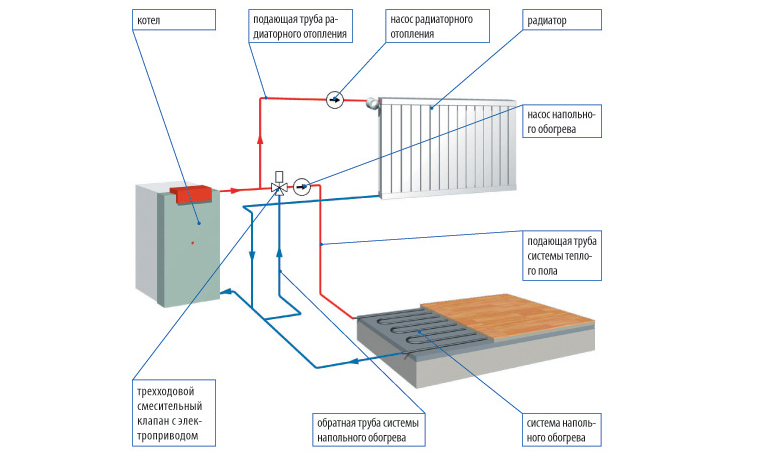

Question about how to make the floor heatedworries almost every domestic inhabitant, especially in the cold season. A warm floor, even in the most severe cold, is the key to the well-being and health of each family member. However, in order to find the best insulation option, the owner will have to go through more than a dozen options. Figure 1. Scheme of combined underfloor heating.

Figure 1. Scheme of combined underfloor heating.

What type of heating is preferable?

When solving the dilemma of how to make warm floors, first of all it is necessary to decide on the technology of execution. Today there are the following categories of warm floors:

- water;

- heating;

- cable.

The first two are the most popular.type due to its economy and ease of use. Water floors are installed mainly in the private sector, as well as in those buildings where there is no centralized water supply. For a house where the heating system is made from scratch, this heating method is an ideal option. In this way, you can significantly save on electricity and eliminate the harmful effects of electromagnetic fields on the body. In addition, any decorative material can be laid on top of warm floors, be it linoleum or laminate. Figure 2. Underfloor heating installation diagram.You can also make your home floors warm using a heating system made in the form of heating mats. The essence of the system is that metal plates with a cable placed inside are laid on a cement screed. The role of the heating element here is performed by carbon powder, which is also responsible for the safety of the structure. Only the carbon filler heats up, while the cable does not heat up. Thanks to this system, the floors heat up extremely quickly, within 15 minutes after switching on. If necessary, the floor temperature can be adjusted, the floor can be made warmer or, conversely, the heat supply can be reduced. In this case, the power consumption will vary depending on the consumed power. Such floors can be heated not around the clock, but only a few hours a day, because they retain heat perfectly. Classic warm floors are made using a cable heating system, which has undergone significant changes over the past few years. Today, single-core models are heating plates installed along the entire perimeter of the room. Such plates are made of foil, which shields the heat on the projection of the floor. When choosing this option for your home, you should correctly calculate the number of sections or plates, depending on the chosen heating model. They should cover the entire area of the room, but be installed in such a way that the room is not too hot, and the floors are warm, but not hot. Return to contents</a>

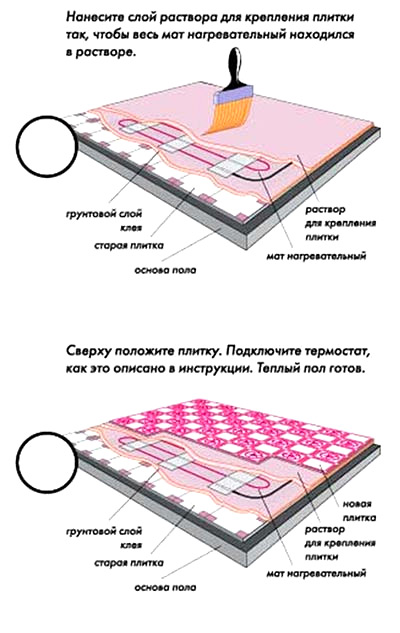

Figure 2. Underfloor heating installation diagram.You can also make your home floors warm using a heating system made in the form of heating mats. The essence of the system is that metal plates with a cable placed inside are laid on a cement screed. The role of the heating element here is performed by carbon powder, which is also responsible for the safety of the structure. Only the carbon filler heats up, while the cable does not heat up. Thanks to this system, the floors heat up extremely quickly, within 15 minutes after switching on. If necessary, the floor temperature can be adjusted, the floor can be made warmer or, conversely, the heat supply can be reduced. In this case, the power consumption will vary depending on the consumed power. Such floors can be heated not around the clock, but only a few hours a day, because they retain heat perfectly. Classic warm floors are made using a cable heating system, which has undergone significant changes over the past few years. Today, single-core models are heating plates installed along the entire perimeter of the room. Such plates are made of foil, which shields the heat on the projection of the floor. When choosing this option for your home, you should correctly calculate the number of sections or plates, depending on the chosen heating model. They should cover the entire area of the room, but be installed in such a way that the room is not too hot, and the floors are warm, but not hot. Return to contents</a>

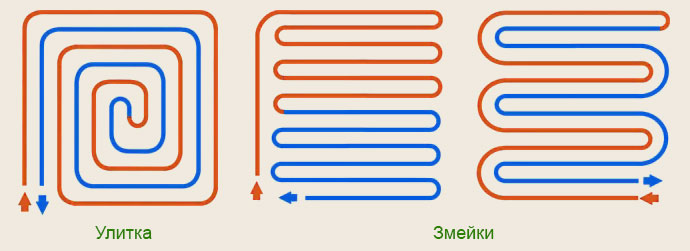

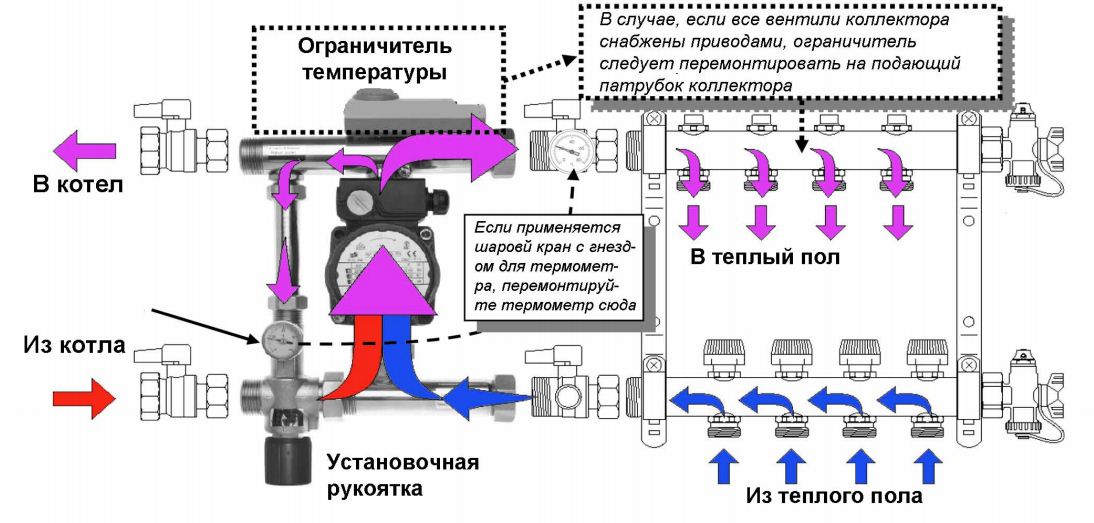

Piping with own hands

After these manipulations, it is time to make the floor warm, by directly laying the pipes. The installation scheme should be drawn up in advance, and only then implemented in practice. Options for laying out underfloor heating pipes.One of the most popular options for the average home is laying the heating elements in a snake-like pattern. This principle is ideal for small rooms, because the space in the center of the pipe will heat up the most. The diameter of the selected pipe should be no more than 20 mm. A more labor-intensive way to make the floor warm is laying the pipes in a spiral. The temperature difference between the supply and return pipes is completely compensated by each other, keeping the floor constantly warm. The laying step is from 20 to 25 cm. After the pipes are completely laid, they are connected to the coolant and checked. The temperature in the heating system should be at least 55 ° C - only in this case can rational heating of the room be ensured. In the event that heated floors are made in several rooms at once, it is recommended to install control panels in each of them and regulate the heating temperature separately. At the next stage, the pipeline is concreted on a layer of 3-4 cm and after hardening is carefully leveled. Here, unlike the initial screed, even small irregularities are not allowed, because linoleum or laminate will be laid on this layer. After the concrete has hardened, its surface is processed with a special grinding machine to eliminate even the smallest roughness. Now the floors can be covered with any decorative material that can withstand high temperatures. Laminate is considered the most suitable for their impact, which, unlike the best linoleum, will not crack or wear out. Return to contents</a>

Options for laying out underfloor heating pipes.One of the most popular options for the average home is laying the heating elements in a snake-like pattern. This principle is ideal for small rooms, because the space in the center of the pipe will heat up the most. The diameter of the selected pipe should be no more than 20 mm. A more labor-intensive way to make the floor warm is laying the pipes in a spiral. The temperature difference between the supply and return pipes is completely compensated by each other, keeping the floor constantly warm. The laying step is from 20 to 25 cm. After the pipes are completely laid, they are connected to the coolant and checked. The temperature in the heating system should be at least 55 ° C - only in this case can rational heating of the room be ensured. In the event that heated floors are made in several rooms at once, it is recommended to install control panels in each of them and regulate the heating temperature separately. At the next stage, the pipeline is concreted on a layer of 3-4 cm and after hardening is carefully leveled. Here, unlike the initial screed, even small irregularities are not allowed, because linoleum or laminate will be laid on this layer. After the concrete has hardened, its surface is processed with a special grinding machine to eliminate even the smallest roughness. Now the floors can be covered with any decorative material that can withstand high temperatures. Laminate is considered the most suitable for their impact, which, unlike the best linoleum, will not crack or wear out. Return to contents</a>

Floor installation instructions

Scheme of the warm floor module.When deciding to make a heated floor yourself, the primary attention should be paid to the cement floor screed. It should not be perfectly flat, but significant distortions should also be excluded. If this factor is ignored, the heated floor will distribute heat unevenly, having different temperatures in different parts of the room. The currently popular dry screed should be neglected, opting for a cement or combined option, which looks like this (Fig. 1). You can make the floor level manually using the most ordinary spatula. The curing period of such a floor is from one to two days. In order to get the maximum effect from the work done, it is recommended to place the screed at a height of at least 1 m above ground level. Thus, additional heat will be provided by the air gap formed between the layers. While the screed is drying, you can mark where the manifold cabinet will be located in the house. All pipes heating the floor will be joined in this cabinet. As a rule, a special niche is made in the wall for it, so that the cabinet does not protrude too much. You should choose products made of steel sheets with a polymer coating. This combination will prevent corrosion. After the screed has dried, layers of waterproofing and thermal insulation are laid on it. This stage is considered one of the simplest, not requiring any skills. It will look like this (Fig. 2). Return to the table of contents</a>

Scheme of the warm floor module.When deciding to make a heated floor yourself, the primary attention should be paid to the cement floor screed. It should not be perfectly flat, but significant distortions should also be excluded. If this factor is ignored, the heated floor will distribute heat unevenly, having different temperatures in different parts of the room. The currently popular dry screed should be neglected, opting for a cement or combined option, which looks like this (Fig. 1). You can make the floor level manually using the most ordinary spatula. The curing period of such a floor is from one to two days. In order to get the maximum effect from the work done, it is recommended to place the screed at a height of at least 1 m above ground level. Thus, additional heat will be provided by the air gap formed between the layers. While the screed is drying, you can mark where the manifold cabinet will be located in the house. All pipes heating the floor will be joined in this cabinet. As a rule, a special niche is made in the wall for it, so that the cabinet does not protrude too much. You should choose products made of steel sheets with a polymer coating. This combination will prevent corrosion. After the screed has dried, layers of waterproofing and thermal insulation are laid on it. This stage is considered one of the simplest, not requiring any skills. It will look like this (Fig. 2). Return to the table of contents</a>

What materials to choose?

Deciding to install a heated floor systemindependently, it is recommended to give preference to the heating or cable option. To implement this project, you should prepare the following materials:

When purchasing this list, you should not try tosave. Often, heating, like repairs in the house itself, is done for a long time and redoing it every few years will be irrational. Floors made even with the most expensive materials will pay for themselves within the first few years of operation.