To make a floor covering, oftenuse plywood. This material is suitable for rough and basic coating. With its help, you can quickly, without spending a lot of money, if necessary, level the floor. When making plywood floors with your own hands, you have to answer natural questions: what type of plywood is best suited for the floor and its base? What are the methods for laying this material? Each type of plywood has its own method.laying the material on the floor. First of all, you need to determine the type of plywood. The main role here is played by the floor covering. For an ordinary apartment, one-sided sanded plywood is suitable. The most suitable is 12 mm plywood. This layered material is glued with compounds that do not contain toxic substances. The best option for covering the main floor is grade E1, with a low formaldehyde content. After selecting the material, you should determine the method by which it will be laid. The most economical, not requiring much time is considered to be laying directly on a concrete base. It is best to use a material with a thickness of more than 12 mm. Another popular method has become the installation of a plywood floor directly on a wooden surface, this is how a subfloor is obtained. Self-tapping screws are used to fasten the plywood covering.

Each type of plywood has its own method.laying the material on the floor. First of all, you need to determine the type of plywood. The main role here is played by the floor covering. For an ordinary apartment, one-sided sanded plywood is suitable. The most suitable is 12 mm plywood. This layered material is glued with compounds that do not contain toxic substances. The best option for covering the main floor is grade E1, with a low formaldehyde content. After selecting the material, you should determine the method by which it will be laid. The most economical, not requiring much time is considered to be laying directly on a concrete base. It is best to use a material with a thickness of more than 12 mm. Another popular method has become the installation of a plywood floor directly on a wooden surface, this is how a subfloor is obtained. Self-tapping screws are used to fasten the plywood covering.

How to properly lay plywood?

Before you start working, you need to have plywoodhas undergone an acclimatization period. It is left in the apartment for at least 1 day. If the storage conditions in the warehouse are very different from those in the apartment, then the acclimatization of the material should take place within 3 days. Scheme of laying plywood on the floor.The moisture resistance of plywood can be increased when necessary. It is impregnated with a putty made on the basis of polyvinyl acetate. First, only one side is impregnated and wait for stains to appear on the opposite side. Then the reverse side is impregnated in the same way. Such plywood is dried, installed horizontally and left for 3 days. The dried plywood is treated with an antiseptic. Before you start laying the prepared material, you need to measure the humidity of the base. Take a polyethylene film and put it on 1 m² of the base, press the edges with a load, the middle part should be slightly raised. If condensation occurs inside the film within 24 hours, then plywood cannot be installed in this room. If a small condensation has formed after 3 days, parchment is placed on the main floor, a mounting mesh is installed and a screed is made. If condensation is not detected after 5 days, then you can safely make a plywood floor. Return to the table of contents</a>

Scheme of laying plywood on the floor.The moisture resistance of plywood can be increased when necessary. It is impregnated with a putty made on the basis of polyvinyl acetate. First, only one side is impregnated and wait for stains to appear on the opposite side. Then the reverse side is impregnated in the same way. Such plywood is dried, installed horizontally and left for 3 days. The dried plywood is treated with an antiseptic. Before you start laying the prepared material, you need to measure the humidity of the base. Take a polyethylene film and put it on 1 m² of the base, press the edges with a load, the middle part should be slightly raised. If condensation occurs inside the film within 24 hours, then plywood cannot be installed in this room. If a small condensation has formed after 3 days, parchment is placed on the main floor, a mounting mesh is installed and a screed is made. If condensation is not detected after 5 days, then you can safely make a plywood floor. Return to the table of contents</a>

Features of preparation

Tools for floor leveling For work you need to have special tools:

Tools for floor leveling For work you need to have special tools:

- perforator;

- Screwdriver;

- laser level;

- a hammer;

- electric jigsaw;

- long roulette.

First, standard sheets are sawn intosquares, they will be much easier to work with. The edges of the plywood after sawing should not have chips. Square sheets must be adjusted taking into account the damper seams. The gap between the sheets should be less than 10 mm. Tight adhesion of plywood sheets to the wall is not allowed, it is necessary to maintain a gap of 15 mm. When the sheets are laid out on the floor, they need to be numbered, or a sketch of the installation should be drawn. The next step is cleaning the concrete base. When performing this operation, the concrete base must be protected from any moisture. It must always be remembered that moisture is the worst enemy of plywood. Using plywood as a subfloor.The simplest and most accessible way to prepare the base for laying the floor covering is to level the existing wooden floor with plywood. This is a unique option, the most accessible for doing it yourself. There are also several technologies for leveling with plywood, when self-leveling mixtures are used. But this work is one of the most labor-intensive. It is not at all necessary to dismantle the old boards in the apartment in order to prepare the floor and install a new covering. Any person can handle this work. He does not need to have extensive experience in home repairs. Before you start installing plywood sheets, you need to remove all defects in the base. All loose boards are fastened with screws. Boards that have completely dried out are best replaced, since the floors will subsequently begin to creak. After preparing the rough base, you can begin to install the plywood. The optimal thickness of the plywood sheets used is considered to be 12 mm. Such a floor will have a smooth, reliable surface. The rough base is made from the last class of plywood. This material must have increased moisture resistance. Return to contents</a>

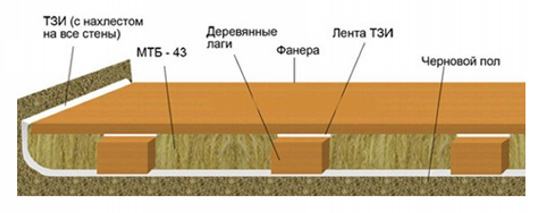

Using plywood as a subfloor.The simplest and most accessible way to prepare the base for laying the floor covering is to level the existing wooden floor with plywood. This is a unique option, the most accessible for doing it yourself. There are also several technologies for leveling with plywood, when self-leveling mixtures are used. But this work is one of the most labor-intensive. It is not at all necessary to dismantle the old boards in the apartment in order to prepare the floor and install a new covering. Any person can handle this work. He does not need to have extensive experience in home repairs. Before you start installing plywood sheets, you need to remove all defects in the base. All loose boards are fastened with screws. Boards that have completely dried out are best replaced, since the floors will subsequently begin to creak. After preparing the rough base, you can begin to install the plywood. The optimal thickness of the plywood sheets used is considered to be 12 mm. Such a floor will have a smooth, reliable surface. The rough base is made from the last class of plywood. This material must have increased moisture resistance. Return to contents</a>

The technology used for the plywood leveling process

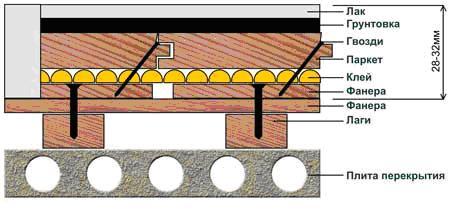

When laying plywood directly onconcrete screed, due to the lack of a wooden base, it is necessary to find out what is the humidity of the existing concrete surface. High humidity can spoil the coating. The screed must be covered with a waterproofing base on top. How to determine the humidity of concrete was described above. Installation of plywood flooring.There is also a technology in which plywood alignment is carried out using logs. For this, a frame made of wooden slats using a special technology is mounted on the concrete floor in advance. After the concrete screed has been thoroughly dried and the wooden floor is well strengthened, it is necessary to cut the plywood sheets. In stores, plywood sheets are sold with dimensions of 1.5 x 1.5 m. It must be said that it is impractical to use sheets of larger dimensions. To align the plywood, you need to cut it into certain squares. Each such sheet is divided into 4 small squares. The cut sheets are laid over the entire floor, but are not fixed. This is necessary to determine the amount of material for the entire floor area. Using the laid sheets, it is easy to make marks on the plywood that will need to be trimmed. Small gaps should be maintained between the sheets fixed to the floor. Typically, the seam width reaches 10 mm. During installation, it is not allowed to mount plywood sheets directly to the wall. The gap between the wall and the last plywood sheet should be up to 2 cm. This allows the floor to "breathe", which will prevent deformations of the ceilings depending on the season. The prepared sheets are fastened in a checkerboard pattern, similar to brickwork. The installed surface must be sanded. After this operation, the plywood floor turns into an ideal base to lay any coating on it.

Installation of plywood flooring.There is also a technology in which plywood alignment is carried out using logs. For this, a frame made of wooden slats using a special technology is mounted on the concrete floor in advance. After the concrete screed has been thoroughly dried and the wooden floor is well strengthened, it is necessary to cut the plywood sheets. In stores, plywood sheets are sold with dimensions of 1.5 x 1.5 m. It must be said that it is impractical to use sheets of larger dimensions. To align the plywood, you need to cut it into certain squares. Each such sheet is divided into 4 small squares. The cut sheets are laid over the entire floor, but are not fixed. This is necessary to determine the amount of material for the entire floor area. Using the laid sheets, it is easy to make marks on the plywood that will need to be trimmed. Small gaps should be maintained between the sheets fixed to the floor. Typically, the seam width reaches 10 mm. During installation, it is not allowed to mount plywood sheets directly to the wall. The gap between the wall and the last plywood sheet should be up to 2 cm. This allows the floor to "breathe", which will prevent deformations of the ceilings depending on the season. The prepared sheets are fastened in a checkerboard pattern, similar to brickwork. The installed surface must be sanded. After this operation, the plywood floor turns into an ideal base to lay any coating on it.