions, they only monitor the maintenance of the required temperature. Their disadvantage is that they do not provide the ability to save energy consumption. Return to the table of contents</a>Preparing the floor for laying heating elements

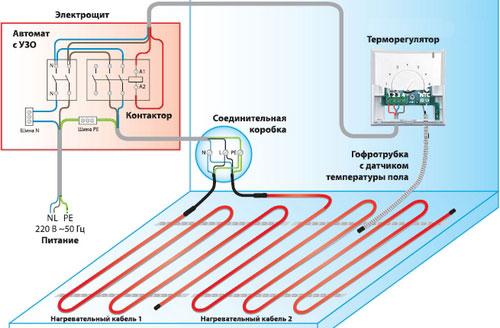

Construction of a resistive twin-core cable.The thermal sensor allows you to control the floor temperature using a thermostat. Its installation is necessary, since the sensor allows you to track the heating temperature of the cable, thereby ensuring safety. The control unit or thermostat has several modes. With its help, you can program the heating system at your discretion. On the central control panel, you can set hourly, daily or weekly temperature control. The thermostat will turn on and off depending on the set mode. Cheaper models of the control unit do not have programming functions, they only monitor the maintenance of the required temperature. Their disadvantage is that they do not provide the ability to save energy consumption. Return to the table of contents</a>Preparing the floor for laying heating elements Electric underfloor heating connection diagram to the electrical panel. Before starting installation, you need to purchase all the necessary materials and tools. For installation you will need:

Electric underfloor heating connection diagram to the electrical panel. Before starting installation, you need to purchase all the necessary materials and tools. For installation you will need:

- system of a warm floor (a grid, a heating cable);

- fasteners;

- a cable for earthing (copper);

- connecting wires;

- temperature sensor;

- thermoregulator;

- waterproofing (polyethylene film);

- heat reflector;

- metal reinforced network;

- sand;

- cement;

- lighthouses;

- rule.

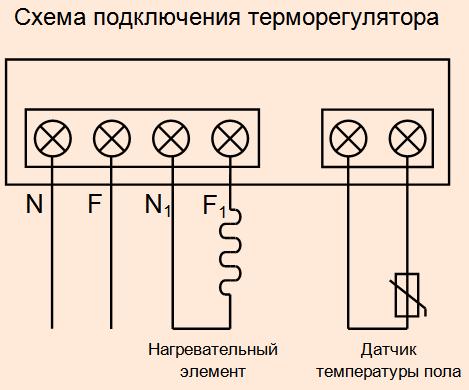

The floor surface needs to be leveled, cleaned andseal all cracks. To ensure that the heat radiated by the cable is directed directly into the room and does not heat the floor slabs, it is worth pouring a new screed. This step is not mandatory, but will allow you to significantly save on energy consumption in the future. A polyethylene film is spread on the floor (it can be replaced with foam plastic), on top of which a heat-reflecting material is laid. The joints of the heat reflector are fastened with tape. Next, it is necessary to give the screed rigidity, therefore the next layer is metal reinforcement. After the "pie" is ready, beacons are set and everything is filled with mortar. To avoid cracking, the thickness of the screed should be at least 50 mm. Return to contents</a>Technology of installation of cable electric underfloor heating Wiring diagram for underfloor heating thermostat.While the screed is hardening, proceed to installing the thermostat. To do this, it is necessary to make a groove in the wall to run the electric cable from the panel to the control unit, and from the latter to the floor. Preparing the place where the control unit will be located consists of drilling a mounting socket, as for a regular switch. A specially designed plastic box is inserted into it and a cable is laid to it. A separate automatic switch is required for the underfloor heating system. In order to do it yourself correctly, you need to learn how to cut the heating mat. It is rolled out to the required length and a cut is made in the mesh without violating the integrity of the cable. Such a cut will allow the mat to be unrolled in the opposite direction when the strip reaches the wall. When the entire floor surface is covered with the heating mat, its mesh is fixed using a building mixture for laying tiles. The next stage of installation is laying the cable for the temperature sensor (cold cable). A mandatory condition that must be observed when laying it is that the cables must run parallel to each other and must not intersect. They are secured with alabaster, and the edges are brought out to the distribution box of the thermostat. The temperature sensor itself is hidden in the corrugation and mounted in a groove made between its mount and the thermostat. For optimal operation of the control unit, it must be placed so that it is located between the turns of the heating cable. On the back of the thermostat there are connection terminals and symbols indicating what and where to connect. In addition, the device must be accompanied by instructions describing the connection diagram, which is suitable specifically for this model of the control unit. To avoid short circuits or other malfunctions during further operation, the ends of the wires connected to it are soldered. Return to contents</a>Technology of laying infrared heated floors

Wiring diagram for underfloor heating thermostat.While the screed is hardening, proceed to installing the thermostat. To do this, it is necessary to make a groove in the wall to run the electric cable from the panel to the control unit, and from the latter to the floor. Preparing the place where the control unit will be located consists of drilling a mounting socket, as for a regular switch. A specially designed plastic box is inserted into it and a cable is laid to it. A separate automatic switch is required for the underfloor heating system. In order to do it yourself correctly, you need to learn how to cut the heating mat. It is rolled out to the required length and a cut is made in the mesh without violating the integrity of the cable. Such a cut will allow the mat to be unrolled in the opposite direction when the strip reaches the wall. When the entire floor surface is covered with the heating mat, its mesh is fixed using a building mixture for laying tiles. The next stage of installation is laying the cable for the temperature sensor (cold cable). A mandatory condition that must be observed when laying it is that the cables must run parallel to each other and must not intersect. They are secured with alabaster, and the edges are brought out to the distribution box of the thermostat. The temperature sensor itself is hidden in the corrugation and mounted in a groove made between its mount and the thermostat. For optimal operation of the control unit, it must be placed so that it is located between the turns of the heating cable. On the back of the thermostat there are connection terminals and symbols indicating what and where to connect. In addition, the device must be accompanied by instructions describing the connection diagram, which is suitable specifically for this model of the control unit. To avoid short circuits or other malfunctions during further operation, the ends of the wires connected to it are soldered. Return to contents</a>Technology of laying infrared heated floors Electric underfloor heating connection diagramthermostat. Preparatory work for laying infrared is the same as for cable. In order not to damage the integrity of the infrared heating plates, the sheets must be cut only in the specified places. It is preferable to start laying the heating strips from the wall, in the direction of the thermostat. This will simplify the connection process. A temperature sensor is attached to the back of the heating plates using a bitumen adhesive strip and insulated with tape. The infrared heated floor must be laid so that the copper contacts are facing down, towards the floor. Next, lay the wires that will go from the infrared plates to the thermostat. Terminals are attached to the copper plates at the ends of the thermal film. A wire is connected to each terminal, which is clamped with pliers. Bitumen adhesive tape is used to insulate the connecting points. The wires and their connections to the infrared film are sunk. To do this, it is necessary to make cuts in the insulation (reflector). All that remains is to connect the wires coming from the heating sheets and the temperature sensor to the control unit. Return to contents</a>Finishing decorative floor covering Beforehow to proceed to the final stage, do-it-yourself warm floors must be checked for operability. Both the cable and the infrared sheets must heat up evenly. There should be no short circuits or sparks. If the warm floor is made correctly, the finishing coating can be laid on it. Cable electric warm floors are filled with a layer of screed, on top of which the selected flooring material is laid. If the finishing coating is tiles, then there is no need for a screed. The tiles are laid on top of the wires using glue specially designed for warm floors. Infrared warm floors, after successfully passing the performance test, are covered with a protective layer of polyethylene film. For laminate, a special underlay is used for the finishing coating. For linoleum or carpet, the floor is reinforced with sheets of plywood or chipboard. Particular attention should be paid to their fasteners so as not to damage the thermal film. If tiles are to be laid on the infrared warm floor, then it is necessary to make a concrete screed. It is worth knowing that the screed layer under the finishing coating will play an important role in the further heating of the room. If it is made thin, the floor will heat up faster, but also cool down. With a thick layer, the screed will warm up longer, but its ability to retain heat increases. It is not difficult to make electric heated floors with your own hands, the main thing is to follow all fire safety rules and recommendations for their installation.</ ul>

Electric underfloor heating connection diagramthermostat. Preparatory work for laying infrared is the same as for cable. In order not to damage the integrity of the infrared heating plates, the sheets must be cut only in the specified places. It is preferable to start laying the heating strips from the wall, in the direction of the thermostat. This will simplify the connection process. A temperature sensor is attached to the back of the heating plates using a bitumen adhesive strip and insulated with tape. The infrared heated floor must be laid so that the copper contacts are facing down, towards the floor. Next, lay the wires that will go from the infrared plates to the thermostat. Terminals are attached to the copper plates at the ends of the thermal film. A wire is connected to each terminal, which is clamped with pliers. Bitumen adhesive tape is used to insulate the connecting points. The wires and their connections to the infrared film are sunk. To do this, it is necessary to make cuts in the insulation (reflector). All that remains is to connect the wires coming from the heating sheets and the temperature sensor to the control unit. Return to contents</a>Finishing decorative floor covering Beforehow to proceed to the final stage, do-it-yourself warm floors must be checked for operability. Both the cable and the infrared sheets must heat up evenly. There should be no short circuits or sparks. If the warm floor is made correctly, the finishing coating can be laid on it. Cable electric warm floors are filled with a layer of screed, on top of which the selected flooring material is laid. If the finishing coating is tiles, then there is no need for a screed. The tiles are laid on top of the wires using glue specially designed for warm floors. Infrared warm floors, after successfully passing the performance test, are covered with a protective layer of polyethylene film. For laminate, a special underlay is used for the finishing coating. For linoleum or carpet, the floor is reinforced with sheets of plywood or chipboard. Particular attention should be paid to their fasteners so as not to damage the thermal film. If tiles are to be laid on the infrared warm floor, then it is necessary to make a concrete screed. It is worth knowing that the screed layer under the finishing coating will play an important role in the further heating of the room. If it is made thin, the floor will heat up faster, but also cool down. With a thick layer, the screed will warm up longer, but its ability to retain heat increases. It is not difficult to make electric heated floors with your own hands, the main thing is to follow all fire safety rules and recommendations for their installation.</ ul>