Almost every person who has everlife made something for your home with your own hands, over time begins to feel the desire to put in your efforts again. After all, it is so nice to see the result of your work every day, especially if this craft becomes a noticeable accent in the interior of the house. Such an accent can be a new glass table. Some people wonder how to make a glass table with their own hands. The glass table does not absorb moisture and grease, and alsovery easy to care for. The process of its manufacture requires caution and accuracy, but the end result is worth it. A little time, and you can proudly show off your new home decor item, made by yourself, to your friends and relatives. Let's consider how to make a glass table.

The glass table does not absorb moisture and grease, and alsovery easy to care for. The process of its manufacture requires caution and accuracy, but the end result is worth it. A little time, and you can proudly show off your new home decor item, made by yourself, to your friends and relatives. Let's consider how to make a glass table.

Pros and cons of the glass table

Advantages of a glass table:

- suitable for any interior;

- hygienic;

- easy to care for;

- relatively easy;

- does not absorb fat;

- glass can be treated with any cleaning agents.

These tables also have some noticeable disadvantages.Glass tabletops do not dampen sound, so the use of the table is accompanied by characteristic sounds. In bright light, stains and fingerprints become visible on the glass. Return to contents</a>

How to make a glass table yourself

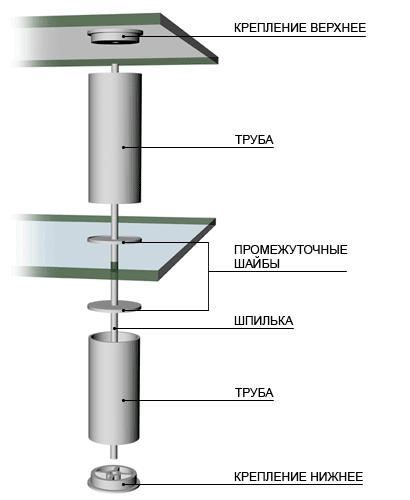

Connection diagram of glass table top and stand.First, you need to choose the shape, style and size of the table. It can be a regular rectangular glass table in a high-tech style or in the style of an oriental fairy tale. You need to decide what role it will play in the already established interior. After all the tasks are defined, it remains to prepare the necessary tools, materials and go! To make a glass table, you will need:

Connection diagram of glass table top and stand.First, you need to choose the shape, style and size of the table. It can be a regular rectangular glass table in a high-tech style or in the style of an oriental fairy tale. You need to decide what role it will play in the already established interior. After all the tasks are defined, it remains to prepare the necessary tools, materials and go! To make a glass table, you will need:

- glass cutter (it can be diamond or roller);

- pliers with rubber gaskets;

- metal ruler;

- hammer of rubber;

- the material itself for making the table (it is better if its thickness is not less than 6 mm).

You can choose the glass for making the tableany. It can be transparent and matte, colorless and colored, smooth or textured and many more options. But if you take ordinary transparent glass and then decorate it using any method, then you can get a unique piece of furniture. The choice of material for making a table base can only be limited by the master's imagination. For these purposes, you can use wood, metal, plastic, glass. In addition to the main tabletop, the table design can also include an additional shelf. Return to contents</a>

Open glass

Cutting out the glass table top.In order to cut the tabletop of the desired shape, it is necessary to apply its future contours to the glass. It is better to do this work on a special table, so as not to move the workpiece from place to place and not expose it to the risk of being broken. First, you need to practice on glass scraps, then it will be a little easier to cut the tabletop itself. The cut must be made using a metal ruler. The force of pressure on the glass cutter is determined by its sharpness. So, you do not need to press as hard on a diamond glass cutter as on a roller one. It is necessary to observe safety precautions when working with glass! Be sure to wear gloves to avoid hand injury. After making the cut, you need to separate the edges of the glass. This can be done with your hands or using pliers. In addition, the glass cutter has a special device necessary for chipping off a thin edge. As a result, we get a glass tabletop of the required size and shape. The next stage of production is processing the edge of the glass. This can be done either manually or using a special machine. For manual glass processing, you will need a file or an emery block. When using a file, you will need a liquid for wetting. This can be turpentine or kerosene. You need to work especially carefully. The movements should be uniform and smooth. After rough processing of the glass edge, it must be ground and polished. This can be done with a drill or grinder, using a special attachment. To grind the edge, the graininess of the emery wheel is successively reduced. The surface is polished using a special paste and felt.

Cutting out the glass table top.In order to cut the tabletop of the desired shape, it is necessary to apply its future contours to the glass. It is better to do this work on a special table, so as not to move the workpiece from place to place and not expose it to the risk of being broken. First, you need to practice on glass scraps, then it will be a little easier to cut the tabletop itself. The cut must be made using a metal ruler. The force of pressure on the glass cutter is determined by its sharpness. So, you do not need to press as hard on a diamond glass cutter as on a roller one. It is necessary to observe safety precautions when working with glass! Be sure to wear gloves to avoid hand injury. After making the cut, you need to separate the edges of the glass. This can be done with your hands or using pliers. In addition, the glass cutter has a special device necessary for chipping off a thin edge. As a result, we get a glass tabletop of the required size and shape. The next stage of production is processing the edge of the glass. This can be done either manually or using a special machine. For manual glass processing, you will need a file or an emery block. When using a file, you will need a liquid for wetting. This can be turpentine or kerosene. You need to work especially carefully. The movements should be uniform and smooth. After rough processing of the glass edge, it must be ground and polished. This can be done with a drill or grinder, using a special attachment. To grind the edge, the graininess of the emery wheel is successively reduced. The surface is polished using a special paste and felt. Figure 1.To avoid damaging the design on the glass table, apply it from the back. So, the base of the tabletop is ready. Now you need to make the base. There can be many options here. All that remains is to attach the tabletop to the base. Fastening is done using special suction cups and glue. In order to fix the suction cups on the legs, you need to drill or cut holes in them. The glass is fixed to the suction cups with a special glue that dries under the influence of ultraviolet rays. The glass table is ready. All that remains is to decorate it. Here are the most common options. Return to contents</a>

Figure 1.To avoid damaging the design on the glass table, apply it from the back. So, the base of the tabletop is ready. Now you need to make the base. There can be many options here. All that remains is to attach the tabletop to the base. Fastening is done using special suction cups and glue. In order to fix the suction cups on the legs, you need to drill or cut holes in them. The glass is fixed to the suction cups with a special glue that dries under the influence of ultraviolet rays. The glass table is ready. All that remains is to decorate it. Here are the most common options. Return to contents</a>

Glass painting in stained glass technique

Materials:

- palette (it is better to use a piece of the same glass);

- stained-glass paints;

- stencil drawing;

- contour paints;

- White paper;

- solvent;

- stationery knife;

- cotton wool;

- ammonia;

- water.

First, you need to degrease it well.glass surface. Then you need to fix the sample of the drawing and carefully transfer it to the glass using contour paint. If it is not very neat, you can remove the excess with cotton wool. If the outline is thin, you can correct it using a cotton swab or toothpick. Figure 2.After painting, the drawing must be covered with a layer of varnish. After the outline is completely transferred, remove the sample drawing and attach the glass to a sheet of white paper. Mix stained glass paints on a palette to obtain the necessary shades and apply to the prepared sketch (Fig. 1). Any bubbles that arise can be removed with a toothpick. The finished drawing must dry completely. To decorate a tabletop, it is better to use this technique on the underside of the glass (Fig. 2). For greater durability, the surface should be covered with a layer of varnish. Return to contents</a>

Figure 2.After painting, the drawing must be covered with a layer of varnish. After the outline is completely transferred, remove the sample drawing and attach the glass to a sheet of white paper. Mix stained glass paints on a palette to obtain the necessary shades and apply to the prepared sketch (Fig. 1). Any bubbles that arise can be removed with a toothpick. The finished drawing must dry completely. To decorate a tabletop, it is better to use this technique on the underside of the glass (Fig. 2). For greater durability, the surface should be covered with a layer of varnish. Return to contents</a>

Decorating tabletops by sandblasting glass

The most important thing in this technology is the selection of the interior that matches the overall style. Tools and materials:

- quartz sand, sifted and dried;

- sandblasting gun;

- stencils.

We thoroughly clean the glass surface anddegrease. Fix the stencil on the glass surface. Fill the sandblasting gun 1/3 full with sand. Connect to a compressor equipped with a reducer. Start processing the surface, which, depending on the size of the sand particles, can be grainy or velvety. After finishing the processing, remove the stencil. The tabletop is ready. Return to contents</a>Glass Etching Technology This technologysomewhat similar to the one described above. Only here, chemical rather than mechanical treatment is used to create a matte surface. Materials and tools:

- brush;

- stationery knife;

- paste for etching;

- copy paper;

- polyethylene film;

- latex gloves.

A stencil for decoration can be purchasedready-made, or you can make it yourself. It is best to make a stencil from self-adhesive film. It is necessary to firmly fix the stencil on the tabletop. Apply a thick layer of etching paste to the free areas with a brush. Important: be sure to work with rubber gloves! Do not allow the paste to come into contact with your skin. If it does, immediately rinse the area with plenty of cold water. The exposure time of the paste is indicated on the packaging and is on average from 6 to 10 minutes. After this time, the glass must be rinsed with plenty of water. Now you need to dry the glass with a lint-free cloth. When the glass is completely dry, you can remove the stencil.