Gaps in floor covering assembled from sheetslaminated wood panel, can ruin the whole look of a wonderful floor in an apartment or office. Knowing the possible reasons that can serve as the basis for damage to the floor covering can protect it from this even at the initial stage of laying the floor. Laminate flooring installation diagram. To avoid the above mentioned troubles, it should be taken into account that laminate flooring installation should be carried out according to certain technological rules.

Laminate flooring installation diagram. To avoid the above mentioned troubles, it should be taken into account that laminate flooring installation should be carried out according to certain technological rules.

Characteristics of laminate flooring

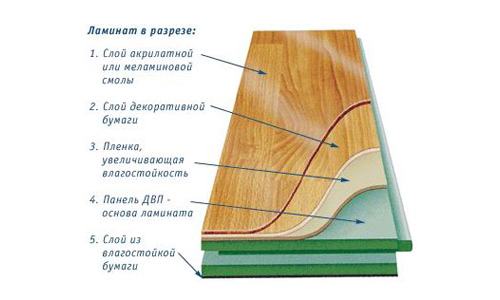

Laminate flooring is a visually appealing floor coveringresembling parquet, but having nothing in common with it except for its appearance. The commonly used shortened name "laminate" implies a modern building material based on fiberboard (FB), the upper part of which is covered with a plastic film of complex composition. This surface layer, sometimes not even one, but a composite layer, serves to protect the sheets of material from moisture, sunlight, dirt and slow down abrasion during mechanical action. The supporting base of the board itself is high-density fiberboard. For example, MDF fiberboard used in furniture production has only medium density and is not used in the production of floor coverings. In European countries, a classification of this type of flooring is used, in which the class assigned to the material corresponds to its resistance to mechanical impact, abrasion. The higher the class, the stronger the laminate. The practicality of this material, its performance characteristics, the ability to choose a laminate of any color and pattern have made it very popular at present. Return to Contents</a>

Technology of laying laminated boards

Laminate flooring installation options.Laminate flooring is supplied in the form of thin (6-11 mm thick) strips, the length of which varies from 1000 to 1400 mm, and the width reaches 200 mm. In the longitudinal and end edges of these strips there are special grooves and hooks, which, when connecting two strips of the same type of material with the same sides, form a specific "lock" connection, tightly holding the said strips relative to each other. The shape of the retaining elements of such "locks" determines the method of connecting the laminate:

Laminate flooring installation options.Laminate flooring is supplied in the form of thin (6-11 mm thick) strips, the length of which varies from 1000 to 1400 mm, and the width reaches 200 mm. In the longitudinal and end edges of these strips there are special grooves and hooks, which, when connecting two strips of the same type of material with the same sides, form a specific "lock" connection, tightly holding the said strips relative to each other. The shape of the retaining elements of such "locks" determines the method of connecting the laminate:

- insertion in the groove "lock" the previous strip of the corresponding elements of the subsequent is made at an angle of 30 ° to the floor plane;

- Entry into the "lock" of the previous strip of the corresponding elements of the subsequent is made in the plane of the floor (the slope of the latter is zero).

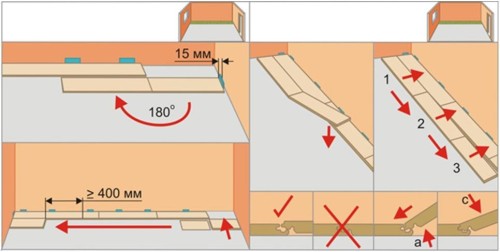

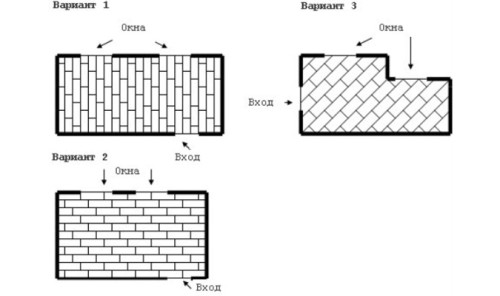

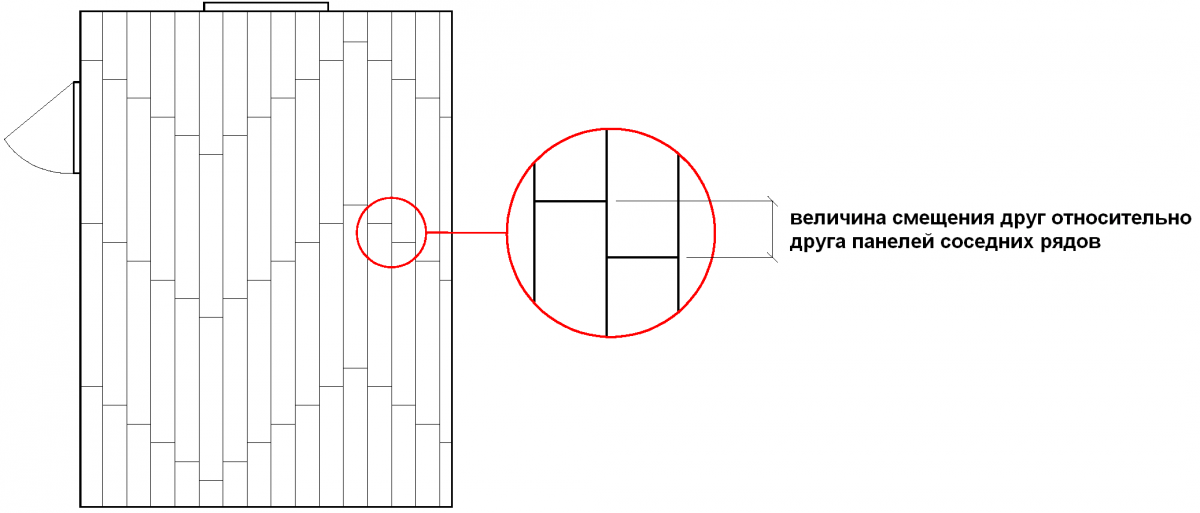

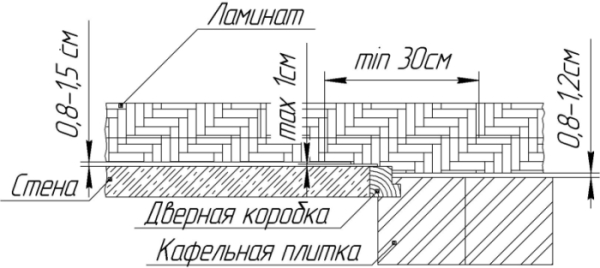

In order to fix the connection being madehas become full, it is recommended to strike the free end of the floor slab being attached with a hammer several times using a suitable wooden block. Moreover, the force applied should be dosed in such a way as not to damage the protruding tongue of the slab with blows. Since, depending on the technological features of using such material, when laying laminate, an initial gap must be provided between the floor covering and the walls of the room, then with a longitudinal arrangement of the slabs, the laying begins with the placement of restrictive elements (template), ensuring its observance. Schematic diagram of the displacement value during layingThe limiting template can be made from scrap materials: slats or simply wooden blocks of the required dimensions. The width of this gap can vary from 10 to 15 mm, but it must be provided. The fact is that under the influence of humidity and temperature of the room, deformation of the slabs of the floor surface laid in it is possible. When the material of the slabs expands in such a situation, the excess laminate that appears needs additional free space to be placed. This space is intended to serve as the initial gap, which is therefore called "expansion". Such a gap is provided not only in relation to the walls of the room, but also in relation to its other elements. This also applies to all engineering communications coming out of the floor. Considering the requirements for the "expansion" gap, it should be noted that when fastening floor plinths and decorative thresholds, after completing the installation work on the floor covering, it is necessary to perform the specified fastening in such a way that there remains a full possibility of using the created gap. General installation advice includes the recommendation to place the strips of flooring perpendicular to the direction of daylight, so that the gaps between their joints are less visible. In addition, it is recommended to space the closest joints of the strips of adjacent rows by more than 40 mm. Return to contents</a>

Schematic diagram of the displacement value during layingThe limiting template can be made from scrap materials: slats or simply wooden blocks of the required dimensions. The width of this gap can vary from 10 to 15 mm, but it must be provided. The fact is that under the influence of humidity and temperature of the room, deformation of the slabs of the floor surface laid in it is possible. When the material of the slabs expands in such a situation, the excess laminate that appears needs additional free space to be placed. This space is intended to serve as the initial gap, which is therefore called "expansion". Such a gap is provided not only in relation to the walls of the room, but also in relation to its other elements. This also applies to all engineering communications coming out of the floor. Considering the requirements for the "expansion" gap, it should be noted that when fastening floor plinths and decorative thresholds, after completing the installation work on the floor covering, it is necessary to perform the specified fastening in such a way that there remains a full possibility of using the created gap. General installation advice includes the recommendation to place the strips of flooring perpendicular to the direction of daylight, so that the gaps between their joints are less visible. In addition, it is recommended to space the closest joints of the strips of adjacent rows by more than 40 mm. Return to contents</a>

Aligning the surface for a laminate

Layout of the laminate.A smooth and clean underlying surface is of great importance when laying laminate, since if the height difference on it is more than 3 mm, the "locks" that hold the joints of the strips together usually cannot withstand the load. It is advisable to adhere to the standard for height changes: no more than 1 mm of vertical per 1 m of floor. Therefore, it is not recommended to use an old wood-panel floor as an underlying surface. It is better to lay such a floor covering on a corresponding concrete screed, all protrusions and depressions of which have been previously removed, and the laying of the laminate is preceded by a thorough cleaning of the surface from debris, dust and sand. In particularly difficult conditions, it makes sense to use self-leveling floors, which can level out differences in surface heights of up to 20 mm. Sometimes, in the technology of installing laminated floors, special materials are used that, when laid on the underlying surface, simultaneously serve as a compensator for underlying unevenness and an insulating base for the top coating. Considering the ability of laminated flooring elements to change their geometric dimensions under the influence of temperature and moisture, its installation is usually carried out by free laying, without rigid attachment to the lower surface. Return to contents</a>

Layout of the laminate.A smooth and clean underlying surface is of great importance when laying laminate, since if the height difference on it is more than 3 mm, the "locks" that hold the joints of the strips together usually cannot withstand the load. It is advisable to adhere to the standard for height changes: no more than 1 mm of vertical per 1 m of floor. Therefore, it is not recommended to use an old wood-panel floor as an underlying surface. It is better to lay such a floor covering on a corresponding concrete screed, all protrusions and depressions of which have been previously removed, and the laying of the laminate is preceded by a thorough cleaning of the surface from debris, dust and sand. In particularly difficult conditions, it makes sense to use self-leveling floors, which can level out differences in surface heights of up to 20 mm. Sometimes, in the technology of installing laminated floors, special materials are used that, when laid on the underlying surface, simultaneously serve as a compensator for underlying unevenness and an insulating base for the top coating. Considering the ability of laminated flooring elements to change their geometric dimensions under the influence of temperature and moisture, its installation is usually carried out by free laying, without rigid attachment to the lower surface. Return to contents</a>

The reasons for the appearance of gaps

Tools for laying laminate flooring.Gaps can be specially organized (technological) and emergency, appearing in places where floor slabs are detached. Questions about what and how can damage laminated flooring material, specially created to withstand the corresponding loads, have long been of interest to specialists working with it. The reasons causing deformation of the flooring, including swelling of the strip surfaces, their detachment from each other, the appearance of gaps between the strips and the "sounding" of the floor, were studied and analyzed by professionals. As a result, a group of main situations was identified in which the conditions of installation work, the operating conditions of the flooring and the "human factor" cause a decrease in the quality of the laminated floor being laid, up to subsequent damage to the latter: Purchase of defective strips of laminate, which:

Tools for laying laminate flooring.Gaps can be specially organized (technological) and emergency, appearing in places where floor slabs are detached. Questions about what and how can damage laminated flooring material, specially created to withstand the corresponding loads, have long been of interest to specialists working with it. The reasons causing deformation of the flooring, including swelling of the strip surfaces, their detachment from each other, the appearance of gaps between the strips and the "sounding" of the floor, were studied and analyzed by professionals. As a result, a group of main situations was identified in which the conditions of installation work, the operating conditions of the flooring and the "human factor" cause a decrease in the quality of the laminated floor being laid, up to subsequent damage to the latter: Purchase of defective strips of laminate, which:

- there were damages to the elements of the interlocking "locks";

- damage to the upper protective plastic coating was noted.

Return to Contents</a>Methods for eliminating gaps that have arisen The first method is to simply prevent them from appearing, for which it is necessary to follow the recommended technology for laying and installing laminate. Gaps during installation Before starting installationThe purchased materials, without unpacking, must be placed in the room where they will be used later for “acclimatization” for two to three days. It is recommended to maintain the room temperature at about 18°C. After opening the package, the material must be checked for defects, primarily the condition of the end and longitudinal parts of the “locks” and the protective top coating. Before starting to install the laminate floor, it should also be borne in mind that, despite the protective layer, the laminate should not be tested with water again, especially in the area of the joints of the boards. It is recommended to remove water that gets on the laminate during operation promptly, within an hour, no more. Taking this into account, it makes sense to think about the possible treatment of future joints of the floor boards with a wax composition. Installation work must be carried out strictly according to the technology, with an additional check of the “lock” elements of the mounted boards for the absence of interfering foreign particles and for damage to their structure. The installed joints should be compacted with hammer blows according to the rules given above, after which they should be visually checked for gaps. Gaps that appear on the exploited floor made of laminate flooring, by their size and time of appearance, can suggest to an attentive person a method for their elimination. If these gaps appear during the heating season, the width of their "opening" is small, and sometimes they disappear, then the reason for the appearance of such gaps is most often low humidity of the air environment of this room. Their appearance can be eliminated by turning on the appropriate humidifiers. If the gaps appeared along with swelling of the floor covering, this may indicate the absence or filling of the "expansion" gap along the perimeter of the room. This can happen for various reasons:

Gaps during installation Before starting installationThe purchased materials, without unpacking, must be placed in the room where they will be used later for “acclimatization” for two to three days. It is recommended to maintain the room temperature at about 18°C. After opening the package, the material must be checked for defects, primarily the condition of the end and longitudinal parts of the “locks” and the protective top coating. Before starting to install the laminate floor, it should also be borne in mind that, despite the protective layer, the laminate should not be tested with water again, especially in the area of the joints of the boards. It is recommended to remove water that gets on the laminate during operation promptly, within an hour, no more. Taking this into account, it makes sense to think about the possible treatment of future joints of the floor boards with a wax composition. Installation work must be carried out strictly according to the technology, with an additional check of the “lock” elements of the mounted boards for the absence of interfering foreign particles and for damage to their structure. The installed joints should be compacted with hammer blows according to the rules given above, after which they should be visually checked for gaps. Gaps that appear on the exploited floor made of laminate flooring, by their size and time of appearance, can suggest to an attentive person a method for their elimination. If these gaps appear during the heating season, the width of their "opening" is small, and sometimes they disappear, then the reason for the appearance of such gaps is most often low humidity of the air environment of this room. Their appearance can be eliminated by turning on the appropriate humidifiers. If the gaps appeared along with swelling of the floor covering, this may indicate the absence or filling of the "expansion" gap along the perimeter of the room. This can happen for various reasons:

- the primary gap at the points of abutment of the floor covering to the walls was incorrectly arranged;

- The flooring material was not sufficiently aged in the microclimate of this room.

In such cases, it is necessary to trim the strips.floors adjacent to the walls in order to restore the necessary perimeter gap. In cases where the "lock" connecting two slabs fails, or a serious gap appears due to water ingress, the damage can be repaired using a suitable sealant or putty matched to the color of the floor slabs. To carry out such repairs, it is necessary to:

- surfaces adjacent to the gap, and the gap itself should be thoroughly cleaned of dust and foreign inclusions;

- edges of the laminate, leaving the gap on both sides, seal with paint tape;

- Clear the gap with a chosen substance for repair, applying it level with the plane of the floor covering.

After the applied putty has dried, tapeshould be removed, the joint should be carefully cleaned and wiped. From the point of view of the possible and necessary elasticity of this substance, a sealant would be more suitable for such an application. If, when loading the laminate flooring, sounds similar to crunching are heard, this means that a certain "locking" part of the laminate elements begins, for some reason, to weaken or fail. This should be given the closest attention and the joint that produces the crunch and the reasons causing it should be determined in order to eliminate the possible appearance of gaps and other unpleasant consequences in time.