Sometimes there is a need to carry outreconstruction of the building. Reconstruction operations also include the installation of openings in the walls. You will learn how to make an opening in the wall so that it does not become less durable, but it should be noted that the advice will only concern the technology of the process, and no recommendations on the design of the redevelopment and the approval of changes in the building structure with the relevant authorities will be given in them. It should also be said that excessive self-confidence when reconstructing walls can lead to very sad consequences. If dismantling part of a non-load-bearing partition only threatens its collapse, then improper reconstruction of a load-bearing wall can lead to the destruction of the building. An opening in the wall can be made with the approval of the BTI,to be absolutely sure that you will not collapse the load-bearing wall. The materials that will reinforce the wall above the place of its dismantling are profile steel products:

An opening in the wall can be made with the approval of the BTI,to be absolutely sure that you will not collapse the load-bearing wall. The materials that will reinforce the wall above the place of its dismantling are profile steel products:

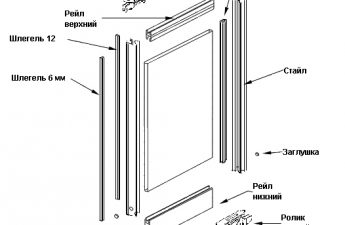

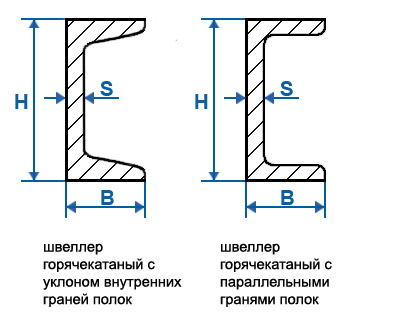

- channel bars;

- I-beams;

- corners.

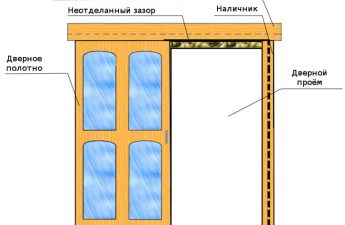

The thicker the wall, the more powerful the profile should be.used to support the structures above. When choosing a lintel, the height of the wall whose load it will bear must also be taken into account. It should be said that the construction of both a doorway and a window opening is carried out in the same way. Its width is of decisive importance (the larger it is, the weaker the structure). However, a window opening (if it is less than 1.5 m) is often reinforced only with a lintel, and for a door it is necessary to strengthen the vertical sections as well, since they will be subject to frequent mechanical impact.

The opening in the interior partition

Return to Contents</a>Dismantling a concrete partition An opening in a concrete wall is made with the help ofa drill and a sledgehammer. It is relatively easy to make a doorway in a wall that is not load-bearing. These partitions are usually not very thick. Brick walls can be folded in half a brick. How to make a doorway in them will be written below, but for now we need to talk about the reconstruction of partitions from concrete. You will need:

An opening in a concrete wall is made with the help ofa drill and a sledgehammer. It is relatively easy to make a doorway in a wall that is not load-bearing. These partitions are usually not very thick. Brick walls can be folded in half a brick. How to make a doorway in them will be written below, but for now we need to talk about the reconstruction of partitions from concrete. You will need:

- diamond grinder, perforator or jackhammer (it will be great if you find a diamond cutter for concrete);

- channels or corners;

- marking tool;

- welding machine;

- sledgehammer.

We also need to think about where they will fall.concrete fragments. If you plan to cut it out in one large piece, then it is simply necessary to put a shock-absorbing covering under the place where it falls. Car tires can also serve as such Reinforcement of an opening in a concrete wall.First of all, make sure that there is no electrical wiring connected to the network in the wall. After de-energizing the area, draw the contours of the future opening on the surface. After that, you can divide the area inside the outlined perimeter into several square sections. You can dismantle the wall by cutting or drilling its surface along the drawn lines. Some fragments will be easy to knock out with a sledgehammer, and in others you will have to cut off the reinforcement. In any case, you need to prepare for long-term work. The whole charm of the device of a doorway in a concrete partition is that it can be cut without preliminary installation of a lintel, since the concrete panel is a monolith. After dismantling the opening, you can begin to strengthen it. Depending on the thickness of the partition, choose a channel or corners that frame the upper crossbar and the verticals of the opening. Return to the table of contents</a>Dismantling brickwork

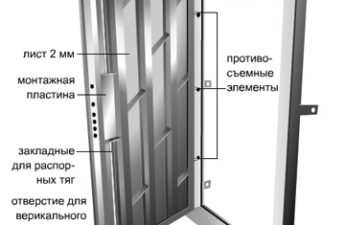

Reinforcement of an opening in a concrete wall.First of all, make sure that there is no electrical wiring connected to the network in the wall. After de-energizing the area, draw the contours of the future opening on the surface. After that, you can divide the area inside the outlined perimeter into several square sections. You can dismantle the wall by cutting or drilling its surface along the drawn lines. Some fragments will be easy to knock out with a sledgehammer, and in others you will have to cut off the reinforcement. In any case, you need to prepare for long-term work. The whole charm of the device of a doorway in a concrete partition is that it can be cut without preliminary installation of a lintel, since the concrete panel is a monolith. After dismantling the opening, you can begin to strengthen it. Depending on the thickness of the partition, choose a channel or corners that frame the upper crossbar and the verticals of the opening. Return to the table of contents</a>Dismantling brickwork Options for strengthening a brick wall.It is not so easy to dismantle a brick wall. No, the masonry itself is easy to dismantle, but there will be no consequences if you pull out 1-2 bricks from the masonry, and before dismantling the entire section, you need to install a lintel that will take the weight of the wall. As already mentioned, the thickness of the partition can be only 12 cm. It is impossible to punch a long through hole for the lintel above the future opening, as this threatens the destruction of the masonry. To prevent this from happening, it is necessary to make grooves on both sides of the wall above the ceiling of the opening, the depth of which should correspond to the width of the corner (60 x 60). Their length should exceed the width of the opening by at least 1 brick. It is not enough to insert both corners into the resulting grooves. They must be fixed. To do this, holes are drilled in the profiles and the wall for studs or bolts with which they will be pulled together. After dismantling the brick, steel strips are welded between the corners, and the fasteners can be removed. The verticals of the wall are also reinforced with channels or angles, which are welded to the lintel into a single structure. Return to contents</a>

Options for strengthening a brick wall.It is not so easy to dismantle a brick wall. No, the masonry itself is easy to dismantle, but there will be no consequences if you pull out 1-2 bricks from the masonry, and before dismantling the entire section, you need to install a lintel that will take the weight of the wall. As already mentioned, the thickness of the partition can be only 12 cm. It is impossible to punch a long through hole for the lintel above the future opening, as this threatens the destruction of the masonry. To prevent this from happening, it is necessary to make grooves on both sides of the wall above the ceiling of the opening, the depth of which should correspond to the width of the corner (60 x 60). Their length should exceed the width of the opening by at least 1 brick. It is not enough to insert both corners into the resulting grooves. They must be fixed. To do this, holes are drilled in the profiles and the wall for studs or bolts with which they will be pulled together. After dismantling the brick, steel strips are welded between the corners, and the fasteners can be removed. The verticals of the wall are also reinforced with channels or angles, which are welded to the lintel into a single structure. Return to contents</a>

How to partition an opening

Installing a lintel in a load-bearing wall.Of course, you have noticed that the work on the doorway is often carried out on both sides of the partition. In this case, the markings are applied on both sides. Its accuracy can be ensured in a simple way.

Installing a lintel in a load-bearing wall.Of course, you have noticed that the work on the doorway is often carried out on both sides of the partition. In this case, the markings are applied on both sides. Its accuracy can be ensured in a simple way.

For thin concrete walls this methodmarking is not so relevant, since in most cases they can be disassembled in the "one-sided" mode. This method is necessary when disassembling brick partitions, as well as load-bearing walls. Just how to make a doorway in the latter will be written below. Return to the table of contents</a>

Wall openings

Channels are used to strengthen the opening.the thickness of which depends on the thickness and height of the wall. Load-bearing brick walls are usually much thicker than concrete ones. To strengthen the opening in them, the following are used:

Channels are used to strengthen the opening.the thickness of which depends on the thickness and height of the wall. Load-bearing brick walls are usually much thicker than concrete ones. To strengthen the opening in them, the following are used:

- channel bars 10P and 10U, 12P and 12U, 14P and 14U (depending on the thickness and height of the walls);

- studs and bolts from M16 to M24 with washers and nuts.

First, the old coating is removed from the wallmasonry. Markings are applied to it. Several through holes are drilled at the corners of the drawn rectangle and at some other points along the lines. The finishing is also removed from the reverse side, and the contours of the opening are drawn. Now, above its horizontal on one side, it is necessary to punch a groove with a length and depth corresponding to the dimensions of the channel or I-beam (and the length of the lintel should exceed the width of the opening by at least 50 cm). Before installing the profiles, holes for studs must be drilled in them. The channels must be pulled together with them every 50 cm, but in any case, there should be at least 3 of them above the opening. The first profile is seated in the groove on the mortar. Through holes for fasteners are drilled in the wall. After this, a groove for the second lintel is knocked out on the other side, after which the channel is inserted into it. Both profiles are pulled together with studs, under the nuts of which there should be washers. After dismantling the wall, the lintel of the opening should be additionally reinforced. Using welding, the channels are connected with a solid strip of 6 mm thick steel or several transverse plates every 20 cm. In addition, the verticals and the floor of the opening are reinforced with corners. Profiles installed on opposite sides of the wall are welded with steel strips. Concrete walls are thinner than brick ones. To make a doorway, it is best to reinforce it with corners of at least 63 x 5 mm. They are used to frame the perimeter of the opening on both sides. Corners can be welded together, connected with plates and pulled together with studs. It is imperative to tighten the profiles with fasteners when installing the lintel, since it will hold the wall during dismantling of the concrete wall. The grooves are made in the same way as when installing corners in partitions, only a more frequent step of fasteners is used to tighten the profile. Dismantling the wall begins with one of the upper squares (the division into which was described above). After removing the first one, you need to weld both corners of the crossbar together. The same thing needs to be done when removing the remaining fragments under the crossbar.