Suspended ceiling is one of the mostrational finishing solutions for rooms with a high basic level. There are many types of suspended systems: these are Armstrong panels, stretch ceilings, and plasterboard cladding. In rooms with high humidity, the installation of anti-corrosion systems is relevant. Such are aluminum slatted ceilings. How to make a slatted ceiling? Complex wave-shaped or oblique structures are best left to professionals, but simple slat cladding is quite possible for any home craftsman. Scheme of suspended slatted ceiling.

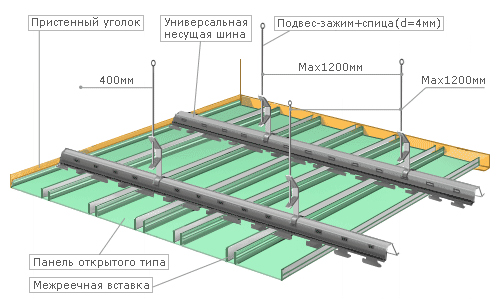

Scheme of suspended slatted ceiling.

Selecting a rack ceiling

The construction market offers a wide selectionslatted ceilings from various manufacturers. According to the type of installation, they are divided into 3 types: open, closed and gapless. Open ones are mounted with gaps between the slats of 14-16 mm. They are installed in rooms with a height of at least 5 m, most often in sales areas. Closed ones are arranged according to the principle of board-lining: the slats overlap each other. Gapless ones are installed end-to-end without gaps. When buying, you should pay attention to the parameters of the slats. The length should be selected so that as little waste as possible remains when cutting. The width of the panels varies from 9 to 20 cm. For small rooms, it is better to choose narrow panels, for spacious ones - wide ones. The thickness of the slats is an indicator of strength and reliability, but thicker ones are more expensive. Panels with a thickness of about 0.5 mm are considered optimal for installation in an apartment. The slats may have some design differences. Rectangular edges are typical for German products, rounded ones - for Italian ones. Wave-curved panels are suitable for the embodiment of bold design ideas. Elements of the slatted ceiling design.The color range of the slats can be any, but the most common shades are: white, black, metallic, gold, chrome (with a mirror surface). In addition to the slats themselves, the kit should include:

Elements of the slatted ceiling design.The color range of the slats can be any, but the most common shades are: white, black, metallic, gold, chrome (with a mirror surface). In addition to the slats themselves, the kit should include:

- guides;

- adjustable suspensions;

- wall-mounted skirting boards;

- installation instructions.

It is important to ensure that the guide railsand the panels had the same manufacturer. Otherwise, you may encounter unsolvable problems during installation and end up with a low-quality ceiling with cracks. The kit is designed for a certain area. When lining large areas, it is more profitable to buy large kits: in total, they will cost less. The slats sold must have a protective coating. Despite the design features of this or that type of slats, their installation is basically similar. In order to make a slatted ceiling, you will need:

- roulette;

- level;

- long ruler;

- marker;

- perforator;

- drill;

- scissors for metal;

- knife;

- home tool;

- fastening (dowels, screws).

Return to Contents</a>

Mounting of the rack ceiling

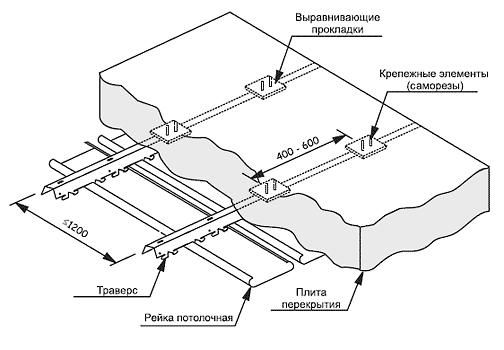

Installation diagram of a slatted ceiling.

Installation diagram of a slatted ceiling.

If you plan to install built-inlamps, then the wiring should be done before the ceiling is installed. The holes in the slats for the lampshades are cut with a drill with a crown attachment. The ceiling is assembled with the lampshades already mounted in the slats.