In the design of private houses, a tree is most oftenis associated with antiquity. Therefore, the lamps of wood have an old look. The most popular designs are chandeliers in the form of a wheel from a trolley.  The scheme of the device of a desktop wooden lamp.

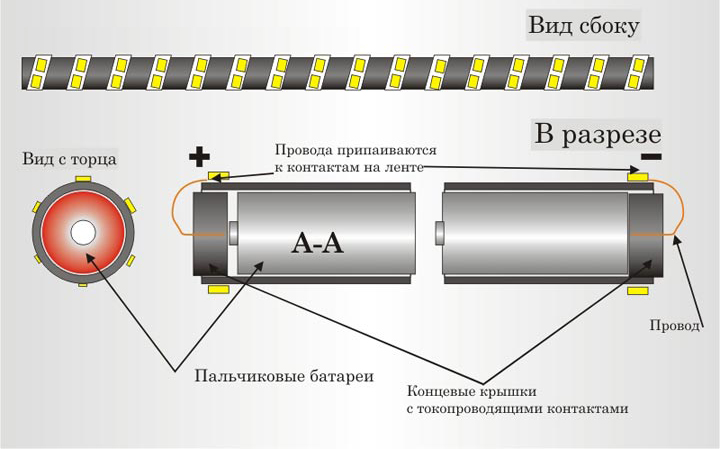

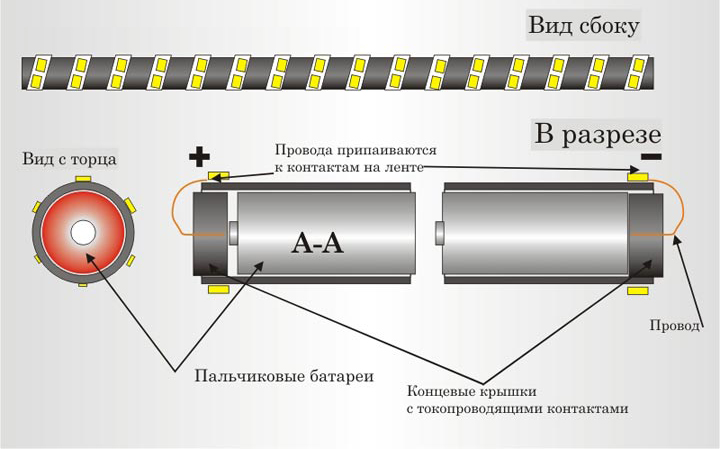

The scheme of the device of a desktop wooden lamp.

How to make a lamp with your own hands made of wood?

Back to contents</a> Advantages and disadvantages of wooden structures The construction of this type has the following advantages:

- if the candles are evenly distributed, the design will give the same illumination of all elements of the room;

- knitting needles will not practically obstruct light.

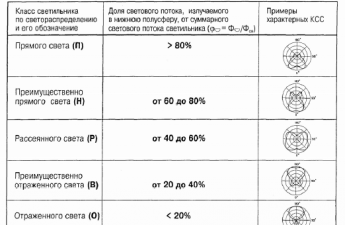

The same merits have modernstylization, but today, instead of candles made from wax and beams, lamps are used. In most cases, such designs are made in the form of a candle. Wooden structures have the following advantages:  Scheme of a round wooden lamp: 1 - segments for the rim, 2 - spoke chisel, 3 - hub.

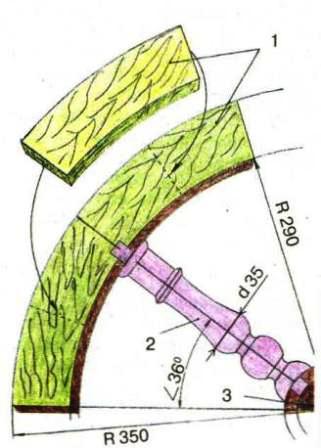

Scheme of a round wooden lamp: 1 - segments for the rim, 2 - spoke chisel, 3 - hub.

The material is environmentally friendly. It will not only not emit harmful substances, but will also saturate the air with aromatic resins that facilitate the breathing of people.

The tree can be easily processed. If special tools are needed to produce a plastic or metal structure, the luminaires can be made from wood by using a minimal set of tools.

Disadvantages of wooden structures:

Wood is a combustible material. It is not recommended to place elements from this material next to incandescent lamps. If a contact is burned in the lamp holder, the structure may catch fire.

Luminaires made of wood for the ceiling are exposedattacks of beetles, fungus and other pests. The conifers of trees are least affected by rot and pests. For hardwoods it is recommended to use antiseptic agents that can reduce the combustibility of the material.

Wood is a hygroscopic material. It absorbs moisture from the air, as a result of which, during drying, the material can change the volume, shape or crack. In order to maintain the structure for a long time, it will be necessary to provide it with a constant temperature and humidity.

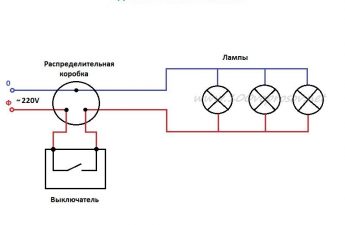

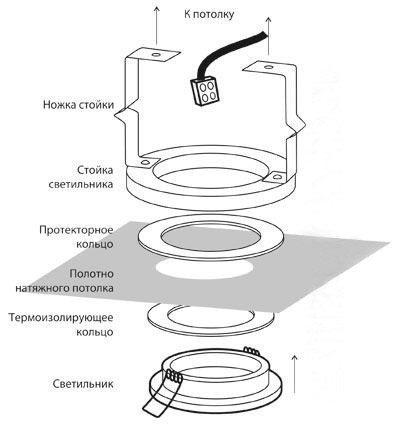

Back to contents</a> Nuances that should be considered when making wooden structures In the process of building fixtures from wood, the following nuances should be considered:  Scheme of the assembly of a lamp from wooden rings.

Scheme of the assembly of a lamp from wooden rings.

Constructions must be of such a form that allThe heating elements were removed from the appliances, which are made of wood. Lamps should look up, as only then the ascending airflow will not cause deformation of the tree.

Fire safety rules forbid placing chandeliers from wood under flammable elements.

The luminaire of wood is excellent forbedroom or living room. In a kitchen or bathroom, where there is a sufficiently large amount of steam, such structures are not allowed to be placed.

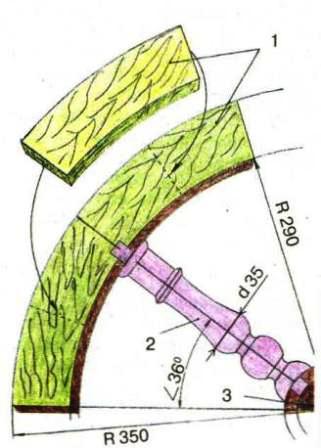

In the case of phase closure, it is easy to get an electric shock. Back to contents</a> Making a lamp in the form of a coffee set To make a lamp yourself, you will need to prepare the following elements:  Diagram of a wooden light fixture.

Diagram of a wooden light fixture.

Dry board of wood of any kind. You can use either ordinary pine or birch, and ash. The oak, which does not need to be painted or varnished, will do.

Several translucent coffee cups and saucers to them.

Several cartridges for a small base with fasteners for them.

Necessary number of bulbs. In this case, it is recommended to use LED elements.

A small number of gaskets made of rubber. Their number will depend on the method of securing the cartridges.

A two-wire copper conductor with a small cross-section and a short length. It is best to use a wire cross-section of 0.75 mm.

A chain of small thickness or a twisted cord. These elements will be used to fix the product on the ceiling structure.

Necessary number of screws with rings. The luminaire will be suspended using these elements.

Electric drill.

Drills for working with wood and tiles.

Combination pliers.

Screwdriver or screwdriver.

The manufacturing process is as follows:

The planed board is processed by sandpaper (at first - rough, after that-thin).

Next, you need to drill a few holes in the places where it is planned to have cartridges.

If noble varieties are usedwood, then in the future processing material is not needed. If other types of wood are used, then the material should be covered with stain, then dried and varnished in several layers. In the open air, nitro-lacquer will dry for several hours, so this process does not take much time.

The next step will need to drill intocoffee cups and saucers holes, while it is very important not to damage them. In this case, you only need to use a drill for working with glass and tiles. Not allowed to make great efforts. Drilling is necessary at a low speed, in the process you need to ensure that there is no distortion. If you strongly push the electric drill, the bowl or saucer can crack.

All the available cartridges need to be attached to the wires. At this stage, they should not be attached to each other.

The whole structure is screwed together. If the cartridges will use a pad with holes for fastening elements, then they need to be pulled to the board through the holes in the saucers or cups. If the end of the cartridge has a threaded pipe and a nut, then they must be passed through the cups, saucers and board. Between metal and glass elements, rubber pads must be installed. Such a device can be made independently from an unused camera from a bicycle or car.

In the back of the board you will need to screw the screws with the rings.

In parallel, the cartridges are connected. Do not leave twists, which are wrapped with electrical tape. Carefully need to do even that part of the lamp, which no one can see. To fasten the wires you will need to use a shoe.

The shoe should be fixed on the back of the board in any way: by a small amount of adhesive mixture or screws. In it, you need to clamp the piece of wire that will be connected to the wiring.

On the back side, chains or cords join the rings. The second end of these elements is fixed to the hook in the ceiling. The wire must be run on any of the circuits. In the end, you need to install the light bulbs.

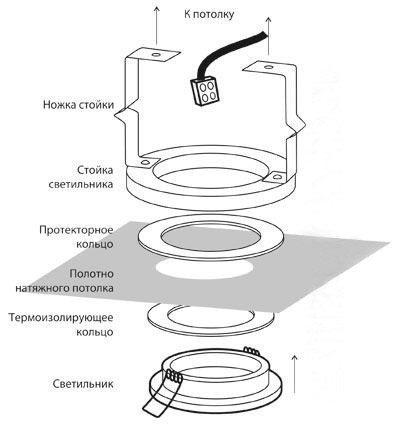

Back to contents</a> Design with lace from plywood  Tools for making woodenlamp. It should be noted that this design is not ideal in terms of fire safety. However, in this case, LED lights are used, which are economical. It should be remembered that such devices are practically not heated. Therefore, the risk of fire in this case is excluded. From plywood of a small thickness with the help of a hand-held jig saw it is possible to make masterpieces of applied art. You can make such lamps yourself:

Tools for making woodenlamp. It should be noted that this design is not ideal in terms of fire safety. However, in this case, LED lights are used, which are economical. It should be remembered that such devices are practically not heated. Therefore, the risk of fire in this case is excluded. From plywood of a small thickness with the help of a hand-held jig saw it is possible to make masterpieces of applied art. You can make such lamps yourself:

First of all, you need to polish the sheet of plywood.

Using the copy paper, you need to transfer the part drawing.

Elements of the construction will need to be cut out along the contour.

Inside each of the pieces that you need to remove, you will need to drill holes. In this case, it is recommended to use a 1 mm thick drill.

The next step is to cut out the internal parts.

Small files of various shapes will need to clean the edges of the structure.

Then you need to fasten all the elements together. To do this, it is recommended to use an adhesive mixture. It should be noted that PVA glue can turn yellow after a while. Therefore, it is best to use a special adhesive solution for wood. Remains of the adhesive mixture on the visible parts of the structure will need to be carefully removed.

At the end, the product should be varnished.

If you plan to use incandescent lamps,it should be remembered that their power should be less than 40 W. Place them at the maximum possible distance from the elements of the tree. Only in this case it is possible to avoid overheating of the lamp. Back to contents</a> Other variants of wooden lamps You can make other lamps yourself:

The construction of boards and ropes. As a light source in this case, several matt plafonds are used. There is nothing difficult in the manufacture of such a structure. It should be noted that in this case, only energy-saving or LED light bulbs should be used. Incandescent bulbs of high power quite often create a fire.

Bars with pots. In order to drill the bottom of the pots, you should use a drill to work with tiles. In this case, it is not allowed to install incandescent lamps of any power.

Chopped log with soffits. It should be taken into account that it is difficult to hollow out a product.

Of wood, lamps themselves make it simple enough. It will only be necessary to show imagination and prepare all the elements that will be needed for the construction.

Comments

Comments

The scheme of the device of a desktop wooden lamp.

The scheme of the device of a desktop wooden lamp.  Scheme of a round wooden lamp: 1 - segments for the rim, 2 - spoke chisel, 3 - hub.

Scheme of a round wooden lamp: 1 - segments for the rim, 2 - spoke chisel, 3 - hub.  Scheme of the assembly of a lamp from wooden rings.

Scheme of the assembly of a lamp from wooden rings.  Diagram of a wooden light fixture.

Diagram of a wooden light fixture.  Tools for making woodenlamp. It should be noted that this design is not ideal in terms of fire safety. However, in this case, LED lights are used, which are economical. It should be remembered that such devices are practically not heated. Therefore, the risk of fire in this case is excluded. From plywood of a small thickness with the help of a hand-held jig saw it is possible to make masterpieces of applied art. You can make such lamps yourself:

Tools for making woodenlamp. It should be noted that this design is not ideal in terms of fire safety. However, in this case, LED lights are used, which are economical. It should be remembered that such devices are practically not heated. Therefore, the risk of fire in this case is excluded. From plywood of a small thickness with the help of a hand-held jig saw it is possible to make masterpieces of applied art. You can make such lamps yourself: