In the process of arranging your own homeQuite often there is a need to make a partition. This may be required during a large-scale redevelopment or if you want to divide the room into several parts. The easiest way to build an internal partition is from plasterboard and metal profiles. It is quite easy to work with this material, so many people want to know how to make a partition from plasterboard. You should know that in the process of forming walls from plasterboard sheets there are a large number of nuances that must be taken into account. To make a partition yourself, you will need to purchase the following profiles: CD profile, UD profile, CW, UW.

To make a partition yourself, you will need to purchase the following profiles: CD profile, UD profile, CW, UW.

Materials that will be needed for the construction of the partition

To ensure strength and correctnesswall configuration, you will first need to make a frame. It consists of metal profiles that are designed for plasterboard. You will also need some other devices. In most cases, the following profiles are used:

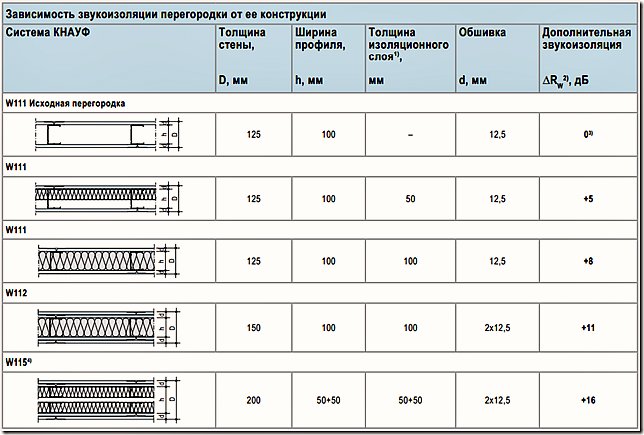

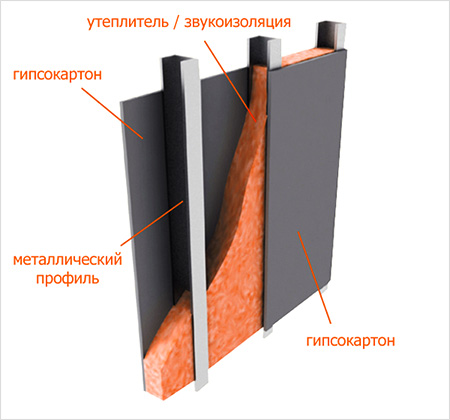

Soundproof partition structures made of plasterboard. Profiles can be supporting and guiding. To make a partition yourself, you will need to purchase the following profiles:

Soundproof partition structures made of plasterboard. Profiles can be supporting and guiding. To make a partition yourself, you will need to purchase the following profiles:

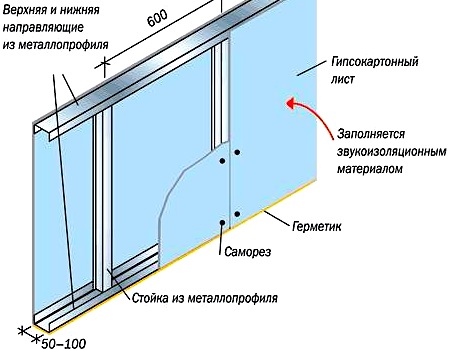

If you plan to build a simple partition50, 75 or 100 mm wide, you will only need CW and UW profiles. To build wide walls, you should additionally purchase CD and UD profiles. To secure the profile to the frame, you will need a hanger and a connector. All elements will be connected with self-tapping screws. You will need flea-type screws and devices with countersunk heads for plasterboard. To secure the entire frame to the main walls, you will need to purchase plastic dowels with impact screws. Plasterboard sheets should be 12.5 mm thick, with a wide chamfer on the sides. If you plan to make a plasterboard partition in the kitchen or bathroom, you should prepare moisture-resistant sheets. Installation diagram of a plasterboard partition. As a result, the following elements will be needed to construct a thin wall or partition:

Installation diagram of a plasterboard partition. As a result, the following elements will be needed to construct a thin wall or partition:

- plasterboard sheets;

- metal profiles;

- wooden bars;

- self-tapping screws;

- dowels;

- tape for sealing;

- mineral wool;

- corner made of metal.

In addition, you will need to prepare the following tools:

- roulette;

- building level;

- plumb bob;

- Screwdriver;

- grater;

- knife;

- scissors;

- electric drill.

Return to Contents</a>

Nuances you need to know

When all the necessary tools and materialsare prepared, you can begin to build the frame. The floor and adjacent walls, to which the partition will be attached, should be at the finishing stage. Layout diagram for installing a partition. The layout of the structure being manufactured must be marked on the floor. The following nuances must be taken into account:

Layout diagram for installing a partition. The layout of the structure being manufactured must be marked on the floor. The following nuances must be taken into account:

Once the starting line on the floor has been determined, it can be transferred to the ceiling and walls. To do this, you will need a plumb line or a laser level. Return to Contents</a>

How to form a frame of a partition from plasterboard?

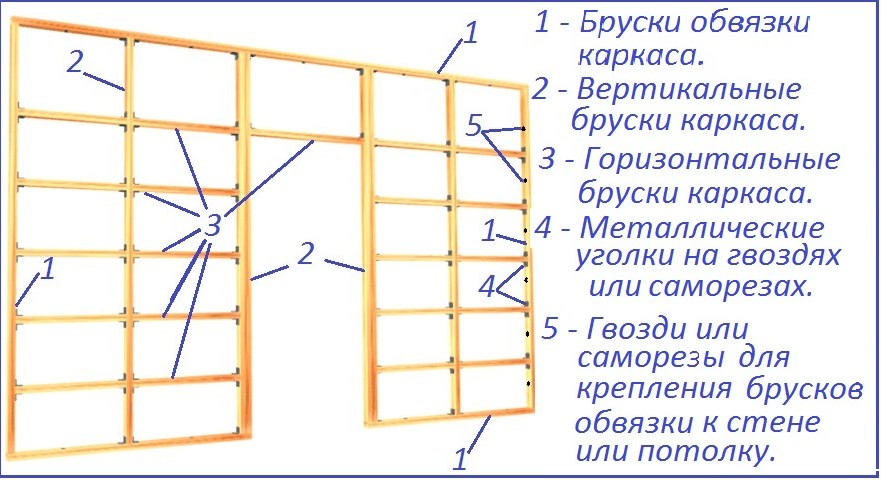

Scheme of the device of a wooden frame forplasterboard partitions. All profiles that are attached to the floor, ceiling or walls are installed using a sealing tape. This tape must be installed between the profile and the supporting base. First of all, you need to fix the UW profile to the floor and ceiling. It can be fixed with dowels and self-tapping screws. The step for installing fasteners is 0.5 m. Along the edges of the guide elements, you need to fix the racks from the CW profile. These devices must also be installed in places where you plan to build a door or window opening. The profiles are first attached to the lower guide element. After that, they need to be threaded through the upper guide element and installed vertically. To determine the correct placement, you need to use a building level. When placing these profiles, you should take into account the reserve for sheathing with plasterboard strips on top of the profile. The products are mounted with the front side facing inside the opening. The racks are attached to the guides using self-tapping screws. Along the perimeter of door and window openings, the support profiles will need to be reinforced with wooden bars, which are installed inside the profile and secured with screws. The bar should be selected based on the width of the profile.

Scheme of the device of a wooden frame forplasterboard partitions. All profiles that are attached to the floor, ceiling or walls are installed using a sealing tape. This tape must be installed between the profile and the supporting base. First of all, you need to fix the UW profile to the floor and ceiling. It can be fixed with dowels and self-tapping screws. The step for installing fasteners is 0.5 m. Along the edges of the guide elements, you need to fix the racks from the CW profile. These devices must also be installed in places where you plan to build a door or window opening. The profiles are first attached to the lower guide element. After that, they need to be threaded through the upper guide element and installed vertically. To determine the correct placement, you need to use a building level. When placing these profiles, you should take into account the reserve for sheathing with plasterboard strips on top of the profile. The products are mounted with the front side facing inside the opening. The racks are attached to the guides using self-tapping screws. Along the perimeter of door and window openings, the support profiles will need to be reinforced with wooden bars, which are installed inside the profile and secured with screws. The bar should be selected based on the width of the profile. Scheme of a partition using insulation.Next, CW support profiles need to be installed along the entire length of the frame. The first element from the adjacent wall is mounted at a distance of 55 cm, all subsequent ones are installed with a step of 60 cm. The distance is measured from the middle of each element. In the process, it is necessary to check the verticality of the profile installation. To determine the upper part of the door opening and the horizontal edges of the window openings, you should use the UW profile. On the front side of the profile, marks should be placed at a distance of 15 cm from the extreme part of the structure. The sides of the profile need to be cut at an angle of 45 °. You need to start from the side of the extreme part. Next, the extreme parts of the product must be bent to obtain a U-shaped structure. The resulting workpiece will need to be put on the racks with the bent edges, and then raised to the desired height. The structure is fastened with self-tapping screws. Next, you need to screw on the oblique ears that appeared on the horizontal part of the product. In the same way, you need to form a window opening. Return to the table of contents</a>

Scheme of a partition using insulation.Next, CW support profiles need to be installed along the entire length of the frame. The first element from the adjacent wall is mounted at a distance of 55 cm, all subsequent ones are installed with a step of 60 cm. The distance is measured from the middle of each element. In the process, it is necessary to check the verticality of the profile installation. To determine the upper part of the door opening and the horizontal edges of the window openings, you should use the UW profile. On the front side of the profile, marks should be placed at a distance of 15 cm from the extreme part of the structure. The sides of the profile need to be cut at an angle of 45 °. You need to start from the side of the extreme part. Next, the extreme parts of the product must be bent to obtain a U-shaped structure. The resulting workpiece will need to be put on the racks with the bent edges, and then raised to the desired height. The structure is fastened with self-tapping screws. Next, you need to screw on the oblique ears that appeared on the horizontal part of the product. In the same way, you need to form a window opening. Return to the table of contents</a>

How to cut gipsokartonnye sheets correctly?

To perform this operation you canuse a regular construction knife with replaceable blades. The sheet should be placed on a flat surface. Next, mark the cut line with a simple pencil, and then cut the top of the cardboard with a knife. Next, move the sheet along the cut line to the outer part of the support and slowly break it. When the sheet is returned to its original position, it will turn on its edge and bend. On the other side, the cardboard also needs to be cut, but not through. Then the sheet needs to be turned over and moved to the outer part of the support. As a result, it can be chipped. To provide a gap that can later be easily sealed with a putty mixture, a bevel-chamfer with an angle of 22.5 ° must be formed on the cut edge of the sheet. To do this, use a plane. The chamfer must also be made on the edge of the sheet that will adjoin the strip of gypsum board placed above or below the sheet. Return to contents</a>

How correctly to fix a drywall to a skeleton?

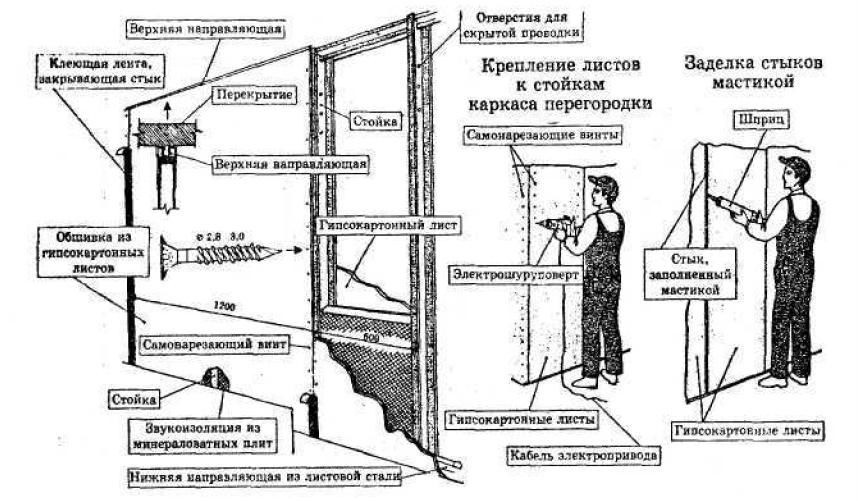

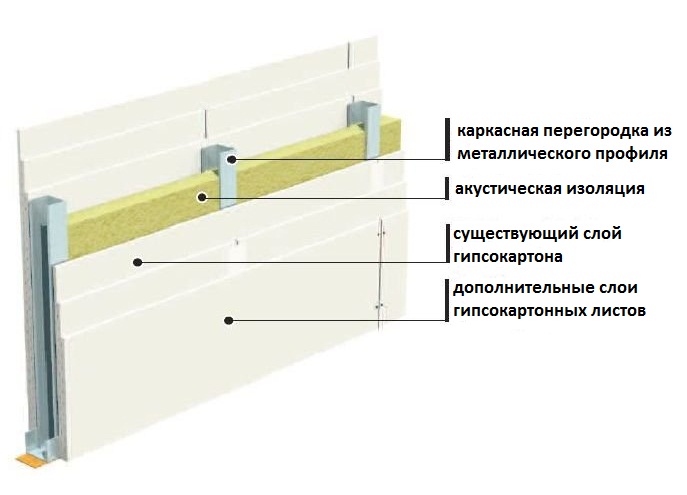

Scheme of additional sound insulation of partitions.Next, the plasterboard sheets are attached to the frame. The sheets can be 120x120 cm, 120x250 cm and 120x300 cm. However, most often in living rooms there are ceilings higher than 2.75 m. Therefore, it will be necessary to add small strips of plasterboard, since one sheet may not be enough. The first sheet, which is installed close to the extreme part of the structure, should be freed from the side chamfer. To do this, a strip 5 cm wide must be cut along its entire length on one side. The sheet is fixed to the frame using 3.5x35 mm self-tapping screws. First, you need to fix the extreme parts of the sheet, after which the product is fixed in the middle. Screws must be installed every 25 cm. In some cases, this distance can be reduced to 10 cm. Fasteners must be screwed in so that the heads are deepened into the sheet. Sheets are fixed at a distance of 1-1.5 cm from the floor. This is necessary to ensure the integrity of the structure during operation. After fixing the first sheet, you will need to measure the remaining distance to the ceiling structure and cut off a piece of gypsum board of the appropriate length. You also need to form a chamfer on it. In the future, all sheets will need to be installed in a checkerboard pattern, there is no need to cut the chamfer. After the first row, the whole sheet must be installed under the ceiling, the missing part is mounted from below. In this way, you can sheathe one side of the wall. Return to the table of contents</a>

Scheme of additional sound insulation of partitions.Next, the plasterboard sheets are attached to the frame. The sheets can be 120x120 cm, 120x250 cm and 120x300 cm. However, most often in living rooms there are ceilings higher than 2.75 m. Therefore, it will be necessary to add small strips of plasterboard, since one sheet may not be enough. The first sheet, which is installed close to the extreme part of the structure, should be freed from the side chamfer. To do this, a strip 5 cm wide must be cut along its entire length on one side. The sheet is fixed to the frame using 3.5x35 mm self-tapping screws. First, you need to fix the extreme parts of the sheet, after which the product is fixed in the middle. Screws must be installed every 25 cm. In some cases, this distance can be reduced to 10 cm. Fasteners must be screwed in so that the heads are deepened into the sheet. Sheets are fixed at a distance of 1-1.5 cm from the floor. This is necessary to ensure the integrity of the structure during operation. After fixing the first sheet, you will need to measure the remaining distance to the ceiling structure and cut off a piece of gypsum board of the appropriate length. You also need to form a chamfer on it. In the future, all sheets will need to be installed in a checkerboard pattern, there is no need to cut the chamfer. After the first row, the whole sheet must be installed under the ceiling, the missing part is mounted from below. In this way, you can sheathe one side of the wall. Return to the table of contents</a>

How to lay wiring, install sockets and switches?

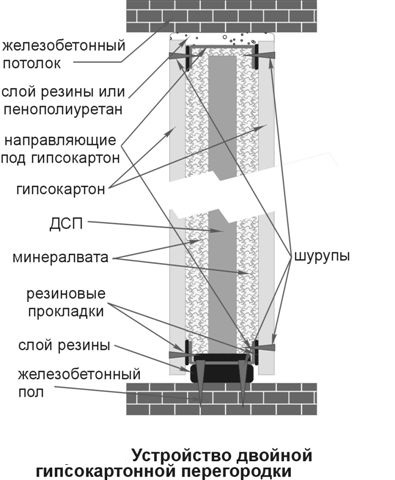

Scheme of the device of a double partition fromplasterboard. Before covering the other side, you will need to lay the wires, if necessary. To pass through the rack profiles, you need to make 3.5 cm holes in the middle of them. It is important to ensure that the extreme parts of the profile are concave in one of the sides. Only in this case the wires will not be damaged by the profiles. The wires must be installed in a corrugated pipe. Mineral wool can be used for soundproofing the walls. If you do not install such material, then all the noise from one room can be heard in another. The material will be needed in rolls 60 cm or 120 cm wide. The second option will need to be cut into two even parts. The wool should be tightly laid between the rack profiles, there should be no gaps. It is not necessary to additionally fix the material. Horizontal lintels can be built from wooden blocks. Mineral wool will rest on these devices. This method can be used in places where there is a risk of moisture penetration into the wall. However, in this case, you will need to take care of the ventilation of the space inside the structure. At this stage, you can complete the lining of the other side of the partition. After this, all the end bases are filled. There should be a distance of 10 cm between the plasterboard sheets, which was formed by chamfers. The joints must be glued with a mounting mesh and leveled with the wall level with a starting putty. It will be necessary to level all the places where the screws are mounted or the entire base completely with a finishing putty mixture, especially if the partition will be painted or pasted over with thin wallpaper in the future. Using an abrasive mesh and a float, you will need to completely level the putty layer. At this stage, the plasterboard partition can be faced with any material you like. The partition can be straight or curved. In some cases, to give the room extravagance, you can install several partitions, the elements of which will be connected to each other at an angle. It should be noted that the process of erecting such a structure is no different from the construction of an ordinary partition. You will only need to decide on the configuration of the structure itself. On the ceiling and on the floor, you need to mark the contour of the product along which the profiles will be mounted. However, in this case, there will be more such contours than in an ordinary partition. In the place where the two parts will be joined at an angle, you will need to mount the racks on all sides of the walls. It is quite simple to do, it is only important to prepare all the necessary tools and materials.

Scheme of the device of a double partition fromplasterboard. Before covering the other side, you will need to lay the wires, if necessary. To pass through the rack profiles, you need to make 3.5 cm holes in the middle of them. It is important to ensure that the extreme parts of the profile are concave in one of the sides. Only in this case the wires will not be damaged by the profiles. The wires must be installed in a corrugated pipe. Mineral wool can be used for soundproofing the walls. If you do not install such material, then all the noise from one room can be heard in another. The material will be needed in rolls 60 cm or 120 cm wide. The second option will need to be cut into two even parts. The wool should be tightly laid between the rack profiles, there should be no gaps. It is not necessary to additionally fix the material. Horizontal lintels can be built from wooden blocks. Mineral wool will rest on these devices. This method can be used in places where there is a risk of moisture penetration into the wall. However, in this case, you will need to take care of the ventilation of the space inside the structure. At this stage, you can complete the lining of the other side of the partition. After this, all the end bases are filled. There should be a distance of 10 cm between the plasterboard sheets, which was formed by chamfers. The joints must be glued with a mounting mesh and leveled with the wall level with a starting putty. It will be necessary to level all the places where the screws are mounted or the entire base completely with a finishing putty mixture, especially if the partition will be painted or pasted over with thin wallpaper in the future. Using an abrasive mesh and a float, you will need to completely level the putty layer. At this stage, the plasterboard partition can be faced with any material you like. The partition can be straight or curved. In some cases, to give the room extravagance, you can install several partitions, the elements of which will be connected to each other at an angle. It should be noted that the process of erecting such a structure is no different from the construction of an ordinary partition. You will only need to decide on the configuration of the structure itself. On the ceiling and on the floor, you need to mark the contour of the product along which the profiles will be mounted. However, in this case, there will be more such contours than in an ordinary partition. In the place where the two parts will be joined at an angle, you will need to mount the racks on all sides of the walls. It is quite simple to do, it is only important to prepare all the necessary tools and materials.