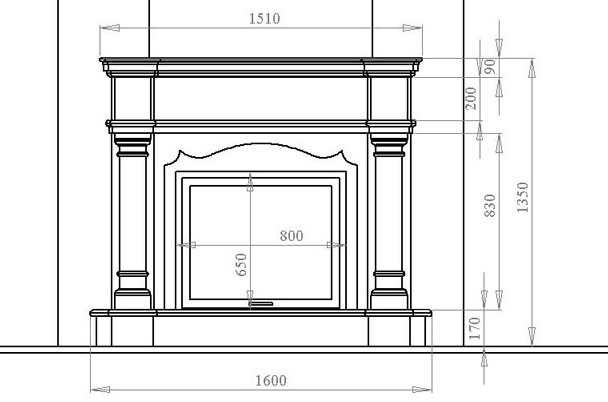

Not every home has the possibility of installationa real fireplace that would warm you up with its heat during the long winter months. Even in a country house, it is not always possible to install such a fireplace, since it is not only difficult, but also requires significant financial expenses. To install such a structure, a separate chimney is required, this should be approached seriously. In modern city apartments, there are no conditions for installing a fireplace, even a small one. Drawing of a fireplace made of plasterboard.However, there is a way out of this situation - this is the installation of a small and attractive false fireplace made of plasterboard. It does not take up much space, is easy to assemble with your own hands and does not require a chimney at all. How to make a fireplace from plasterboard in your apartment, what should be provided?

Drawing of a fireplace made of plasterboard.However, there is a way out of this situation - this is the installation of a small and attractive false fireplace made of plasterboard. It does not take up much space, is easy to assemble with your own hands and does not require a chimney at all. How to make a fireplace from plasterboard in your apartment, what should be provided?

Installation of gypsum cardboard fireplace with own hands

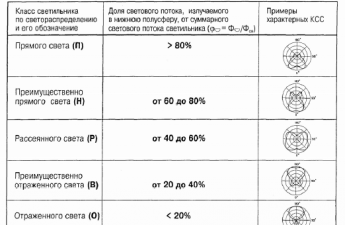

Before making a fireplace with your own handsplasterboard, it is necessary to carefully choose the place for its installation. Attention should be paid to the area of the room, the features of the interior. For example, for a small bedroom, even a false fireplace, for the lining of which plasterboard is used, is inappropriate. But for a living room or home office, such a design will be excellent. The work should be planned so that the fireplace does not interfere with the passage through the room, its use. It is best to make the design in the corner or in the center of the wall. For a false fireplace, you can use a small step on which you can put figurines and favorite books or just sit, admiring the flame of candles in the firebox. All plasterboard structures are divided into several types: Diagram of the false fireplace device.

Diagram of the false fireplace device.

Return to Contents</a>

Frame construction

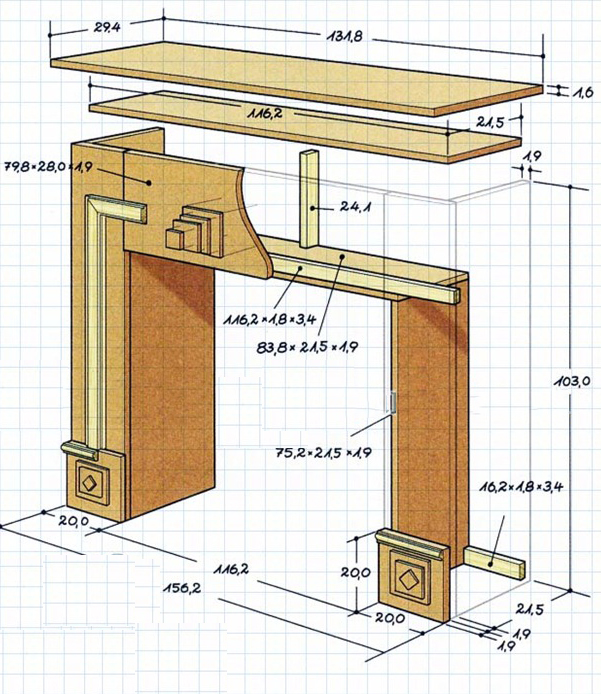

You can make a fireplace from wooden slats orspecial metal plasterboard profile. It is necessary to strictly follow the instructions prepared in advance. The profile is first screwed to the floor and to the wall surface, i.e. a frame is formed. After this, vertical and horizontal elements are installed, which are fastened together with screws. If there is a need to cut the profile, then metal shears are used for this. Types of profile for the frame of a false fireplace. The work itself does not take much time, to complete the assembly you need to prepare:

Types of profile for the frame of a false fireplace. The work itself does not take much time, to complete the assembly you need to prepare:

- metal profile for gypsum board or wooden slats;

- self-tapping screws for metal;

- Screwdriver;

- scissors for metal;

- building level;

- pencil;

- roulette;

- metal ruler.

Return to Contents</a>

Fireplace casing

Regular plasterboard is used for claddingwall, but if you plan to install hot candles or an electric fireplace for heating in the firebox, then you need to take a special fire-resistant red one. The calculation of the material must be done in advance, although usually one standard sheet is enough. Cutting is done based on the drawing. Drywall must be cut with a sharp knife with replaceable blades, while the layer is not cut completely, the sheet breaks after the cut. All ends must be treated with sandpaper before installation, fix the gypsum board with self-tapping screws. It is recommended to start cladding from the most difficult areas. Drywall must be fastened in such a way that the heads of the screws are slightly recessed into the material. When the work is finished, all seams and fastening points are carefully treated with putty. When the composition dries, the drywall is treated with sandpaper so that the surface is even and smooth. Installation diagram of a false fireplace. To make a fireplace from plasterboard, you need to prepare the following materials:

Installation diagram of a false fireplace. To make a fireplace from plasterboard, you need to prepare the following materials:

- gypsum board of the chosen type (conventional or fireproof);

- self-tapping screws;

- putty;

- a metal spatula;

- ruler;

- pencil;

- knife with replaceable blades.

Return to Contents</a>

Decorative finishing

After the fireplace is ready, its decorative finishing is done. For these purposes, the following are used:

- textured plaster or paint;

- wooden carved and polished panels;

- ceramic tile;

- a natural stone;

- wallpaper and decorative films, etc.

One of the most attractive optionsis decorating with gypsum tiles that imitate real tiles. To decorate a plasterboard fireplace with such tiles, you need to prepare the following materials and tools: Tools for installing a false fireplace.

Tools for installing a false fireplace.

- Special silicone molds or plastic boxes of small size from cookies (their bottom should be embossed);

- gypsum;

- lubricant for silicone molds;

- adhesive for tiles;

- plasticizers for gypsum mixture;

- acrylic paints;

- brushes;

- a simple pencil;

- ruler;

- building level;

- ceramic tiles;

- tile cutting machine;

- hacksaw;

- putty knife.

The work begins with what is being designedfinishing. To do this, you need to make a sketch on paper, having previously measured the structure. It is advisable to know the dimensions of one tile to be able to calculate the required amount of finishing. It is recommended to immediately make a layout diagram of the imitation tiles so as not to be distracted during work. Then you can start making tiles for the fireplace from gypsum board. The gypsum mass is diluted with water and mixed, it should turn out homogeneous. The molds are greased so that the tiles can be easily removed from them, and the molds themselves can be used for the next batch. Pouring is done carefully, there should be no air pockets. The tiles in the molds are placed, for example, on the balcony so that the gypsum can dry completely, which can take 2 days. At this time, according to the drawn up diagram, markings are made for the tiles. You can start laying out the firebox and the step in front of the fireplace with ordinary ceramic tiles. The color of the tiles must be selected so that it matches the main decoration, but stands out a little. You can take brown, golden, brick colors. The tiles are laid on glue, the laying can be butt-joint or with seams, it depends only on the wishes of the master. Return to the table of contents</a>

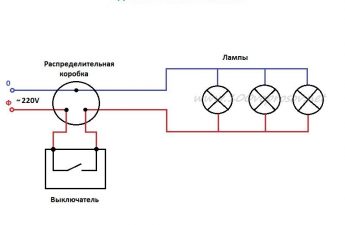

Decoration of plasterboard fireplace

When the imitation tiles have dried, you need to start painting themdecoration. The tiles are removed from the molds and laid out on a film or newspaper. Acrylic paints should be used for this, the colors are selected individually. When the paint dries, the surface is varnished. This type of finish is laid on tile adhesive, if necessary, the tiles are cut. The result is a plasterboard fireplace of an unusual, but very stylish appearance. The costs for it are small, but the result is impressive. It is not so difficult to make an imitation of a fireplace at home, it is important to choose its shape and place for installation, and then start working. A profile and gypsum board are used for production. The process does not take much time, usually decorating a structure takes longer. As a result, the decor will become luxurious, the interior will be much more comfortable and attractive. As a source of lighting or fire, you can use ordinary candles or a lamp connected to the electrical network. Many people install an electric fireplace in the firebox, but in this case, the materials must be fire-resistant, this also applies to plasterboard.</ ul>