The wooden floor has a warm surface andgood performance characteristics, but over time the planks may begin to creak. This occurs due to the drying out of some elements or the accumulation of moisture by the planks, which entails a change in their linear dimensions. There are several ways to get rid of this problem. Installation of a wooden floor on floor beams.

Installation of a wooden floor on floor beams.

Repair of wooden coverings

If you want to completely get rid of the squeakboards, then you can replace them, this is true if a huge number of planks have failed. And with a local creaking, you can simply get rid of cracks and potholes. To do this, you can use putty, the shade of which will match the color of the parquet, while potholes can be eliminated by applying the composition more extensively. Instead, you can use casein glue, which contains sawdust. After this kind of work, the surface will need to be sanded and covered with varnish intended for wood work. If there are more impressive cracks on the floor, then you will not be able to get rid of them in this way, the creaking will not be eliminated. Therefore, it is recommended to replace the parquet plank. To do this, you will need to stock up on planks, the shade of which corresponds to the color and size of the eliminated ones. Eliminate creaking wood floors withanchors. In this case, you can remove the creaking of the parquet board by breaking the dried-out plank into several pieces with a chisel. Then the remains must be removed, starting from the middle, removing the adhesive base. The depression left after removing the plank should be cleaned, leveling the surface. The ridge is cut off from the new board, the cut area is sanded with a plane. If necessary, it will be necessary to remove the ridges and grooves from the adjacent planks. Then, bitumen mastic, which has a temperature of 150-170 ° C, must be poured onto the released base, you can use a suitable glue instead. Riveting is placed on top, excess mastic is removed. Then oppression should be placed on the new board. After the mastic dries, the restored area must be treated with sandpaper, removing dust, the base on top must be varnished. To carry out the work, you need to stock up on the following materials and tools:

Eliminate creaking wood floors withanchors. In this case, you can remove the creaking of the parquet board by breaking the dried-out plank into several pieces with a chisel. Then the remains must be removed, starting from the middle, removing the adhesive base. The depression left after removing the plank should be cleaned, leveling the surface. The ridge is cut off from the new board, the cut area is sanded with a plane. If necessary, it will be necessary to remove the ridges and grooves from the adjacent planks. Then, bitumen mastic, which has a temperature of 150-170 ° C, must be poured onto the released base, you can use a suitable glue instead. Riveting is placed on top, excess mastic is removed. Then oppression should be placed on the new board. After the mastic dries, the restored area must be treated with sandpaper, removing dust, the base on top must be varnished. To carry out the work, you need to stock up on the following materials and tools:

- plane;

- chisel;

- bituminous mastic;

- wood;

- varnish;

- sandpaper.

Return to Contents</a>

Repair of the base of parquet

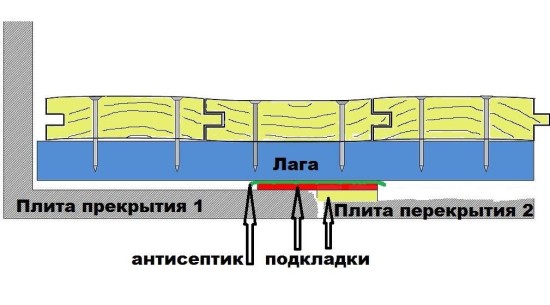

If you are wondering about the question of howremove the creaking of a flat floor, then you need to lay sheets of plywood on top of the glue, which are 12 mm thick. It is recommended to lay at an angle to the direction of the main laying of the floor panels. These procedures will eliminate the creaking for a long time. If the parquet floor was laid on bitumen mastic, then to get rid of the creaking, you need to expose all the planks to hot air, this should be done with a building hair dryer, but you should not overdo it. Eliminating creaking by using wedges.The procedure will melt the bitumen so that the planks can be pressed well afterwards. You can also eliminate the creaking of the parquet board by driving in wedges, since the cause of the sounds when walking can be precisely elements that are poorly fixed to the beams or joists. In order to eliminate friction, it is necessary to drive in wedges between the board and the beam. If there is no access to the lower part of the floor, the panels should be attached to the joists from above. Wedges can be driven into the cracks, maintaining a distance of 15-20 cm between them. In this case, the driven-in elements should not protrude onto the floor surface. Talc can be poured into the cracks between the panels, which can be replaced with graphite powder. Return to contents</a>

Eliminating creaking by using wedges.The procedure will melt the bitumen so that the planks can be pressed well afterwards. You can also eliminate the creaking of the parquet board by driving in wedges, since the cause of the sounds when walking can be precisely elements that are poorly fixed to the beams or joists. In order to eliminate friction, it is necessary to drive in wedges between the board and the beam. If there is no access to the lower part of the floor, the panels should be attached to the joists from above. Wedges can be driven into the cracks, maintaining a distance of 15-20 cm between them. In this case, the driven-in elements should not protrude onto the floor surface. Talc can be poured into the cracks between the panels, which can be replaced with graphite powder. Return to contents</a>

The use of liquid formulations for the elimination of violin

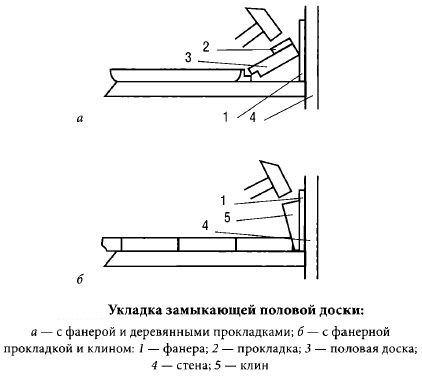

Scheme of laying the closing board during repairwooden floor. If you still do not know how to remove the squeak, then you can use glue for this. Before starting work, it is necessary to mark the defective places in the center, the marking points should be removed by 15 cm. The marking can be done with masking tape, so that later through holes with a diameter of 2 mm can be made in these places. This is necessary in order to pour glue into the holes, using a syringe for this. In this state, the floor should be left for an hour, after which the tape should be removed. If glue drips onto the surface of the parquet, it is permissible to use a solvent, which is designed to remove polyurethane foam. The parquet board should be pressed to the base, for which you should use a heavy load, leaving everything without movement. In advance, you should purchase wax crayons to match the shade of the coating, so that after 24 hours you can fill the holes with wax. Finally, the surface must be polished, using a rag for this. The creaking of the floor is sometimes eliminated with a cement-based solution. To do this, you need to make a hole Ø1.6-2 cm in the floor using a hammer drill. This will fill the underground space with a cement solution; you can also use heated bitumen. A plug is driven into the hole and the surface is painted. Another way to eliminate the creaking involves the use of a lubricating composition made on the basis of wax with the addition of a solvent. This method involves introducing the composition into the underground space into micro-holes by syringing. You can also use polyurethane foam. The underground space has an average height of 9 cm, its foam will completely occupy it after swelling. But with mechanical action during operation, the formed layer can sag and collapse, which indicates the possible short-lived nature of the method. Return to the table of contents</a>

Scheme of laying the closing board during repairwooden floor. If you still do not know how to remove the squeak, then you can use glue for this. Before starting work, it is necessary to mark the defective places in the center, the marking points should be removed by 15 cm. The marking can be done with masking tape, so that later through holes with a diameter of 2 mm can be made in these places. This is necessary in order to pour glue into the holes, using a syringe for this. In this state, the floor should be left for an hour, after which the tape should be removed. If glue drips onto the surface of the parquet, it is permissible to use a solvent, which is designed to remove polyurethane foam. The parquet board should be pressed to the base, for which you should use a heavy load, leaving everything without movement. In advance, you should purchase wax crayons to match the shade of the coating, so that after 24 hours you can fill the holes with wax. Finally, the surface must be polished, using a rag for this. The creaking of the floor is sometimes eliminated with a cement-based solution. To do this, you need to make a hole Ø1.6-2 cm in the floor using a hammer drill. This will fill the underground space with a cement solution; you can also use heated bitumen. A plug is driven into the hole and the surface is painted. Another way to eliminate the creaking involves the use of a lubricating composition made on the basis of wax with the addition of a solvent. This method involves introducing the composition into the underground space into micro-holes by syringing. You can also use polyurethane foam. The underground space has an average height of 9 cm, its foam will completely occupy it after swelling. But with mechanical action during operation, the formed layer can sag and collapse, which indicates the possible short-lived nature of the method. Return to the table of contents</a>

Mechanical methods for eliminating violin

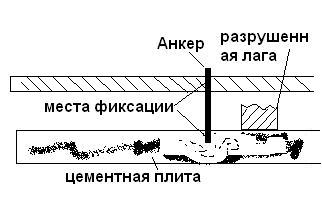

The process of eliminating creaking on a wooden floor.If the base of the floor is a concrete slab, it is permissible to use steel anchors, which are installed manually. First, you need to drill a hole, mount a steel shell and screw in the anchor stud. Although this method is effective, it can entail significant financial costs, since up to 200 anchors may be required to carry out the work, which will depend on the floor area. If you act directly at the junction of the board and the joist, this can give a positive result. You can use the technology of pulling with self-tapping screws. Before starting work, you need to determine whether there are communications under the defective strip, since about 3 self-tapping screws will have to be screwed in there. First, you need to prepare a hole using a drill. It is necessary to act from one side of the strip, rushing into the beam. A screw of the appropriate size is installed in the hole, the head should be recessed into the board. You can tighten it, which, although labor-intensive, allows you to get a good result. During the work, it is necessary to replace the nails with screws. After performing manipulations to strengthen the parquet, it is necessary to sand the surface, which was previously puttied, then the base should be covered with wax. If after the work it is not possible to achieve a positive result, then you will have to call specialists or dismantle the floor yourself to lay it again.

The process of eliminating creaking on a wooden floor.If the base of the floor is a concrete slab, it is permissible to use steel anchors, which are installed manually. First, you need to drill a hole, mount a steel shell and screw in the anchor stud. Although this method is effective, it can entail significant financial costs, since up to 200 anchors may be required to carry out the work, which will depend on the floor area. If you act directly at the junction of the board and the joist, this can give a positive result. You can use the technology of pulling with self-tapping screws. Before starting work, you need to determine whether there are communications under the defective strip, since about 3 self-tapping screws will have to be screwed in there. First, you need to prepare a hole using a drill. It is necessary to act from one side of the strip, rushing into the beam. A screw of the appropriate size is installed in the hole, the head should be recessed into the board. You can tighten it, which, although labor-intensive, allows you to get a good result. During the work, it is necessary to replace the nails with screws. After performing manipulations to strengthen the parquet, it is necessary to sand the surface, which was previously puttied, then the base should be covered with wax. If after the work it is not possible to achieve a positive result, then you will have to call specialists or dismantle the floor yourself to lay it again.