When there is a need to install a wall,for example, to divide a room or make a door for a niche, modern experts advise using a universal material - plasterboard. This, unlike a concrete wall, significantly saves space and money. Before starting work, you need to decide how the structure should look: perhaps it will be a solid wall or maybe with sliding doors. A false wall made of plasterboard is lighter than a concrete one, and it also saves money and space in the house.

A false wall made of plasterboard is lighter than a concrete one, and it also saves money and space in the house.

How to make a false wall

Before you go out to get the material,it is necessary to calculate its quantity. Drywall is purchased based on the entire wall area in square meters, and profiles - from the surface where the structure will be. An angular profile is also required, since it is installed along the entire perimeter. This is necessary in order to protect the material from crumbling and breakage. You will also need the following tools and materials: Tools for installing a false wall made of plasterboard.

Tools for installing a false wall made of plasterboard.

- perforator or drill;

- screwdriver, intended for drywall;

- a hammer;

- hacksaw for metal;

- construction level;

- roulette and ruler;

- various spatulas and trowel;

- knife stationery;

- profile rail and profile rack;

- self-tapping screws;

- dowel-nails;

- sealing tape;

- putty;

- sandpaper and pencil.

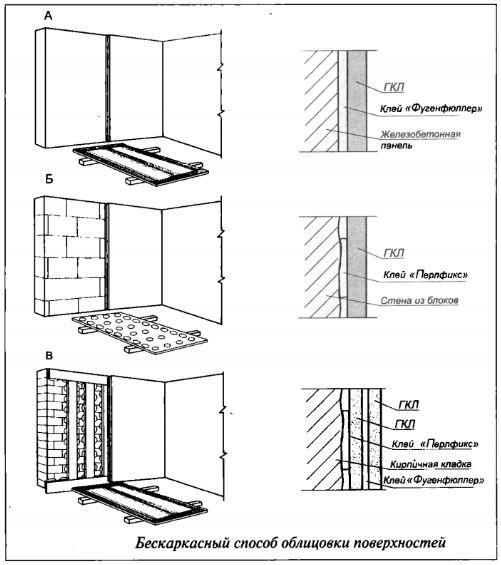

Try to choose quality materials,because the quality of the partition depends on it. If there are any communications in the chosen place, they must be prepared in advance. Return to the table of contents</a>Types of frames In fact, there are two types of frames for installing partitions. The first, the most durable and popular, is profile. The other type can be made of wood. Scheme of frameless method of wall finishingplasterboard. Of course, wooden lathing will cost much less and it is easier to install, but in order for such a structure to have a long service life, it must be treated with an antiseptic, which is not so cheap. If not treated, mold, fungus, etc. may form in the wood. The metal profile is more durable and long-lasting. It is even used repeatedly, since the metal can be straightened. It is quite easy to work with the profile, it takes up less space and is quite light in weight. That is why experts recommend using this material for the frame. If you decide to use wooden lathing, you may face the problem of leveling the wood. Because perfectly flat wood does not exist. Sometimes you can find bars with knots and the like inside. So try not to buy cheap materials. When cutting wood, keep in mind that the distance between the rack profiles should be equal. Return to contents</a>Assembly, installation of the frame on the wall Initiallyit is necessary to make the appropriate markings on the place where the false wall will be located, that is, on the floor and ceiling. After that, the guide profile strip is installed vertically and horizontally. Stiffening ribs are strengthened on the rack profile. The frame is fixed with self-tapping screws to the floor, ceiling and walls.

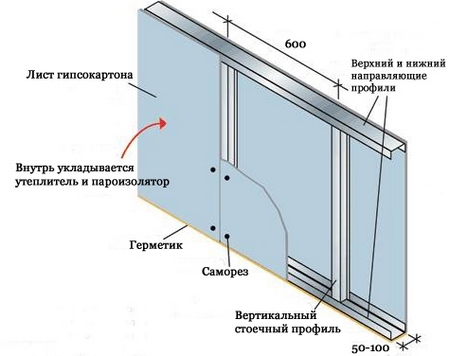

Scheme of frameless method of wall finishingplasterboard. Of course, wooden lathing will cost much less and it is easier to install, but in order for such a structure to have a long service life, it must be treated with an antiseptic, which is not so cheap. If not treated, mold, fungus, etc. may form in the wood. The metal profile is more durable and long-lasting. It is even used repeatedly, since the metal can be straightened. It is quite easy to work with the profile, it takes up less space and is quite light in weight. That is why experts recommend using this material for the frame. If you decide to use wooden lathing, you may face the problem of leveling the wood. Because perfectly flat wood does not exist. Sometimes you can find bars with knots and the like inside. So try not to buy cheap materials. When cutting wood, keep in mind that the distance between the rack profiles should be equal. Return to contents</a>Assembly, installation of the frame on the wall Initiallyit is necessary to make the appropriate markings on the place where the false wall will be located, that is, on the floor and ceiling. After that, the guide profile strip is installed vertically and horizontally. Stiffening ribs are strengthened on the rack profile. The frame is fixed with self-tapping screws to the floor, ceiling and walls. Scheme of fastening plasterboard sheet to the frame.Here you can use notches, they will save on screws (then you will need fewer of them). In order for the structure to be strong, you need to make stops from the same profile. You can make them from pieces that remain after trimming. These trims should be about 23 cm in size. It must be bent to 18 cm and fixed in this position to the wall, but with the short side. The long side must be pulled to the frame, then check the level and dimensions, and then fix it with screws. The number of spacers is determined by trial and error, in other words, they need exactly as many as necessary so that the overall structure is not shaky. Otherwise, the profiles may wobble. Craftsmen advise using a sealing tape when installing the profile on the wall, which is glued to the inner side. This tape performs the function of sound insulation and connecting parts. The structure is attached starting from the ceiling, then attached to the floor and on the sides. The distance between the fasteners should be at least 50-55 cm. If necessary, you can put soundproofing material in the frame, but this should be done before installing the drywall. This method of installing a profile frame is considered generally accepted, so it can be used for any type of partition. Each drywall wall can have a different number of profile strips, which can be different in size and thickness. Return to contents</a>Drywall installation and recommendations

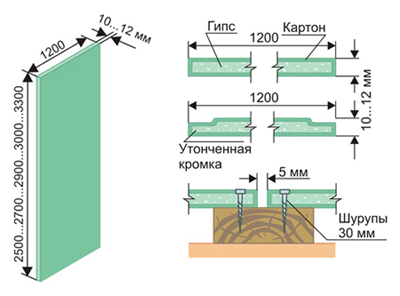

Scheme of fastening plasterboard sheet to the frame.Here you can use notches, they will save on screws (then you will need fewer of them). In order for the structure to be strong, you need to make stops from the same profile. You can make them from pieces that remain after trimming. These trims should be about 23 cm in size. It must be bent to 18 cm and fixed in this position to the wall, but with the short side. The long side must be pulled to the frame, then check the level and dimensions, and then fix it with screws. The number of spacers is determined by trial and error, in other words, they need exactly as many as necessary so that the overall structure is not shaky. Otherwise, the profiles may wobble. Craftsmen advise using a sealing tape when installing the profile on the wall, which is glued to the inner side. This tape performs the function of sound insulation and connecting parts. The structure is attached starting from the ceiling, then attached to the floor and on the sides. The distance between the fasteners should be at least 50-55 cm. If necessary, you can put soundproofing material in the frame, but this should be done before installing the drywall. This method of installing a profile frame is considered generally accepted, so it can be used for any type of partition. Each drywall wall can have a different number of profile strips, which can be different in size and thickness. Return to contents</a>Drywall installation and recommendations Scheme of fastening plasterboard to the wall.It is quite easy to make a false partition using plasterboard. This material is sold in large sheets of different sizes and thicknesses. You need to start with whole slabs, installing them in a frame. The plasterboard sheets must be applied to the profile structure one by one, while markings are made. In these places, the plasterboard is attached to the frame using a screwdriver and self-tapping screws. The sheets are pressed as tightly as possible. The distance between the screws should be within 20 cm, the fastener should have a recess of 8 mm, the caps are installed flush. Fastening work is carried out starting from the upper section, gradually moving down. After the plasterboard is securely mounted, you can do the finishing. First of all, it is necessary to seal all the seams and gaps, after which the surface must be primed. You can seal the cracks with ordinary putty, which must be applied with careful movements so that the surface is perfectly smooth. After everything has dried well, you need to sand the drywall with sandpaper. The next step is facing work. Plastic decorative trim, wallpaper, paint, cork material, etc. are perfect for this. There are many decorating options today. Experienced specialists recommend sinking the screw heads into the drywall as deeply as possible, this will allow the surface to be as smooth as possible. If dents have formed while working with the gypsum board, feel free to cover them up. It is necessary to make a false wall only in a dry and warm room, high humidity and low temperatures are unacceptable. After working with putty material, you need to thoroughly ventilate the room, otherwise dampness may remain on the drywall. Try to use only galvanized fasteners, because they do not rust. Work with pleasure and then you will succeed.

Scheme of fastening plasterboard to the wall.It is quite easy to make a false partition using plasterboard. This material is sold in large sheets of different sizes and thicknesses. You need to start with whole slabs, installing them in a frame. The plasterboard sheets must be applied to the profile structure one by one, while markings are made. In these places, the plasterboard is attached to the frame using a screwdriver and self-tapping screws. The sheets are pressed as tightly as possible. The distance between the screws should be within 20 cm, the fastener should have a recess of 8 mm, the caps are installed flush. Fastening work is carried out starting from the upper section, gradually moving down. After the plasterboard is securely mounted, you can do the finishing. First of all, it is necessary to seal all the seams and gaps, after which the surface must be primed. You can seal the cracks with ordinary putty, which must be applied with careful movements so that the surface is perfectly smooth. After everything has dried well, you need to sand the drywall with sandpaper. The next step is facing work. Plastic decorative trim, wallpaper, paint, cork material, etc. are perfect for this. There are many decorating options today. Experienced specialists recommend sinking the screw heads into the drywall as deeply as possible, this will allow the surface to be as smooth as possible. If dents have formed while working with the gypsum board, feel free to cover them up. It is necessary to make a false wall only in a dry and warm room, high humidity and low temperatures are unacceptable. After working with putty material, you need to thoroughly ventilate the room, otherwise dampness may remain on the drywall. Try to use only galvanized fasteners, because they do not rust. Work with pleasure and then you will succeed.