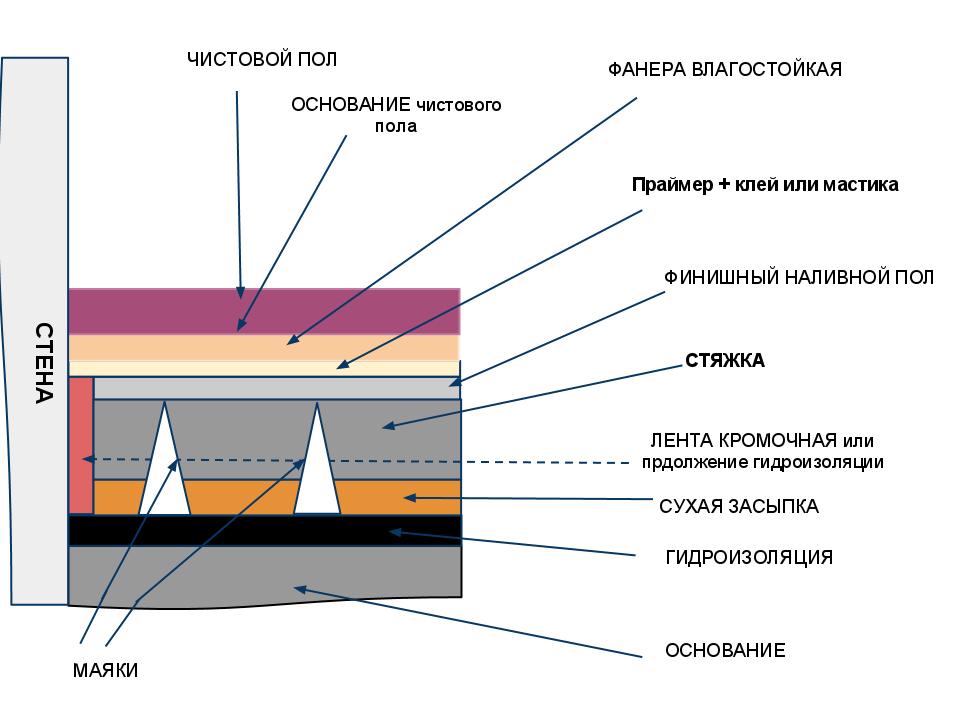

Для выравнивания полов применимы различные options. These are traditional concrete screeds, dry floor mixes, wooden joists and other methods. The so-called self-leveling mixtures have become popular recently, which after pouring provide the most even and smooth surface. Pouring the floor with a self-leveling mixture is done in several stages, it is relatively simple, but demanding. It is easy to work with the compositions, they are excellent as a surface preparation for any flooring material, can act as an independent coating in garages, warehouses, industrial or commercial buildings. Floor screed device diagram.

Floor screed device diagram.

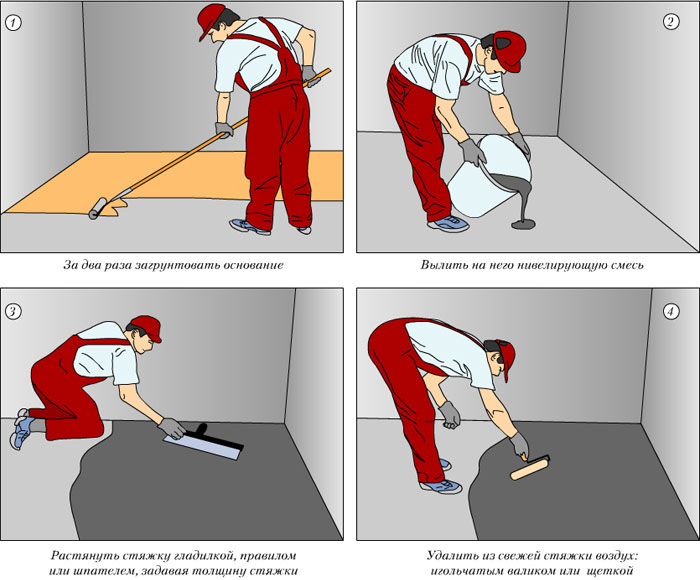

The process of filling the floor

Preparation of the base is simple and includes the following steps:

Pouring floors with self-leveling mixture is not possible without the following materials and tools:

- dry mixture for pouring;

- mixing tank;

- a drill with a nozzle-mixer;

- Needle roller;

- special studded shoes.

Return to Contents</a>

Mixing of the solution

Necessary tools for pouring the floor.To level the floor according to all the rules, you must first mix the solution. This stage is one of the most important, since the quality of the future coating depends on it. For example, too much water leads to excessive fluidity and low strength. Lack of water, on the contrary, leads to the fact that the mixture is difficult and poorly distributed on the floor, the quality is low. When mixing the mixture, you must strictly follow the instructions given by the manufacturer. You can pre-mix a test portion, see how exactly it spreads, whether there is a need to add or subtract water. Checking the quality of the mixture is simple, for this you only need to take an empty aerosol can. Its diameter should be 5 cm, and the height - about 4.5 cm. Cut off the bottom, and remove the lid. After this, pour a little mixed solution into the lid, turn it over so that the resulting mixture can spread over the surface. After about 2 minutes, you need to measure the diameter of the resulting puddle. If everything is done correctly, it should be 16-18 cm in size. If the diameter is smaller, then you need to add water. If it is larger, then the amount of water is too much. In order for the pouring of the self-leveling mixture to be of high quality, you must first pour water into the container, then carefully pour in the mixture and stir it. There should be no lumps left in the resulting mass. When preparing the mixture, you must remember that the fluidity lasts only 40 minutes. Therefore, the work must be carried out as quickly as possible. It is necessary to mix in small portions, otherwise the solution will simply be unsuitable for use. Return to the table of contents</a>

Necessary tools for pouring the floor.To level the floor according to all the rules, you must first mix the solution. This stage is one of the most important, since the quality of the future coating depends on it. For example, too much water leads to excessive fluidity and low strength. Lack of water, on the contrary, leads to the fact that the mixture is difficult and poorly distributed on the floor, the quality is low. When mixing the mixture, you must strictly follow the instructions given by the manufacturer. You can pre-mix a test portion, see how exactly it spreads, whether there is a need to add or subtract water. Checking the quality of the mixture is simple, for this you only need to take an empty aerosol can. Its diameter should be 5 cm, and the height - about 4.5 cm. Cut off the bottom, and remove the lid. After this, pour a little mixed solution into the lid, turn it over so that the resulting mixture can spread over the surface. After about 2 minutes, you need to measure the diameter of the resulting puddle. If everything is done correctly, it should be 16-18 cm in size. If the diameter is smaller, then you need to add water. If it is larger, then the amount of water is too much. In order for the pouring of the self-leveling mixture to be of high quality, you must first pour water into the container, then carefully pour in the mixture and stir it. There should be no lumps left in the resulting mass. When preparing the mixture, you must remember that the fluidity lasts only 40 minutes. Therefore, the work must be carried out as quickly as possible. It is necessary to mix in small portions, otherwise the solution will simply be unsuitable for use. Return to the table of contents</a>

Filling the floor

Scheme of preparatory work before pouringfloor with a self-leveling mixture. In order to fill the floor with the prepared mixture qualitatively, it is recommended to start all work from the far corner. The process itself is simple, even beginners who have no experience can handle it. It is only necessary to follow all the recommendations. It is necessary to pour a new portion in such a way that the boundaries between the individual layers are not visible. This is important not only for the appearance, but also for the strength of the future structure. Therefore, you should work quickly, without interrupting for trifles. When working in a thin place, the coating thickness can be from 5 mm, and for the thickest place this value should be up to 20 mm. Such parameters will affect the quality, so this rule should not be neglected. It is necessary to immediately determine such differences during the marking. Then it will be possible to accurately calculate the consumption of the composition, and the work can be done quickly, saving money. The floor must be poured correctly so that it lasts as long as possible. The composition is poured in small portions, after which it is distributed with a special needle roller. Walk on the floor only in special shoes with spikes on the sole, this will prevent damage to the already poured surface. The needle roller allows not only to distribute the mixture correctly, but also to get rid of air bubbles that remain in it after pouring and negatively affect the quality.

Scheme of preparatory work before pouringfloor with a self-leveling mixture. In order to fill the floor with the prepared mixture qualitatively, it is recommended to start all work from the far corner. The process itself is simple, even beginners who have no experience can handle it. It is only necessary to follow all the recommendations. It is necessary to pour a new portion in such a way that the boundaries between the individual layers are not visible. This is important not only for the appearance, but also for the strength of the future structure. Therefore, you should work quickly, without interrupting for trifles. When working in a thin place, the coating thickness can be from 5 mm, and for the thickest place this value should be up to 20 mm. Such parameters will affect the quality, so this rule should not be neglected. It is necessary to immediately determine such differences during the marking. Then it will be possible to accurately calculate the consumption of the composition, and the work can be done quickly, saving money. The floor must be poured correctly so that it lasts as long as possible. The composition is poured in small portions, after which it is distributed with a special needle roller. Walk on the floor only in special shoes with spikes on the sole, this will prevent damage to the already poured surface. The needle roller allows not only to distribute the mixture correctly, but also to get rid of air bubbles that remain in it after pouring and negatively affect the quality. Scheme of using self-leveling mixture.After the work is completely done, it is necessary to leave the coating to dry. It should be protected from drafts and bright sunlight. Therefore, the windows in the room must be closed, the surface must be covered with polyethylene film. The film must be kept for about two days, after which it can be removed. The drying time of the self-leveling floor depends entirely on how thick it is. Most often it is 2 weeks, although it may take longer. The peculiarity of the technology is that there is no need to use special beacons and other materials for leveling. This greatly facilitates the work, makes it much faster. It takes less time to dry than for cement screed, which can dry for 4 weeks. Return to the table of contents</a>

Scheme of using self-leveling mixture.After the work is completely done, it is necessary to leave the coating to dry. It should be protected from drafts and bright sunlight. Therefore, the windows in the room must be closed, the surface must be covered with polyethylene film. The film must be kept for about two days, after which it can be removed. The drying time of the self-leveling floor depends entirely on how thick it is. Most often it is 2 weeks, although it may take longer. The peculiarity of the technology is that there is no need to use special beacons and other materials for leveling. This greatly facilitates the work, makes it much faster. It takes less time to dry than for cement screed, which can dry for 4 weeks. Return to the table of contents</a>

Is it possible to use a self-leveling mixture for floors made of wood?

Is it possible to level a wooden base like this?mixture? Experts do not recommend doing this work, as the floor will be heavy. A wooden base may not be able to withstand such a load, especially if it is old. This will also have a negative effect on the screed, which will quickly begin to crack and deteriorate. Subfloor construction diagram oncombined screed. Despite this, many manufacturers of cement-based self-leveling floors claim that it is not only possible, but even necessary to use mixtures for leveling wooden floors. However, following this recommendation leads to the fact that soon it will be necessary to repair not only the screed, but also the base, and this is a considerable expense. Therefore, it is not worth the risk, there are many more economical solutions for wooden floors, for example, using adjustable logs. Self-leveling mixture is used if it will be poured onto a recently repaired and strong base that can withstand the load. The pouring process is not much different from the standard one. It is necessary to first prepare the base, carefully inspect it. If there are cracks or other defects, they should be repaired immediately, weak elements should be replaced with new ones, all boards with traces of rot should be removed. After this, the solution is mixed in the proportions specified by the manufacturer, poured from the far corner. You need to work in studded shoes, distribute the mixture with a needle roller. It may be necessary to treat the surface with a special mop with a rubber tip. Self-leveling pouring mixtures are an excellent option for giving the floor exactly the properties that are needed. The surface is not only even, but also smooth and durable. It is perfect for laying any flooring material. The process of installing such a screed is simple, it involves pouring the mixture onto the surface of the base, spreading it with a needle roller. The composition easily takes exactly the shape that is required of it. The result is an even and smooth base.

Subfloor construction diagram oncombined screed. Despite this, many manufacturers of cement-based self-leveling floors claim that it is not only possible, but even necessary to use mixtures for leveling wooden floors. However, following this recommendation leads to the fact that soon it will be necessary to repair not only the screed, but also the base, and this is a considerable expense. Therefore, it is not worth the risk, there are many more economical solutions for wooden floors, for example, using adjustable logs. Self-leveling mixture is used if it will be poured onto a recently repaired and strong base that can withstand the load. The pouring process is not much different from the standard one. It is necessary to first prepare the base, carefully inspect it. If there are cracks or other defects, they should be repaired immediately, weak elements should be replaced with new ones, all boards with traces of rot should be removed. After this, the solution is mixed in the proportions specified by the manufacturer, poured from the far corner. You need to work in studded shoes, distribute the mixture with a needle roller. It may be necessary to treat the surface with a special mop with a rubber tip. Self-leveling pouring mixtures are an excellent option for giving the floor exactly the properties that are needed. The surface is not only even, but also smooth and durable. It is perfect for laying any flooring material. The process of installing such a screed is simple, it involves pouring the mixture onto the surface of the base, spreading it with a needle roller. The composition easily takes exactly the shape that is required of it. The result is an even and smooth base.